Steel pipe lifting carrier roller device

A technology for lifting brackets and steel pipes, which is applied in the direction of lifting devices, lifting frames, roller tables, etc., can solve problems such as inability to land on the roller frame, swing left and right at the suspended section of steel pipes, and production accidents, so as to improve production efficiency, improve operating efficiency, and avoid The effect of spray quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

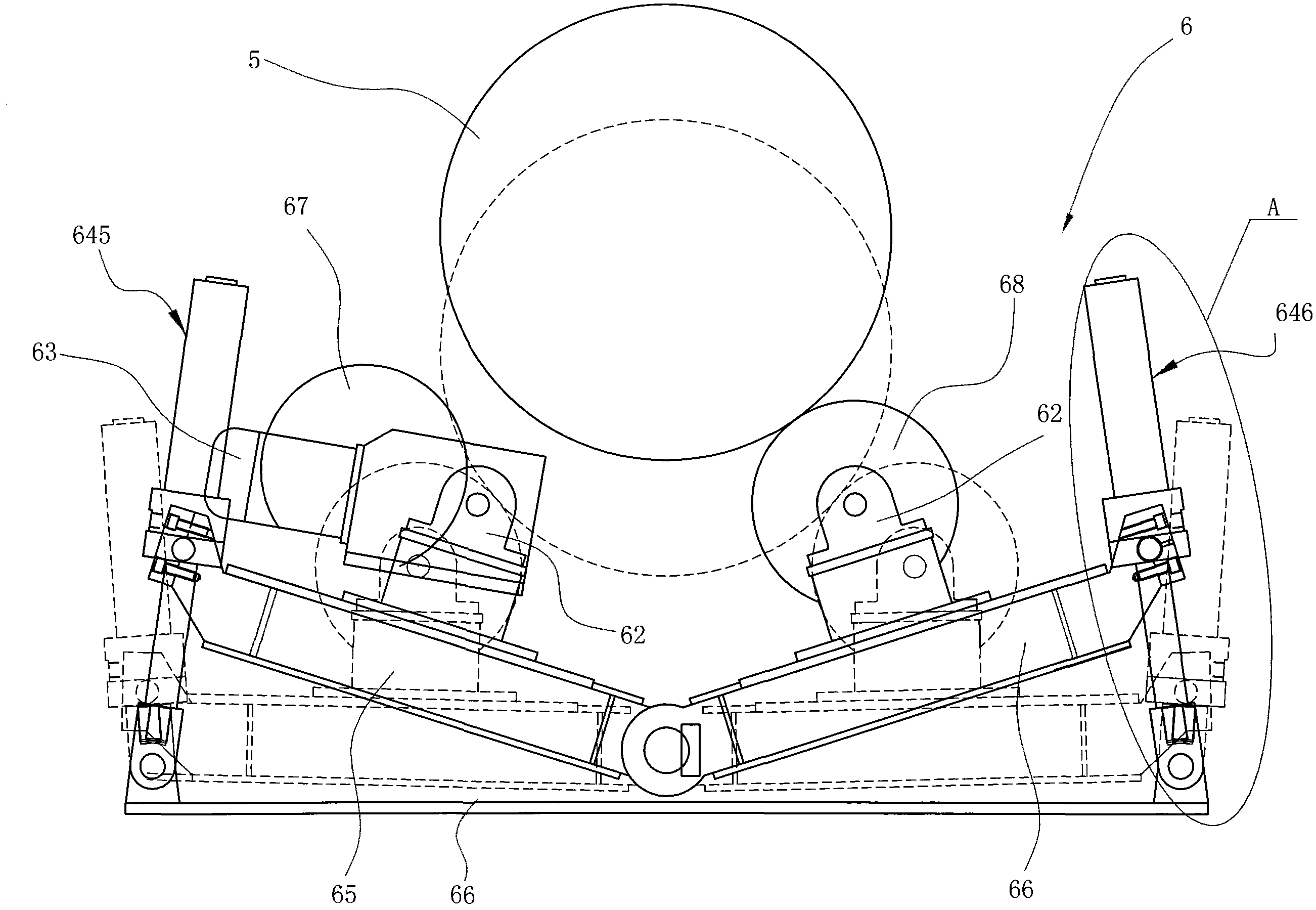

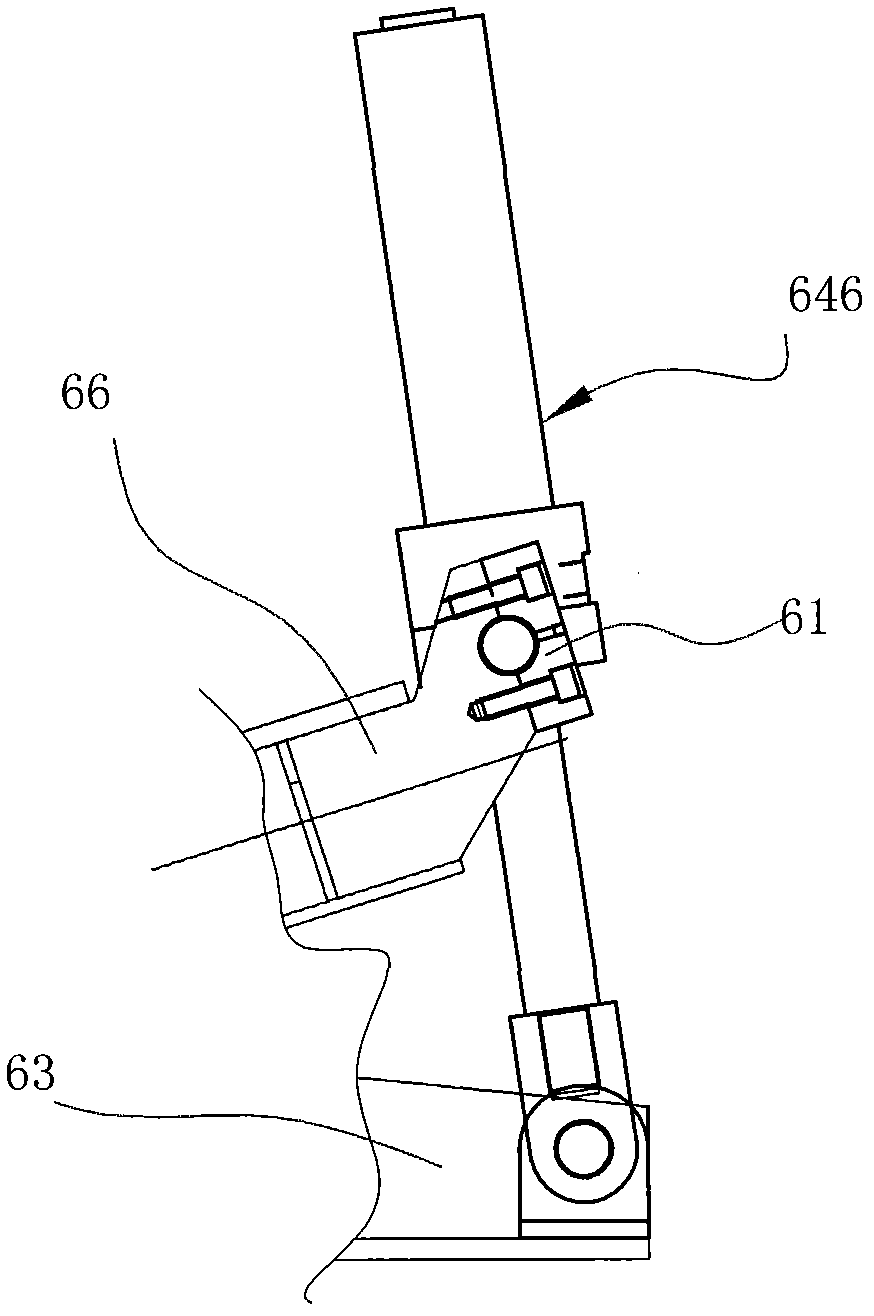

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] This embodiment is a detailed description of the automatic lifting roller device for steel pipes in combination with the operation of large steel pipes on the automatic coating production line.

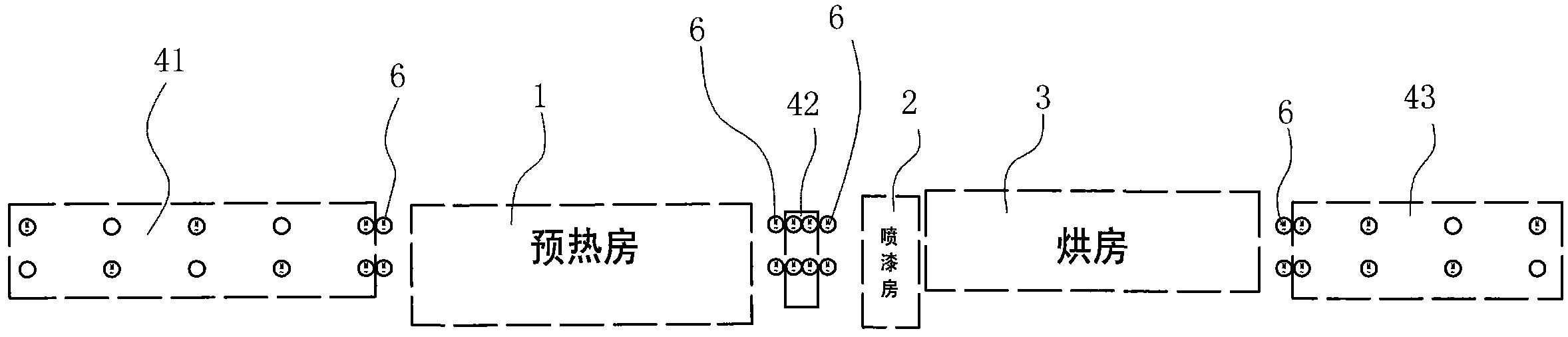

[0028] Such as figure 1 As shown, according to the running route of the steel pipe, the large-scale steel pipe automatic coating production line includes a preheating room 1, a painting room 2 and a drying room 3 in sequence. The distance between the drying room and the drying room is very small, so there is no transmission mechanism between the two. The transmission mechanism in this embodiment adopts a roller frame group, such as figure 1 As shown, the production line is provided with three groups of roller frames from front to back, that is, the first roller frame group 41 , the second roller frame group 42 and the third roller frame group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com