Film sending and cutting method for plastic film machine

A film feeding and plastic film technology, which is applied in packaging and other directions, can solve the problems of plastic film feeding not in place, affecting production efficiency, running out of the film cutting axis, etc., achieving smooth transfer of film feeding, improving stability and production efficiency, The effect of consistent film pulling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

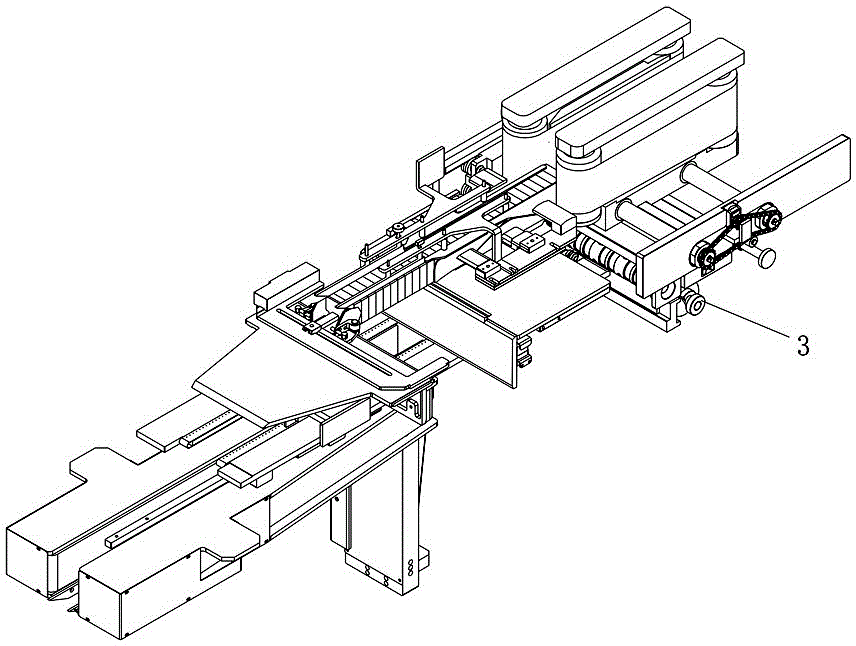

Image

Examples

Embodiment Construction

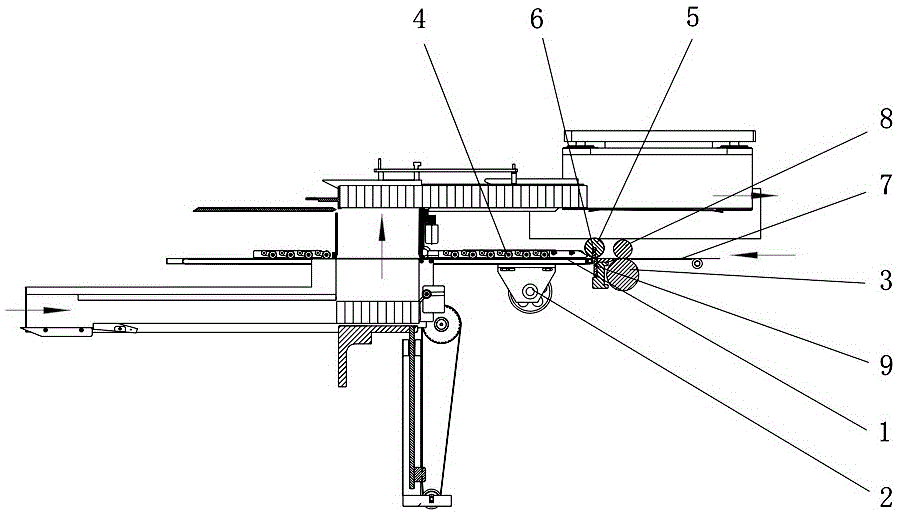

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] In the film feeding and cutting method of the plastic film machine of the present invention, the film feeding operation is first started, and the plastic film is moved to a set distance s to level the plastic film. During this process, the film pulling operation and the rotation of the film cutter are not started or suspended; start The film pulling operation and the film cutting knife are rotated, and the film pulling operation is controlled to have the same tangential line speed as the film feeding operation; when the plastic film is running until the film cutting operation is required, the tangential line of the film feeding operation and the film pulling operation are synchronously reduced Speed, so that the film feeding operation, film pulling operation and film cutting knife rotation have the same tangential line speed. Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com