Weft knitting machine with transferring mechanism and transferring method

A technology of stitch transfer and flat knitting, which can be used in flat knitting with separate action needles, textile and paper making, weft knitting, etc., and can solve problems such as thread breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

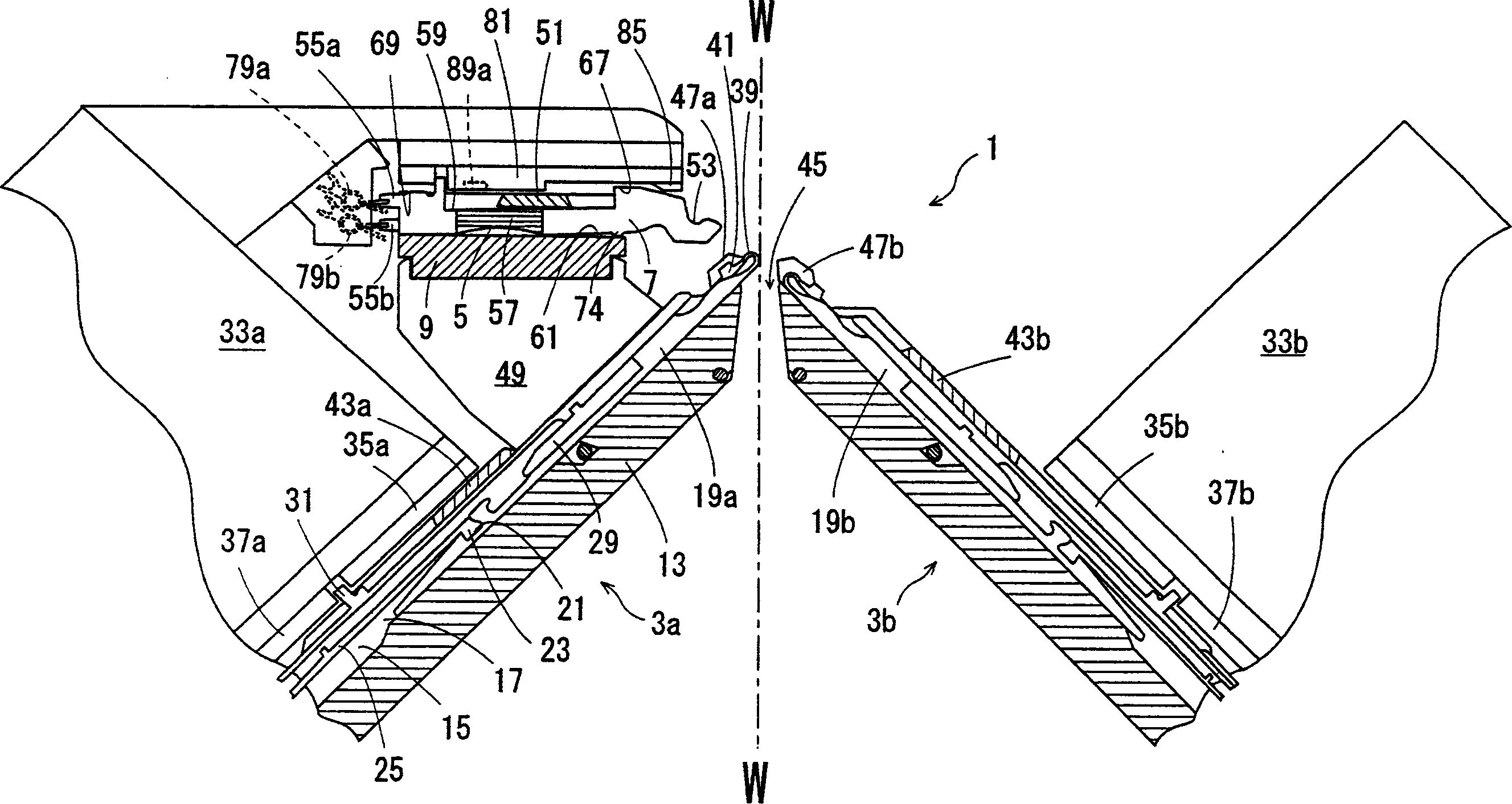

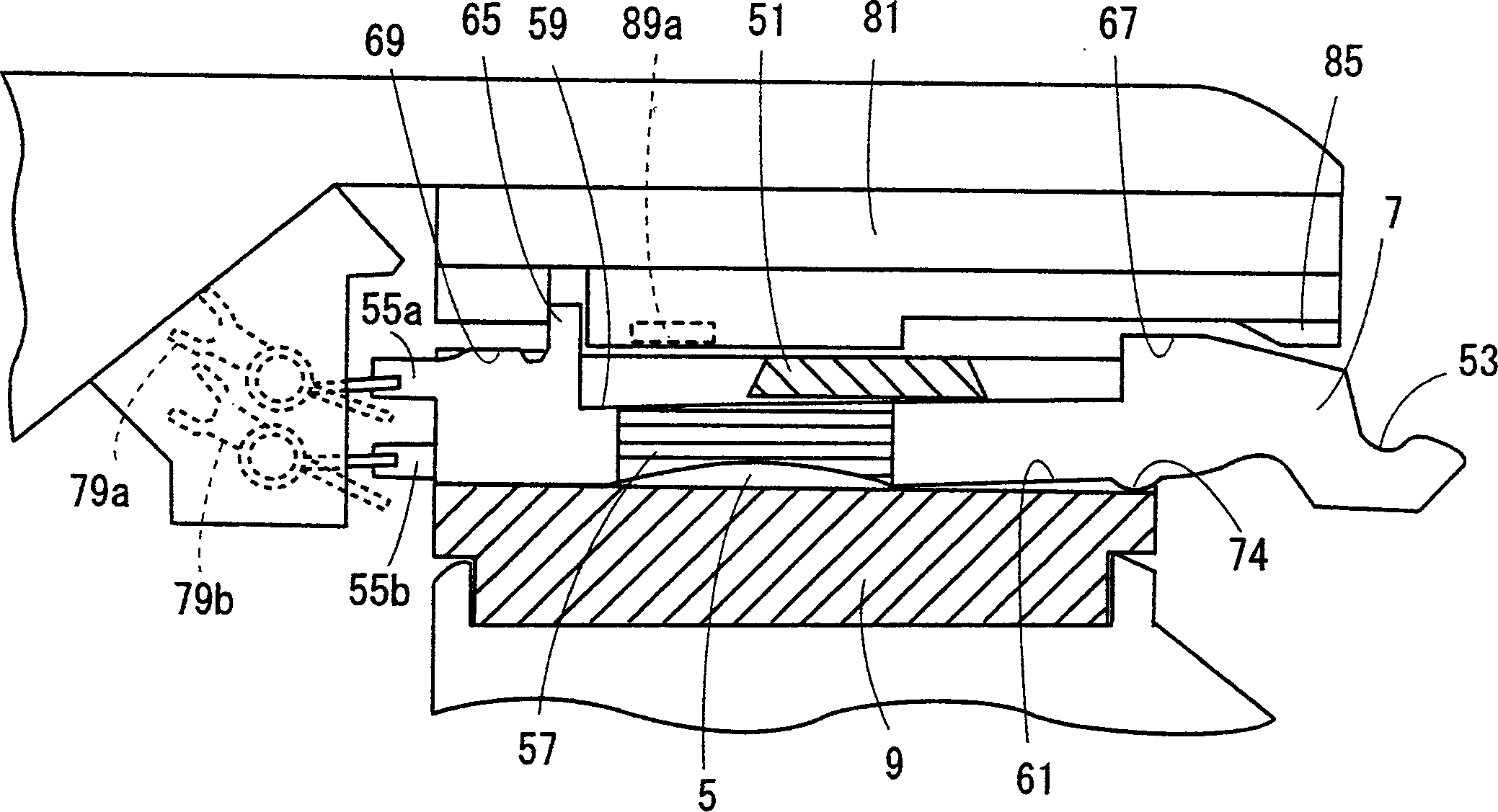

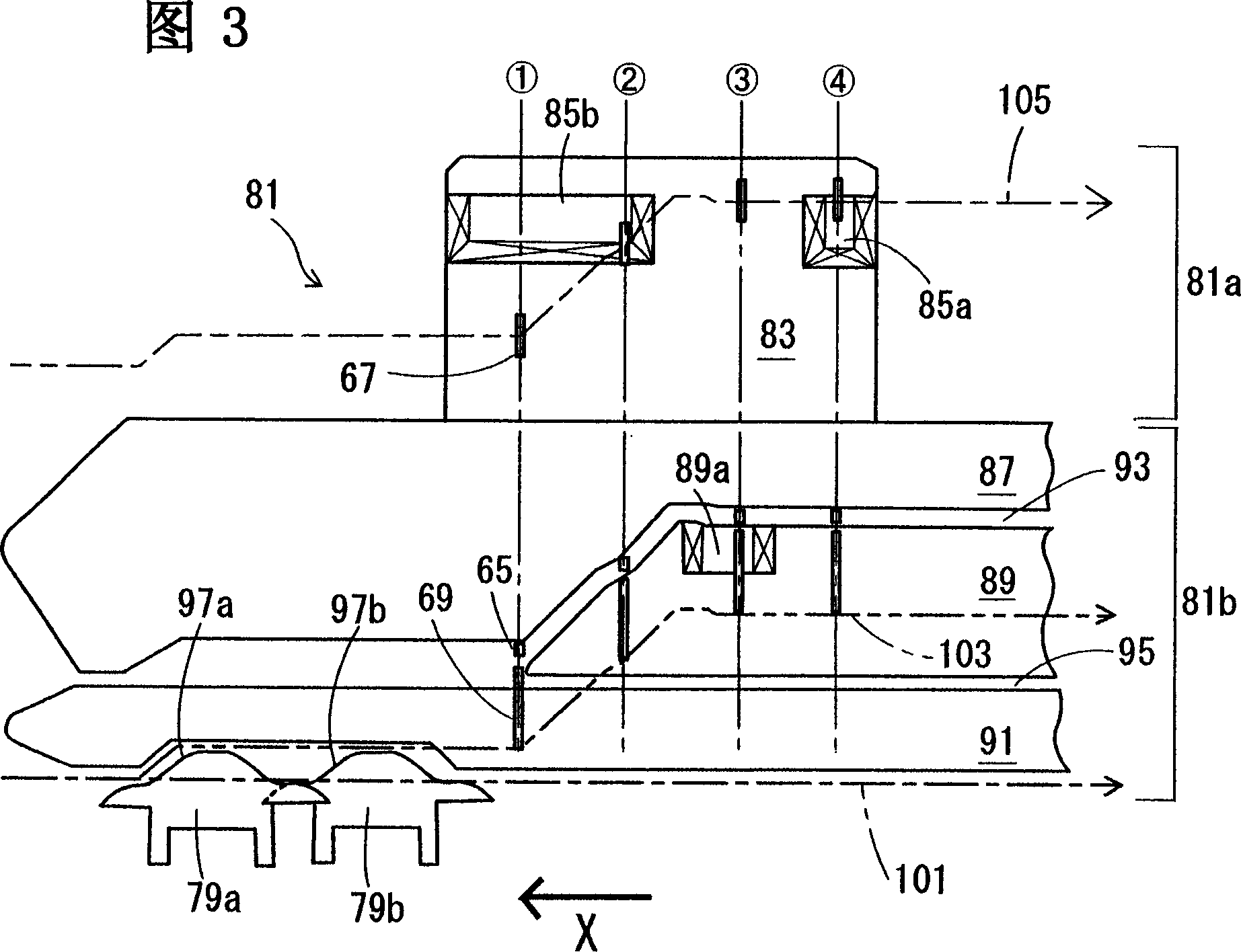

[0026] Examples of the present invention will be described. use figure 1 ~ Figure 3 illustrates the structure of the flat knitting machine. The flat knitting machine has a pair of front and back lower needle beds 3a, 3b arranged opposite to each other, and a TR foot piece groove 5 formed on the top of the front lower needle bed (hereinafter referred to as the front bed 3a) to hold the TR. TR footer bed 9 for footer 7. In the lower needle beds 3a and 3b, needle plates 17 are erected in the grooves formed on the needle bed base plate 13, and needle grooves 15 are formed between adjacent needle plates 17, 17. The tooth mouth central line W-W between the beds can move forward and backward to keep the needle 19. The rear needle bed 3b (hereinafter referred to as the rear bed 3b) is driven by a driving device not shown to be movable in the longitudinal direction of the needle bed (hereinafter referred to as a pushing operation).

[0027]In this embodiment, the needle 19 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com