A strip splicing one-way cloth oven

A technology of unidirectional cloth and oven, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of gaps or overlapping of strip unidirectional cloth, avoid gaps or overlapping, avoid offset, and increase ventilation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

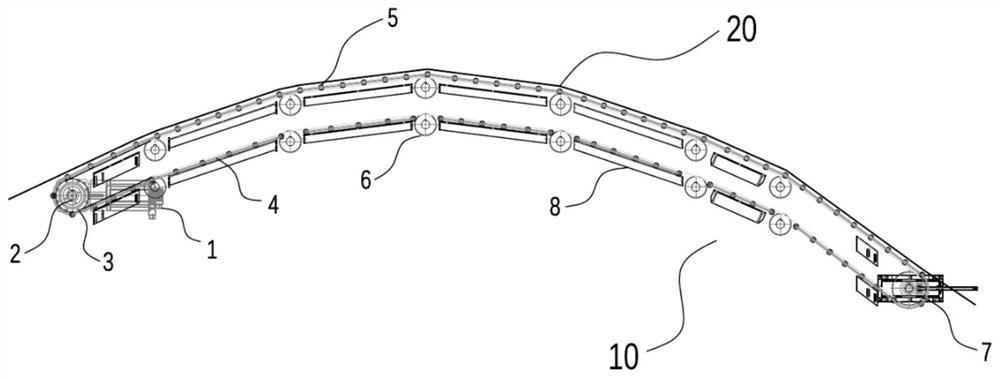

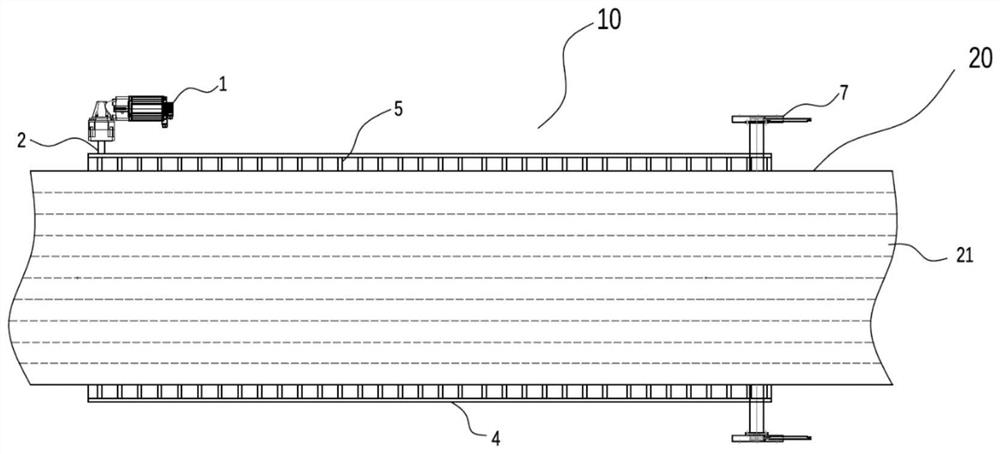

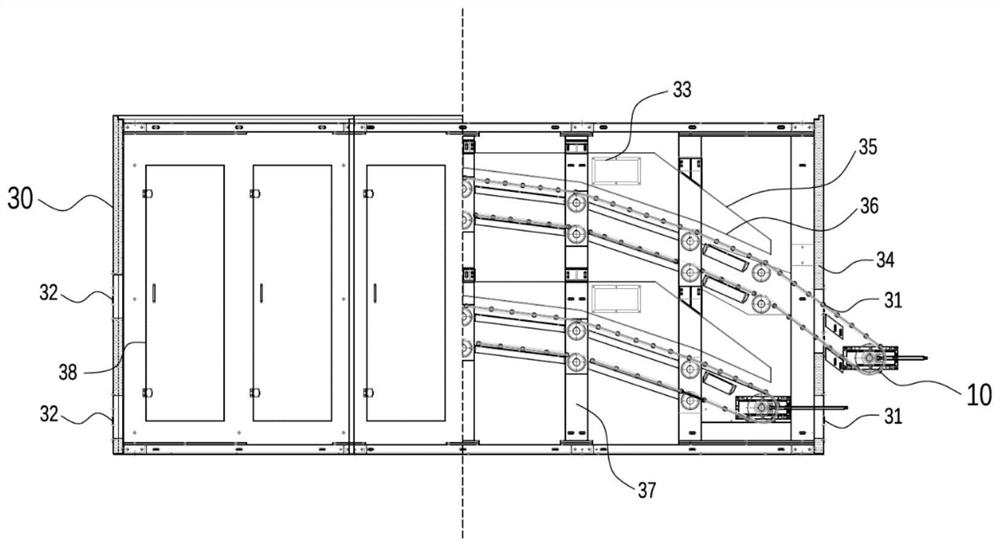

[0073] This embodiment relates to an oven for splicing unidirectional cloth with strips. like Figure 1-4 shown, image 3 , Figure 4 is a schematic structural diagram of the oven described in this embodiment, figure 1 , figure 2 It is a schematic diagram of the transmission device in the oven of this embodiment.

[0074] The oven for splicing unidirectional cloth with strips in this embodiment includes an oven body 30 and a gas circulation device 40 , the transmission device 10 is arranged in the box body 30 , and the transmission rod 5 of the transmission device 10 is made of carbon fiber composite material , the maximum deformation of the transmission rod 5 in the transmission process perpendicular to the axial direction of the transmission rod is less than 1 mm. Due to the small thermal expansion coefficient, low density and high rigidity of carbon fiber, it is not easy to deform in the synchronous transmission of wide-format materials such as unidirectional cloth 20...

Embodiment 2

[0082] This embodiment is a further description of the structure of the transmission device 10 in the oven of the embodiment 1 on the basis of the embodiment 1.

[0083] like figure 1 and figure 2 As shown, the transmission device 10 includes: a drive motor 1, the drive motor 1 is connected to a drive shaft 2, the drive shaft 2 is provided with two drive sprockets 3, and the distance between the two drive sprockets 3 is greater than the distance between the two drive sprockets 3 The width of the one-way cloth 20 conveyed by the device, the outer circular surface of the driving sprocket 3 is provided with meshing teeth, the transmission device 10 is provided with a transmission chain 4, there are two transmission chains 4, and the two transmission chains 4 are arranged at intervals. A plurality of transmission rods 5 are respectively fixed at both ends of the transmission rods 5 on two transmission chains 4 , and the two transmission chains 4 are respectively engaged with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com