Cleaning method and device for masking sheet for model printing

A cleaning device and masking technology, applied to the cleaning method using tools, cleaning methods and utensils, cleaning flexible objects, etc., can solve problems such as film pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

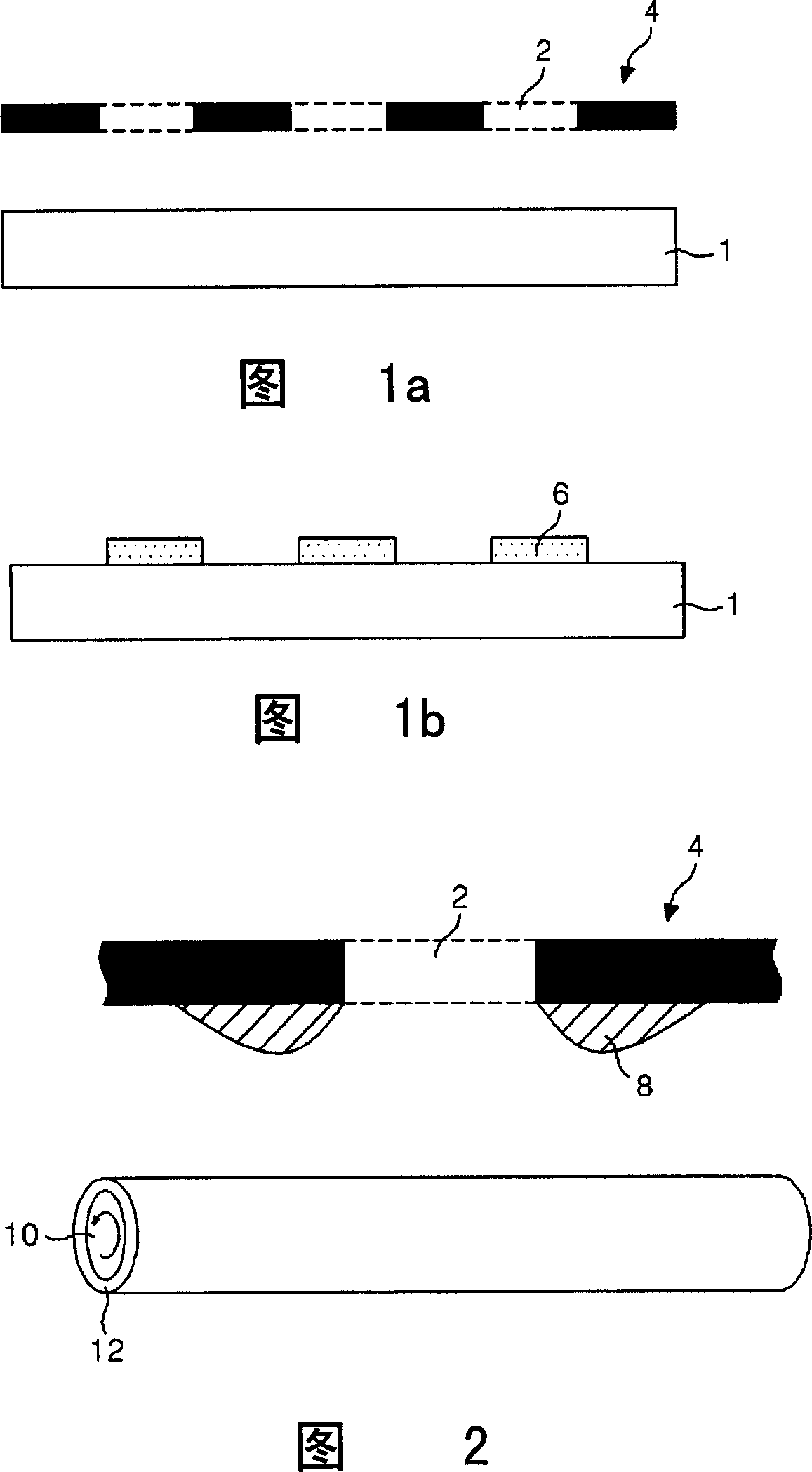

[0040] Embodiments of the cleaning method and device for a model printing mask of the present invention will be described in detail below with reference to the accompanying drawings.

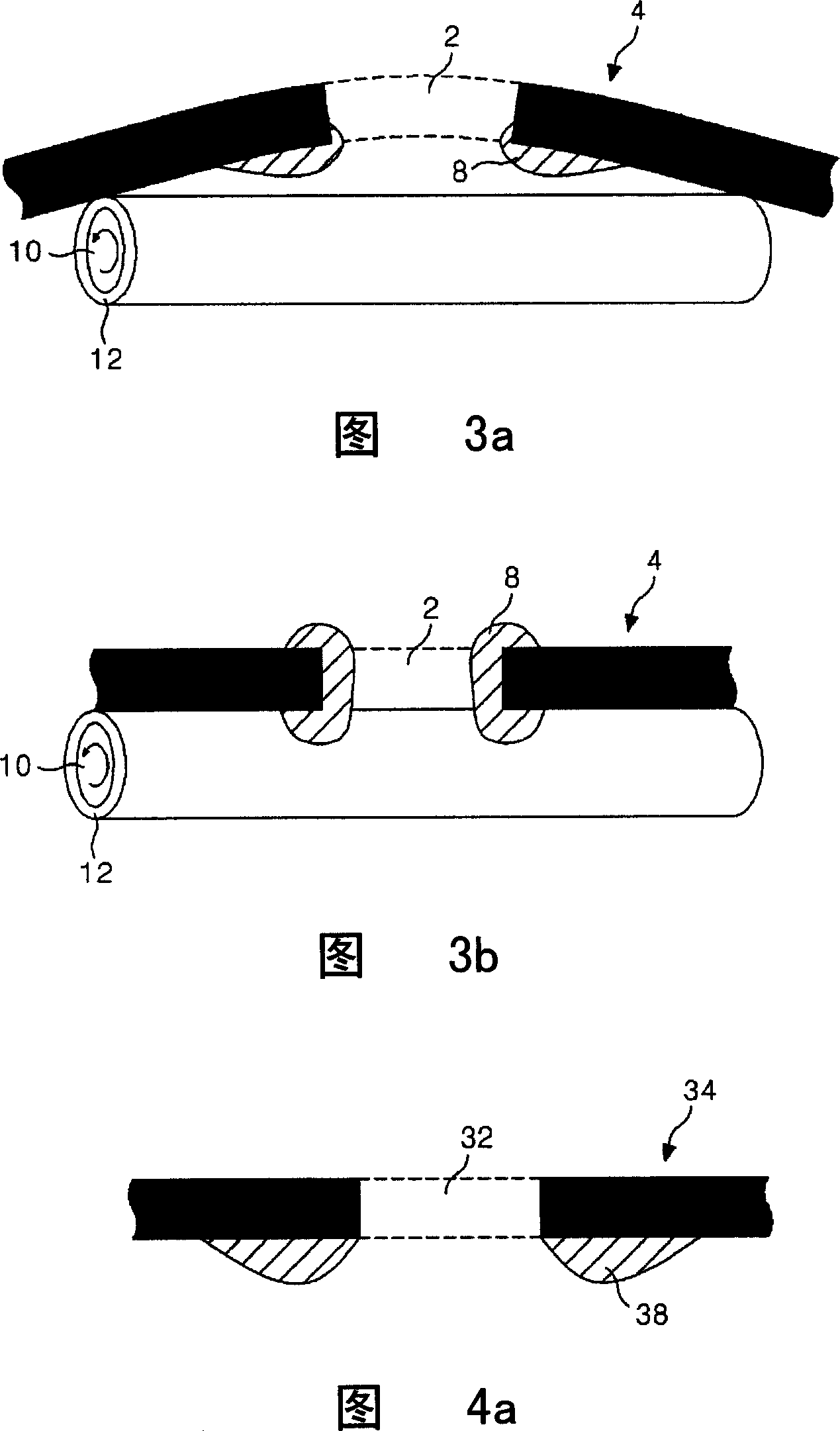

[0041] 4a and 4b are explanatory views of the cleaning method of the screen mask in the present invention.

[0042] First, if the electrode paint or the intermediate paint is coated at least once on the substrate, as shown in FIG. 34 back. In order to remove these foreign objects 38, the first cleaning roller 40 wound with the first cleaning tape 42, as shown in FIG. remove. At the same time, due to the pressure of the first cleaning roller 40, the foreign matter adhering to the back and side surfaces of the screen cover is removed by the second cleaning roller 50 wound with the second cleaning tape 52.

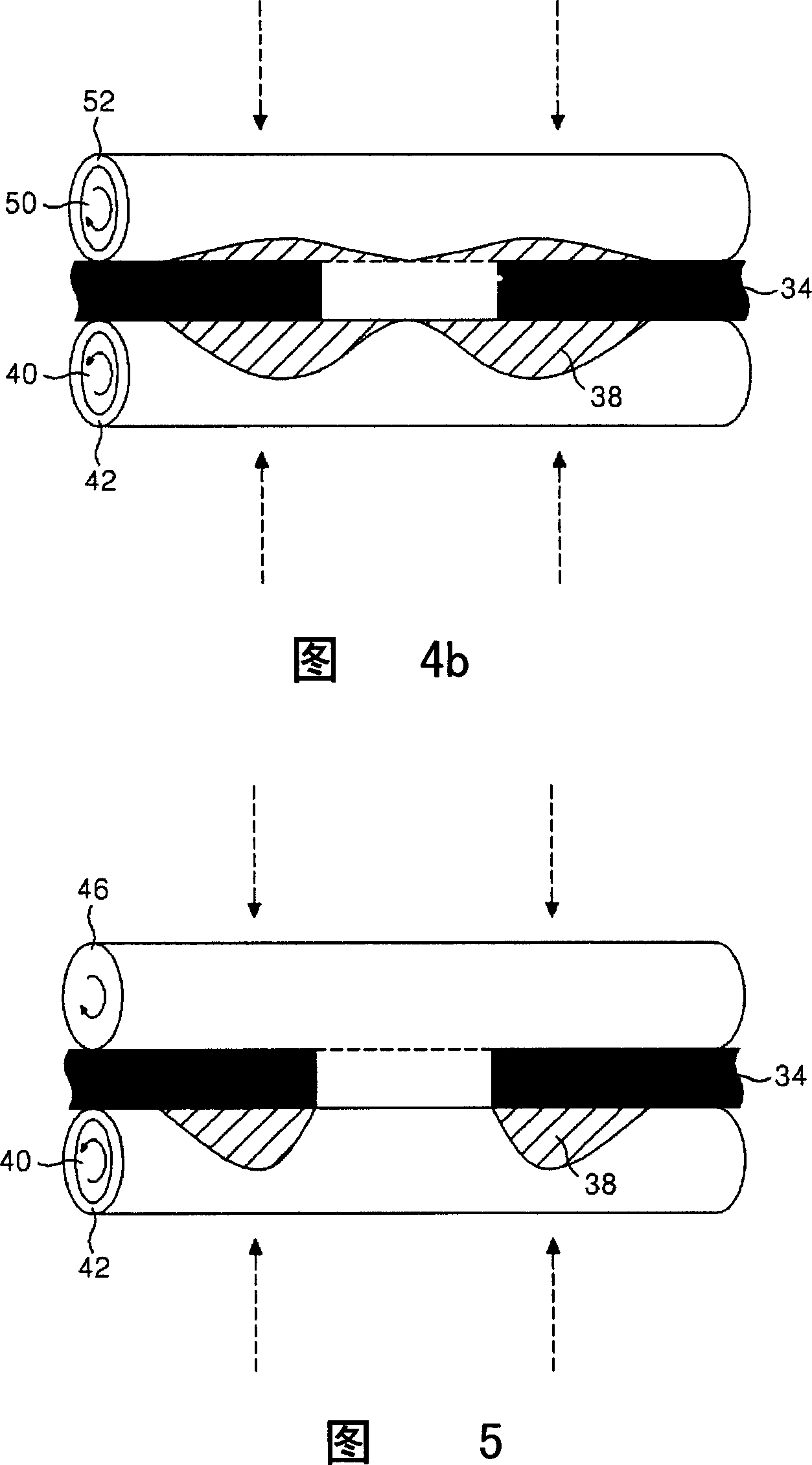

[0043] Replace the 2nd cleaning roller 50 that is wound with the 2nd cleaning tape 52 as shown in Figure 5, utilize the supporting material 46 to exert the same pressure on the front of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com