A cold pad-batch dyeing machine for knitted fabrics

A technology of cold pad-batch and dyeing machine, which is applied in the direction of fabric surface trimming, heating/cooling fabric, mechanical cleaning, etc. It can solve the problems of large spacing, sensitive tension and easy curling of knitted fabrics, etc., and achieve short process flow, Effect of improving dye utilization rate and preventing wrinkles and edge curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

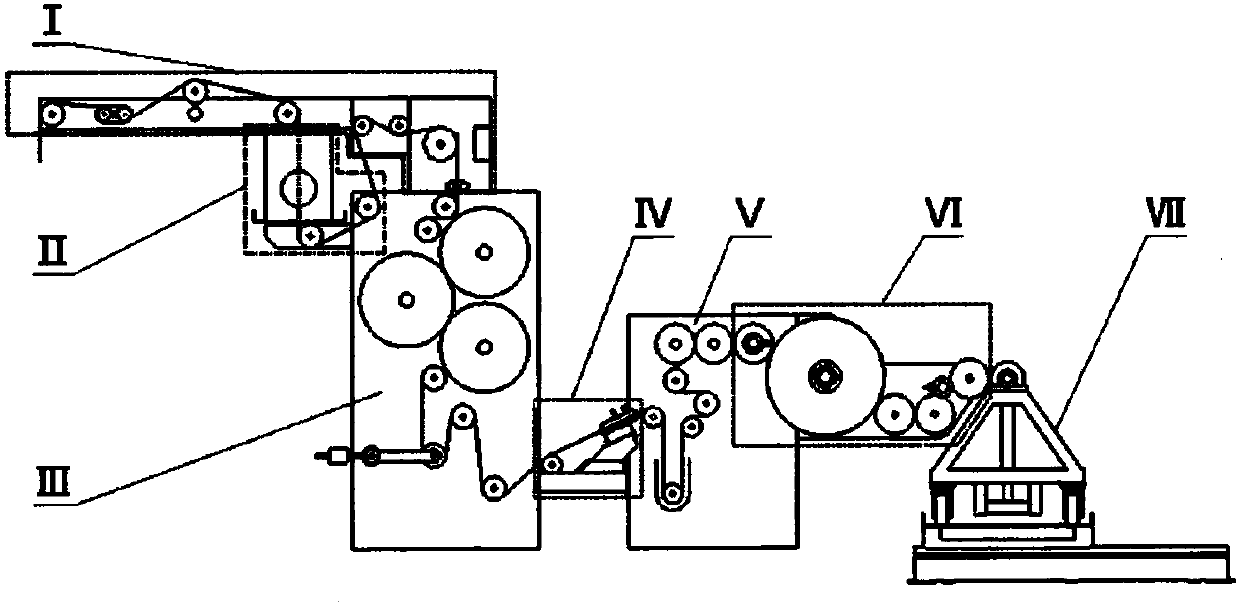

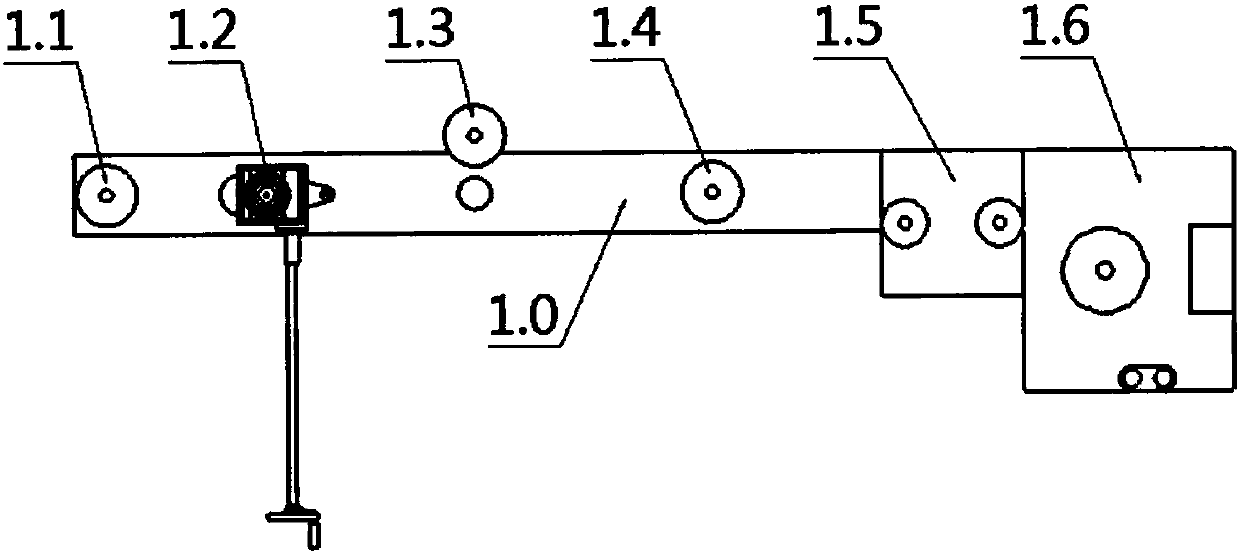

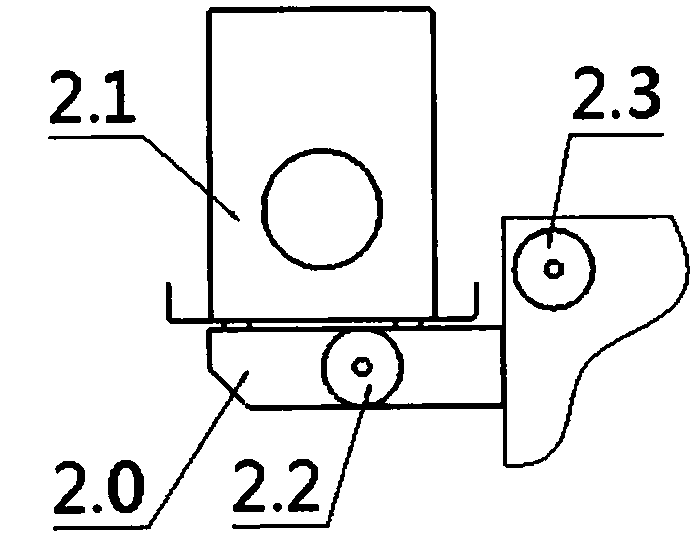

[0037] Such as figure 1 As shown, the cold pad-batch dyeing machine for knitted fabrics of the present invention includes an open-width cloth feeding unit I, a vacuum unit II, a cooling unit III, an edge spreading unit IV, a dyeing unit V, a cloth output unit VI and a moving winding unit VII; the open-width feeding unit I is used to increase the radial tension of the knitted fabric and fully expand it; the dust suction unit II is used to absorb the remaining impurities on the knitted fabric; the cooling unit III is used to to lower the surface temperature of the knitted fabric; the spreading unit IV is used to fully spread the edge of the knitted fabric before dyeing; the dyeing unit V is used for cold pad-batch dyeing of the knitted fabric; the cloth output unit VI is used to fully unfold the knitted fabric before winding, and can also measure the tension value of the fabric online; the mobile winding unit VII can ensure that the rolled shape of the knitted fabric is good, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com