Retreating method for knitting yarn and flat knitting machine

A technology for knitting yarn and flat knitting machine, which is applied in the direction of flat knitting machine, knitting, weft knitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

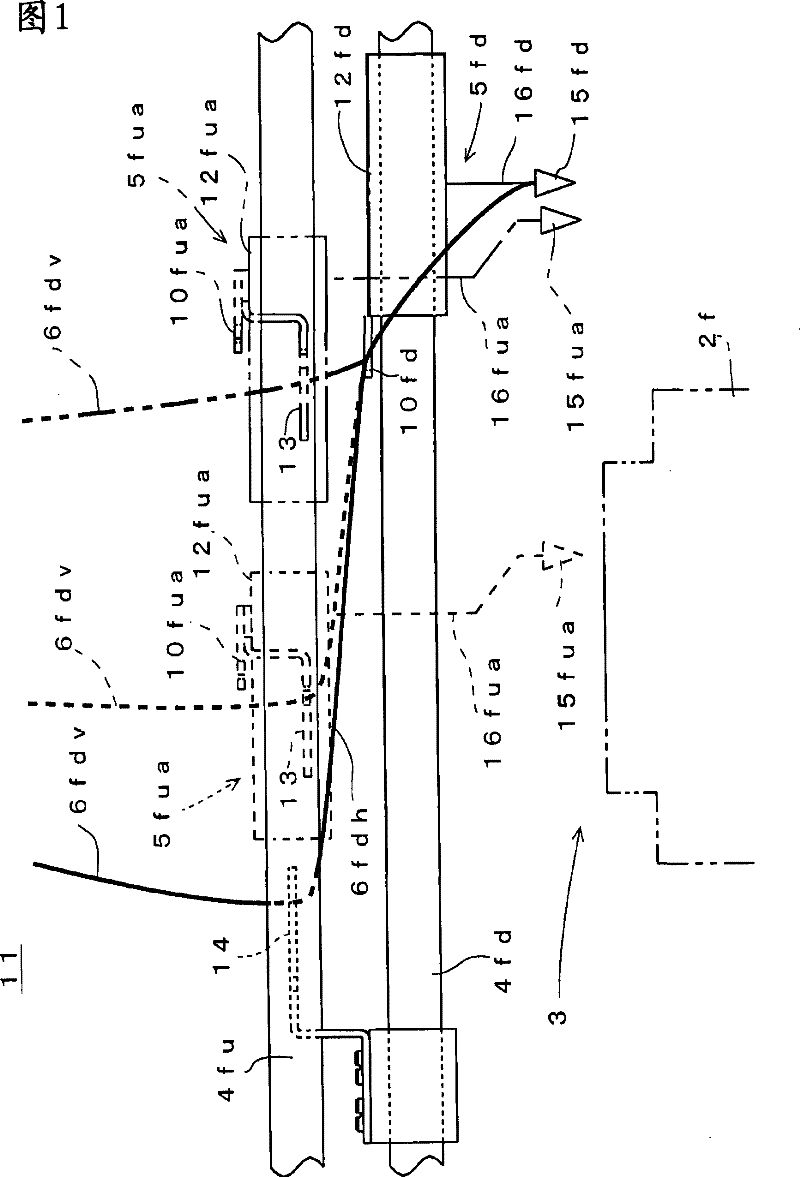

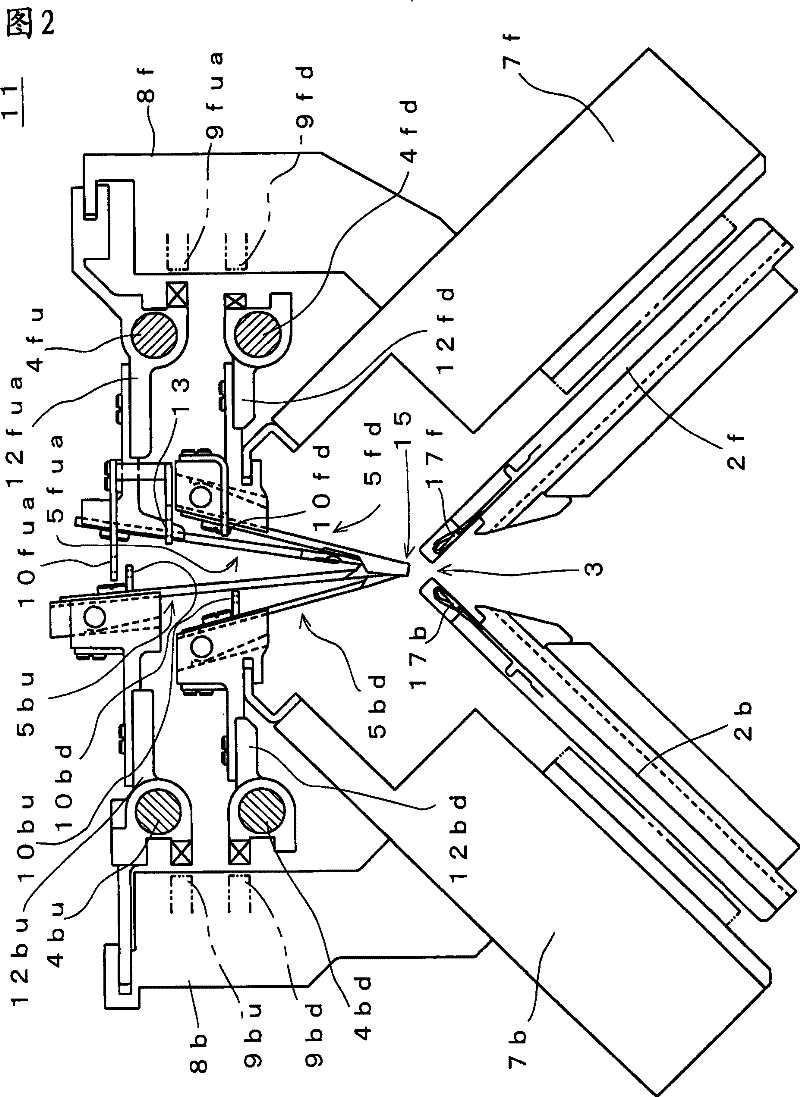

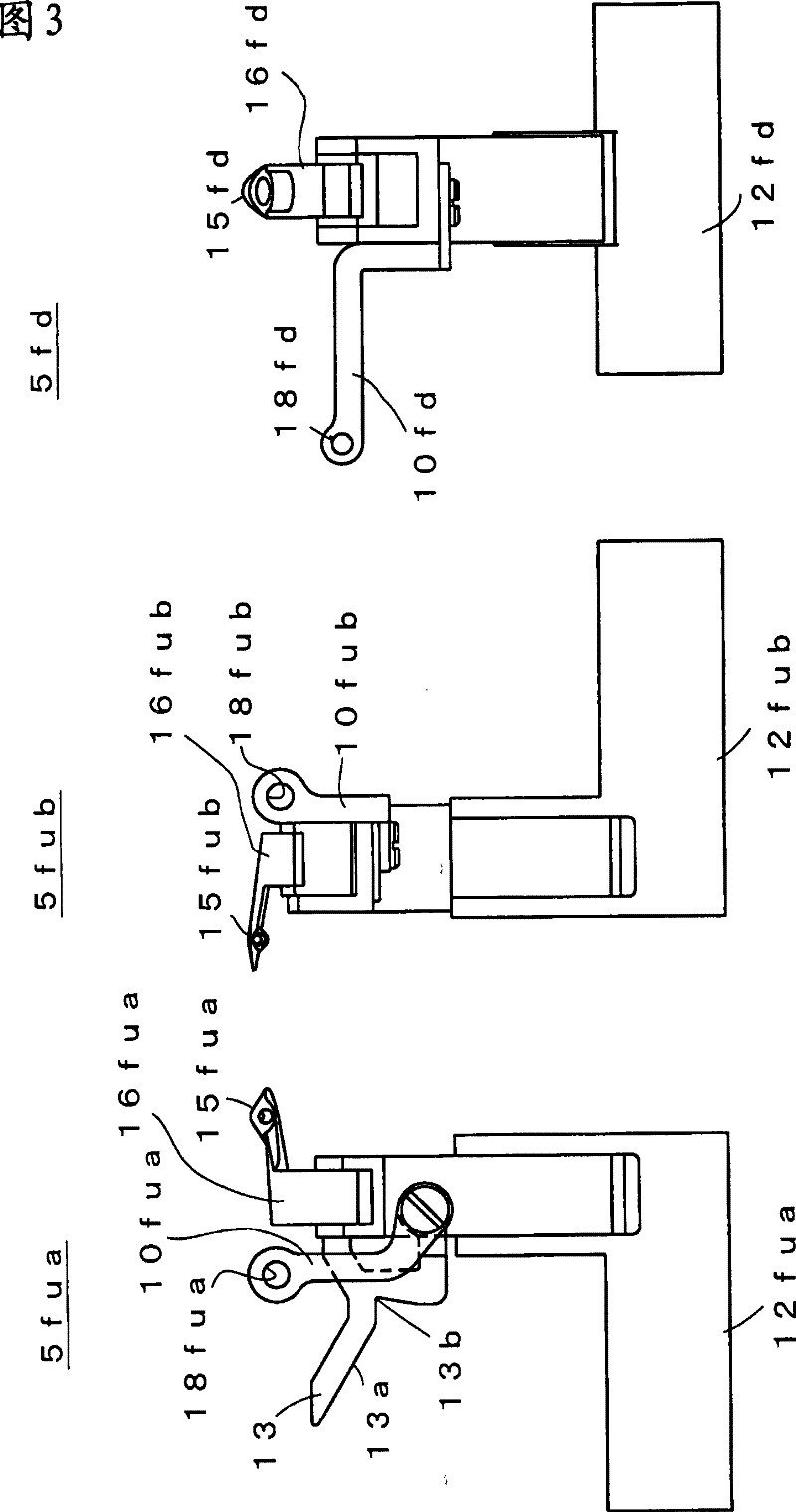

[0062] Figure 1 to Figure 6 The schematic structure of the sock knitting machine 11 which is one embodiment of this invention is shown. Also, in the description below, for the Figure 7 as well as Figure 8 The parts corresponding to the descriptions of the above and below are marked with the same symbols, and repeated descriptions are omitted. In addition, the description about the structure of the yarn feeders 5fua and 5fd described below also corresponds to other yarn feeders, and the description thereof will be omitted.

[0063] figure 1 and Figure 8 Correspondingly, the method of retracting the knitting yarn 6 in the sock knitting machine 11 of the present embodiment is shown. The configuration of each part is basically the same as Figure 7 same. Escape is performed to prevent interference when the yarn feeder 5fd provided on the lower traveling rail 4fd is stopped and the yarn feeder 5fua provided on the upper traveling rail 4fu is moved. Each of the yarn feede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com