Device for two-stage constant-tension wire loading during fine wire cutting procedure of high-speed reciprocating wire-cut electrical discharge machining process

A technology of reciprocating wire walking and electric discharge wire, which is applied in the direction of accessory devices, electrode manufacturing, electric processing equipment, etc., can solve the problems of poor rigidity and strength, low safety, difficult to uniform tension wire, etc., to improve the safety of use performance, improve processing efficiency, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

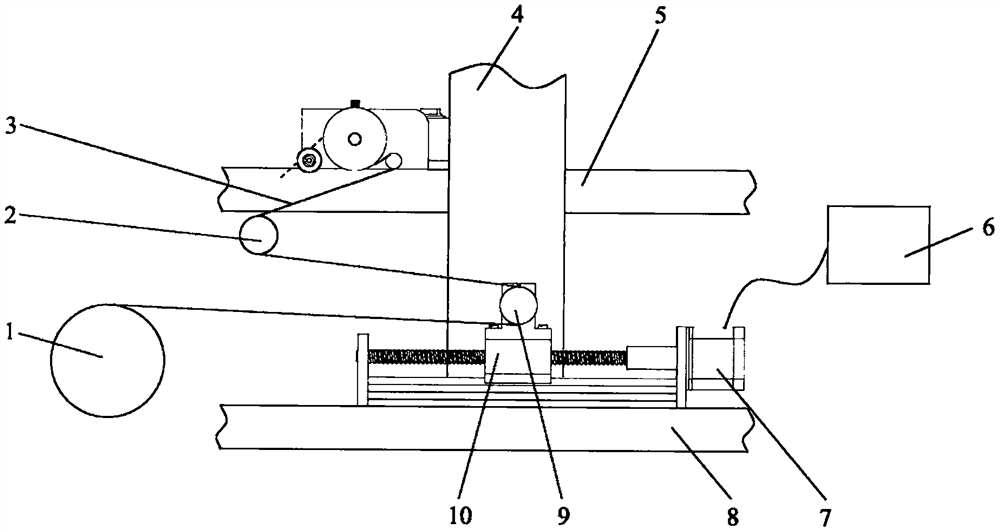

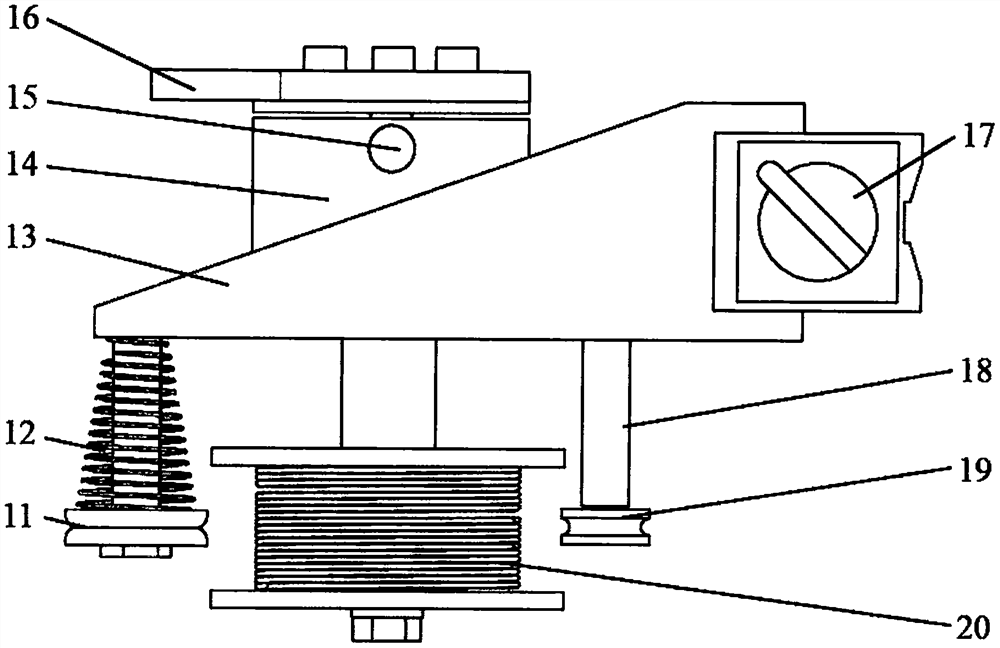

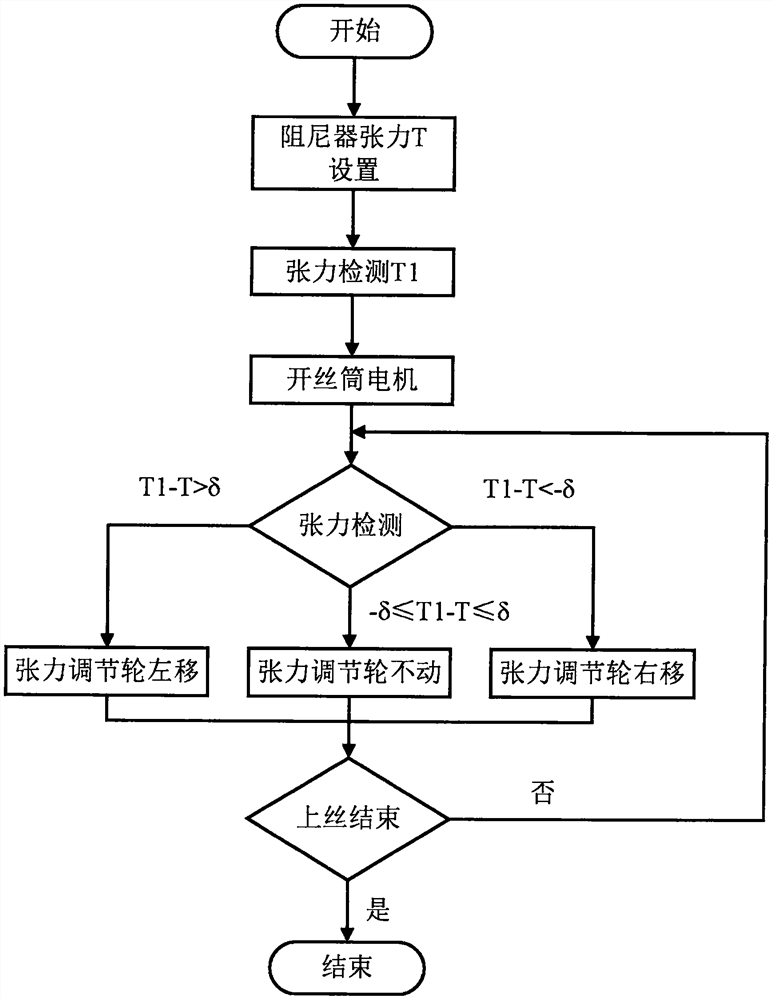

[0024] The present invention proposes a high-speed reciprocating wire electric discharge wire cutting filament cutting two-stage constant tension wire feeding device, such as figure 1 and figure 2 As shown, it includes wire drum 1, tension detection wheel 2, electrode wire 3, machine column, 4, upper wire rack 5, upper computer 6, stepper motor 7, lower wire rack 8, tension adjustment wheel 9, and screw slide module 10. Wire clip 11, wire clip spring 12, wire reel base 13, magnetic damper 14, tightening bolt 15, adjustment wrench 16, magnetic seat 17, support stud 18, wire pressing wheel 19, electrode wire reel 20.

[0025] The magnetic damper 14 is fixed on the wire reel base 13 through bolt connection, and the wire reel base 13 and the adjustment wrench 16 are both made of PLA material through FDM molding technology 3D printing rapid prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com