Patents

Literature

33results about How to "Small tension change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

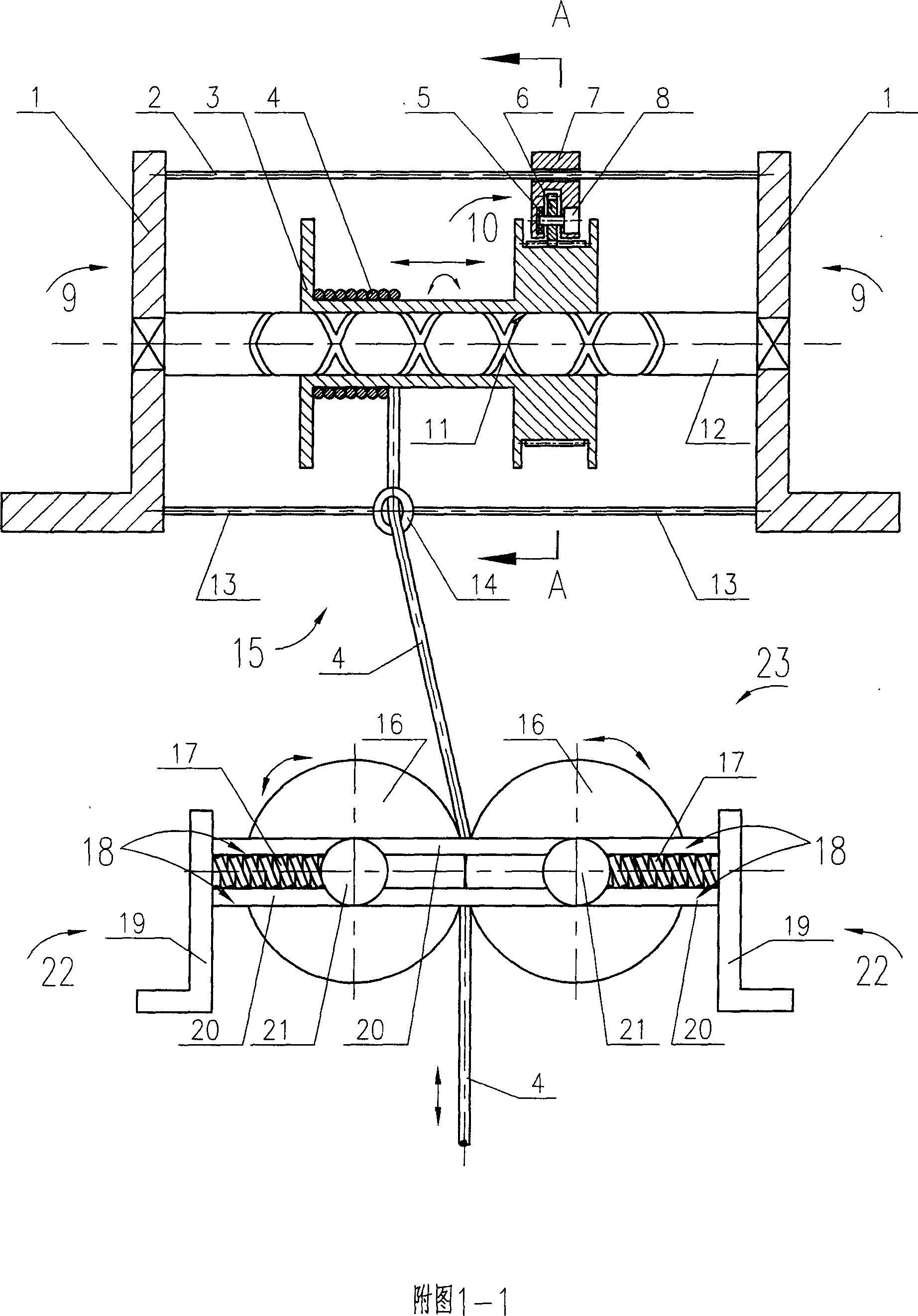

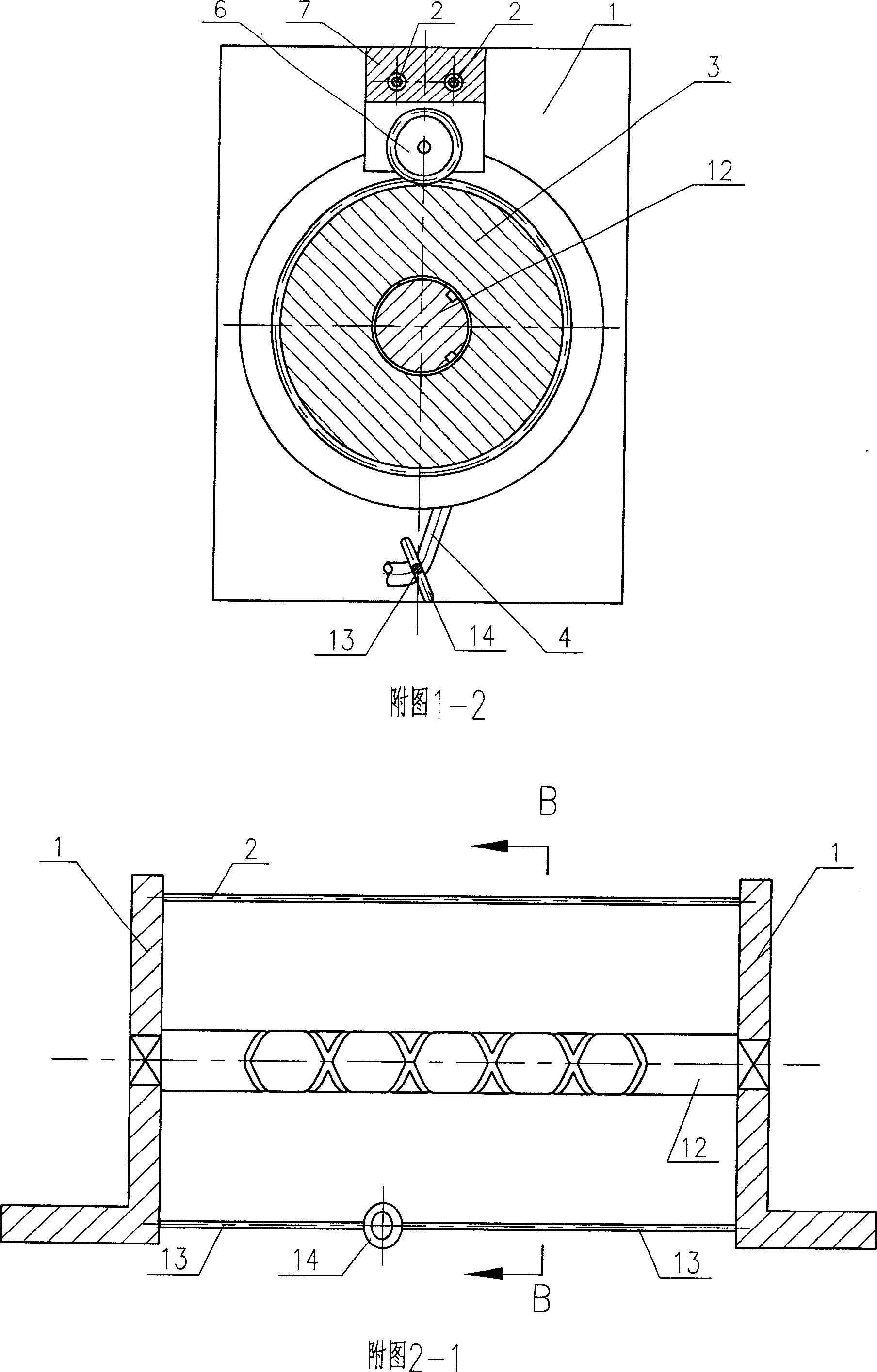

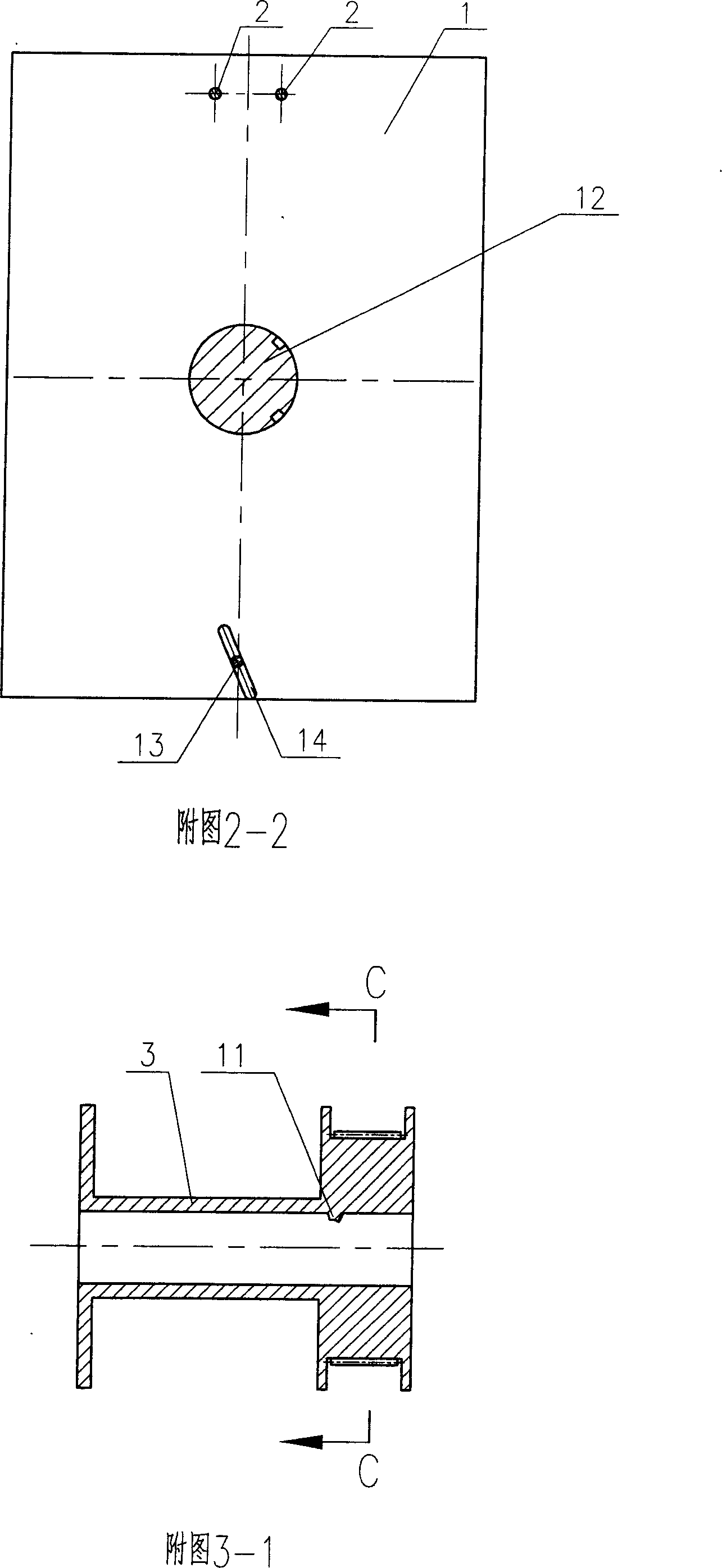

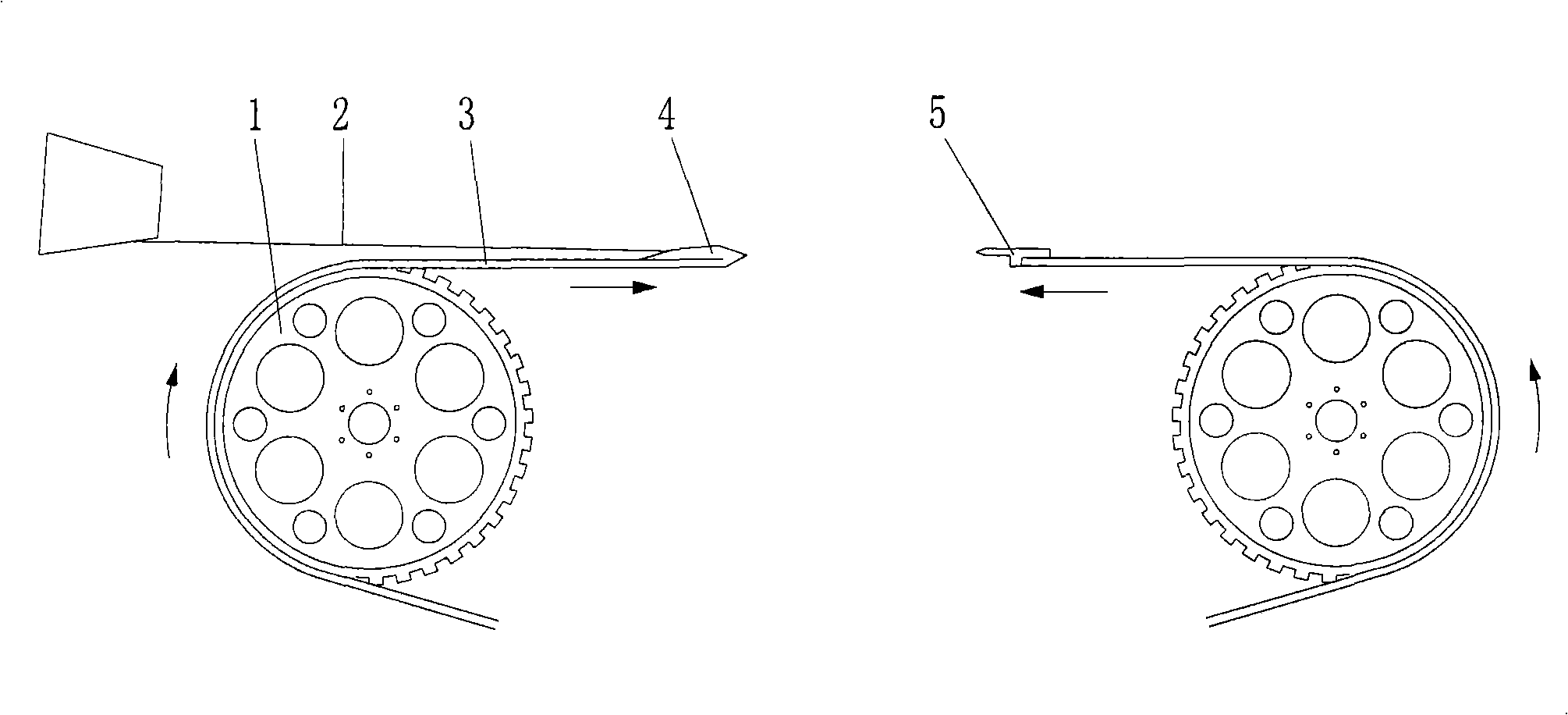

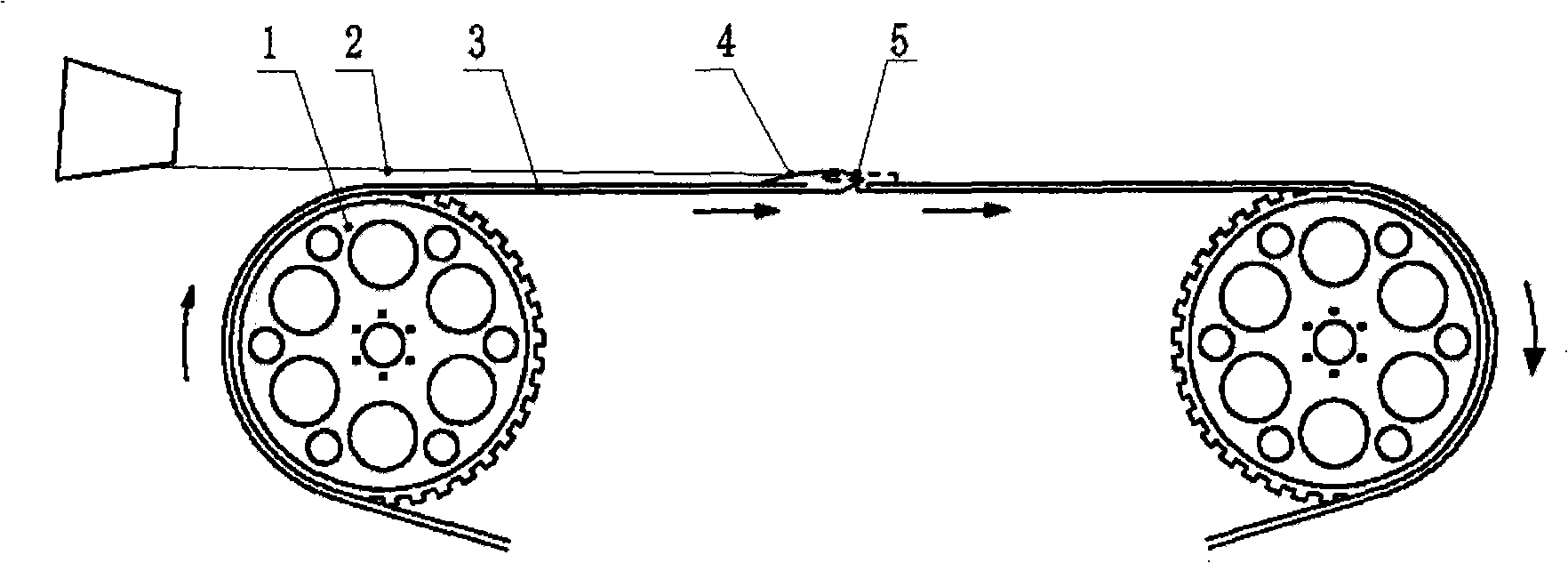

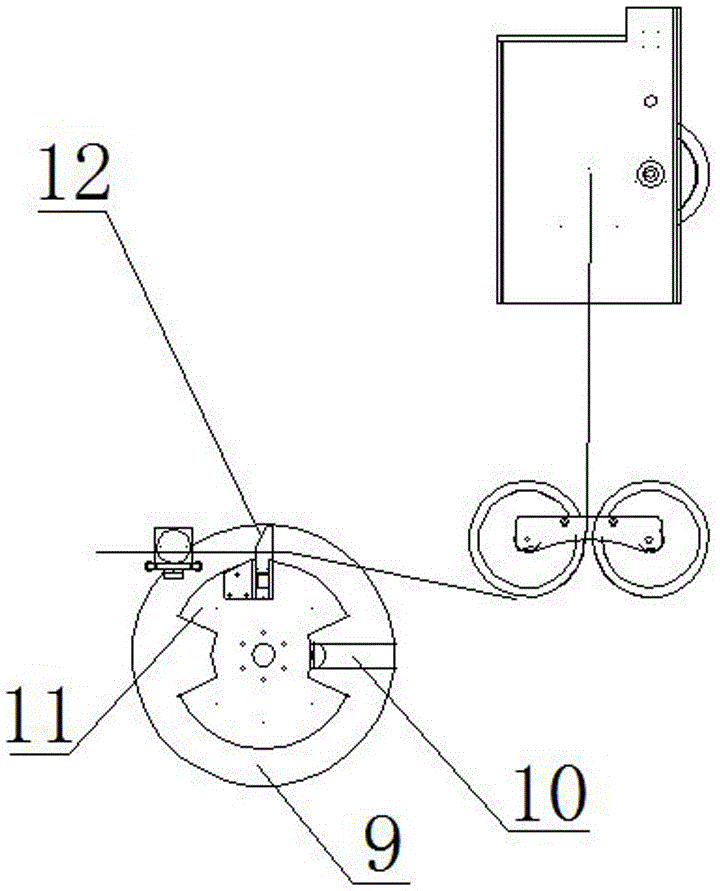

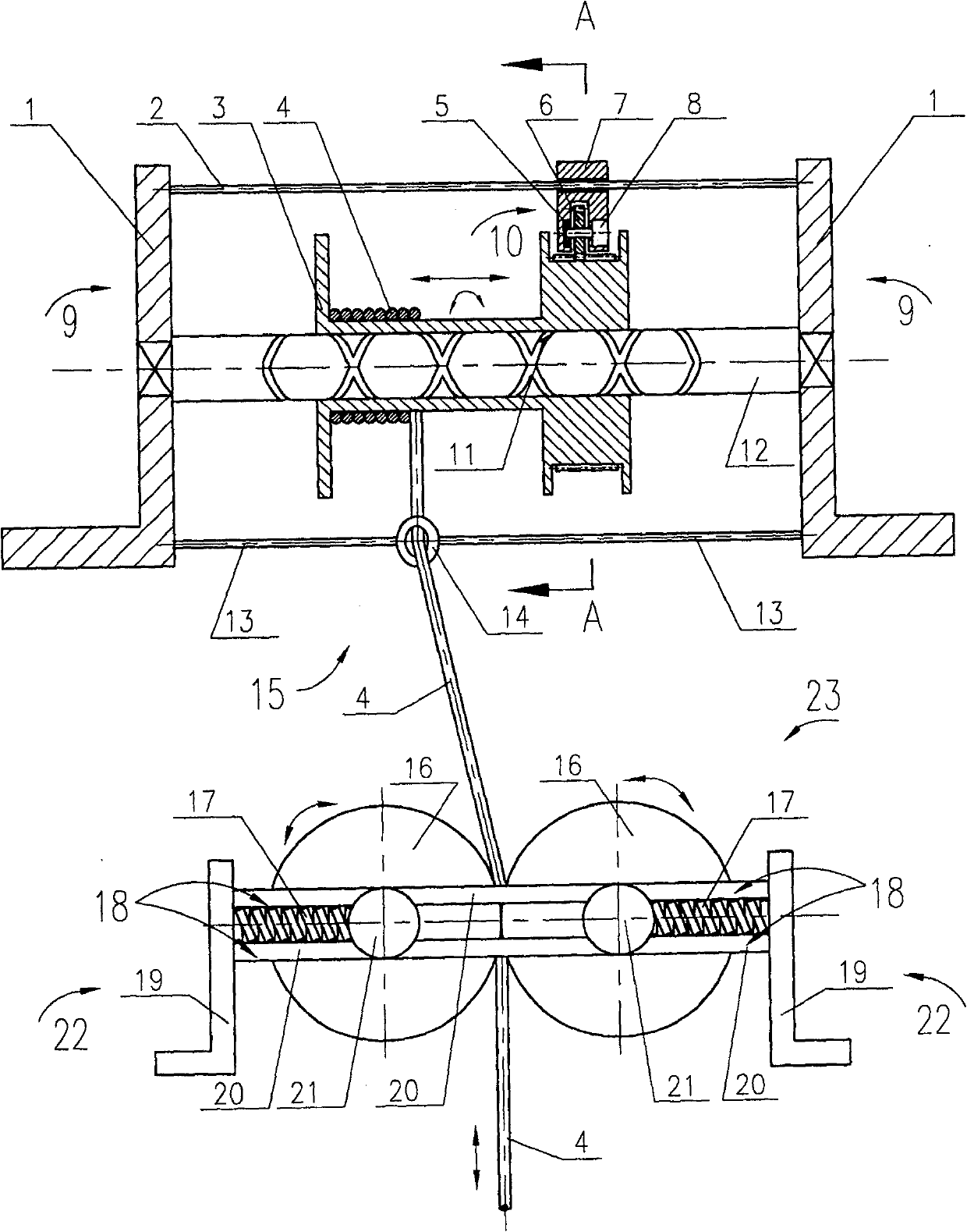

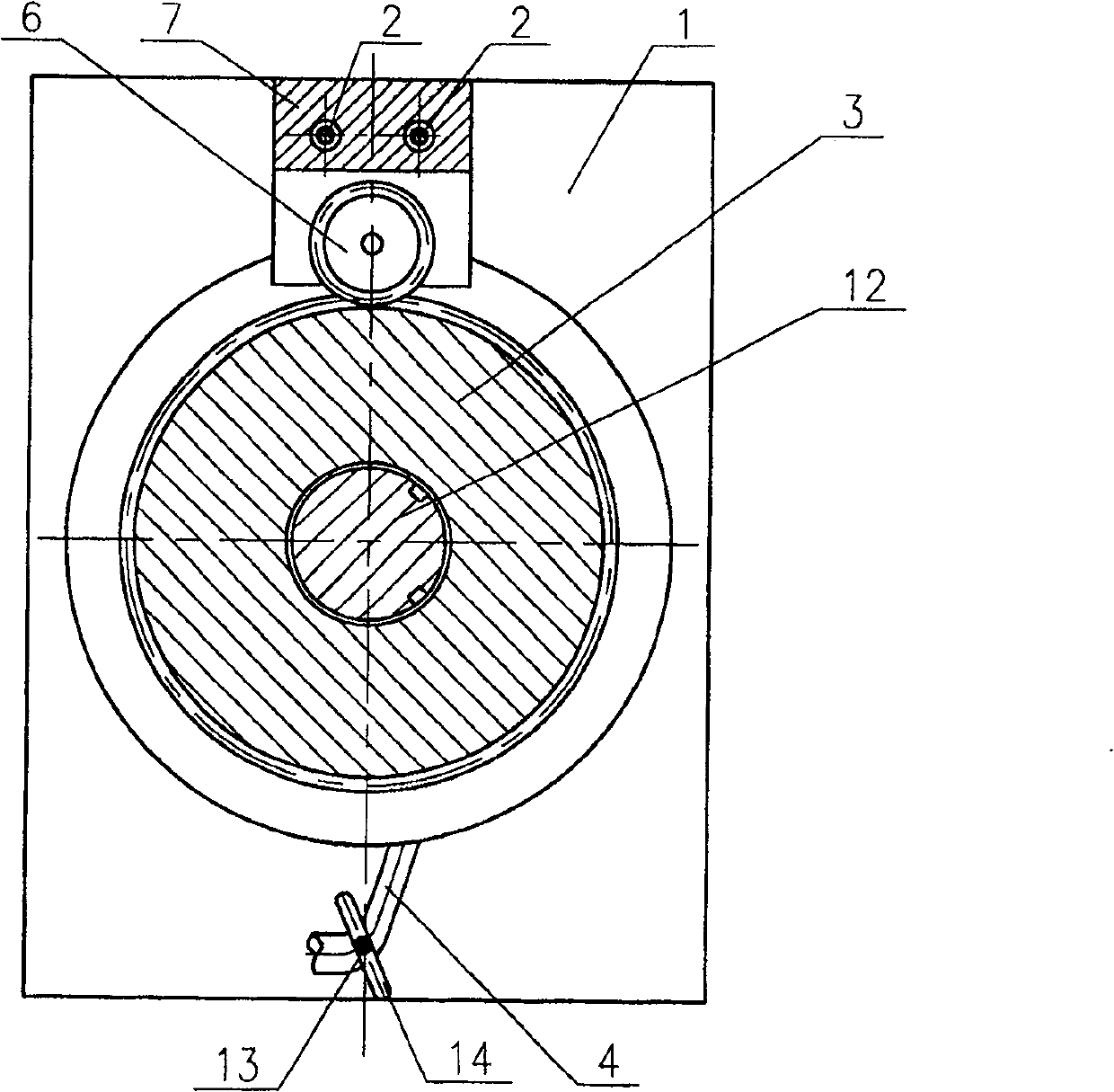

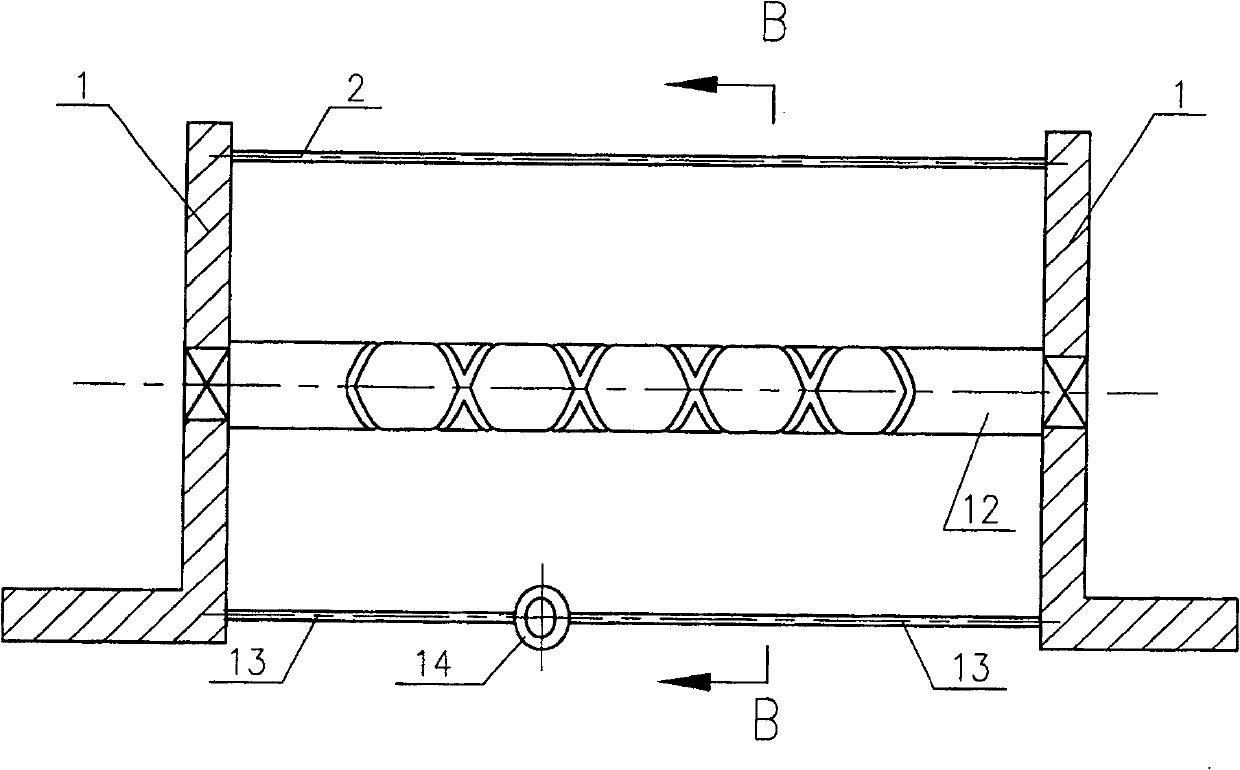

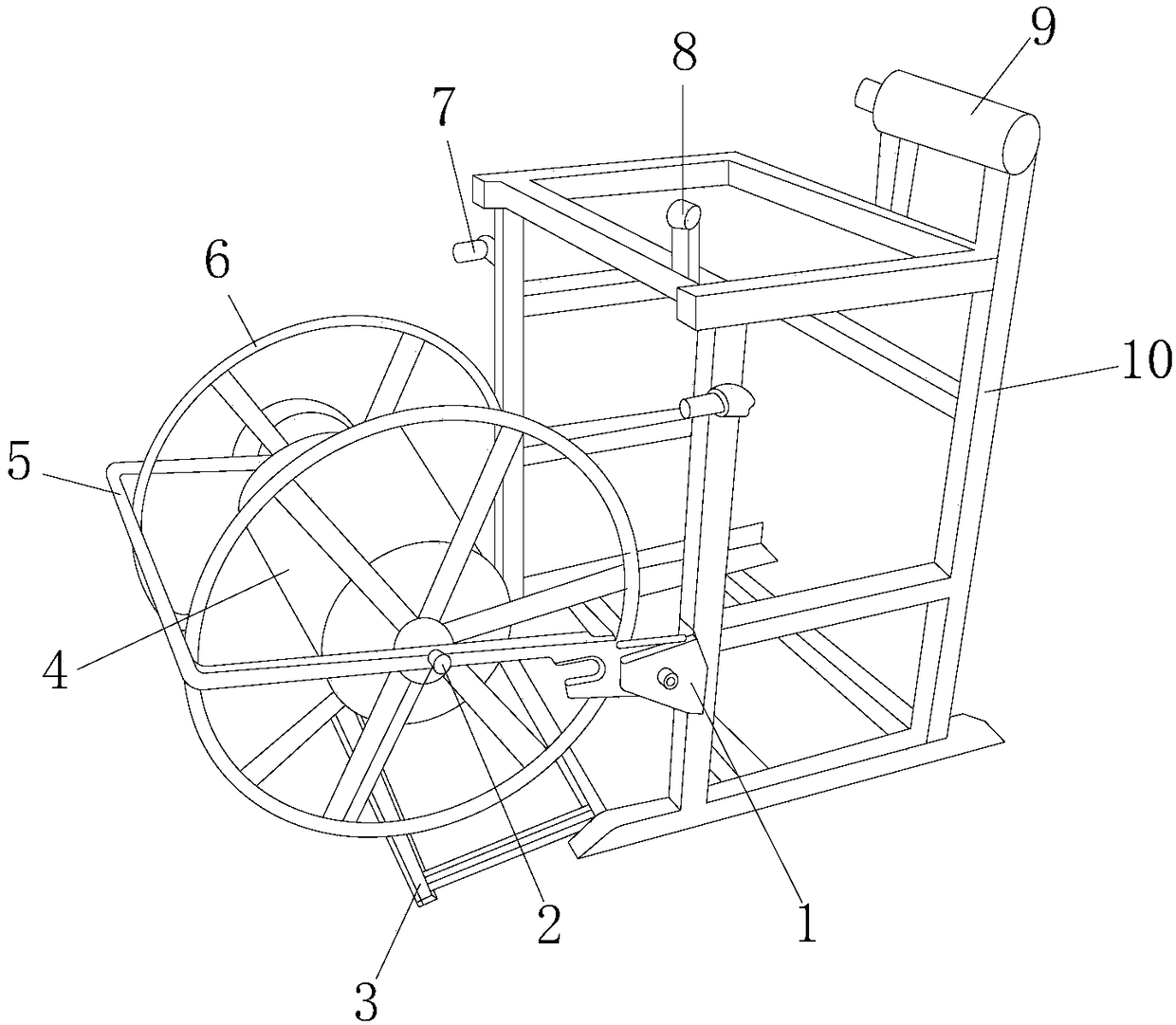

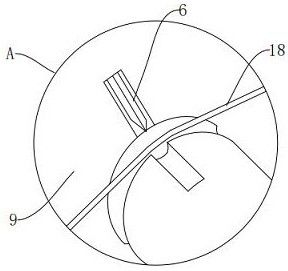

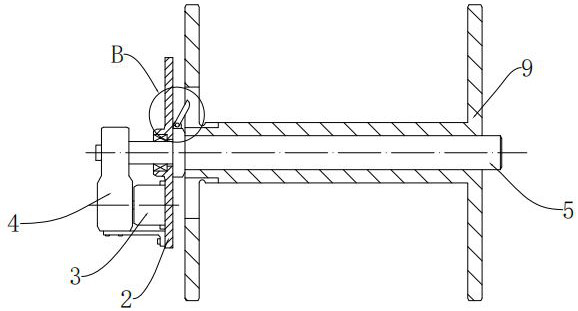

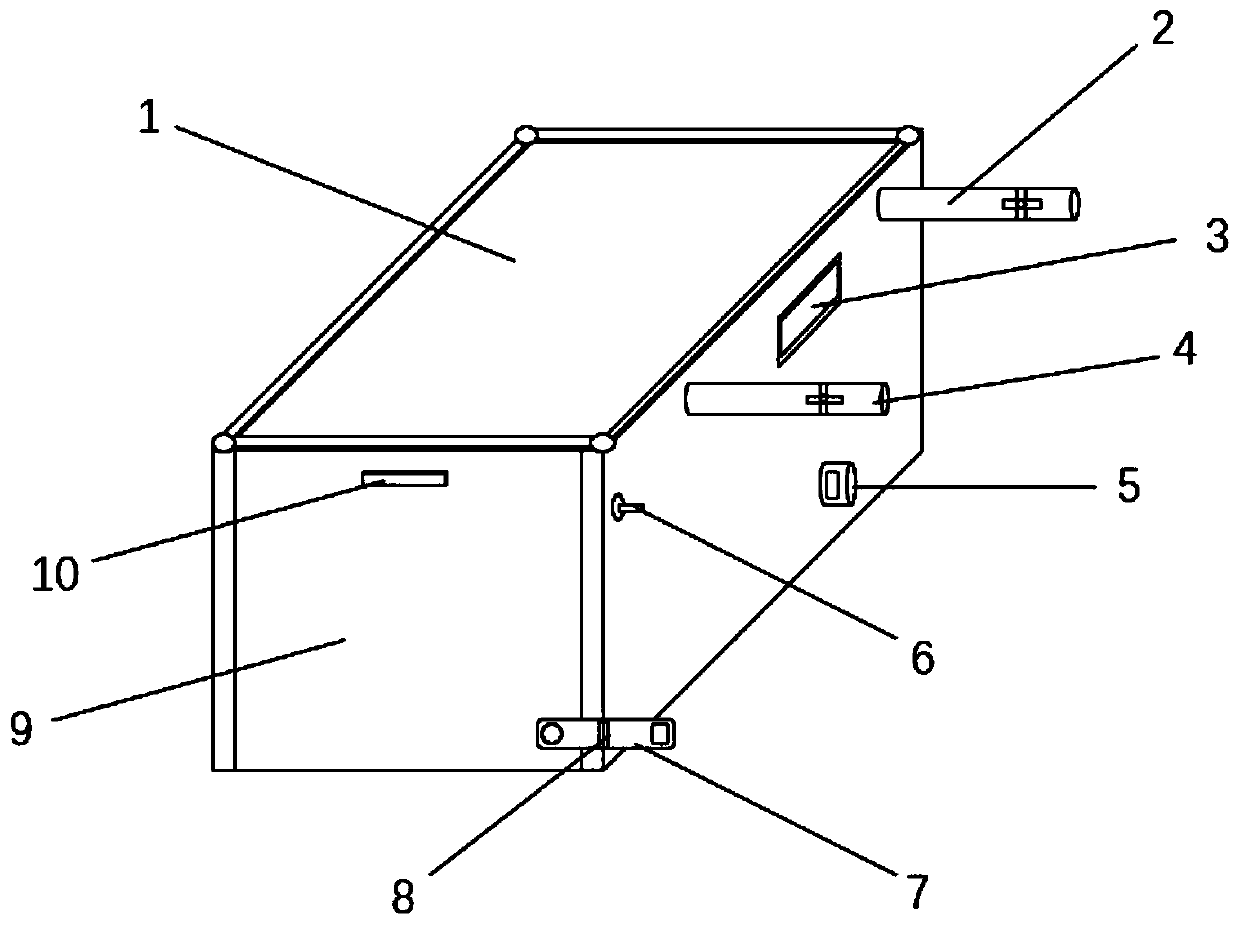

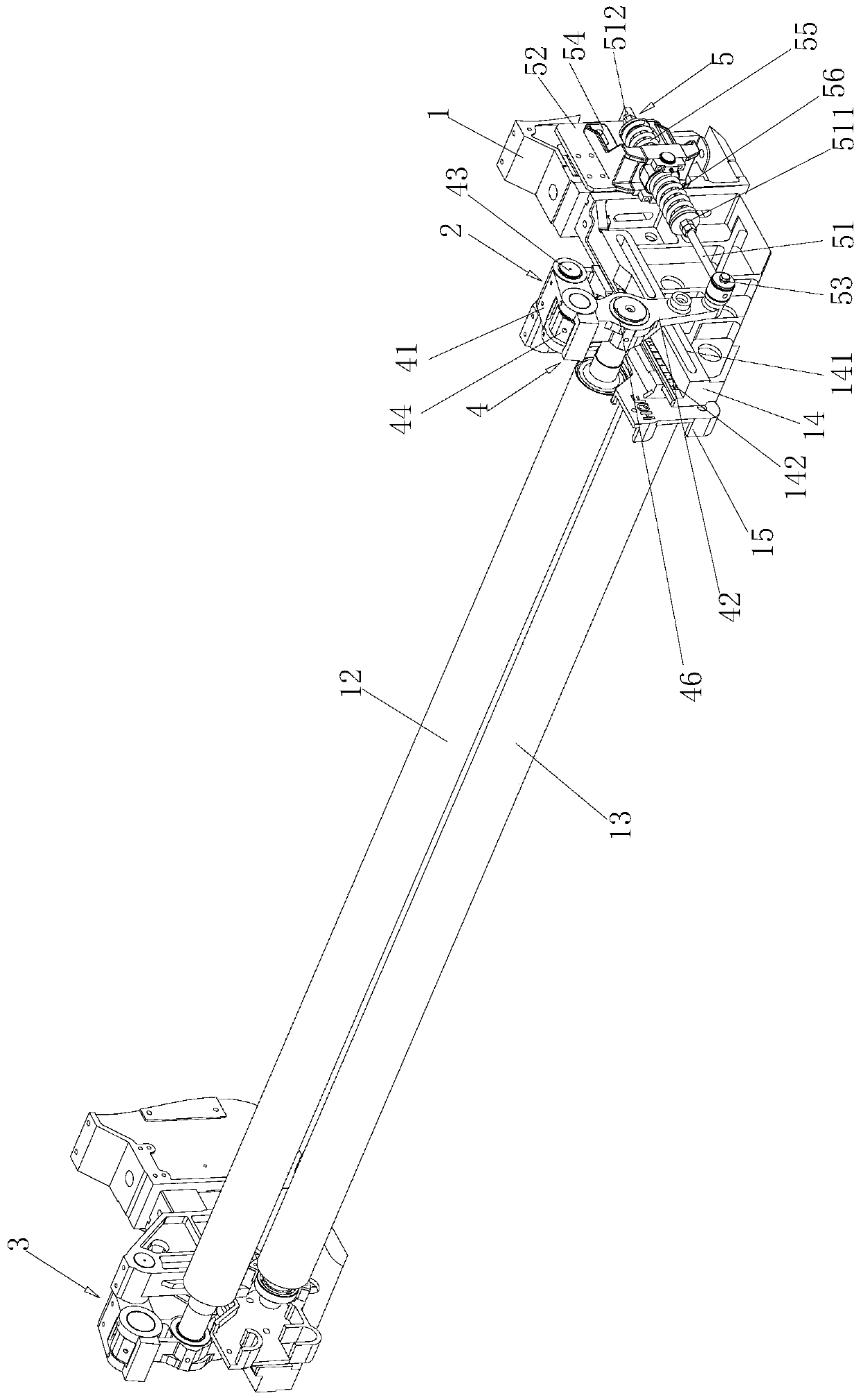

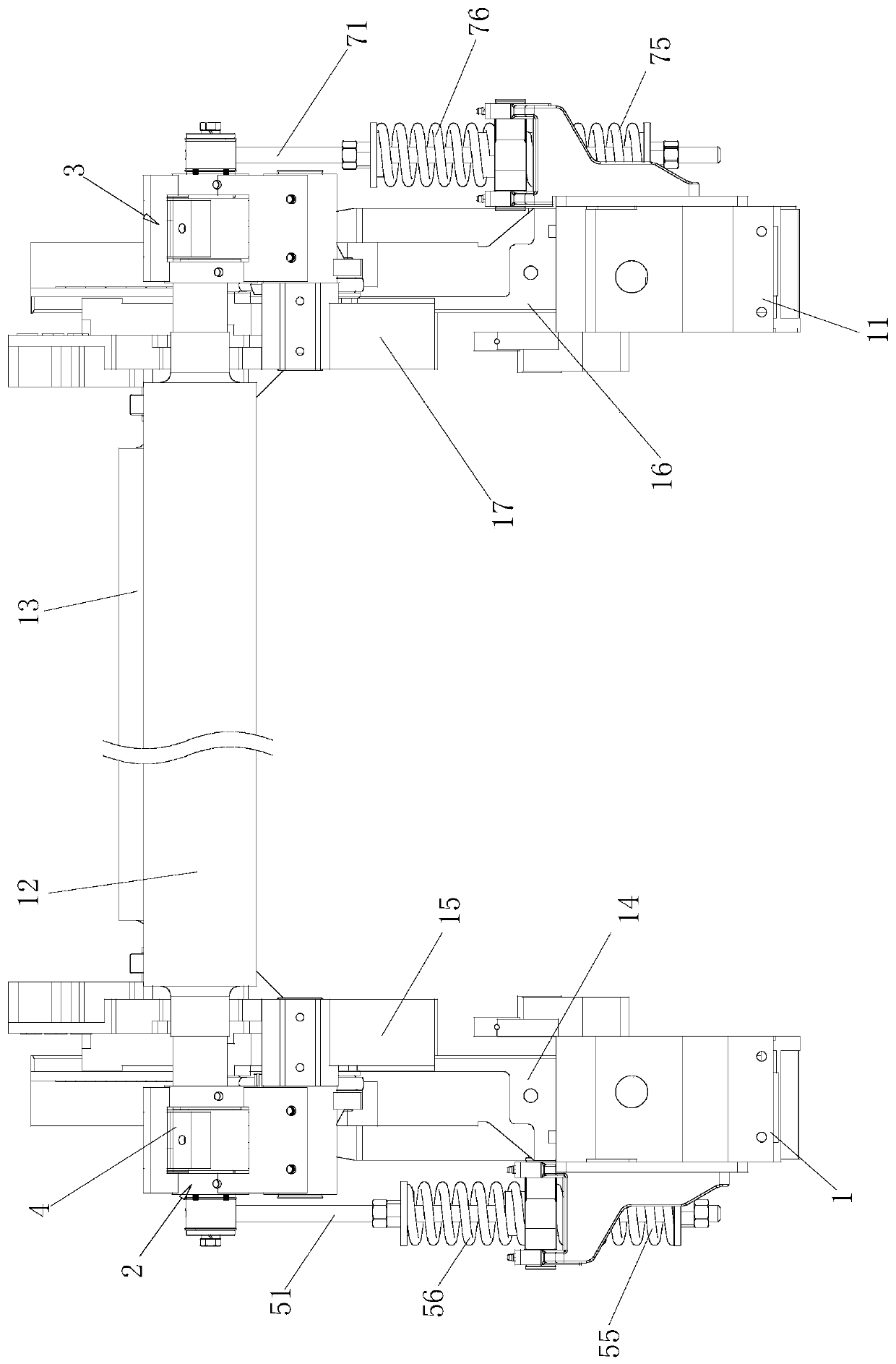

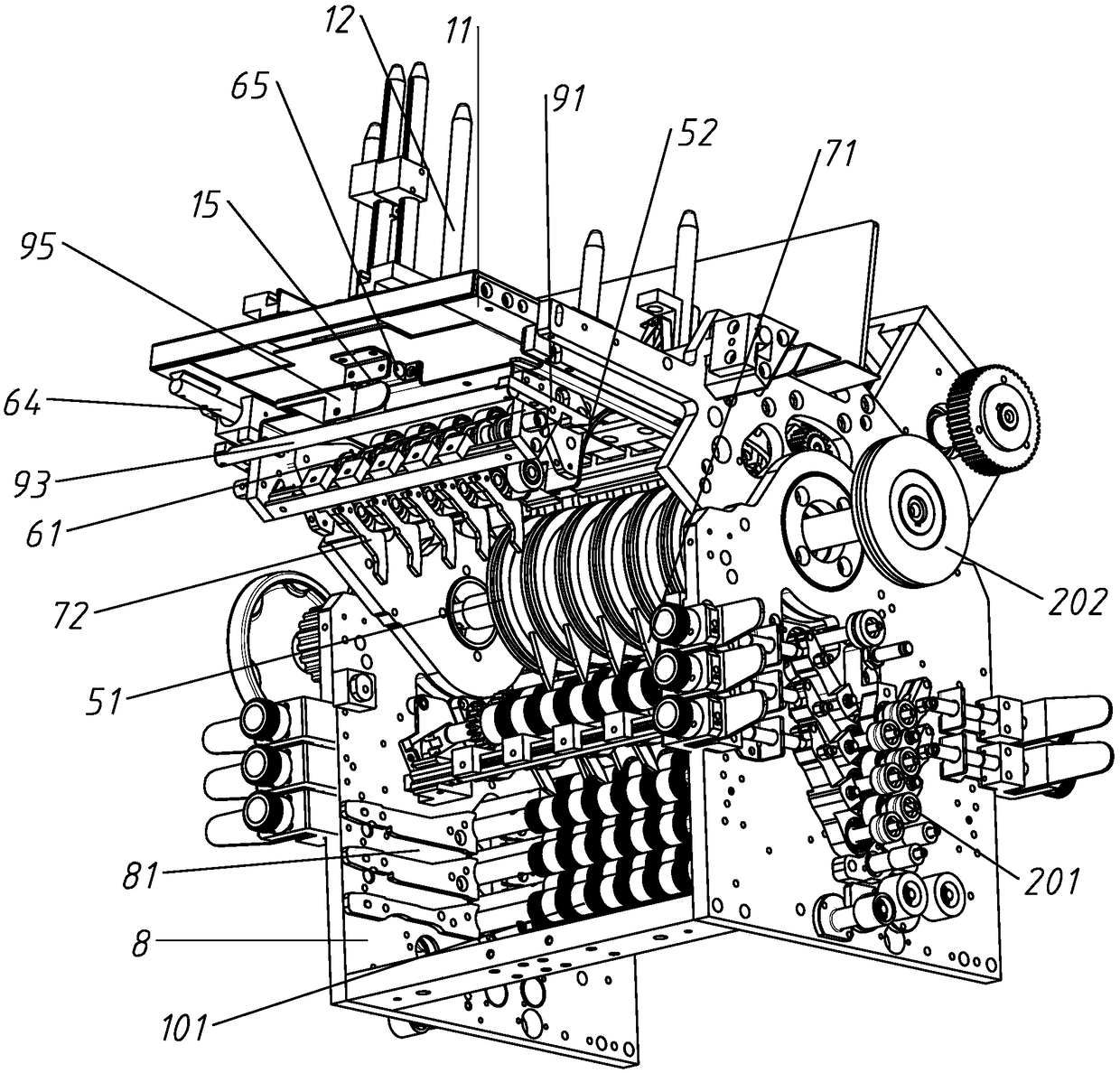

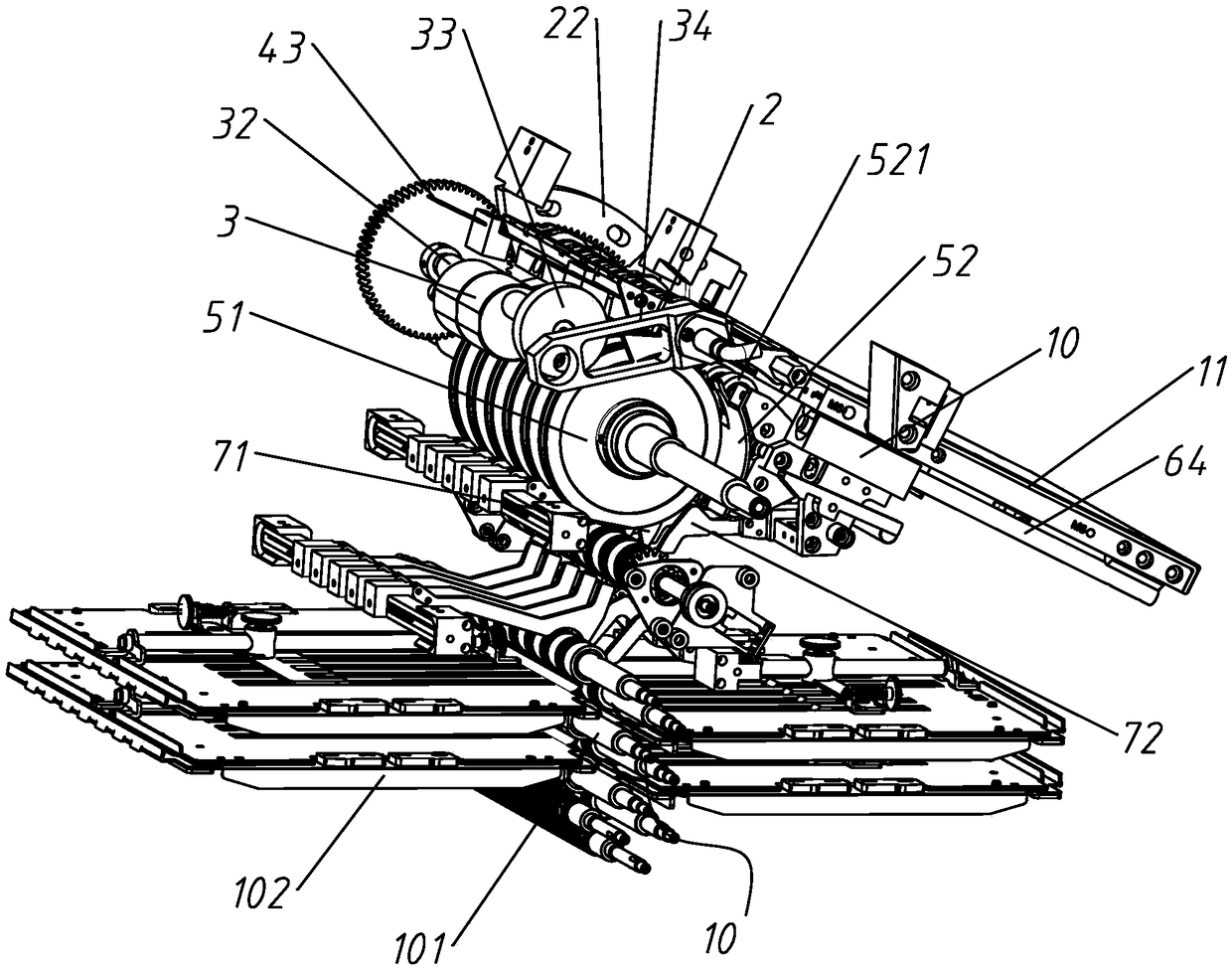

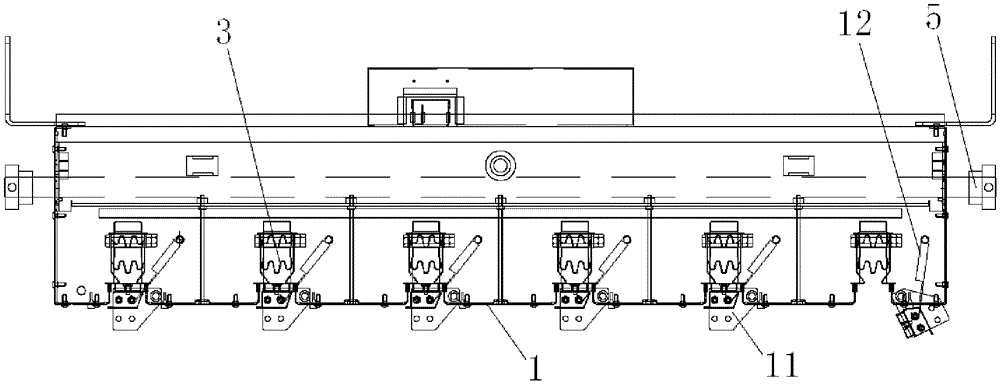

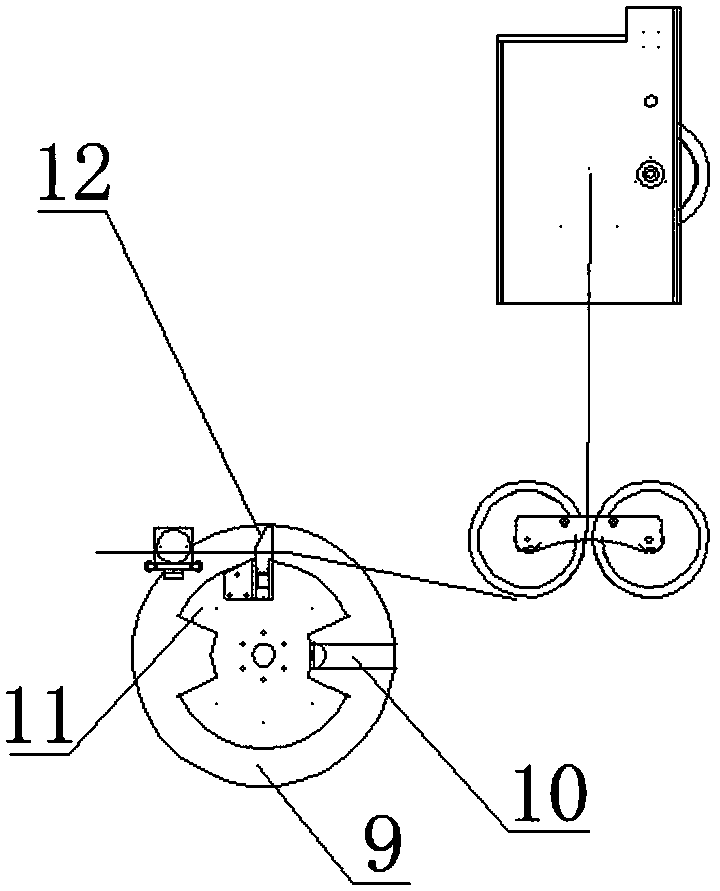

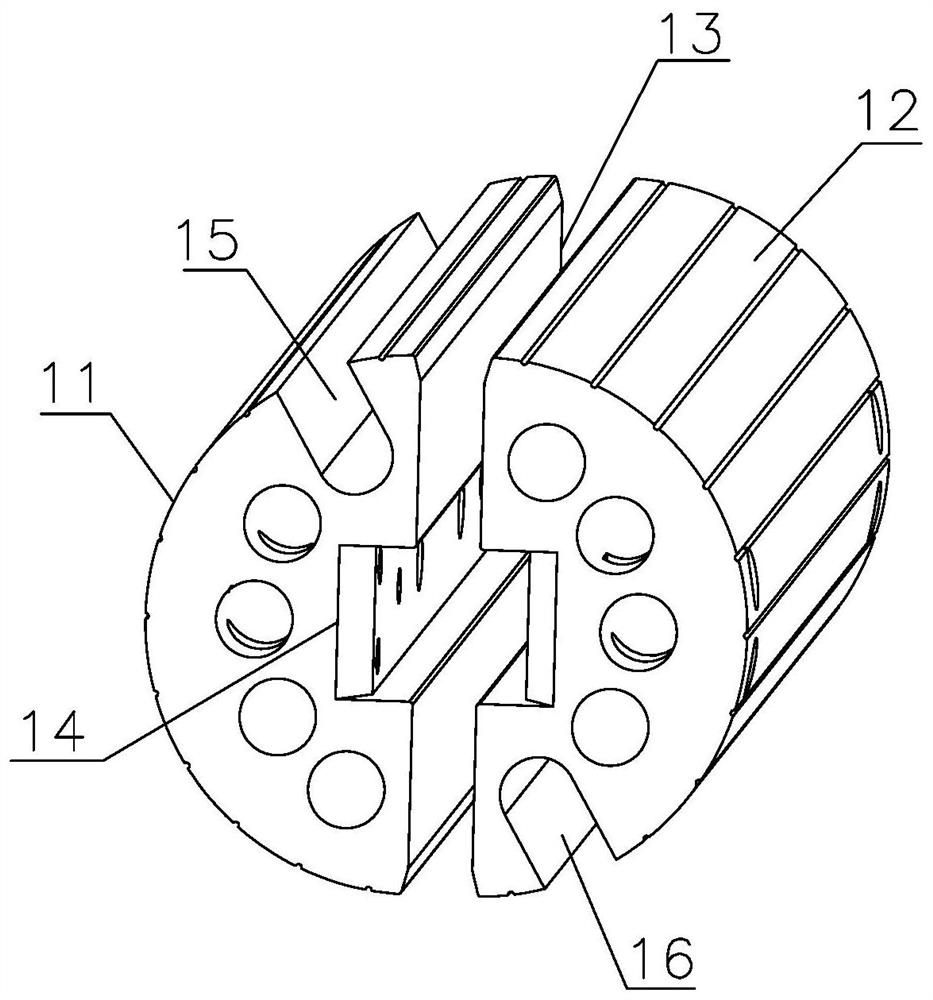

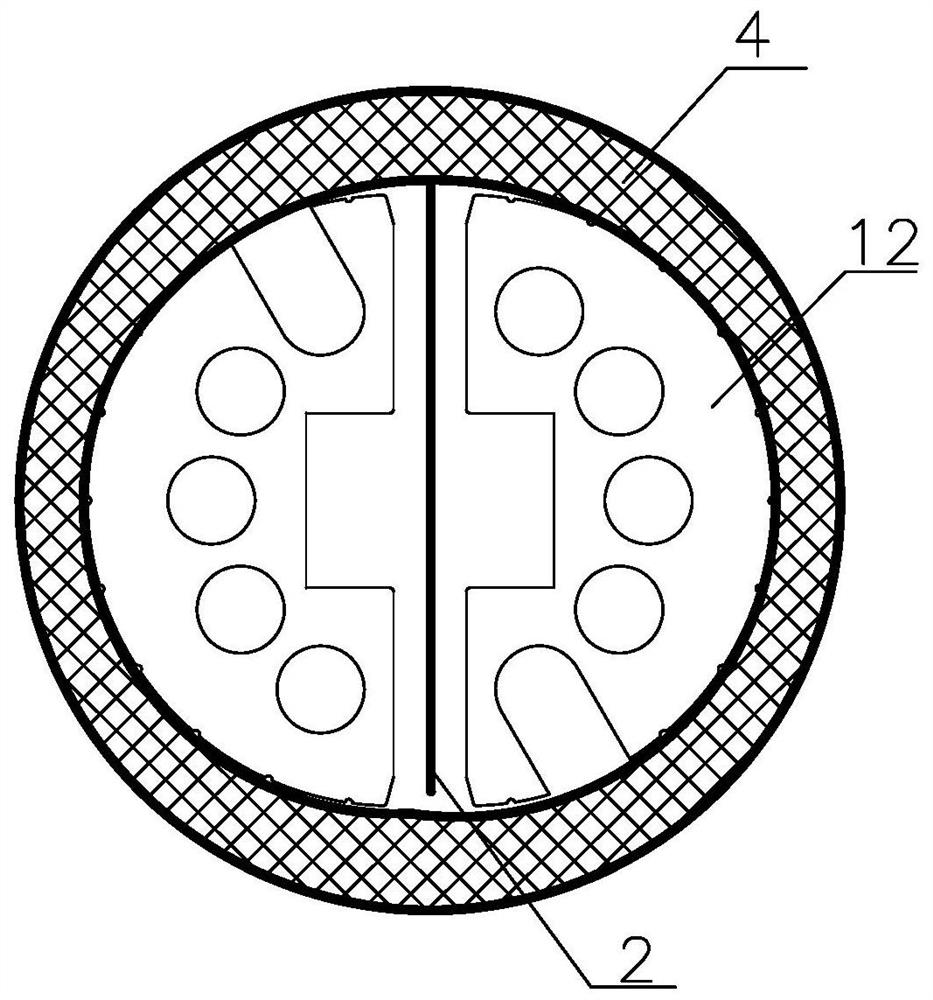

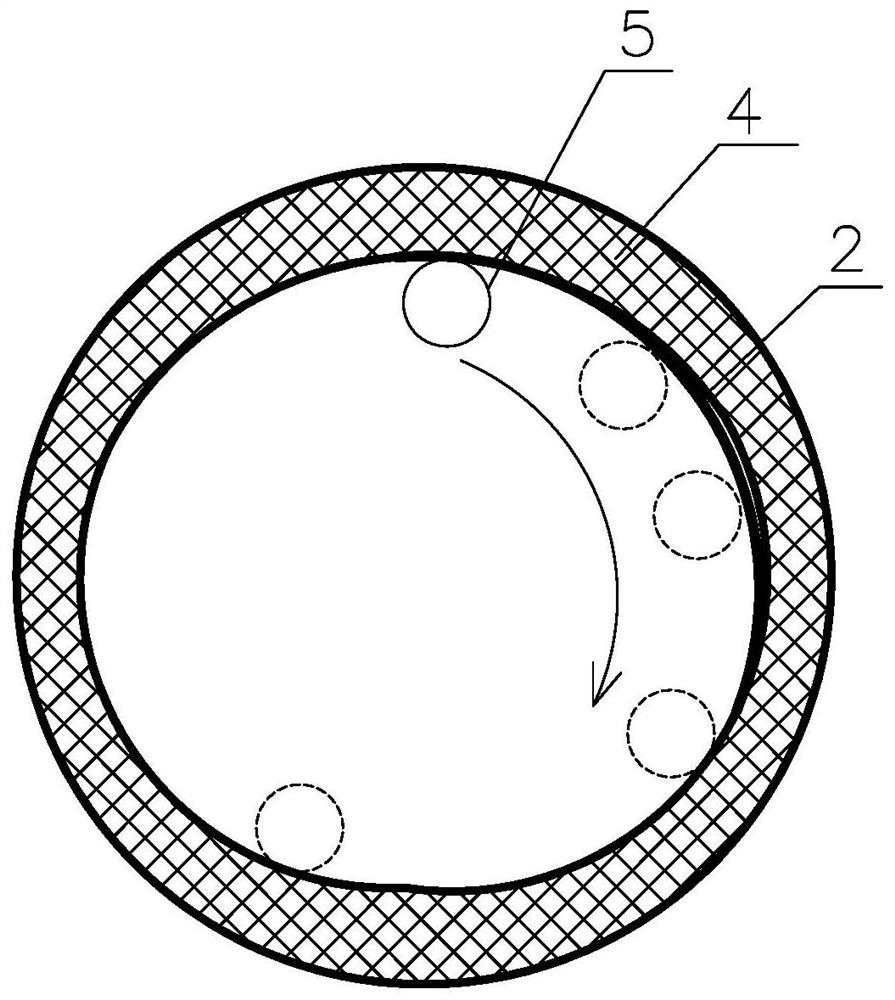

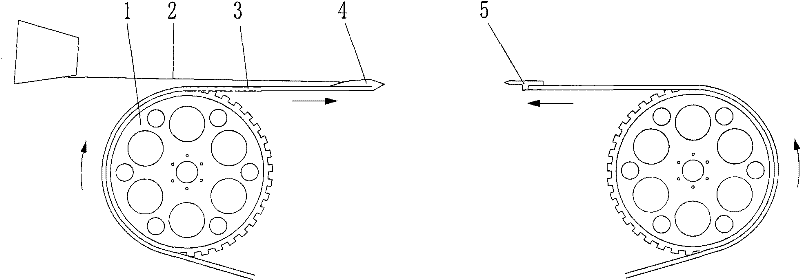

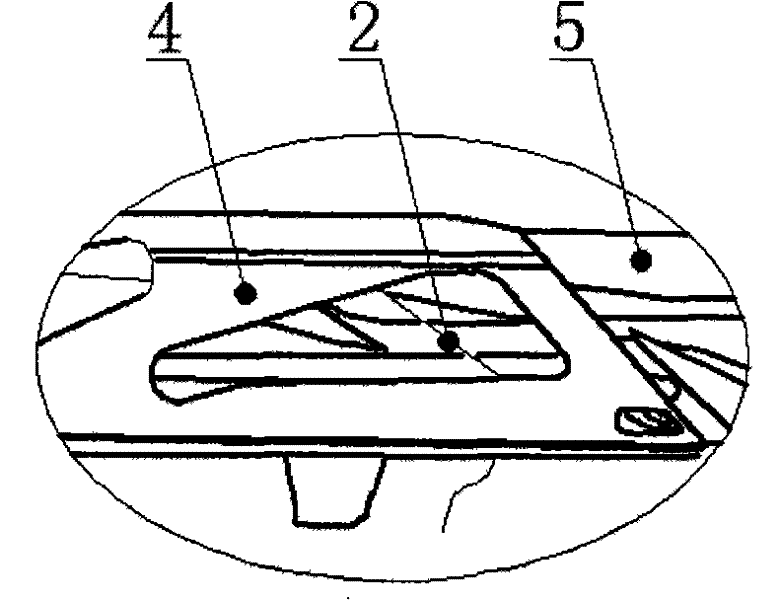

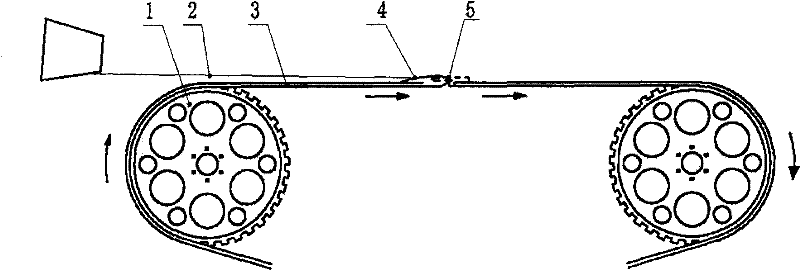

Underwater cable retracting mechanism

The invention discloses an underwater cable folding and unfolding device, it consists of cable, unfolding equipment and folding equipment, among them the unfolding equipment and folding equipment compose the main body of the invention; one end of cable is twined in the folding equipment interior after passing through the unfolding equipment. The invention can ensure cable is arranged in the cable storing space ordered, uniformly and densely in underwater environment, and avoid cable twined each other due to the attack of water flow in the folding and unfolding course, and also can reduce cable stretching force changing and release the attack to folding and unfolding device from cable.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

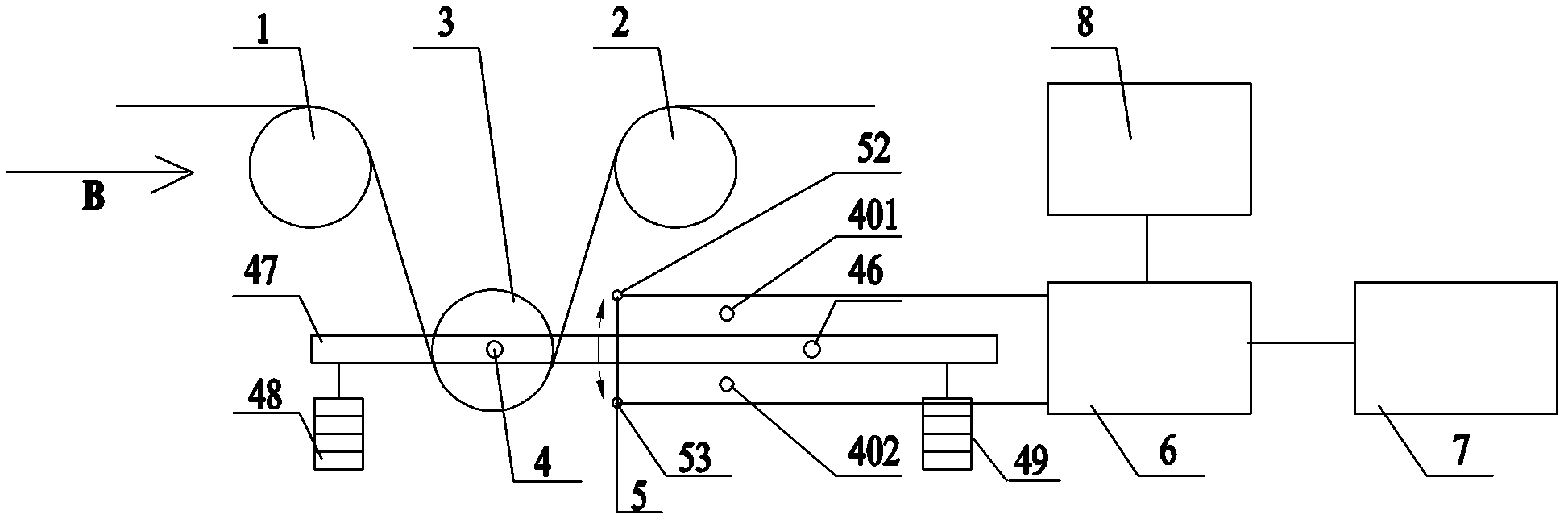

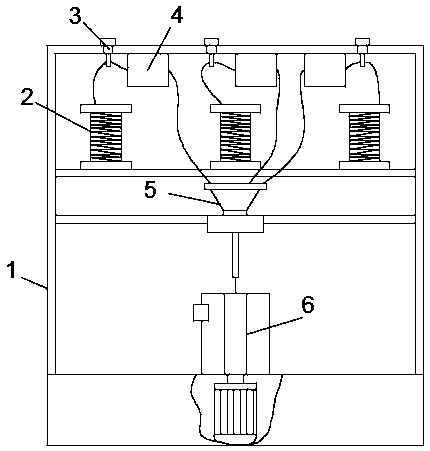

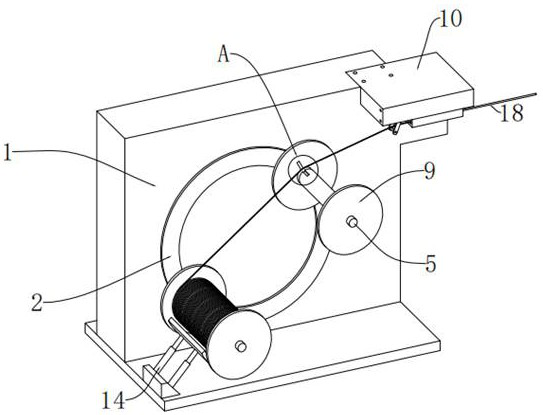

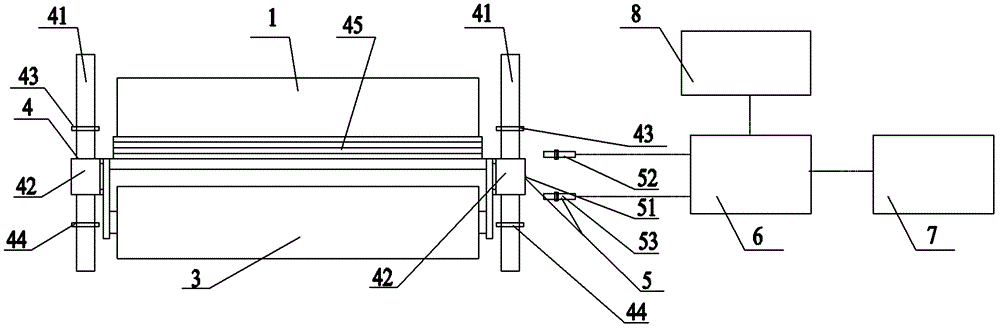

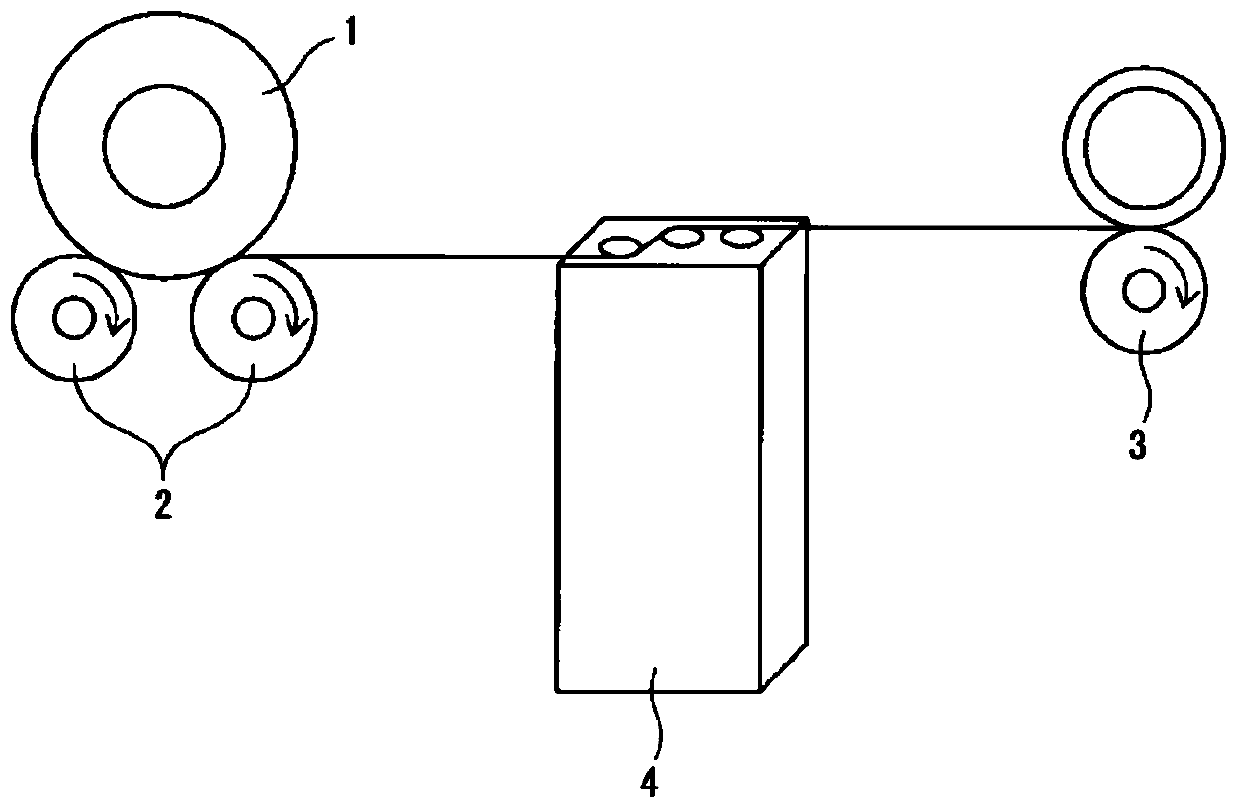

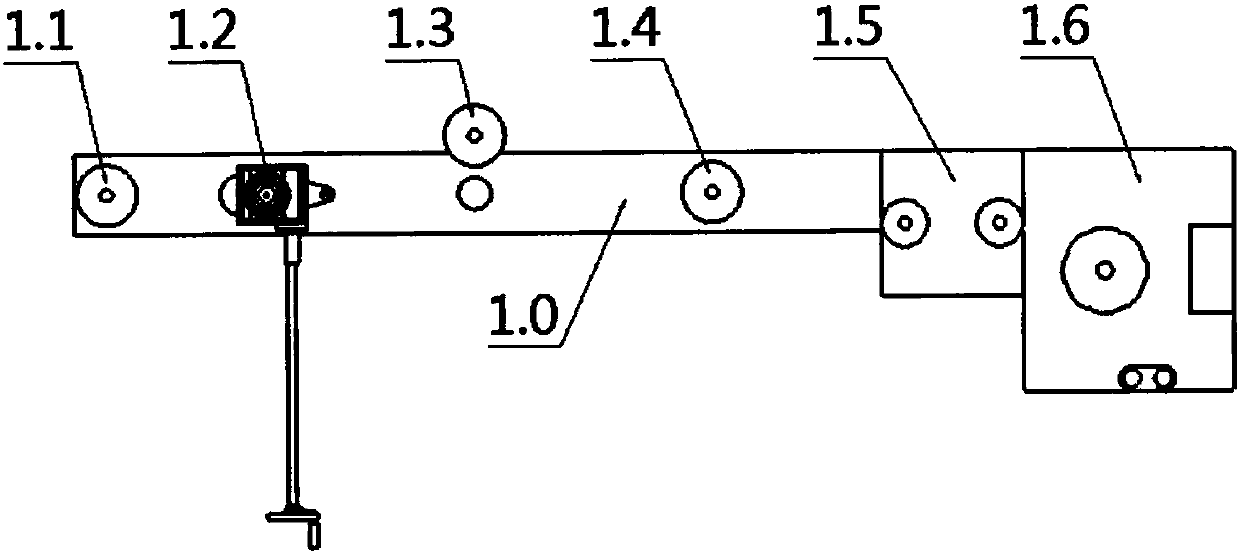

Tension control device for fiber tows

The invention discloses a tension control device for fiber tows. The tension control device comprises a first positioning roller, a second positioning roller, a tension roller, a guide device, a detection device, a controller and a motor speed regulator, wherein the guide device is used for guiding the movement of the tension roller; the detection device is used for detecting position change of the tension roller; the tension roller is positioned in a region between the first positioning roller and the second positioning roller; the axes of the tension roller, the first positioning roller andthe second positioning roller are parallel to one another; the tension roller is connected with the guide device; the detection device is used for feeding detection information of position change of the tension roller to the controller; and the controller is used for controlling the motor speed regulator to regulate the speed of a driving roller motor. By adopting the tension control device, the walking tension of carbon fiber tows can be regulated and controlled effectively, and carbon fibers with uniform and consistent quality can be produced; and the tension control device is suitable for large-scale industrial production, and has very good economic benefit and very wide application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

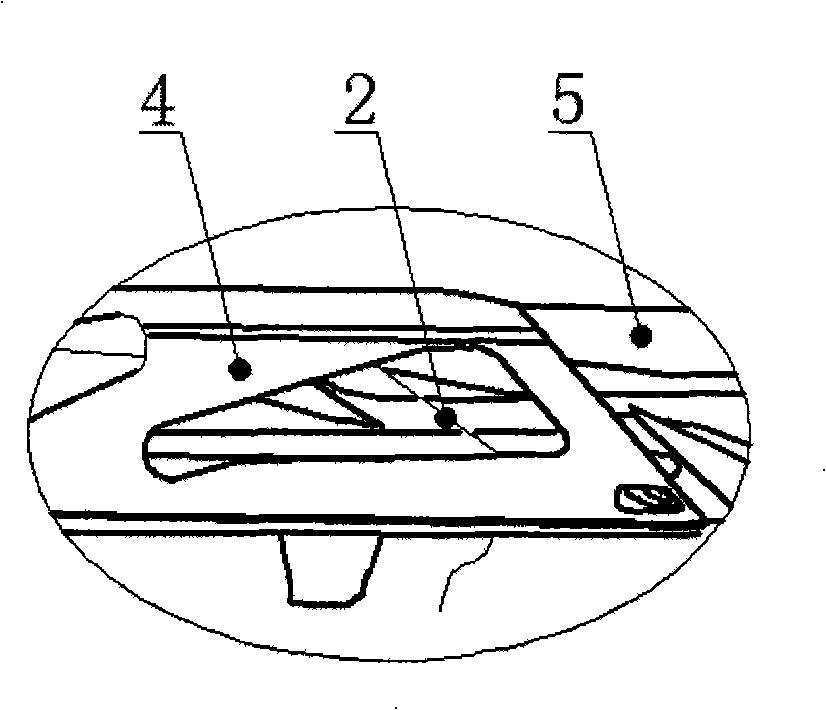

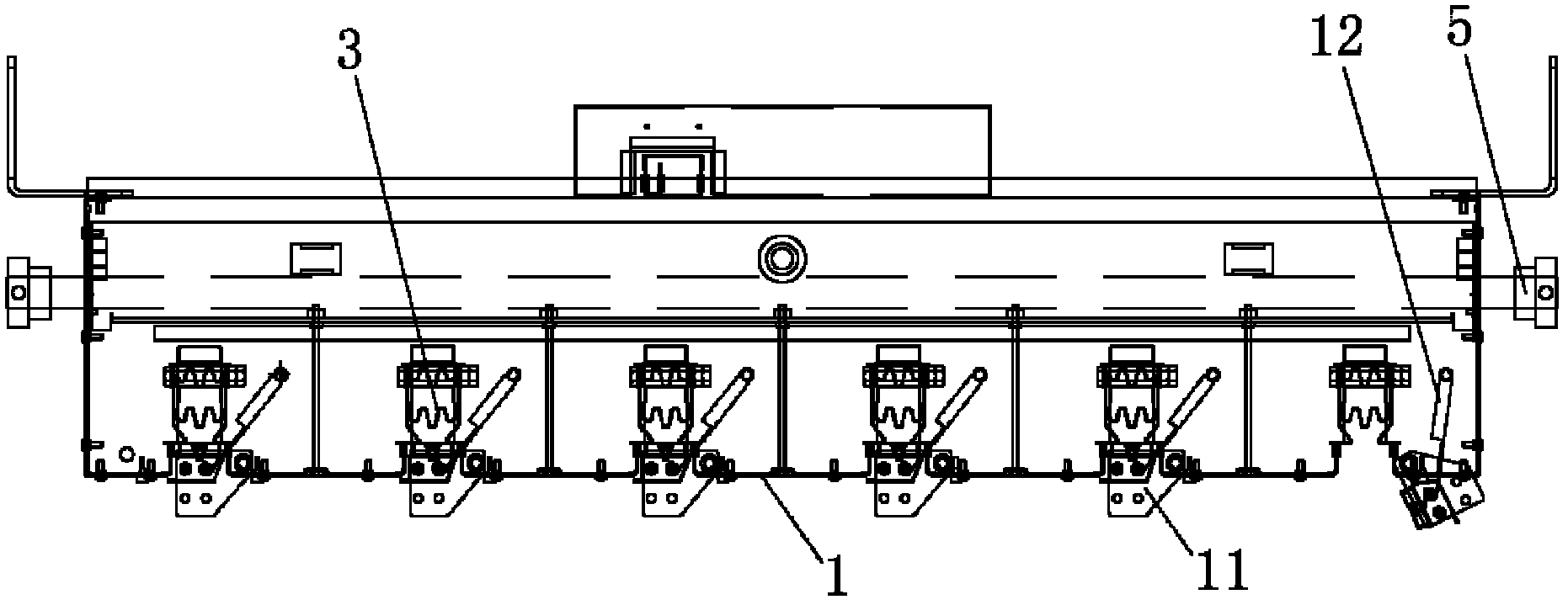

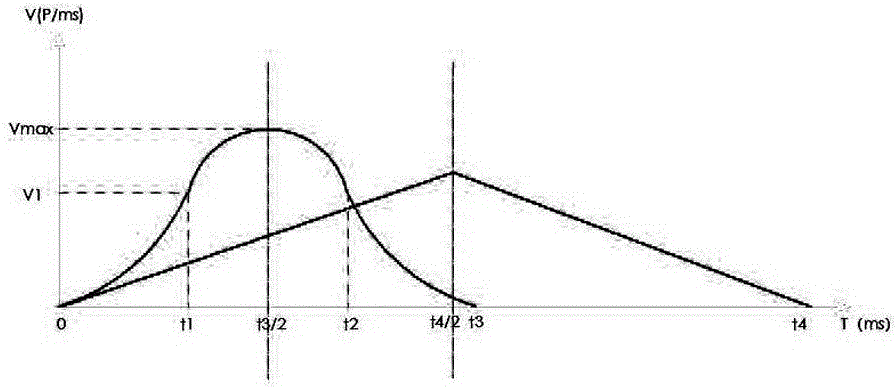

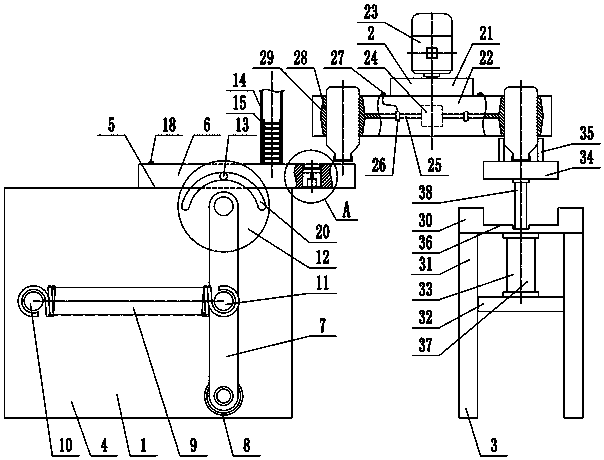

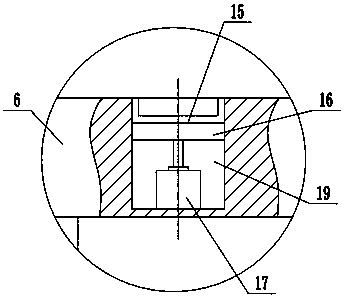

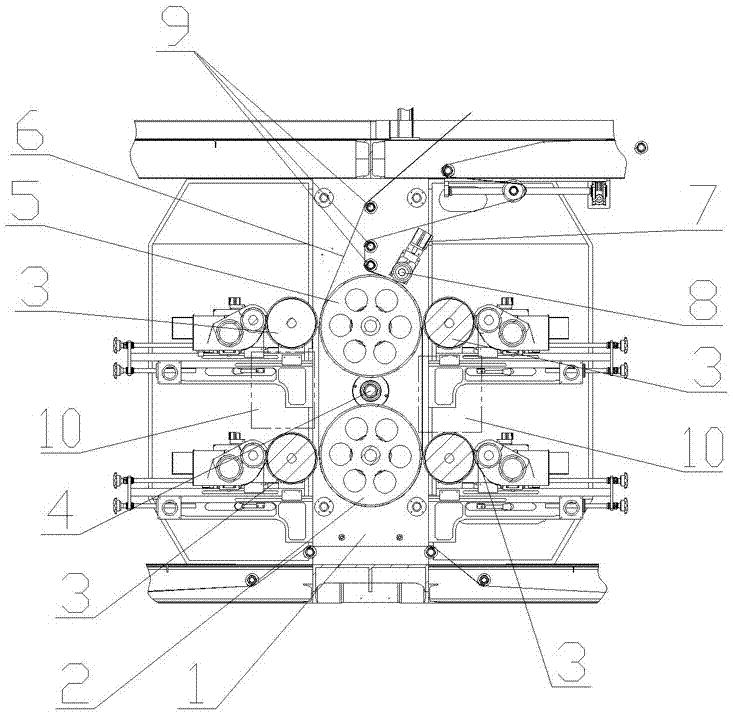

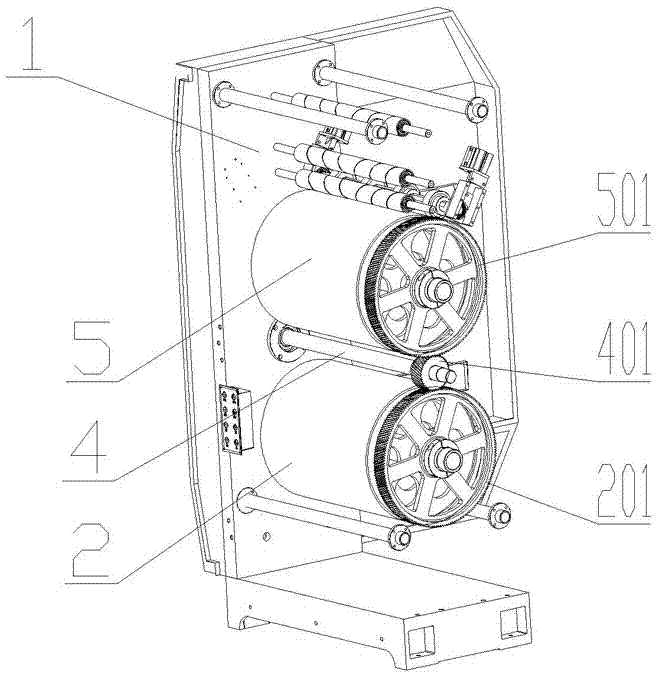

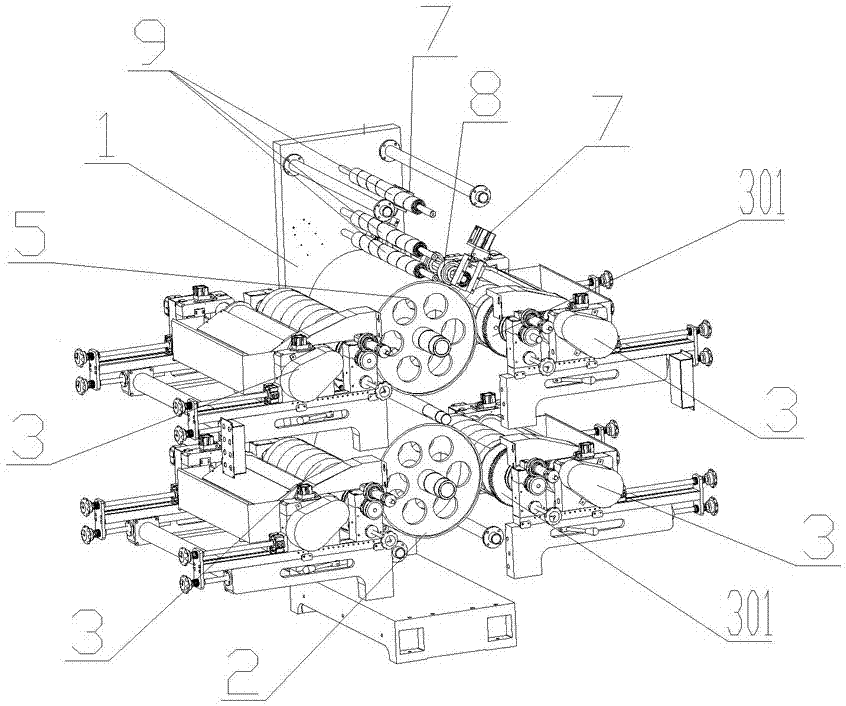

Woof-intersecting method and device thereof for weaving machine

The invention provides a woof-intersecting method and a device thereof for a weaving machine. The method utilizes the motion phase difference between a woof-feeding gripper head and a woof-receiving gripper head, enables the woof-receiving gripper head to move to a limit position in the advance direction and enables yarn brought by the woof-feeding gripper head to get across a yarn-hooking head of the woof-receiving gripper head so that the woof-receiving gripper head starts to retreat, the woof-feeding gripper head still advances to a limit position in the advance direction to finish yarn intersection before the woof-feeding gripper head retreats until the yarn is finished. The device comprises a woof-feeding mechanism and a woof-receiving mechanism which are respectively arranged at both sides of a weaving machine main shaft, and a relative mounting angle between the weaving machine main shaft and a woof-feeding main shaft fixing part at one end of the weaving machine main shaft is larger than a relative mounting angle between the weaving machine main shaft and a woof-receiving main shaft fixing part at the other end of the weaving machine main shaft. The invention enables the tension of the yarn to have little change during the yarn intersection, does not influence the detection of a yarn-stopping device, improves the success rate of the yarn intersection, reduces false yarn stops due to the high-speed motion of the weaving machine and can improve the rotating speed of the weaving machine so as to improve the production efficiency.

Owner:林东

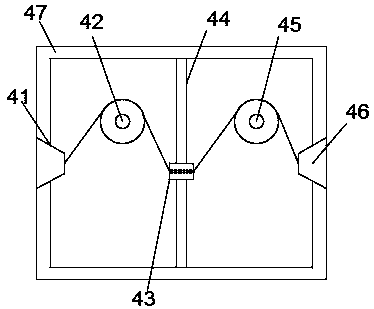

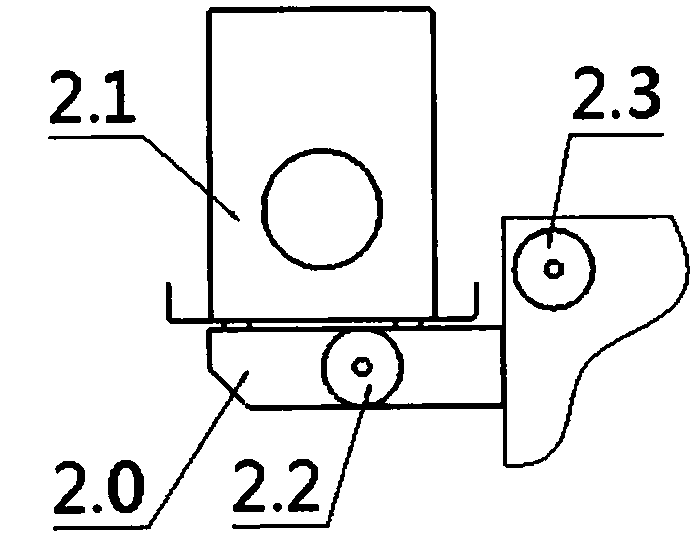

Tension self-adjusting multi-strand twister and thread twisting method thereof

PendingCN109629052ASmall tension changeSatisfy twist tension requirementsTextiles and paperYarnEngineering

The invention relates to a tension self-adjusting multi-strand twister and a thread twisting method thereof. In order to solve the problem that a twister in the prior art can not adjust tension independently, the invention provides the tension self-adjusting multi-strand twister and the thread twisting method thereof. According to the technical scheme, the twister includes a machine frame, a yarnbarrel, a yarn guide device, a winding device, a tension fine-adjusting device and a thread twisting device. The yarn barrel is fixed on the machine frame. The tension fine-adjusting device includes ashell, a first thread guide wheel, a tension fine-adjustment component, a sliding rod and a second thread guide wheel. The first thread guide wheel and the second thread guide wheel are rotatably connected with the shell; the sliding rod is rotatably connected with the shell, the thread twisting device includes a yarn guide rod, a tensioner, a twisting spindle and an installation base, the installation base is fixed on the machine frame, the twisting spindle is installed on the installation base, and the twisting spindle is provided with a filament inlet and a filament outlet. The tension ofeach yarn can be adjusted according to the need, the change of the tension of the yarn in the twisting process is effectively reduced, and the product quality is improved.

Owner:桐乡市龙琪纺织有限公司

Hot-rail deformation hot box

The invention discloses a hot-rail deformation hot box, which comprises a shell, and a heating liner container, hot rails and temperature sensors, which are arranged inside the shell; a thermal insulation material is filled between the shell and the heating liner container; heating medium is arranged inside the heating liner container, and the outer wall of the heating liner container is detachably and fixedly provided with a plurality of groups of heating elements; the quantity of the hot rails is multiple, the hot rails are fixed on the shell, one end of each hot rail is in welding connection with the heating liner container, each hot rail is of a hollow structure, and an inner cavity of each hot rail is communicated with an inner cavity of the heating liner container; and the upper end and the lower end of the heating liner container are respectively provided with one temperature sensor. The outer wall of the heating liner container is provided with the groups of heating elements, which work simultaneously, so that not only is rapidness in heating speed realized, but also a yarn path is uniformly heated.

Owner:墨瑞新材料(常州)有限公司

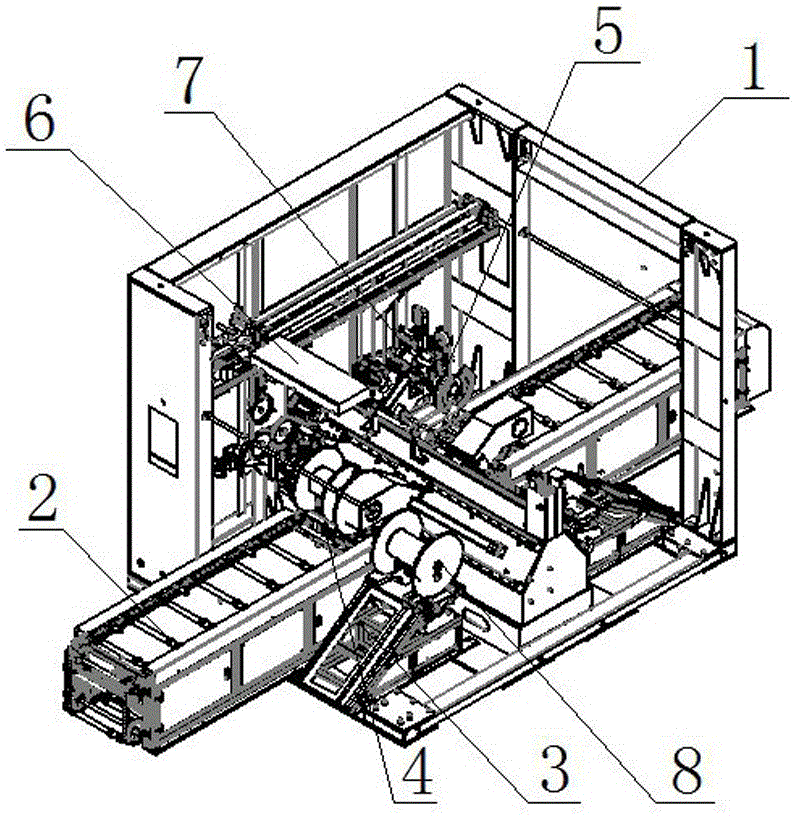

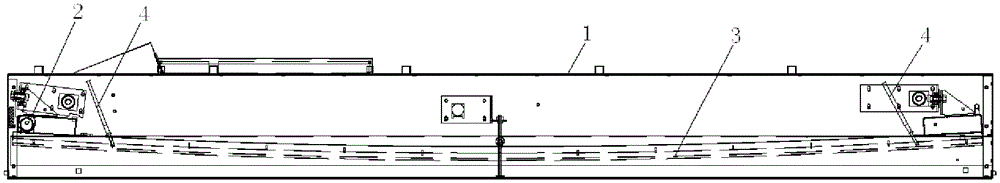

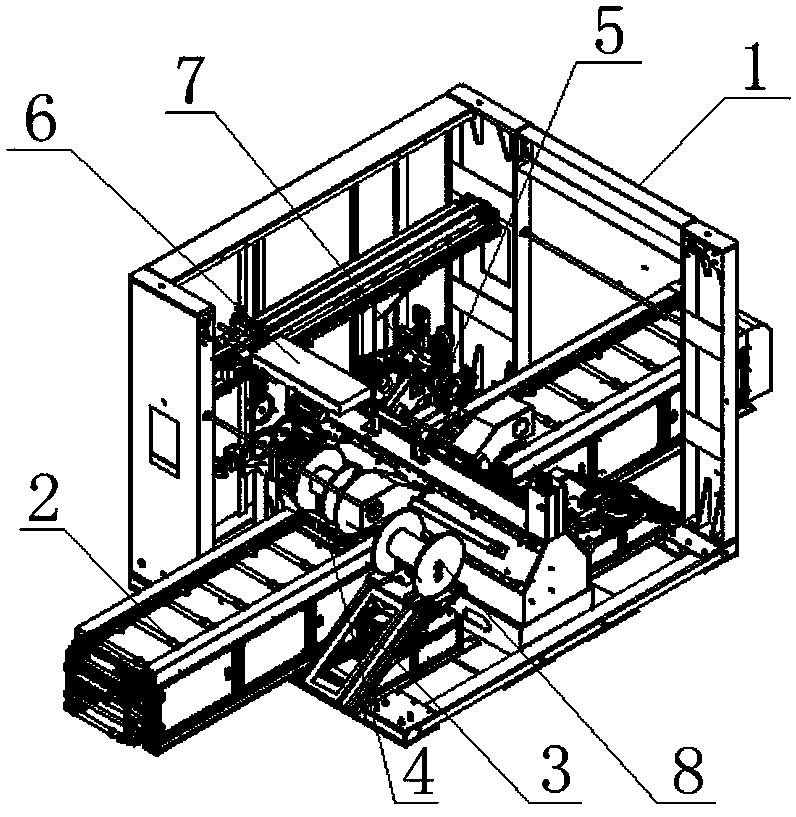

Leather cable feeding and winding method

ActiveCN106315307ASmall tension changeAvoid breaking or deforming cablesFilament handlingEngineeringConductor Coil

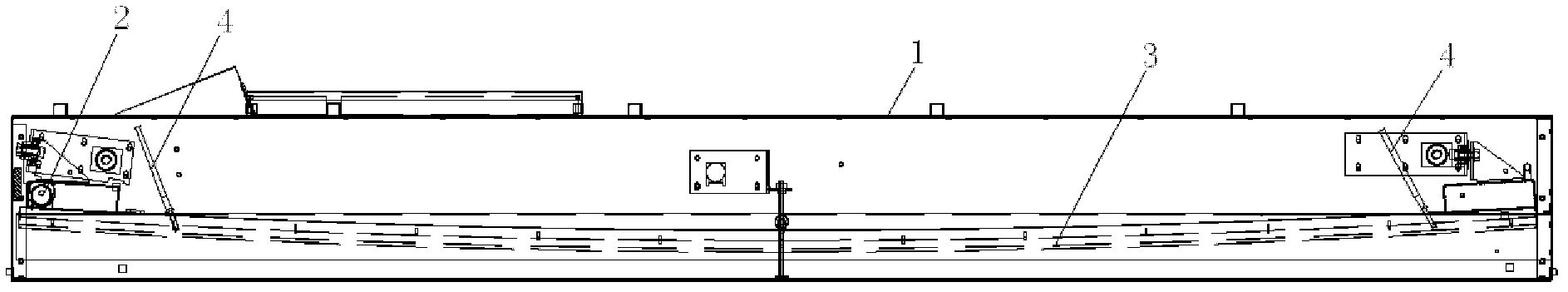

The invention discloses a leather cable feeding and winding method. A disc cable feeding opening is vertically and downwards arranged on a disc sending mechanism. The cable clamp initial position of the side face of a winding disc is located in the clockwise 90-degree direction of the disc cable feeding opening; a disc is conveyed to the designated position on the disc sending mechanism, the disc is lifted and clamped through a lifting mechanism and a cable disc clamping and rotating mechanism, and the cable disc clamping and rotating mechanism drives the disc to rotate clockwise by 90 degrees so that a cable clamp can be located over the winding disc; a transverse cable arranging mechanism and the cable clamp act to conduct cable catching, a cable is clamped in the cable clamp and then rotates by 90+alpha degrees, and therefore the cable is right located at the position of the disc cable feeding opening; and the transverse cable arranging mechanism moves towards the inner side of the winding disc and drives the cable disc clamping and rotating mechanism to clockwise drive the winding disc to rotate to conduct winding. The leather cable feeding and winding method suitable for mechanical operation is provided, the cable feeding and catching success rate is high, cable cracking or deforming caused by sudden tension changes is avoided, and meanwhile the winding efficiency is improved.

Owner:中天智能装备有限公司

Underwater cable retracting mechanism

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Paying-off device for wire of excessively small diameter

InactiveCN109368374AReduce tensionTension drop and stabilityFilament handlingNitrile rubberEngineering

The invention discloses a paying-off device for a wire of an excessively small diameter. The paying-off device for the wire of the excessively small diameter structurally comprises locking pieces, a rotating shaft, a tension adjusting device, a paying-off disk, a loading and unloading frame, rotating wheels, locking bolts, a wire outlet hole, a traction guide roller and a paying-off body. When thepaying-off device for the fine wire starts to pay off the wire with the diameter smaller than 0.05 mm, the pressure and friction force between the paying-off disk and a tray are reduced, so that theconstraint borne by the paying-off disk during rotation is reduced; when paying-off is stopped, the pressure and friction force between tension wheels and a tension disk are increased, the rotating wheels are controlled through nitrile rubber mats, the tension disk assists the tray to adjust the speed of the paying-off disk, so that the paying-off disk and the rotating wheels evenly reduce the paying-off speed until stop, the tension change degree during paying off is reduced, the quality and yield of the wire are guaranteed, and the production efficiency and the paying-off efficiency of the wire are improved.

Owner:泉州台商投资区五季网络有限公司

Automatic winding displacement device for PC steel strand rewinding

PendingCN114084742AEfficient windingEffective contactFilament handlingArticle deliveryReduction driveElectric machinery

The invention provides an automatic winding displacement device for PC steel strand rewinding; the device comprises a rack and is characterized in that a rotating disc which is driven by a motor to axially rotate along a central point is arranged on the rack, and two winding rotating shafts with symmetrical stations are arranged on the rotating disc; the winding rotating shafts are in transmission connection with a driving motor fixedly installed on the back side of the rotating disc through speed reducers, the winding rotating shafts are sleeved with a winding disc, the winding disc and the winding rotating shafts are in circumferential transmission through a key groove structure, and the winding rotating shafts are provided with cutting-off mechanisms which extend out of a notch in the side surface of the winding disc, cut off the steel strand and fix the end. A feeding mechanism is arranged on one side of the rack and used for feeding materials towards the winding disc side. According to the automatic winding displacement device, due to the arrangement of the double-station alternate winding disc and the automatic cutting mechanism, the steel strand can be automatically cut off without shutdown and efficiently wound, and the automatic winding displacement device has a good development prospect.

Owner:武汉钢铁江北集团金属制品有限公司

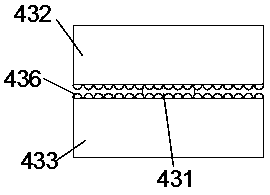

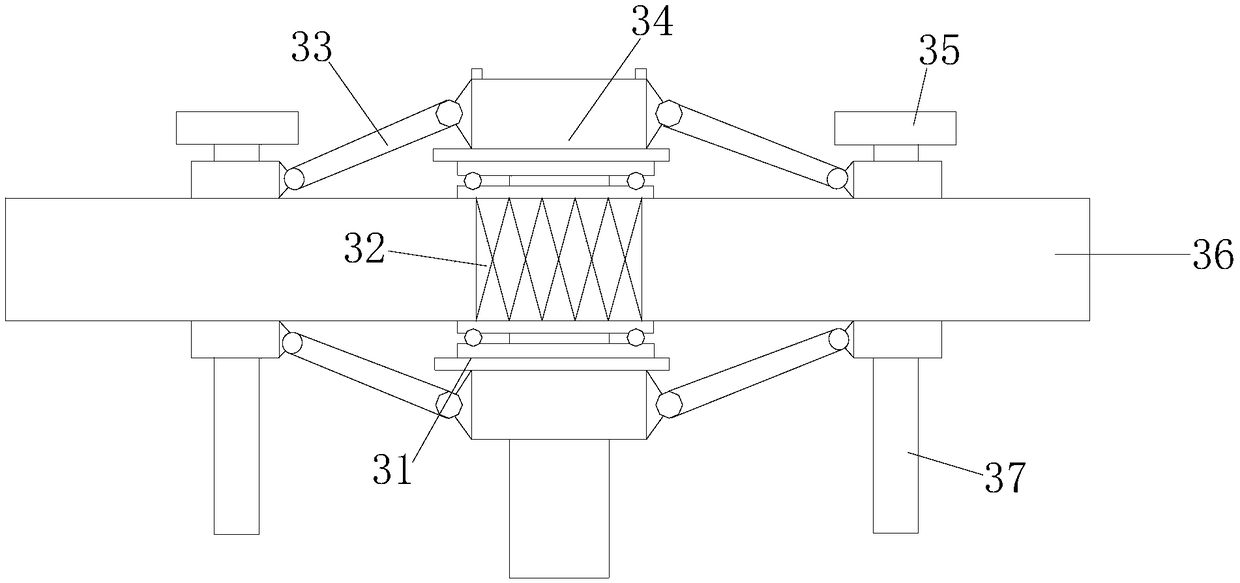

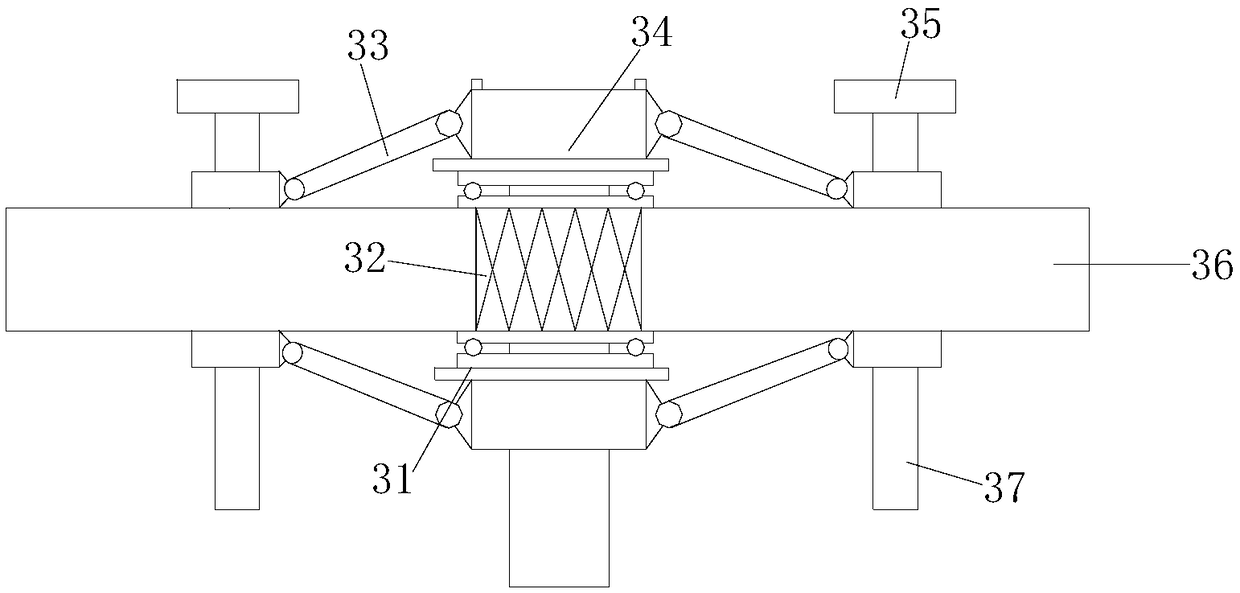

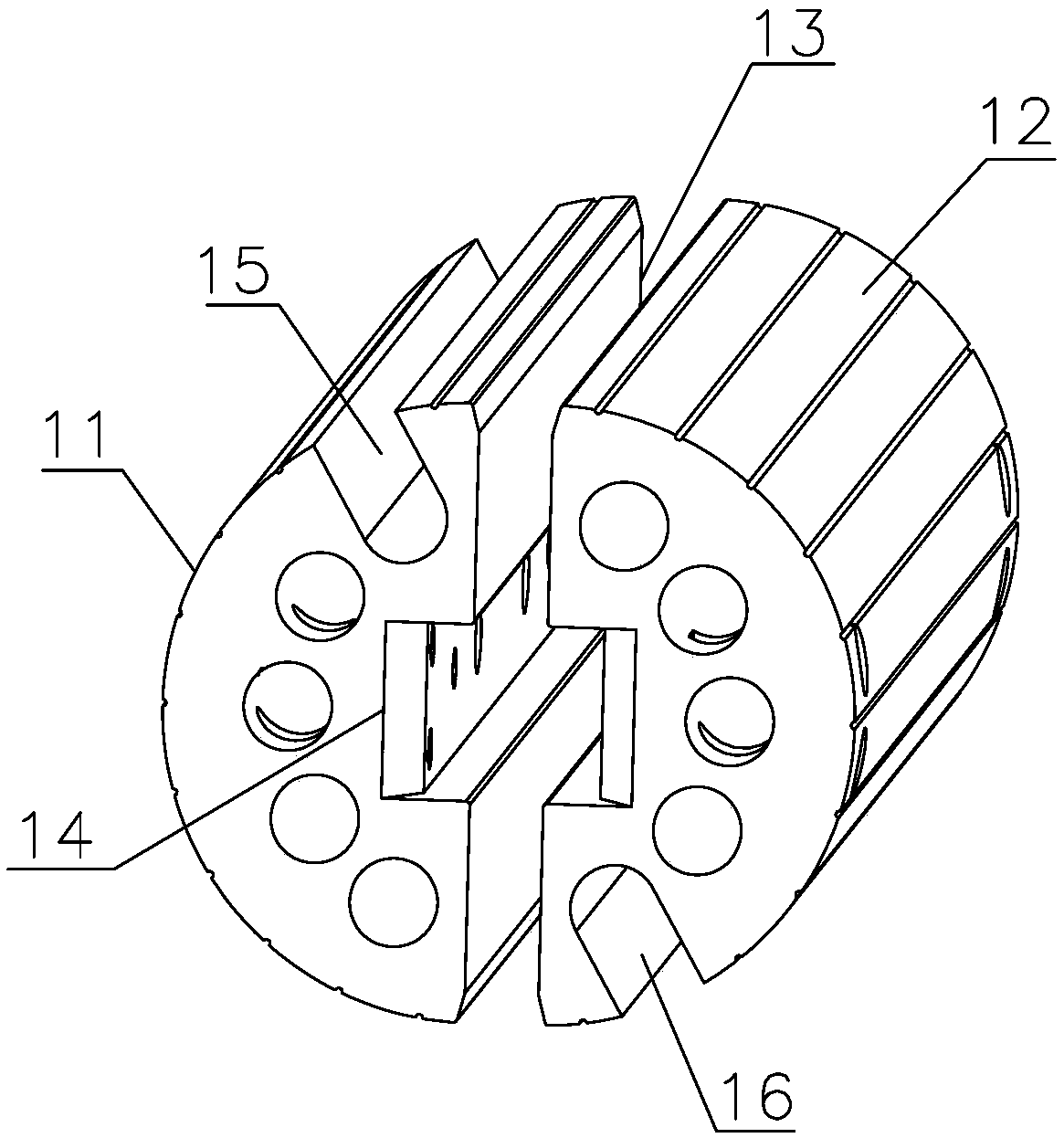

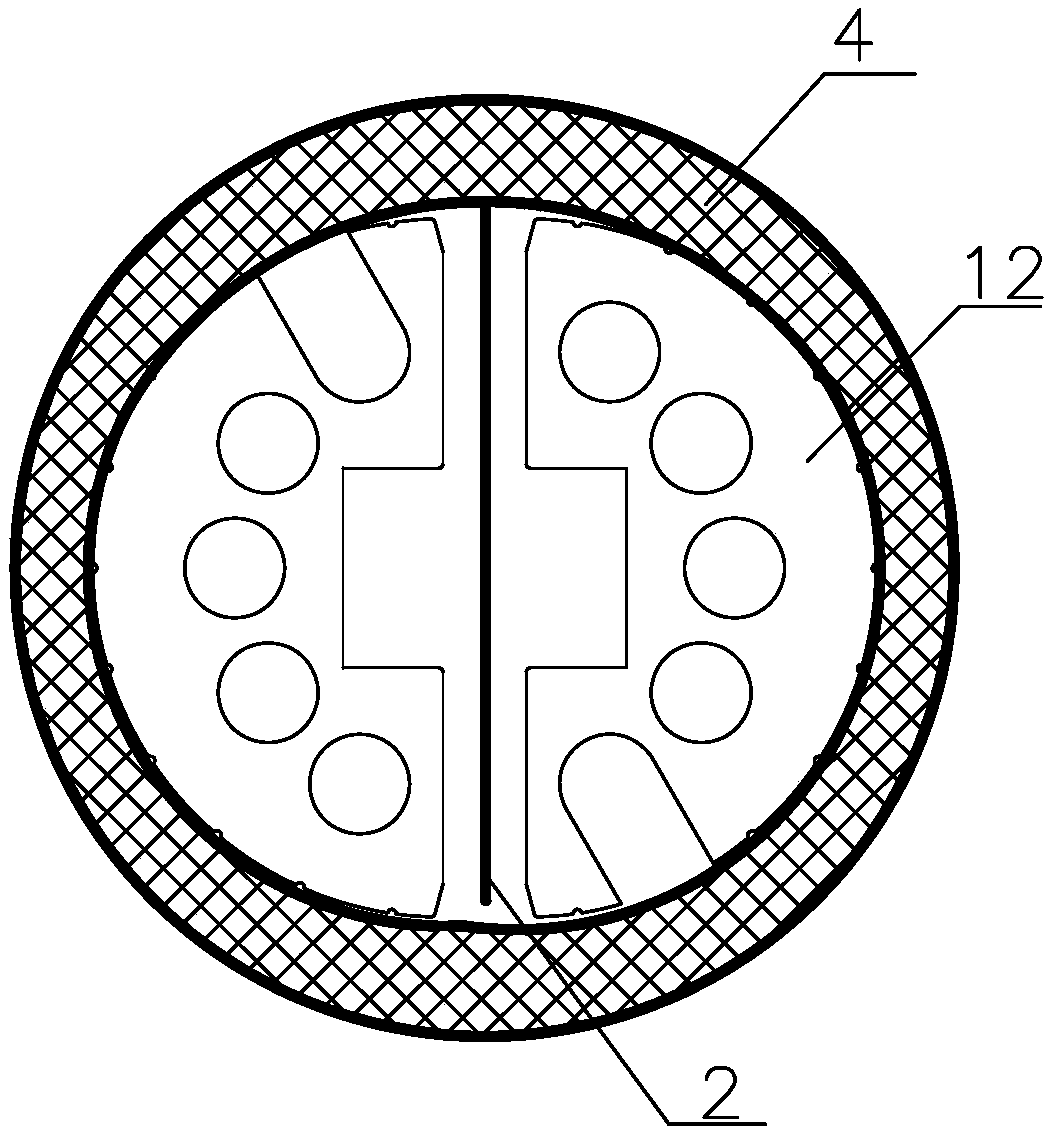

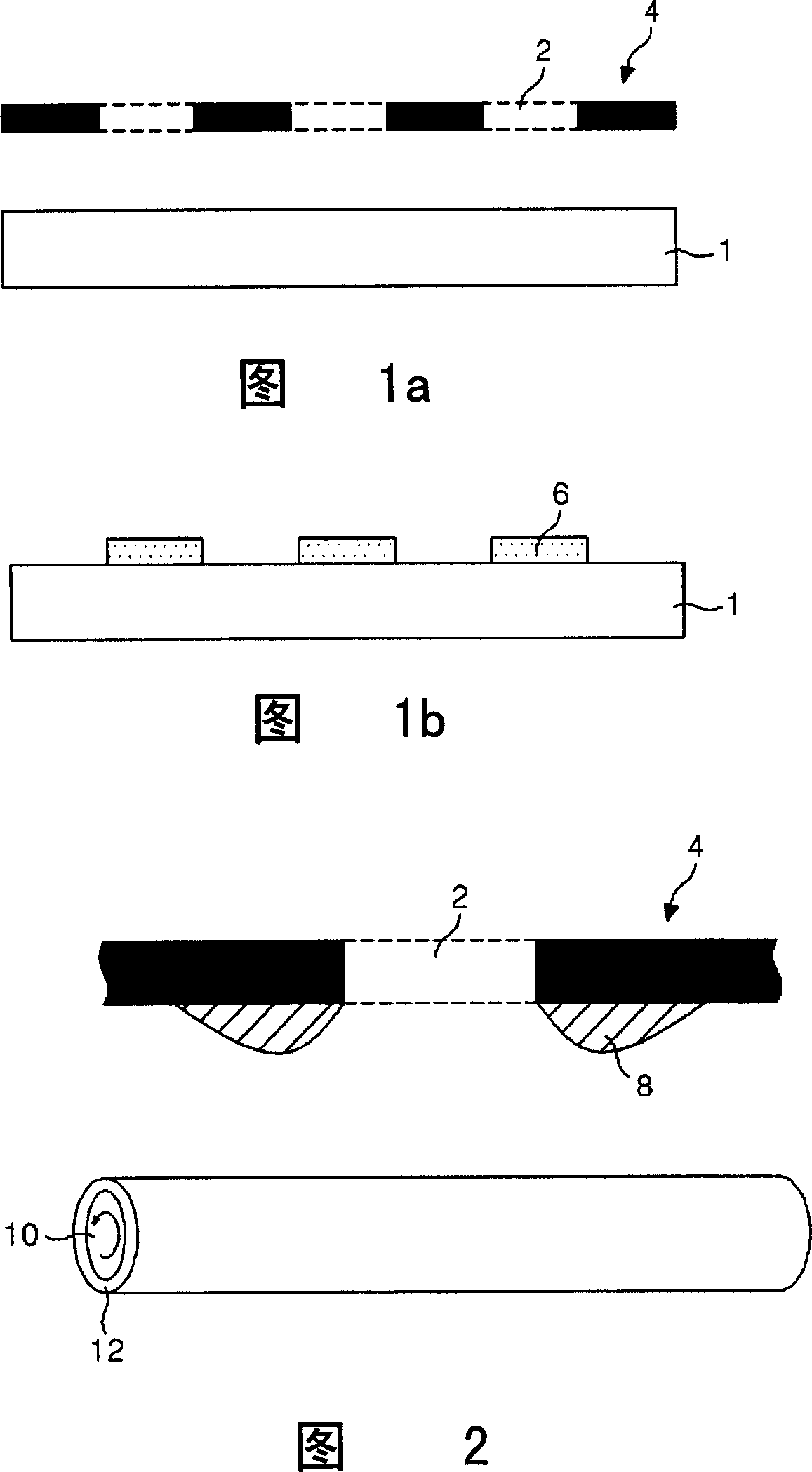

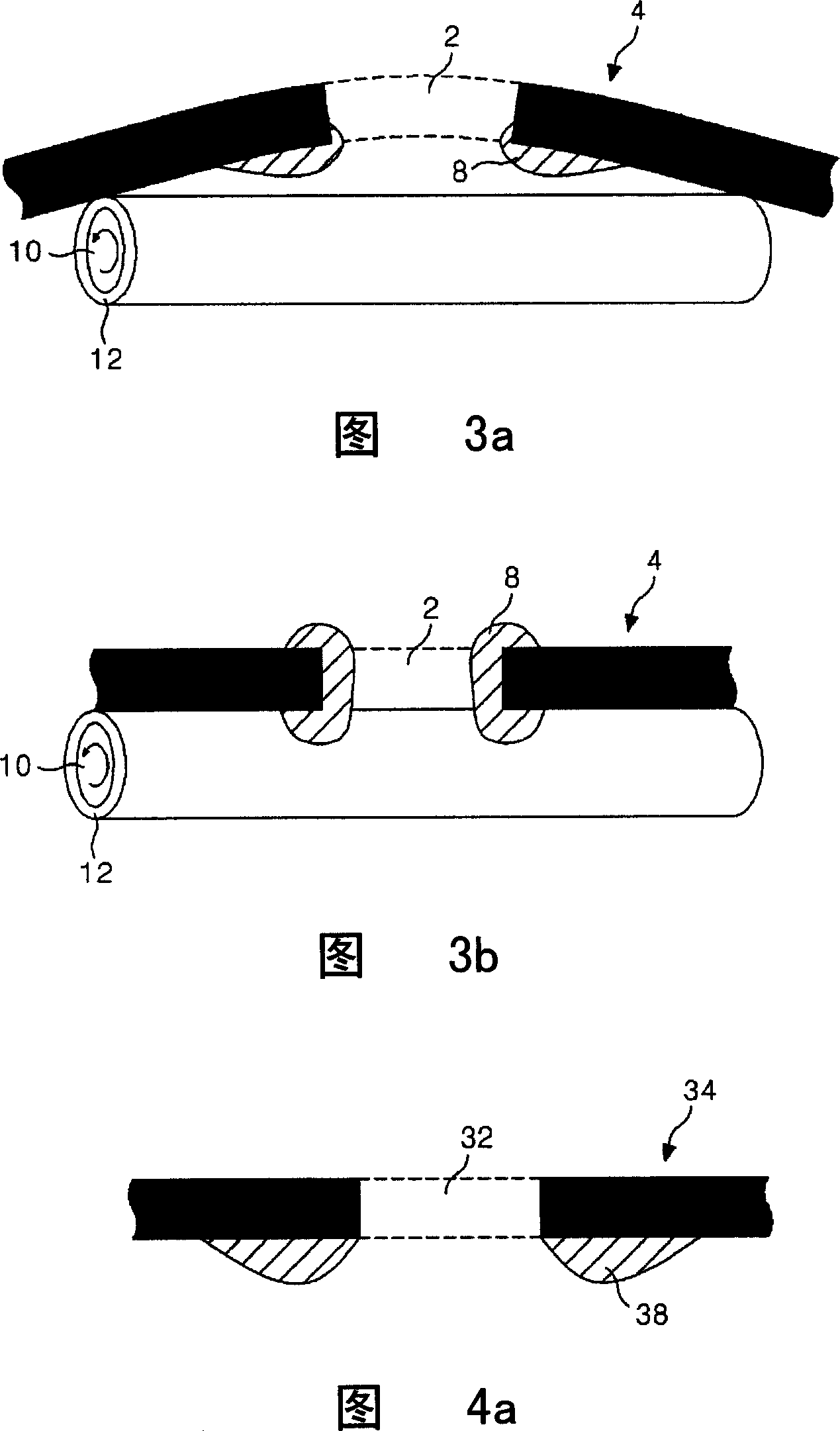

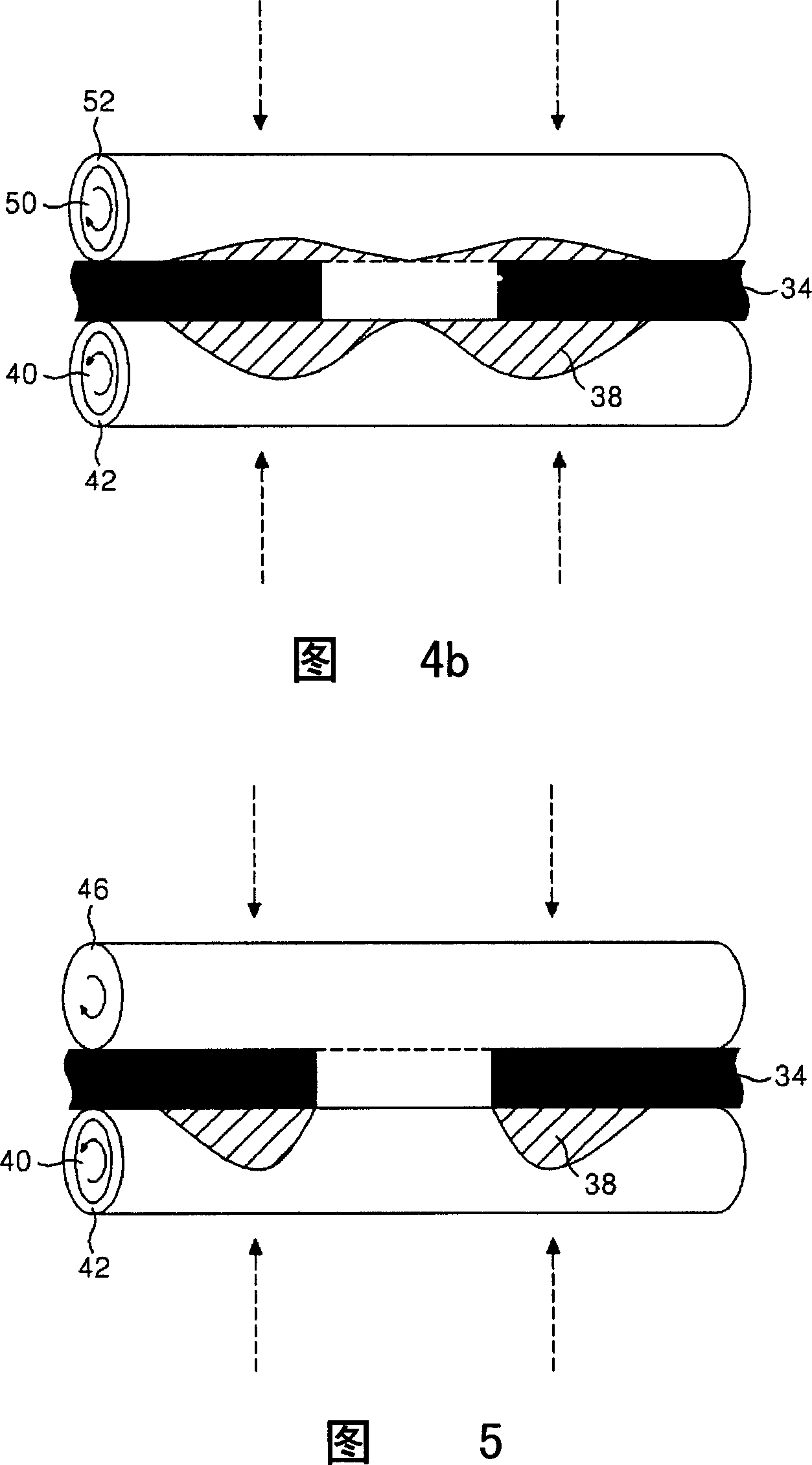

Winding needle capable of improving deformation of coiled cell and winding method

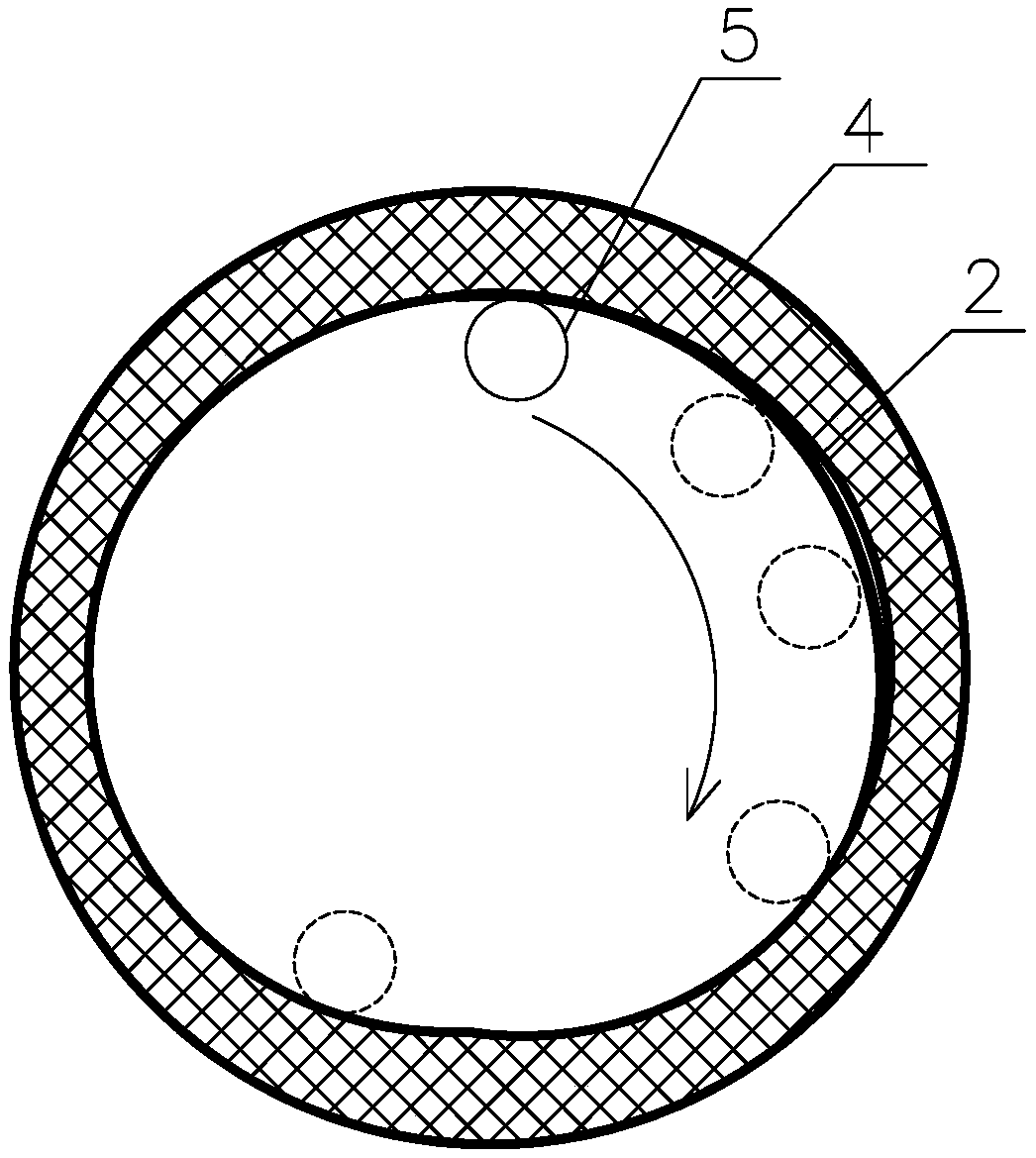

ActiveCN108832194AImprove deformationSmall tension changeFinal product manufactureSecondary cellsEngineeringLithium

The invention relates to the technical field of cell manufacturing, and especially relates to a winding needle capable of improving the deformation of a coiled cell and a winding method. A round winding needle is adopted, thus the tension change during the winding process of a cell becomes smaller and more uniform, the internal deformation of the coiled cell is improved; the situation that after formation, reactions in batteries are not complete and lithium is precipitated out is avoided, and the battery performance is improved.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

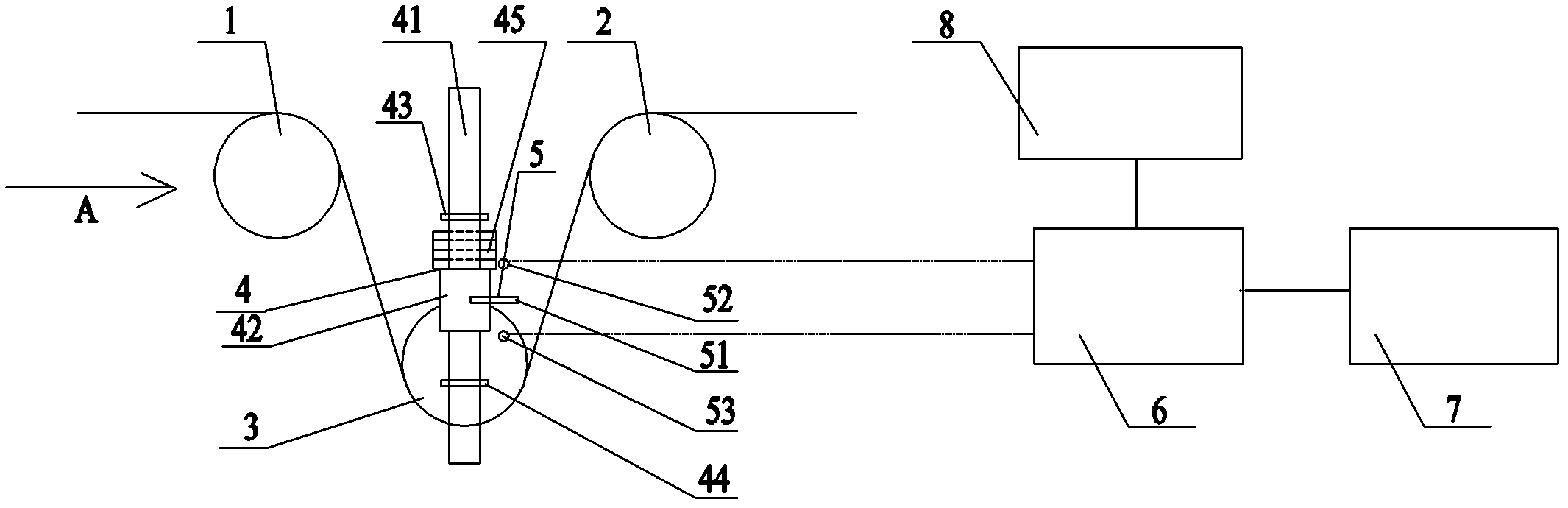

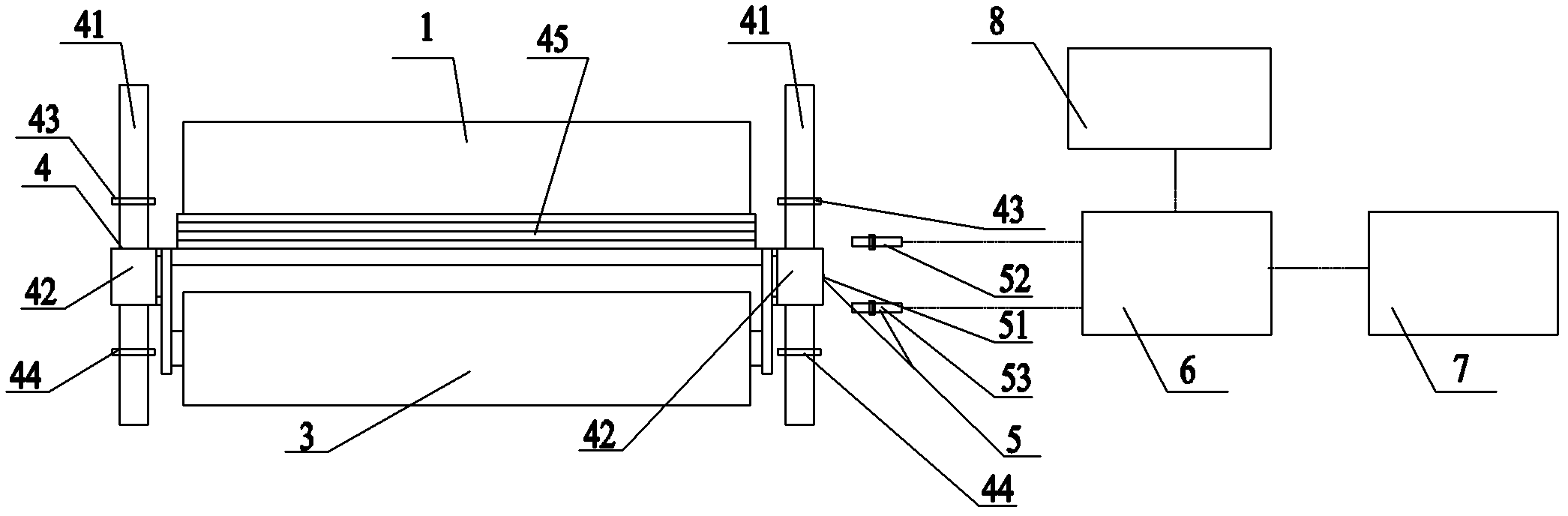

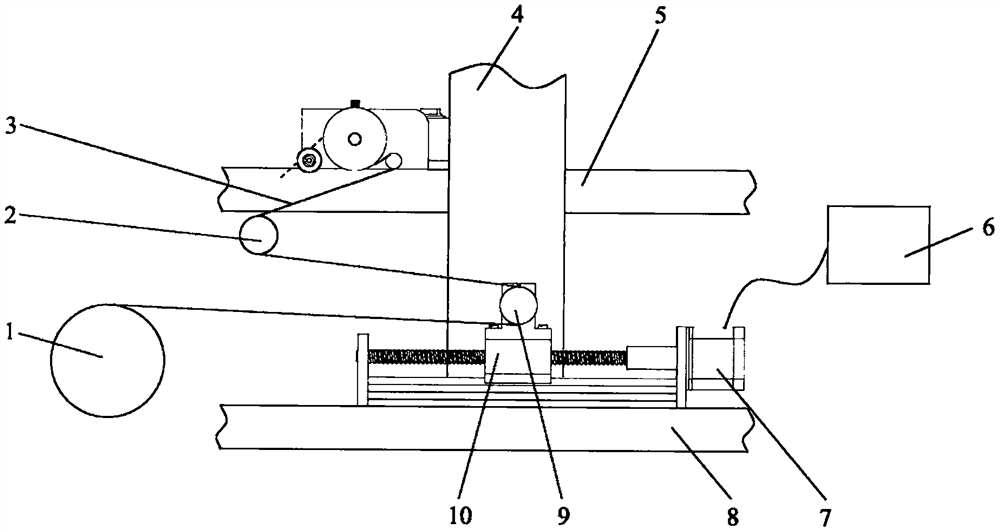

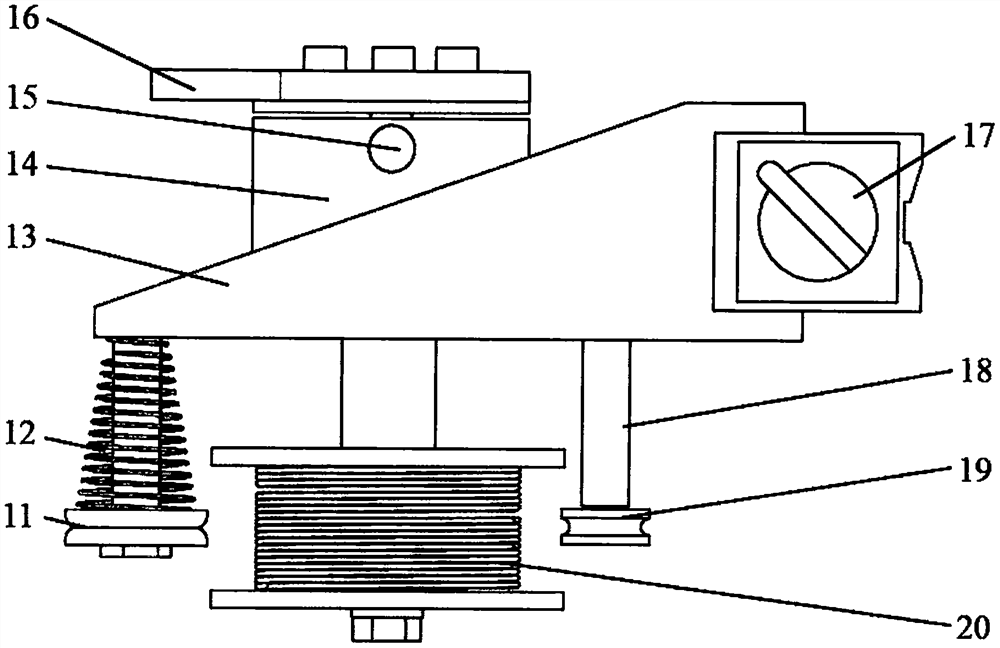

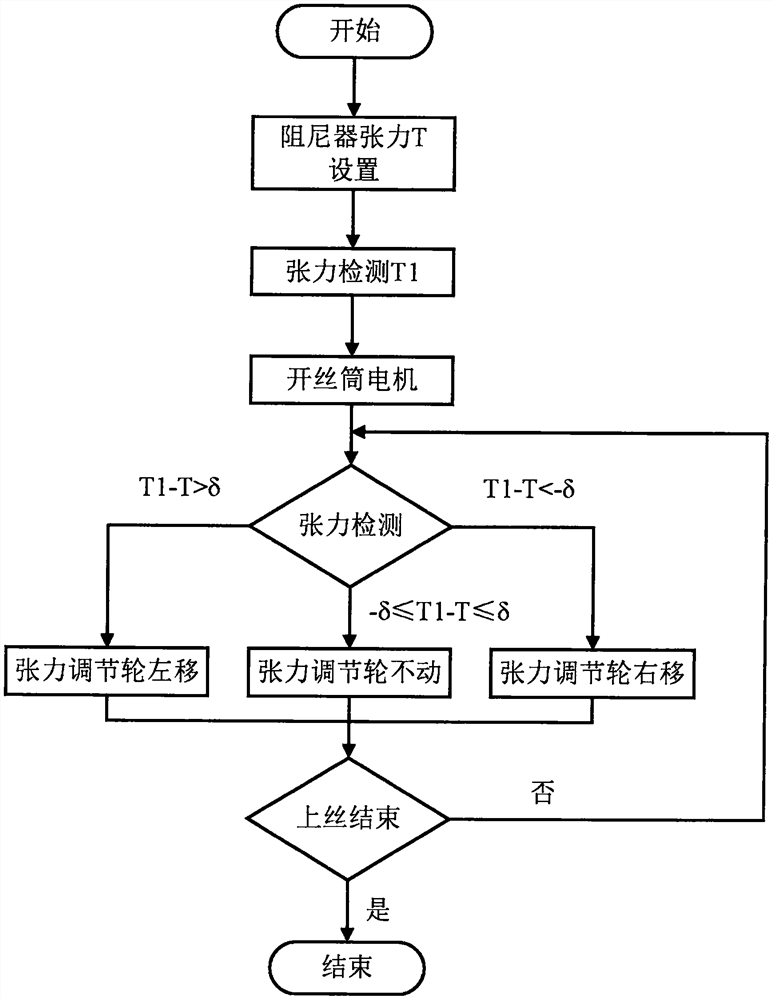

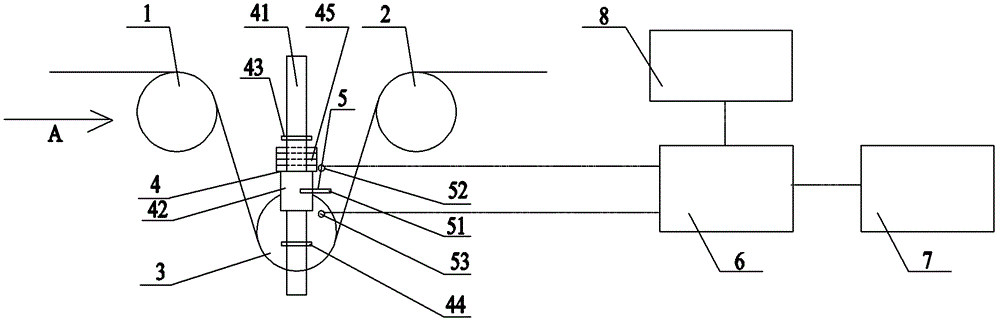

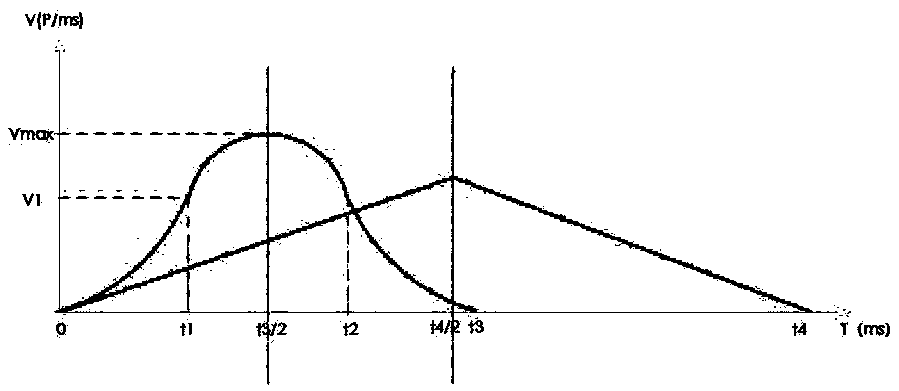

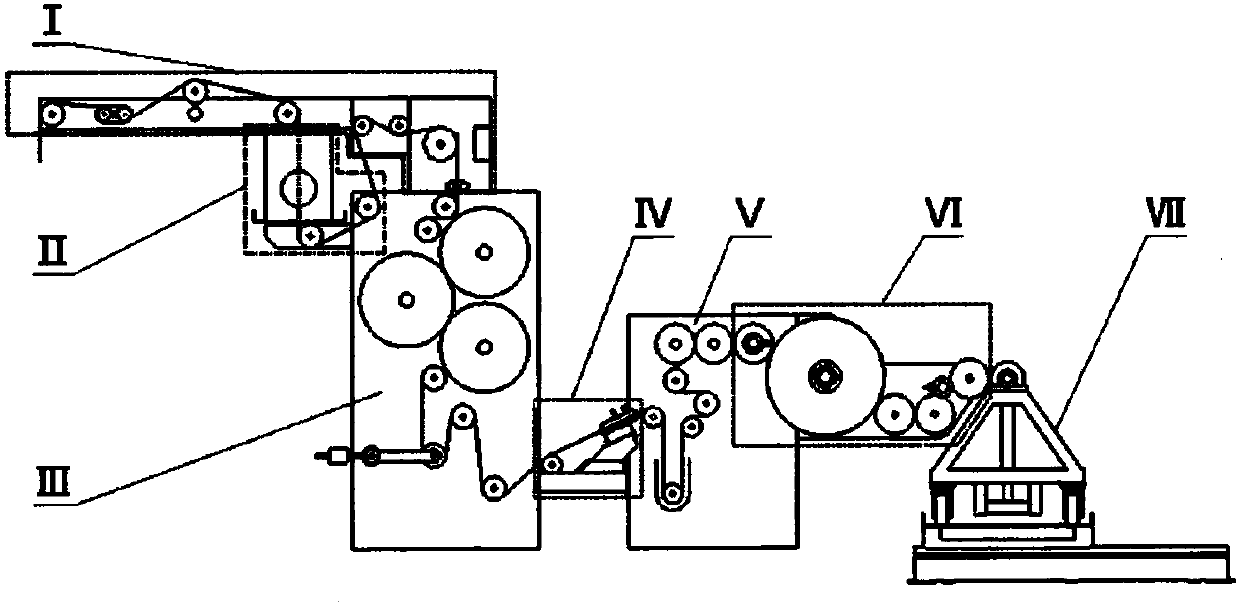

Device for two-stage constant-tension wire loading during fine wire cutting procedure of high-speed reciprocating wire-cut electrical discharge machining process

PendingCN111673213ASmall tension changeExtended service lifeElectrical-based machining electrodesElectrical-based auxillary apparatusPhysicsWire cutting

This design discloses a device for two-stage constant-tension wire loading during a fine wire cutting procedure of a high-speed reciprocating wire-cut electrical discharge machining process. The device mainly comprises a first-stage tension regulating device and a second-stage tension regulating device, wherein the first-stage tension regulating device comprises wire clamping sheets, a wire clamping spring, a wire disc base, a magnetic damper, a tightening bolt, a regulating wrench, a magnetic attracting seat, a supporting stud, a wire pressing wheel and an electrode wire disc; and the second-stage tension regulating device comprises a tension detecting wheel, a tension regulating wheel, a screw rod sliding table module, a stepper motor and a host computer. The first-stage tension regulating process is achieved by presetting tension through the magnetic damper; through the real-time tension feedback by the tension detecting wheel, the stepper motor is controlled by the host computer todrive the tension regulating wheel to move, and then the second-stage tension regulating effect process within a certain range is achieved; the wire loading tension uniformity is guaranteed; accordingly, the device is designed to be an automatic and tension-controllable wire loading system; through the device, the phenomenon of unilateral wire loosening caused by tension non-uniformity is greatlyreduced, the situation of wire breakage during fine wire processing is reduced, and the fine wire processing stability is improved; and meanwhile, the fine wire replacement efficiency and the operation safety are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

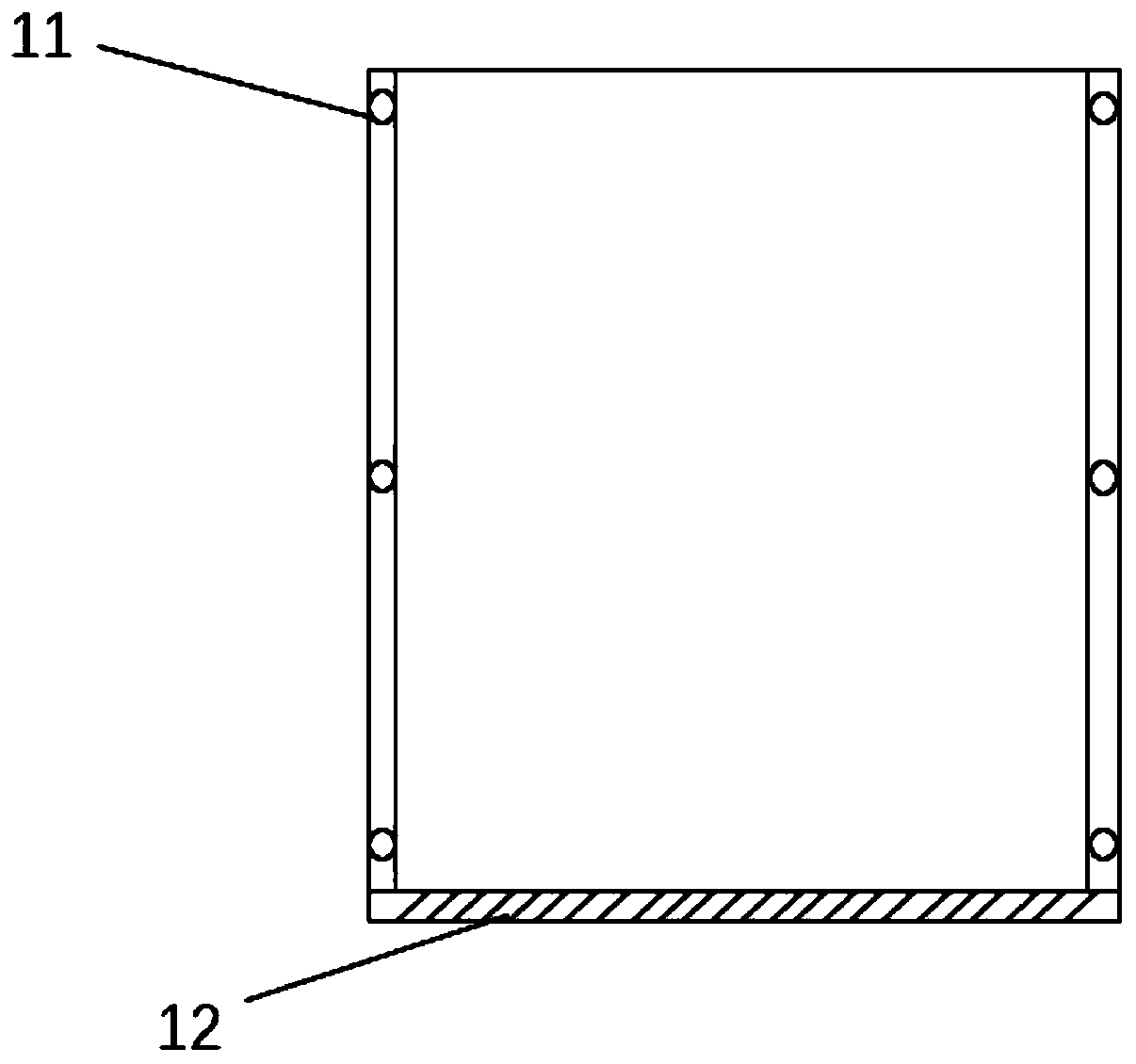

Carbon dioxide concentration control device, control method and terminal

PendingCN109739274AIncrease in sizeControl accessControlling ratio of multiple fluid flowsNeural architecturesControl engineeringProtection KIT

The invention belongs to the technical field of slaughtering, and discloses a carbon dioxide concentration control device, a control method and a terminal. The carbon dioxide concentration control device is provided with a box body, an air inlet tube is fixed to one side of the box body through a nut, a display a screen is arranged on one side of the air inlet tube in an inlaid mode, an air outletpipe is fixed to the other side of the display screen through a nut, and an air inlet is fixed to the lower part of the display screen through a nut. A movable door is connected to the front end of the box body in a clamped mode, and a lifting handle is arranged at the front end of the movable door in an inlaid mode, a sleeve ring is fixed to the lower end of the movable door through a nut, pulleys are fixed to the two sides of the movable door through nuts, and a protective sleeve is arranged under the movable door in an inlaid mode. A carbon dioxide asphyxiation method is adopted to suffocate pigs to be treated, the meat quality is ensured, and the efficiency of slaughtering is improved.

Owner:修水县畜牧水产局

Tension control device suitable for light fabric

PendingCN111348466ASmall tension changeCause wear and tearWebs handlingStructural engineeringControl theory

The invention discloses a tension control device suitable for light fabric. The device comprises a left rack, a right rack, a tension roller and a transition roller, wherein the left rack is connectedwith a left roller support through a left lifting support, the right rack is connected with a right roller support through a right lifting support, the upper portion of the left roller support is connected with a left buffering linkage mechanism, the upper portion of the left buffering linkage mechanism is rotationally connected with the left end of the tension roller, the lower portion of the left buffering linkage mechanism is in positioning connection with the left rack, the upper portion of the right roller support is connected with a right buffering linkage mechanism, the upper portion of the right buffering linkage mechanism is connected with the right end of the tension roller, the lower portion of the right buffering linkage mechanism is in positioning connection with the right rack, the transition roller is located below the tension roller, and the transition roller is connected between the lower portion of the left roller support and the lower portion of the right roller support through a bearing. The tension control device is more suitable for weaving small-tension variable fabrics in a high-speed running state, and is more novel in structure and higher in practicability.

Owner:青岛天一红旗特种织机科技有限公司

Bottle cap feeding and assembling device

InactiveCN108946605APrecise angle of rotationPrevent accidentsFlanged caps applicationEngineeringAir compressor

The invention provides a bottle cap feeding and assembling device and belongs to the technical field of bottle and can processing. The bottle cap feeding and assembling device comprises a feeding mechanism, a rotating assembling mechanism and a discharging mechanism; a feeding slider of the feeding mechanism is arranged on a feeding guide rail in a left and right sliding manner; a feeding notch isformed in the right side of a feeding material way; an electromagnet is connected with a top plate; the lower end of a swinging rod is connected with a swinging cylinder; a movable groove wheel is rotationally arranged at the upper end of the swinging rod; a pin shaft installed on the feeding slider is inserted into an arc-shaped groove of the movable groove wheel; the two ends of a spring are connected with a spring left pulling rod and a spring right pulling rod correspondingly; bottle and can clamping grooves are uniformly arranged on a rotating disk of the rotating assembling mechanism; aclamping gas bag is installed in the bottle and can clamping grooves of the rotating disk; the two ends of a gas sucking pipeline are connected with the clamping gas bag and an air compressor correspondingly; the gas sucking pipeline is provided with a gas valve; and the upper end of a discharging piston rod of the discharging mechanism is connected with a discharging bearing frame. The bottle cap feeding and assembling device can achieve feeding and assembling of bottle caps, tensile force of the spring is small in changing, and the service life of the spring is greatly prolonged.

Owner:徐晓伟

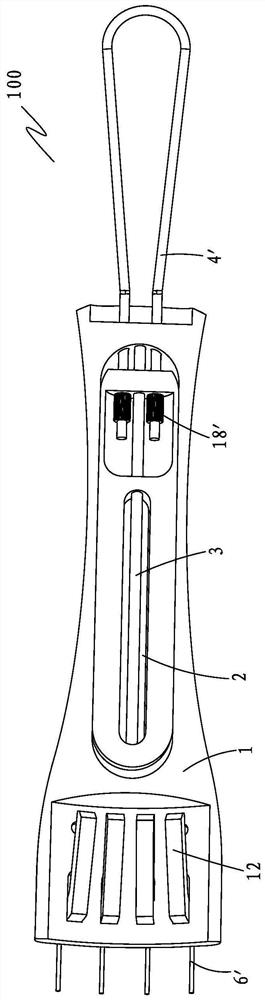

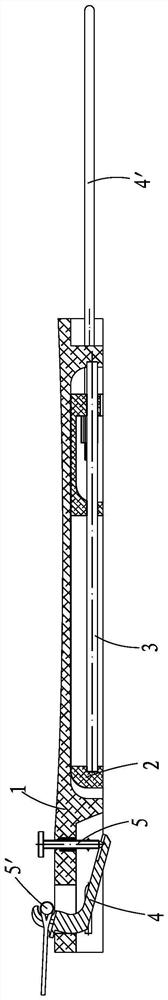

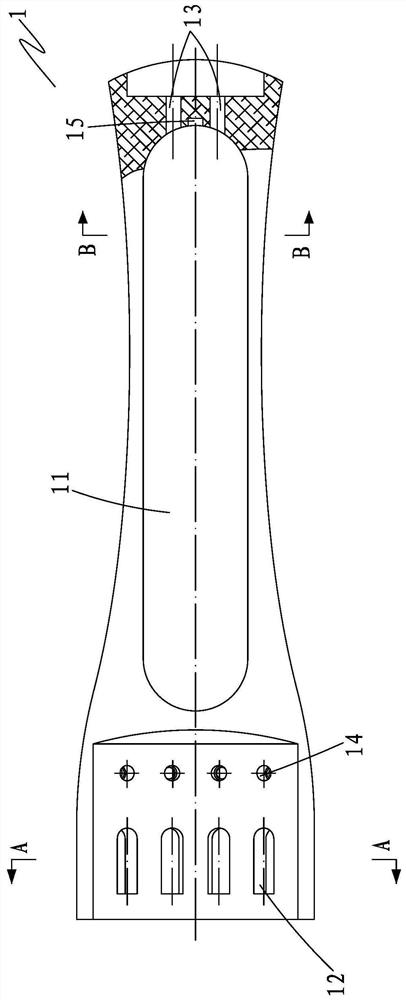

Violin tailpiece with reciprocating lengthening and wide-arc involute groove string hooks

The invention provides a violin tailpiece with reciprocating lengthening and wide-arc involute groove string hooks in the technical field of musical instruments, and the violin tailpiece comprises: amain tailpiece which is provided with a chute at the central part, four string hook through grooves at the head part, and a main blind hole and two tail rope through holes at the bottom part, whereina screw hole is formed between each string hook through groove and the sliding groove; an auxiliary tailpiece which is arranged in the sliding groove, wherein an ejector rod positioning hole and an auxiliary blind hole are formed in the two ends of the auxiliary tailpiece respectively. an ejector is arranged, one end of the ejector rod abuts against the auxiliary blind hole, the other end of the ejector rod abuts against the main blind hole, and reciprocating relay lengthening of the main tailpiece and the auxiliary tailpiece is formed; four wide-arc involute groove string hooks which are provided with involute grooves and wide arc surfaces and are arranged in the string hook through grooves, wherein the involute grooves do not damage a string ball head string hook, and the wide arc surfaces are used for finely adjusting noise reduction intonation of the wide cambered surface and the inner wall of the rolling string hook through groove. The invention has the advantages that: intonationshift, bridge bending and surface damage caused by environmental humidity change are greatly reduced, the damage of string cores and ball head winding wires is avoided, and the noise is effectively reduced.

Owner:陈平怀

Tension control device for fiber tows

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

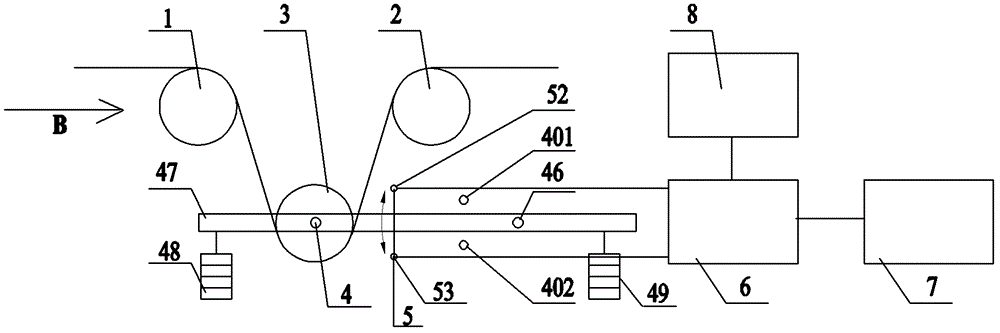

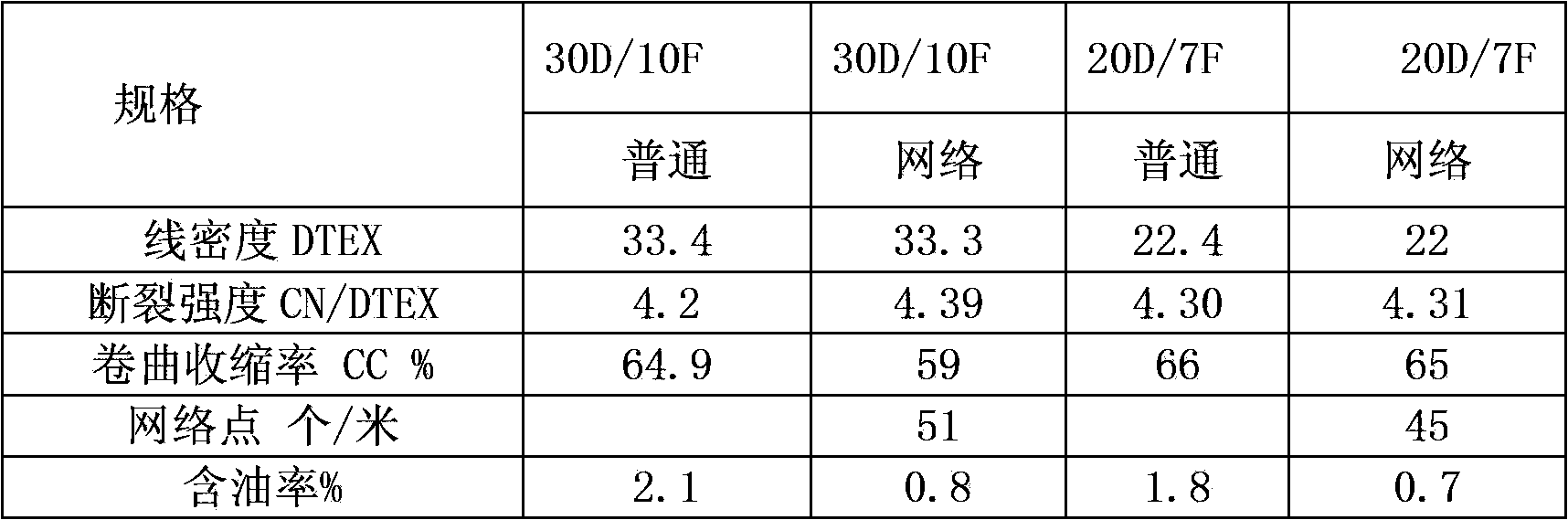

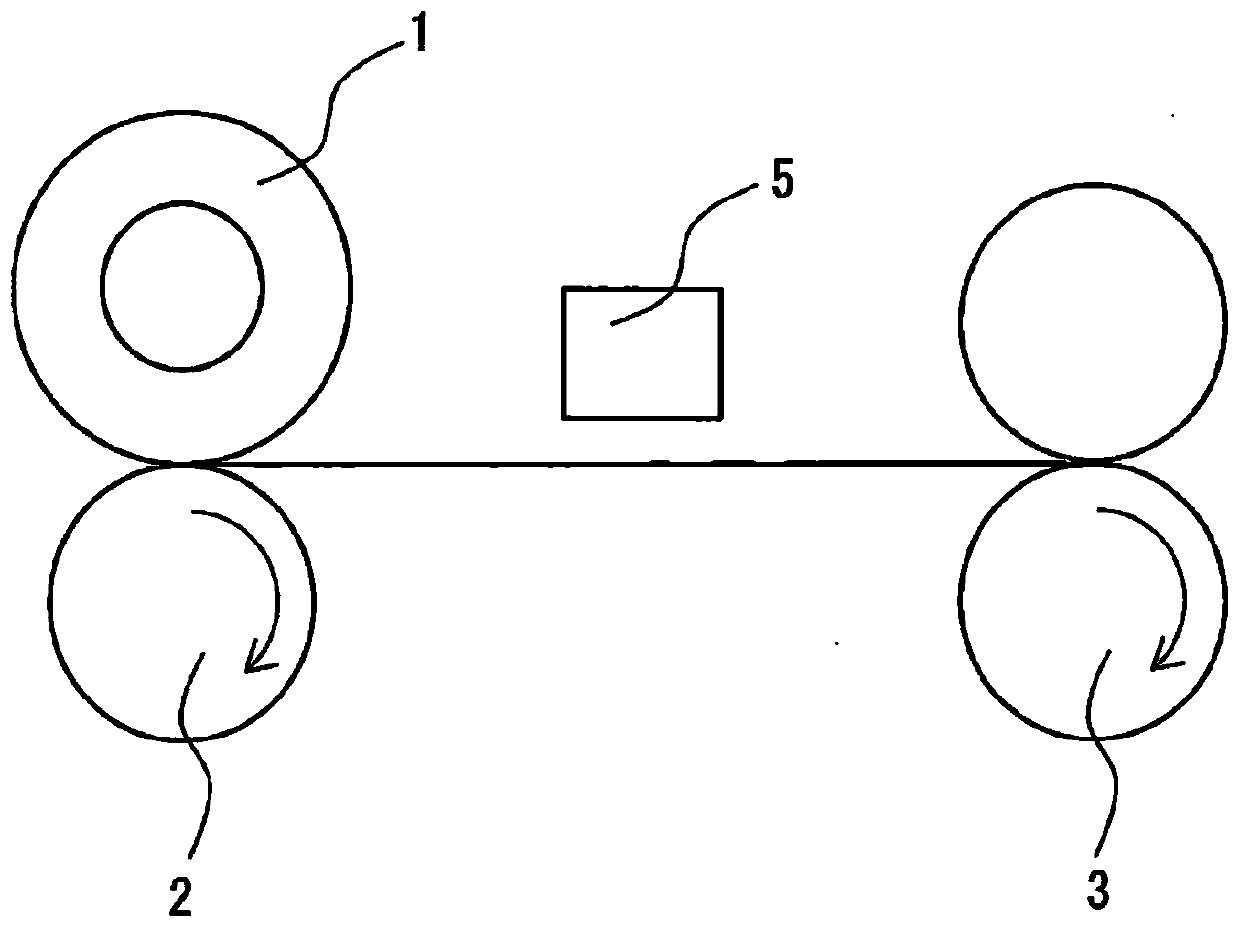

Production technology of nylon 6 fine denier network stretch yarn suitable for hydraulic loom

The invention relates to a production technology of a nylon 6 fine denier network stretch yarn. The production technology of the nylon 6 fine denier network stretch yarn suitable for a hydraulic loom comprises the steps that after a raw POY (Pre Oriented Yarn) is put on a raw yarn shelf, and the POY passes through a first roller, a heating box, a cooling plate, a false twister, a second roller, an oiling device and a winding roller in sequence; the production technology is characterized in that a network device and an auxiliary second roller are arranged between the second roller and the winding roller, the stretch yarn between the second roller and the winding roller passes through the network device, the auxiliary second roller and the oiling device in sequence, wherein the distance between the auxiliary second roller and the second roller is 0.2-0.4m, and the linear speed of the auxiliary second roller is less than that of the second roller. Network points of the nylon 6 fine denier network stretch yarn produced by the technology are distributed uniformly and stably, so that the nylon 6 fine denier network stretch yarn is high in strength, good in cohesion and low in bulkiness.

Owner:烟台华润锦纶有限公司

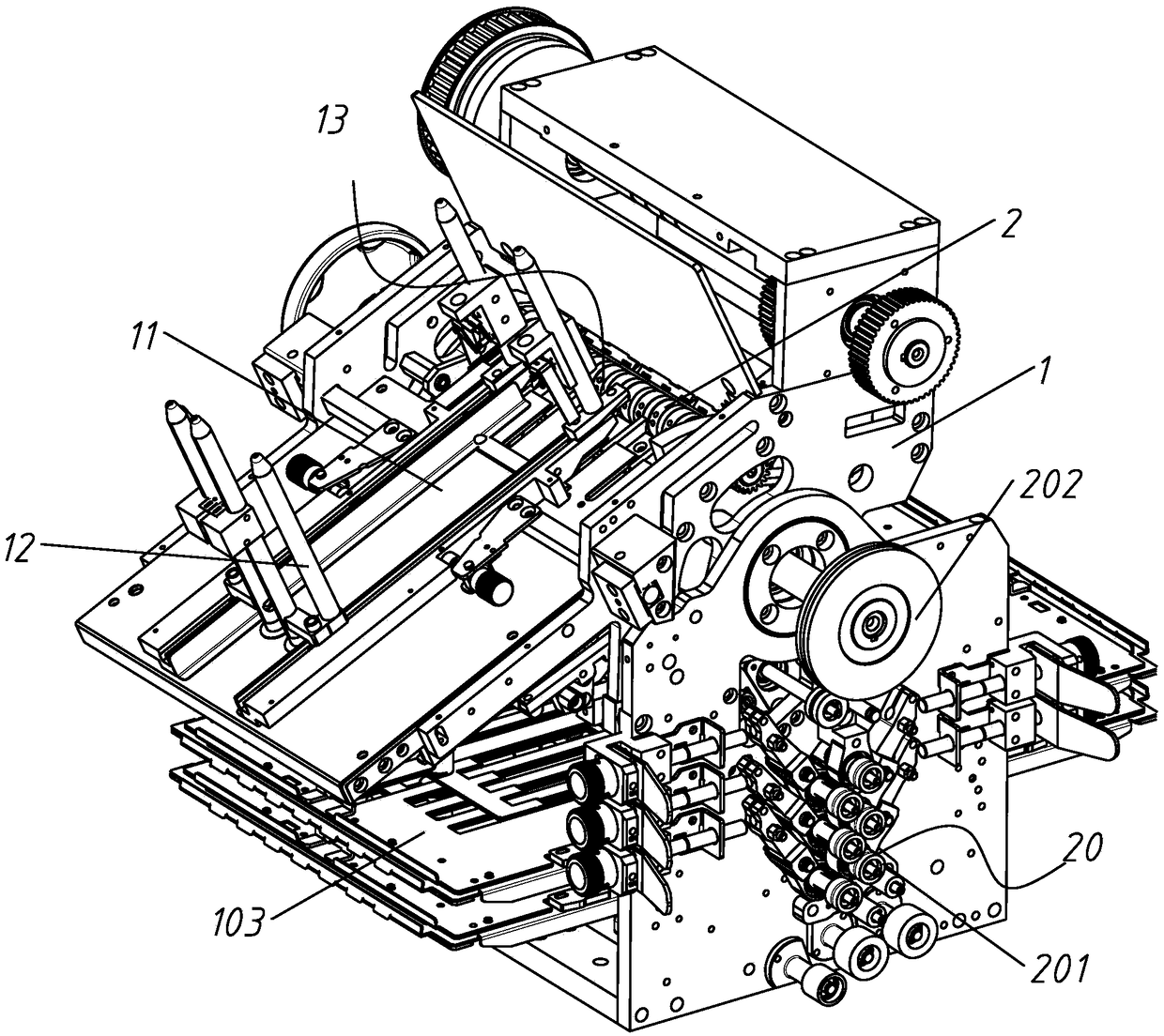

High-speed paper drawing mechanism, paper feeding mechanism and jamming removal mechanism as well as high-speed paper folding machine

ActiveCN108860844AReduce exposureLow failure rateFolding thin materialsPackagingCardboardPulp and paper industry

The invention belongs to the field of packaging machinery and puts forwards a high-speed paper drawing mechanism, paper feeding mechanism and jamming removal mechanism as well as a high-speed paper folding machine. The high-speed paper folding machine comprises the jamming removal mechanism and further comprises a paper folding mechanism arranged on a fixing rack; paper is delivered to the paper folding mechanism along a paper baffle by the aid of conveying wheels; the paper folding mechanism comprises a plurality of paper folding rollers and paper folding disks arranged on the fixing rack; fixing grooves for fixing the paper folding disks are formed in the fixing rack; and the two sides of the paper folding disks are inserted in the fixing grooves. According to the technical scheme, the technical problem that the paper folding machine is jammed due to the fact that folds are caused easily by the relatively high stress produced by a paper drawing mechanism on the paper during paper drawing in the prior art is solved.

Owner:固安县晨泰精密机械有限公司

Cleaning method and device for masking sheet for model printing

InactiveCN1970174AAvoid tension changesReduce tensionFlexible article cleaningCleaning using toolsFilm coatingForeign matter

Owner:LG ELECTRONICS(NANJING) PLASMA CO LTD

Planetary printing machine

The invention discloses a planetary printing machine. The planetary printing machine comprises a first printing roller, a main drive shaft and a second printing roller which are arranged on a machineframe. The main drive shaft is arranged between the first printing roller and the second printing roller. A main drive gear is installed at one end of the main drive shaft and is further engaged witha first gear on the first printing roller and a second gear on the second printing roller at the same time so as to drive the first printing roller and the second printing roller. The main drive shaftis driven by a servo motor. The first printing roller and the second printing roller are provided with two sets of printing color units in a matched mode correspondingly. A compression roller is further arranged at the feeding side above the second printing roller and can further adjust the pressure for pressing printed objects onto the second printing roller by the compression roller through anair cylinder installed on the machine frame. Drying devices are further arranged between the first printing roller and the second printing roller. The first gear and the second gear are engaged with anilox roller gears of the printing color units matched with the first gear and the second gear separately. The planetary printing machine has the advantages of being simple in transmission structure,low in manufacturing and productive maintenance difficulty, good in printed product quality, high in production efficiency and capable of achieving linkage easily.

Owner:温州海多堡机械科技有限公司

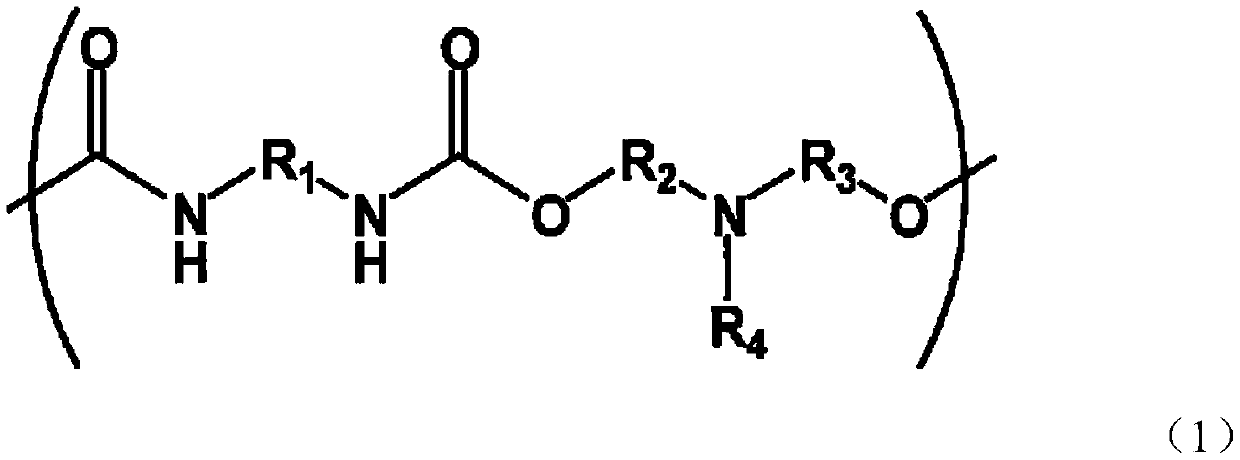

Polyurethane elastic fiber and wound body thereof

ActiveCN111433396ANot easy to loose hairSmall tension changeMonocomponent polyurethanes artificial filamentFibre typesDicarboxylic acidElastic fiber

Provided is a polyurethane elastic fiber that is a multifilament yarn, the polyurethane elastic fiber being characterized in that the content of an ester or a phosphoric acid ester that is a product of the condensation of a compound A with a compound B is 50 ppm or more and 5% or less relative to the weight of the polyurethane elastic fiber, the compound A is at least one compound selected from amonocarboxylic acid having 4 to 30 carbon atoms inclusive, a dicarboxylic acid having 4 to 30 carbon atoms inclusive, a tricarboxylic acid having 4 to 30 carbon atoms inclusive and phosphoric acid, and the compound B is at least one compound selected from a monol having 1 to 30 carbon atoms inclusive, a diol having a molecular weight of 3000 or less and a triol having a molecular weight of 3000 orless.

Owner:ASAHI KASEI KK

Hot rail deformation heating box

The invention discloses a hot-rail deformation hot box, which comprises a shell, and a heating liner container, hot rails and temperature sensors, which are arranged inside the shell; a thermal insulation material is filled between the shell and the heating liner container; heating medium is arranged inside the heating liner container, and the outer wall of the heating liner container is detachably and fixedly provided with a plurality of groups of heating elements; the quantity of the hot rails is multiple, the hot rails are fixed on the shell, one end of each hot rail is in welding connection with the heating liner container, each hot rail is of a hollow structure, and an inner cavity of each hot rail is communicated with an inner cavity of the heating liner container; and the upper end and the lower end of the heating liner container are respectively provided with one temperature sensor. The outer wall of the heating liner container is provided with the groups of heating elements, which work simultaneously, so that not only is rapidness in heating speed realized, but also a yarn path is uniformly heated.

Owner:常州留夏新材料科技有限公司

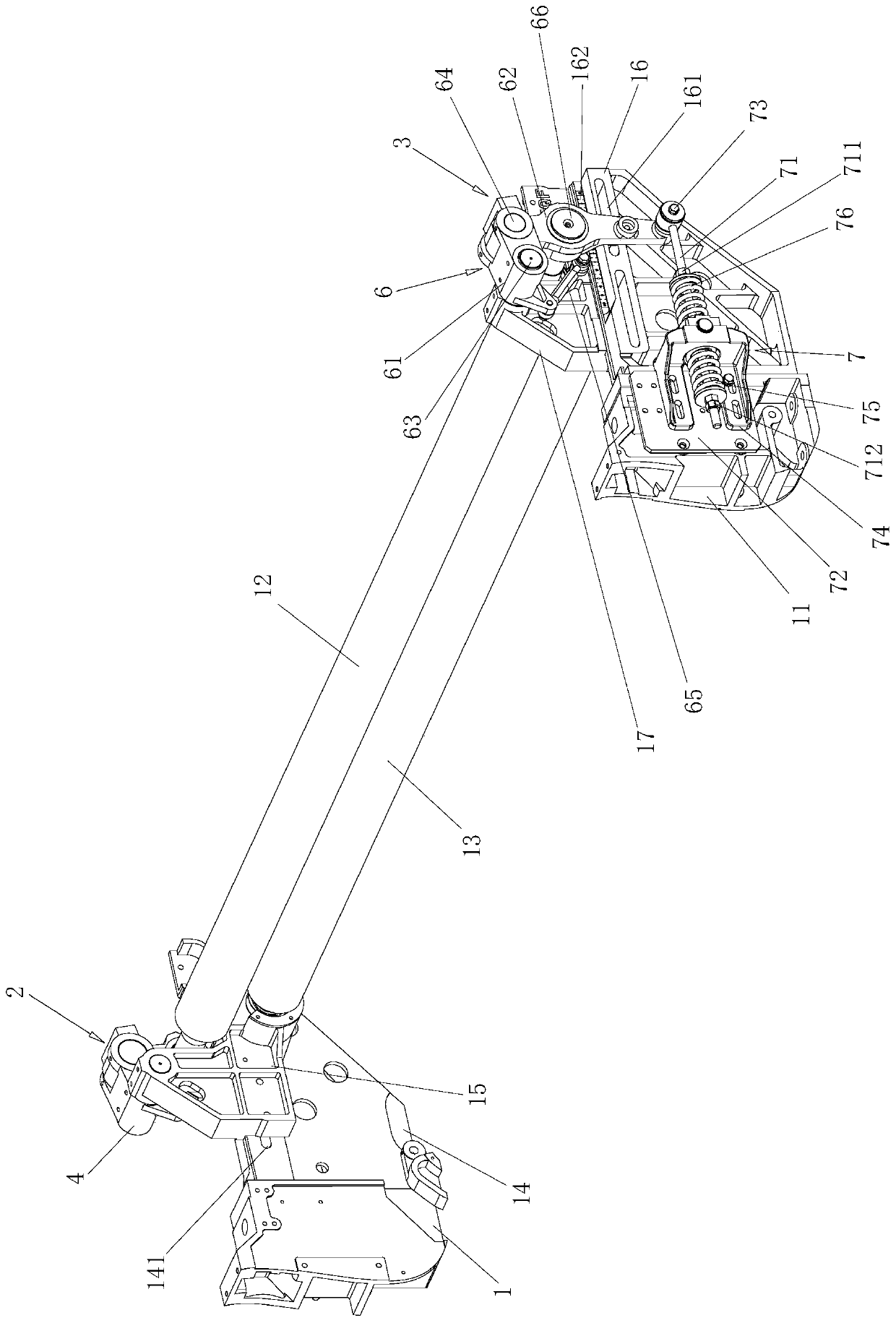

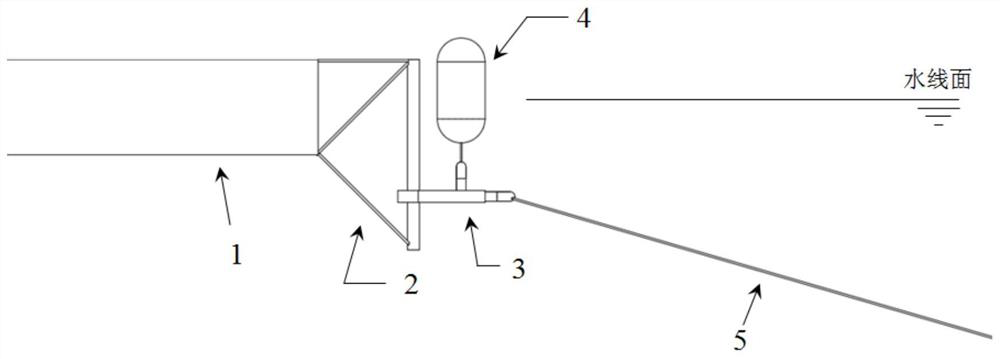

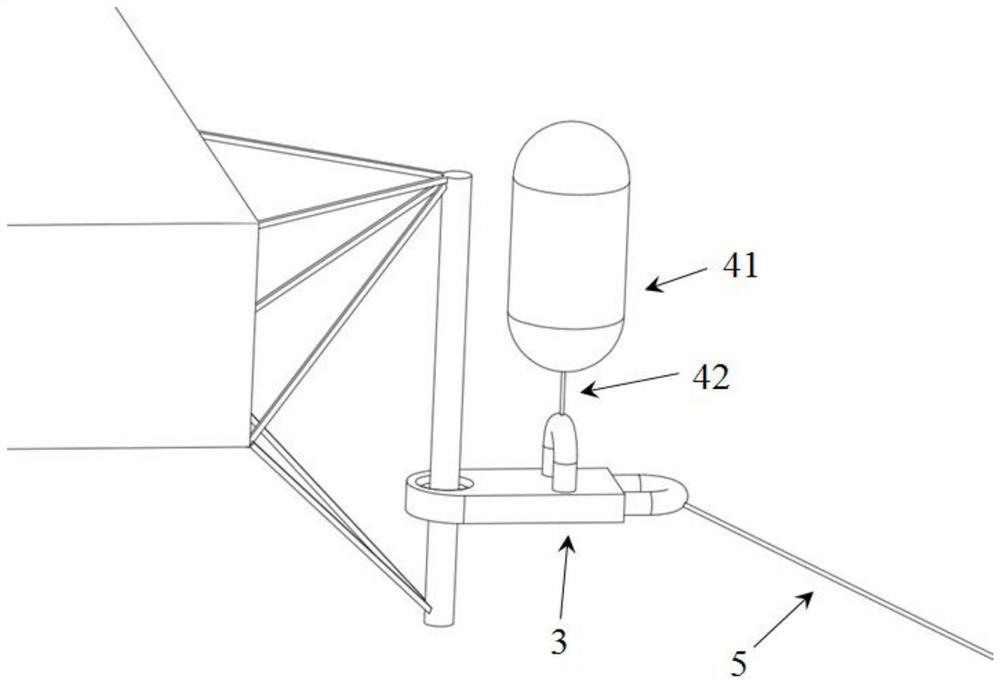

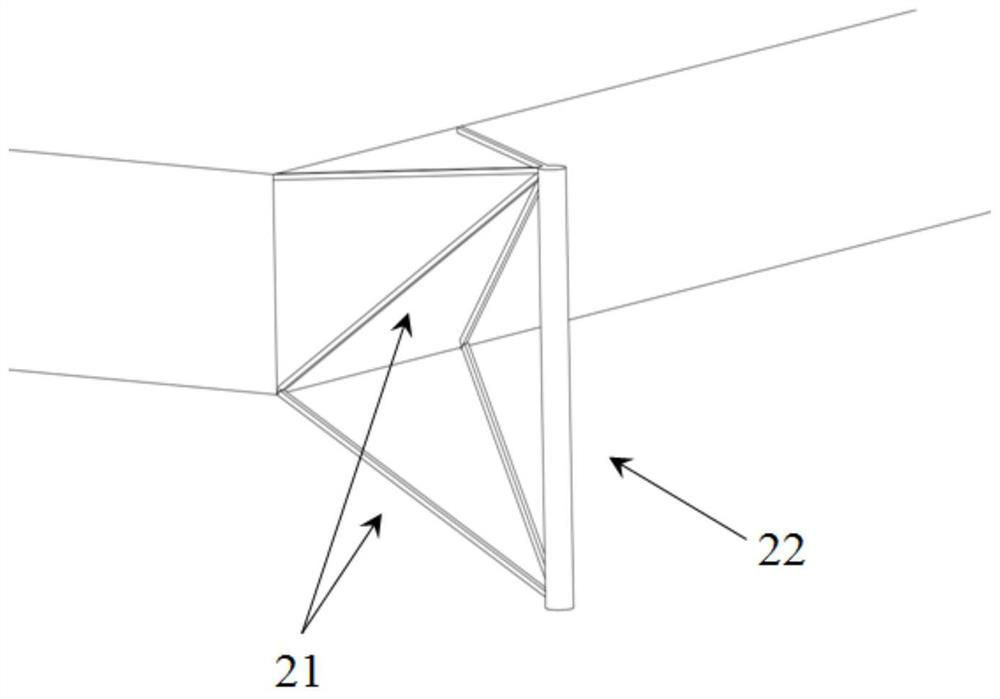

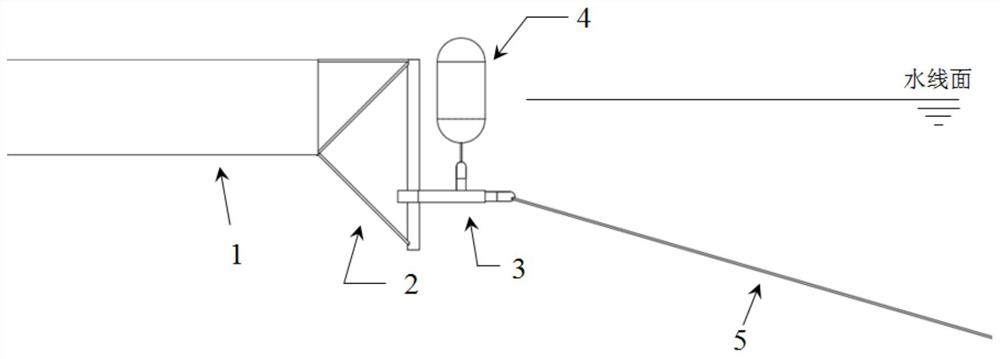

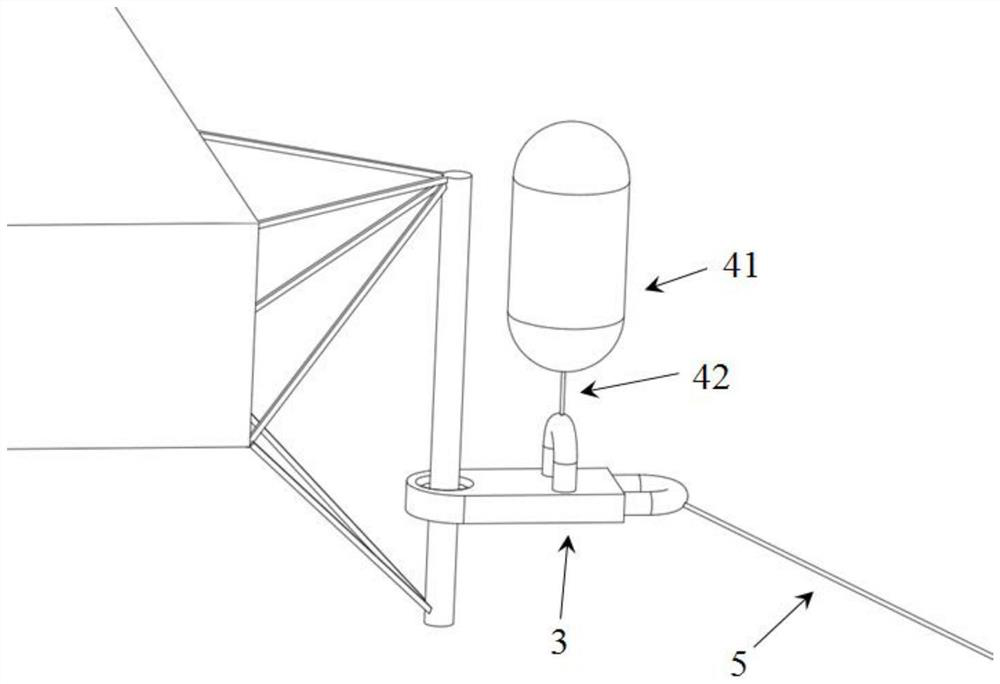

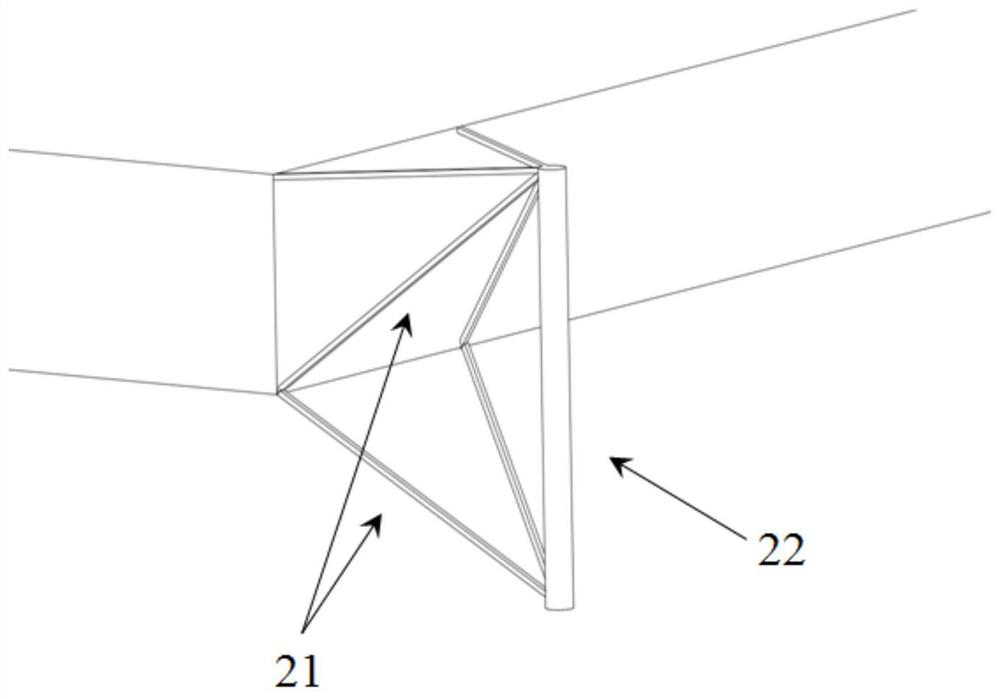

Moorings for large water level changes

ActiveCN112678116BSmall tension changeLow costWaterborne vesselsMarine engineeringClassical mechanics

The invention relates to a mooring device suitable for large water level changes. The mooring device includes a floating structure, a mooring bracket, a sliding device, a buoy box system and a mooring cable. The sliding straight rod of the mooring bracket passes through The sliding hole of the sliding device ensures that the sliding device can carry out relative movement in the vertical direction with the mooring bracket; The tension components in the vertical direction are balanced to keep the slide from sinking to the bottom of the mooring structure. When the water level changes, the position of the floating structure moves up and down with the water surface. Since the sliding device and the mooring bracket can slide relative to each other, the floating tank system does not change its position with the lifting of the floating structure under the constraint of the mooring cable. The tension of the mooring lines has always been within a certain range to avoid excessive displacement of floating structures due to water level changes and excessive mooring loads caused by excessive tension of mooring lines.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Mooring device suitable for large water level change

The invention relates to a mooring device suitable for large water level change, and the mooring device comprises a floating structure, a mooring support, a sliding device, a buoyancy tank system and a mooring cable. A sliding straight rod of the mooring support penetrates through a sliding hole of the sliding device to ensure that the sliding device can move relative to the mooring support in the vertical direction; the buoyancy tank system and the mooring cable are both connected to the sliding device, and the buoyancy of the buoyancy tank system, the gravity of the sliding device and the tension component of the mooring cable in the vertical direction are kept balanced so as to maintain that the sliding device cannot sink to the bottom of the mooring structure. When the water level changes, the position of the floating structure moves up and down along with the water surface, the sliding device and the mooring support can slide relatively, the position of the buoyancy tank system does not change along with rising and falling of the floating structure under the constraint of the mooring cable, and therefore the tension of the mooring cable is within a certain range all the time. therefore, the excessive displacement of the floating structure caused by water level change and excessive mooring load caused by excessive tensioning of the mooring cable are avoided.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

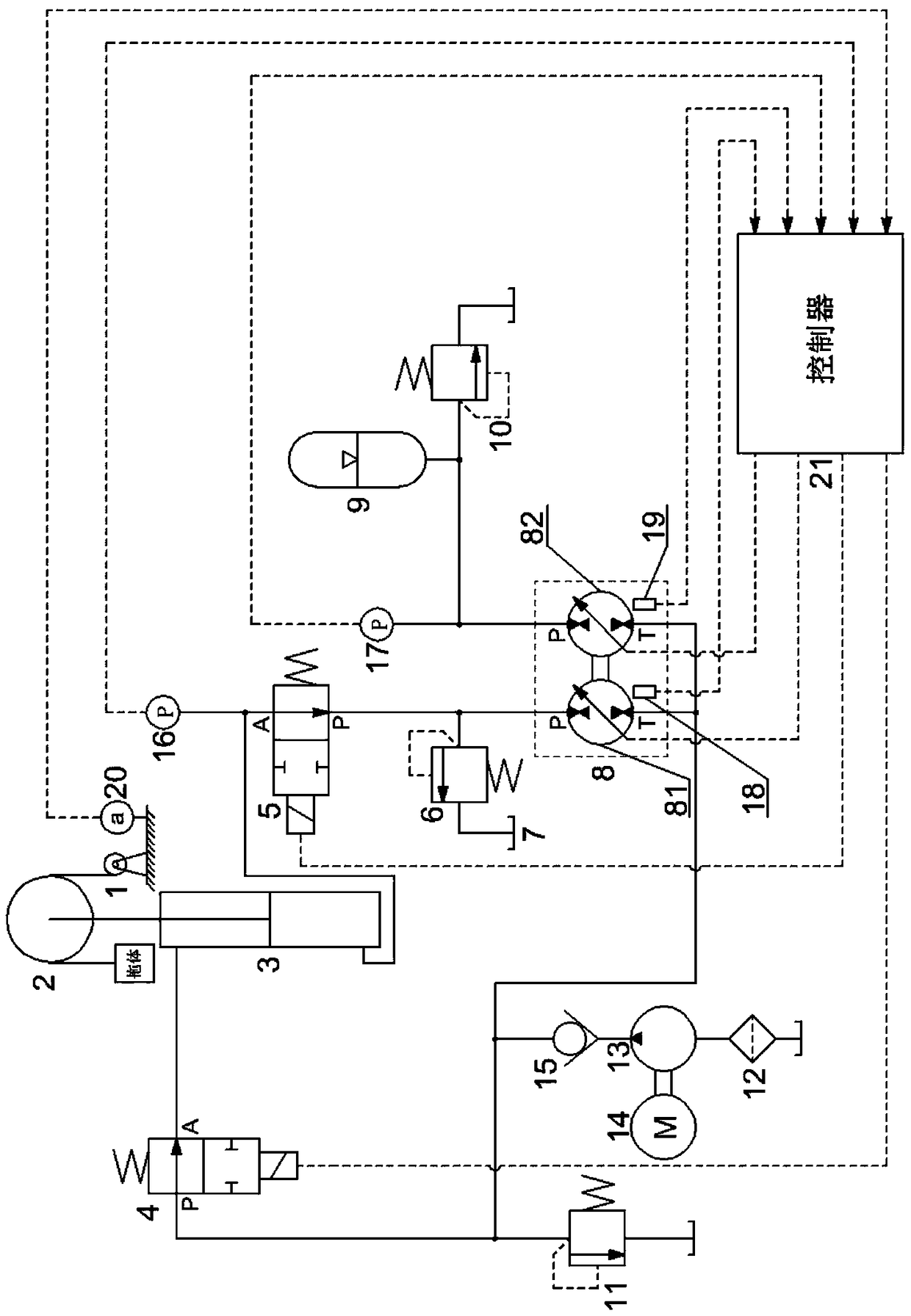

A Hydraulic Cylinder Type Passive Heave Compensation System Based on Hydraulic Transformer

ActiveCN108278232BReduce volumeSmall pressure changeServomotor componentsServomotorsFuel tankSafety control

Owner:ZHEJIANG UNIV

A kind of wire winding method for leather cable

The invention discloses a leather cable feeding and winding method. A disc cable feeding opening is vertically and downwards arranged on a disc sending mechanism. The cable clamp initial position of the side face of a winding disc is located in the clockwise 90-degree direction of the disc cable feeding opening; a disc is conveyed to the designated position on the disc sending mechanism, the disc is lifted and clamped through a lifting mechanism and a cable disc clamping and rotating mechanism, and the cable disc clamping and rotating mechanism drives the disc to rotate clockwise by 90 degrees so that a cable clamp can be located over the winding disc; a transverse cable arranging mechanism and the cable clamp act to conduct cable catching, a cable is clamped in the cable clamp and then rotates by 90+alpha degrees, and therefore the cable is right located at the position of the disc cable feeding opening; and the transverse cable arranging mechanism moves towards the inner side of the winding disc and drives the cable disc clamping and rotating mechanism to clockwise drive the winding disc to rotate to conduct winding. The leather cable feeding and winding method suitable for mechanical operation is provided, the cable feeding and catching success rate is high, cable cracking or deforming caused by sudden tension changes is avoided, and meanwhile the winding efficiency is improved.

Owner:中天智能装备有限公司

Winding needle and winding method for improving deformation of wound electric core

ActiveCN108832194BImprove deformationSmall tension changeFinal product manufactureSecondary cellsEngineeringMechanical engineering

The invention relates to the technical field of electric core production, in particular to a winding needle and a winding method for improving the deformation of a wound electric core. The use of a circular winding needle makes the tension change of the electric core smaller and more uniform during the winding process, which can improve The internal deformation of the wound battery reduces the occurrence of insufficient internal reaction or lithium precipitation in the battery after formation, and improves battery performance.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

A kind of stretching net stress release process

ActiveCN110116543BFast stress reliefFull stress reliefForme preparationScreen printingPolymer science

The invention discloses a screen pulling stress releasing technology. The technology specifically comprises the following steps: 1) adding an infrared heating technology while standing after radial and transverse stretching of a silk screen; and 2) selecting an infrared heating device of which the released radiation frequency is close to molecular vibration frequency of a silk screen body so as torealize resonance absorption, and thus accelerating the releasing of the stress of the silk screen body. According to the technology adopting the abovementioned mode, the screen stretching time can be greatly decreased, so that the screen stretching efficiency can be greatly improved, the production cost is decreased, and the stress of the silk screen can be quickly fully released; the silk screen in later preparation process is high in stability and low in tension variation value, so that the preparation efficiency and the yield can be greatly increased; the silk screen is small in deformation, extension and contraction during printing, so that the service life is greatly prolonged, the printing quality is greatly improved, and as a result, the screen printing plate market competitiveness can be greatly increased.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

Woof-intersecting device for weaving machine

The invention provides a woof-intersecting method and a device thereof for a weaving machine. The method utilizes the motion phase difference between a woof-feeding gripper head and a woof-receiving gripper head, enables the woof-receiving gripper head to move to a limit position in the advance direction and enables yarn brought by the woof-feeding gripper head to get across a yarn-hooking head of the woof-receiving gripper head so that the woof-receiving gripper head starts to retreat, the woof-feeding gripper head still advances to a limit position in the advance direction to finish yarn intersection before the woof-feeding gripper head retreats until the yarn is finished. The device comprises a woof-feeding mechanism and a woof-receiving mechanism which are respectively arranged at both sides of a weaving machine main shaft, and a relative mounting angle between the weaving machine main shaft and a woof-feeding main shaft fixing part at one end of the weaving machine main shaft is larger than a relative mounting angle between the weaving machine main shaft and a woof-receiving main shaft fixing part at the other end of the weaving machine main shaft. The invention enables the tension of the yarn to have little change during the yarn intersection, does not influence the detection of a yarn-stopping device, improves the success rate of the yarn intersection, reduces false yarn stops due to the high-speed motion of the weaving machine and can improve the rotating speed of the weaving machine so as to improve the production efficiency.

Owner:林东

A cold pad-batch dyeing machine for knitted fabrics

InactiveCN105696232BAvoid wrinklesAvoid curlMechanical cleaningPressure cleaningWater savingEngineering

The invention provides a cold pad-batch dyeing machine for knitted fabric.The cold pad-batch dyeing machine is characterized by comprising an open-width cloth inlet unit, a dust suction unit, a cooling unit, an edge unfolding unit, a dyeing unit, a cloth outlet unit and a moving and rolling unit.The open-width cloth inlet unit is arranged on the upper side of the dust suction unit and the cooling unit.The dust suction unit is arranged on the left side of the cooling unit.The cooling unit, the edge unfolding unit, the dyeing unit, the cloth outlet unit and the moving and rolling unit are sequentially arranged from left to right.An open-width processing mode is adopted, the structure is compact, the knitted fabric is effectively prevented from being wrinkled or crimped in the processing process, tension changes are small in the deformation process of the knitted fabric, and the effect of even dyeing can be achieved.According to the cold pad-batch dyeing machine, low-tension control can be effectively carried out over the knitted fabric in the whole drying link; all the technological processes are short, the utilization rate of dyes can be greatly improved, water saving and consumption reducing are achieved, production cost is reduced, and environmental pollution is small.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com