Bottle holding type transfer star wheel and achievement method thereof

A star-wheel, bottle-type technology, applied in the field of bottled product transfer devices, can solve the problems of easily inverted bottles, bottle surface damage, easy to be scratched, etc., to avoid damage, stabilize the liquid level, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

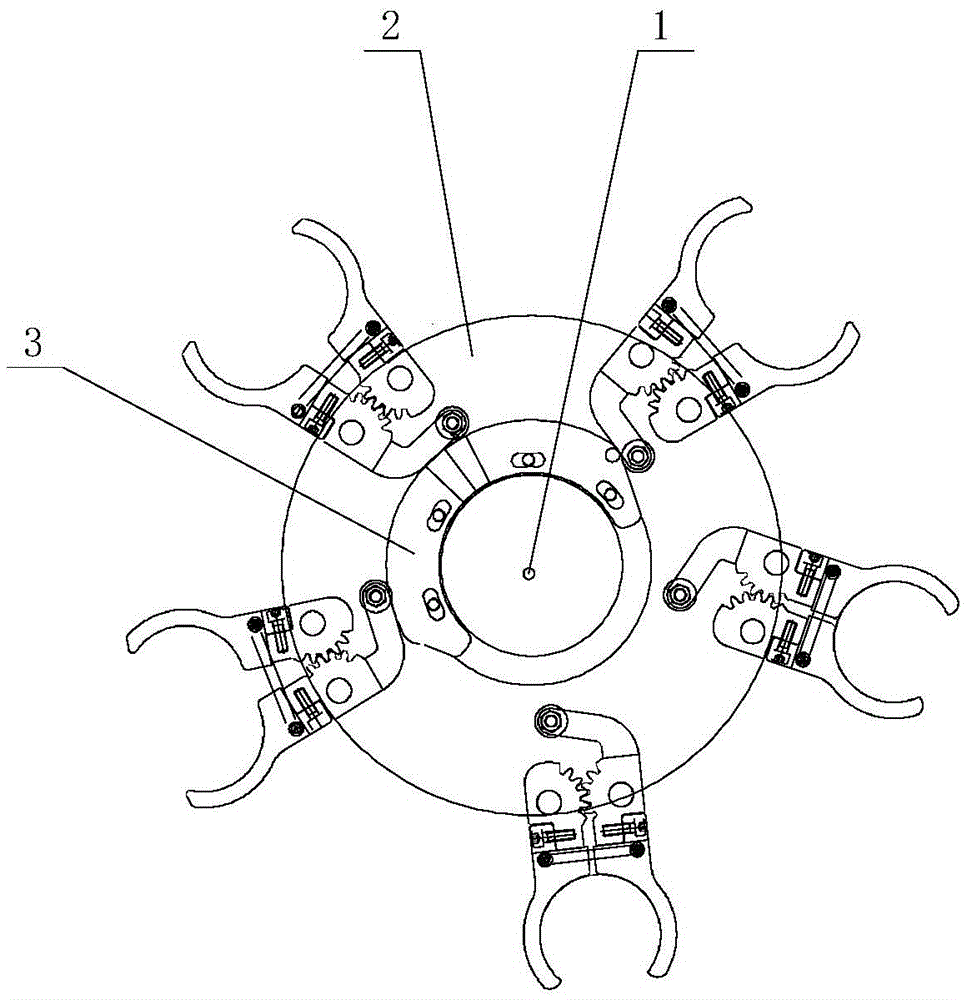

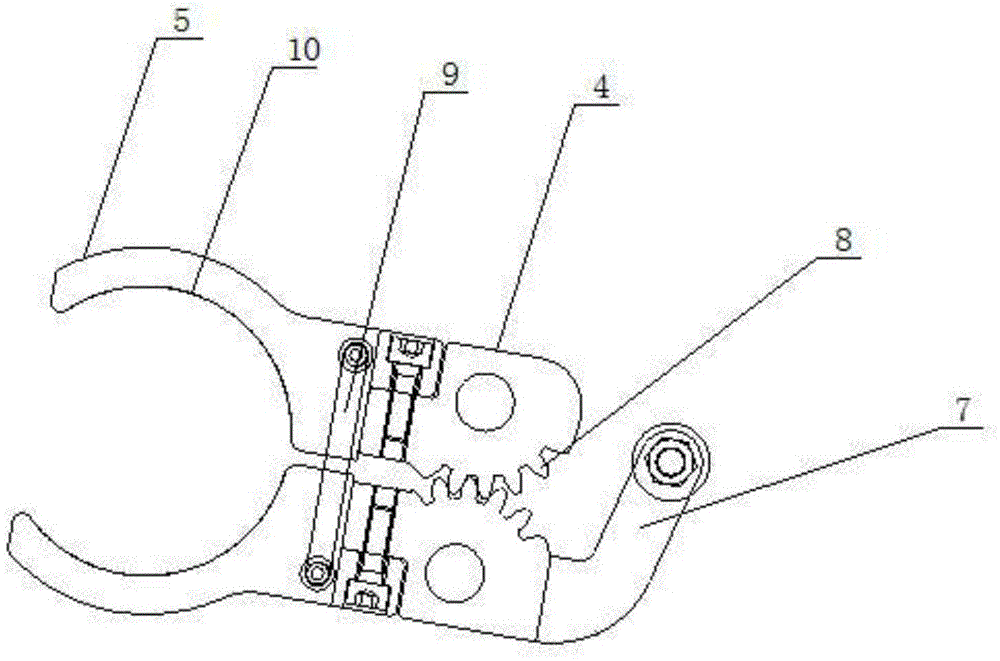

[0022] Such as figure 1 and figure 2 As shown, the bottle-holding type transfer star wheel includes a turntable 2, a motor 1 driving the turntable, at least one cam 3, and a support column for fixing the cam 3; the edge of the turntable 2 is connected with a plurality of jaws; the cam 3 is located in the turntable; The jaw at the highest point of the cam is in an open state, and the jaw at the lowest point of the cam is in a closed state; the jaws include two connecting blocks 4 connected by side contact; one end of the connecting block 4 is connected with at least one arc clip 5, two The concave surfaces of the arc clips 5 on the connecting block face each other; the free end of any connecting block 4 is connected with a brake lever 7; the highest point of the cam 3 squeezes the brake lever 7 outward to control the opening of the jaws; two groups Anti-scratch pads 10 are connected to opposite surfaces of the arc clip 5 .

[0023] How to use the bottle-holding transfer star...

Embodiment 2

[0026] Such as figure 1 and figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the contact surfaces of the two connecting blocks 4 are provided with gear teeth 8, and the gear teeth 8 on the two connecting blocks 4 are engaged; the two connecting blocks 4 are connected It is compact and not easy to slip, which makes the work of the present invention more stable and reliable.

Embodiment 3

[0028] Such as figure 1 and figure 2 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that an elastic component 9 is connected between the two connection blocks 4; The equipment of a connection block 4 replaces; Make the connection of two connection blocks 4 better, and it is not easy for any connection block 4 to fall off, so that the present invention can work more stably and reliably.

[0029] Such as figure 1 and figure 2 As shown, when the embodiment 1-3 is in use, the motor 1 drives the jaws to move, and when the jaws are located at the lower part of the cam 3, the arc clamp 5 in the jaws hugs the bottle body of the bottle, and the arc clamp 5 can be adjusted according to the bottle body. The radian design of the body makes it fit the bottle body better, and can hold the bottle body better without causing damage to the bottle. When the jaws are at the height of the cam 3, the height of the cam 3 will squeeze the brake lever outwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com