Woof-intersecting method and device thereof for weaving machine

A loom and weft connection technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of misreported weft stop and weft connection, low loom production efficiency, poor weft connection and other problems, so as to reduce the false alarm of weft stop , The effect of improving production efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In this embodiment, a weft handover method utilizes the movement phase difference between the weft sending rapier and the weft receiving rapier to make the weft yarn handover smoothly, specifically including the following steps:

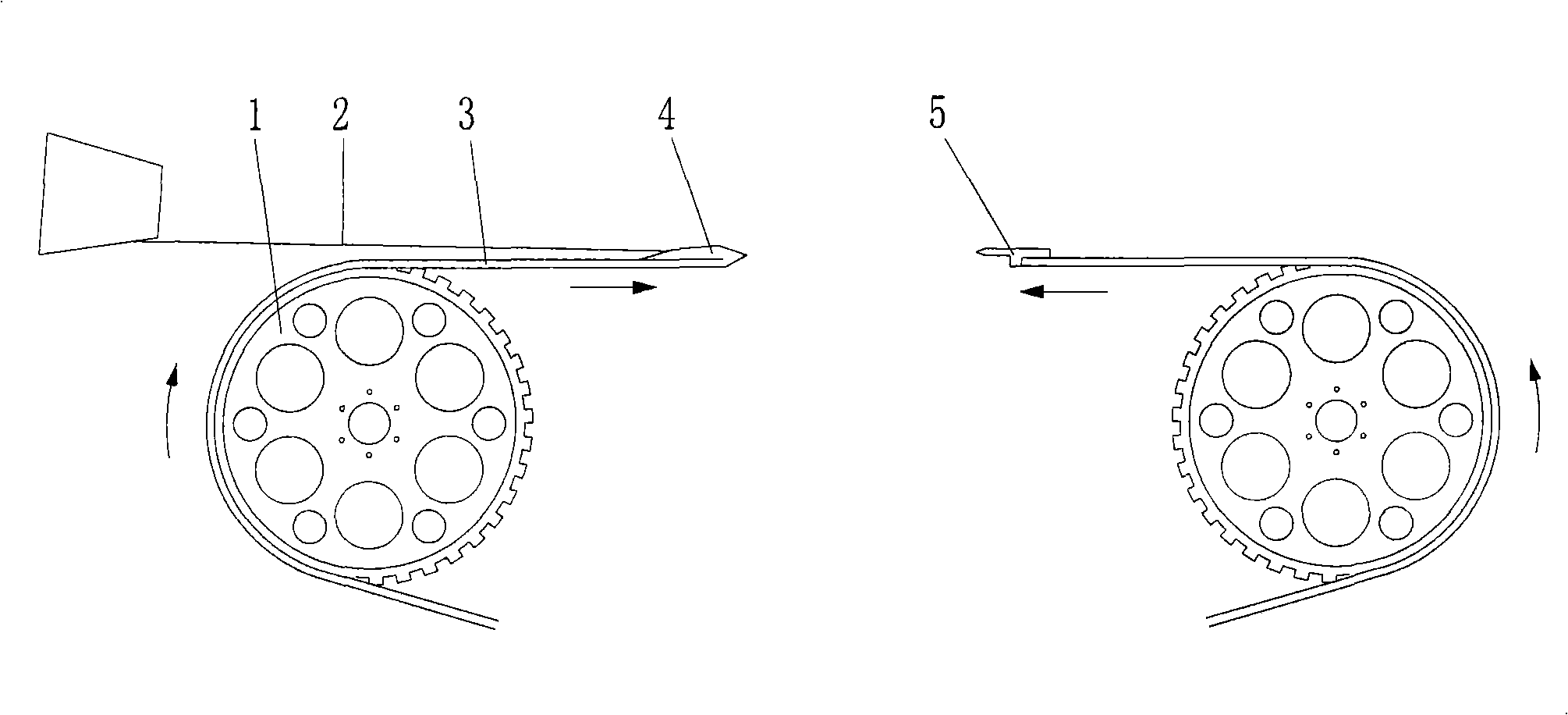

[0036] (1) Start the loom, and after the weft sending sword head completes the weft selection, it will carry the weft yarn and the weft receiving sword head toward each other. This process is as follows: figure 1 As shown in the figure, 1 is the sword wheel, 2 is the weft yarn, 3 is the weft sending sword belt, 4 is the weft sending sword head, and 5 is the weft receiving sword head;

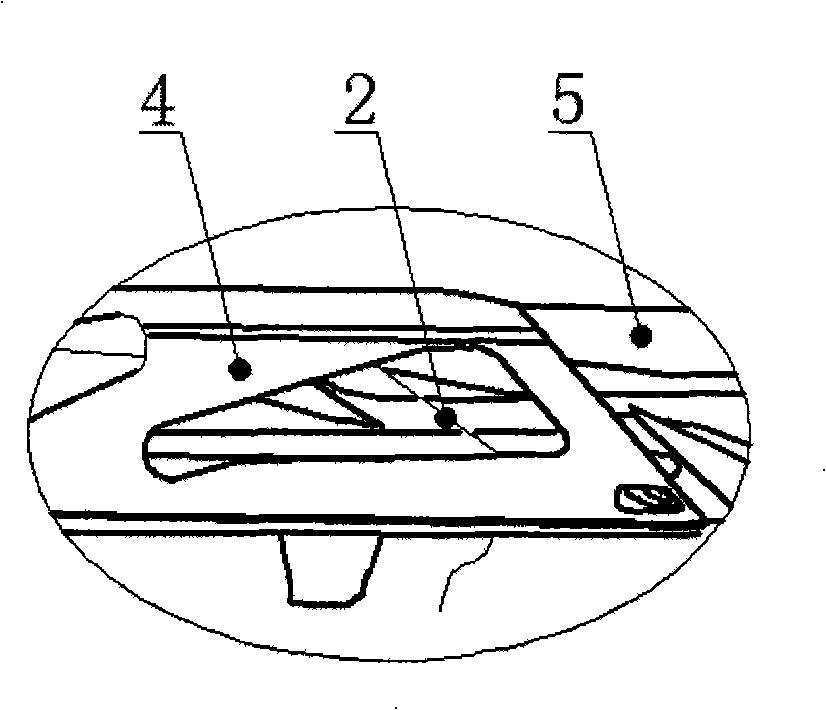

[0037] (2) When the main shaft of the loom rotates at a certain angle, the weft-connecting rapier 5 reaches the limit position of its advancing direction. The structure at the junction of the head 4 and the weft-joining sword head 5 is as follows figure 2 As shown, the weft yarn handover starts;

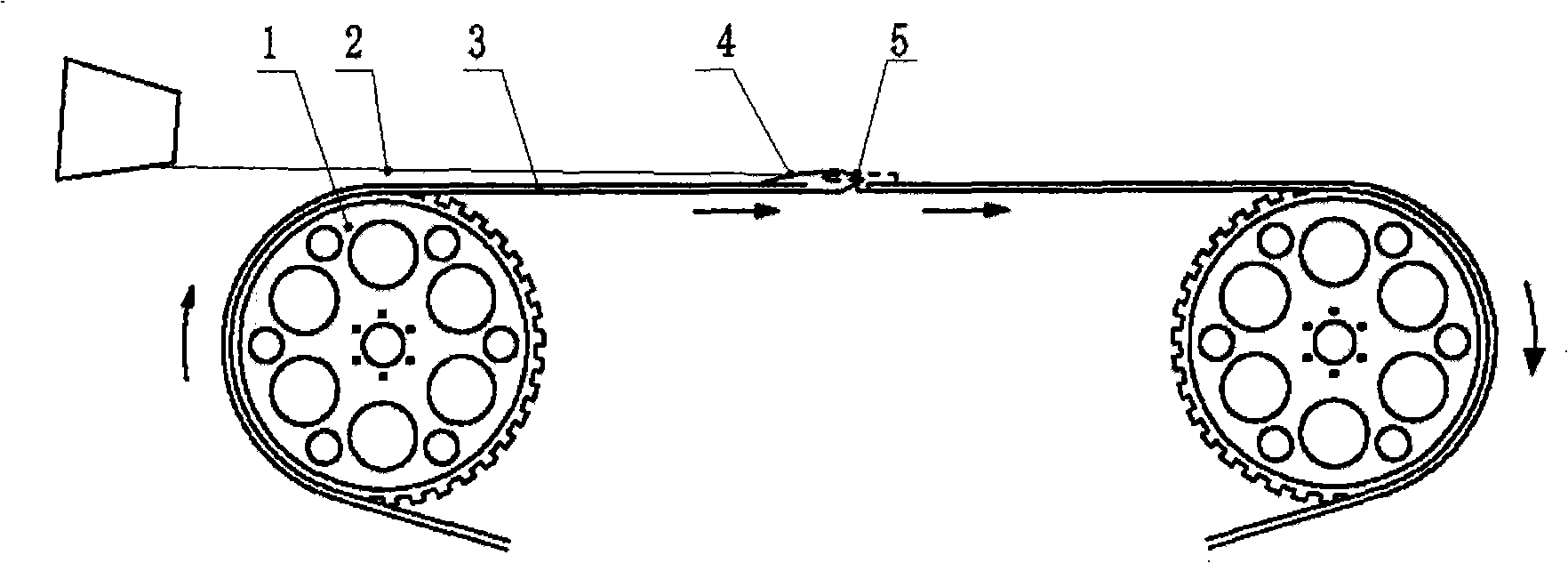

[0038] (3) After the weft-connecting rapier 5 reaches the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com