A kind of wire winding method for leather cable

A winding method and cable technology, applied in the field of wire winding on leather cables, to achieve the effects of avoiding cable breakage or deformation, small tension changes, and optimizing winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

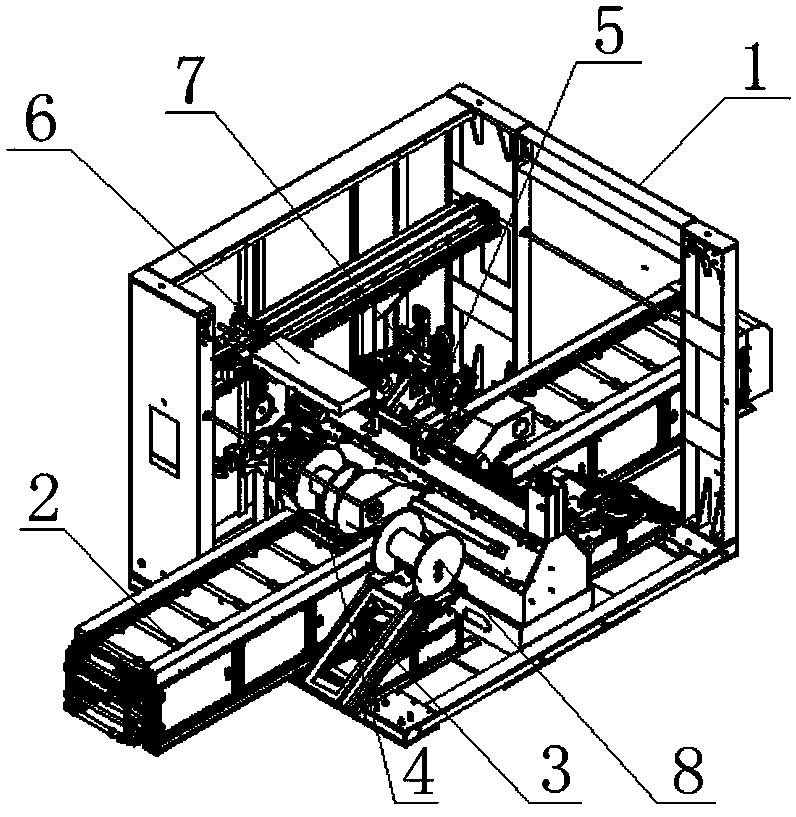

[0027] A wire winding method for a leather cable, comprising the following steps:

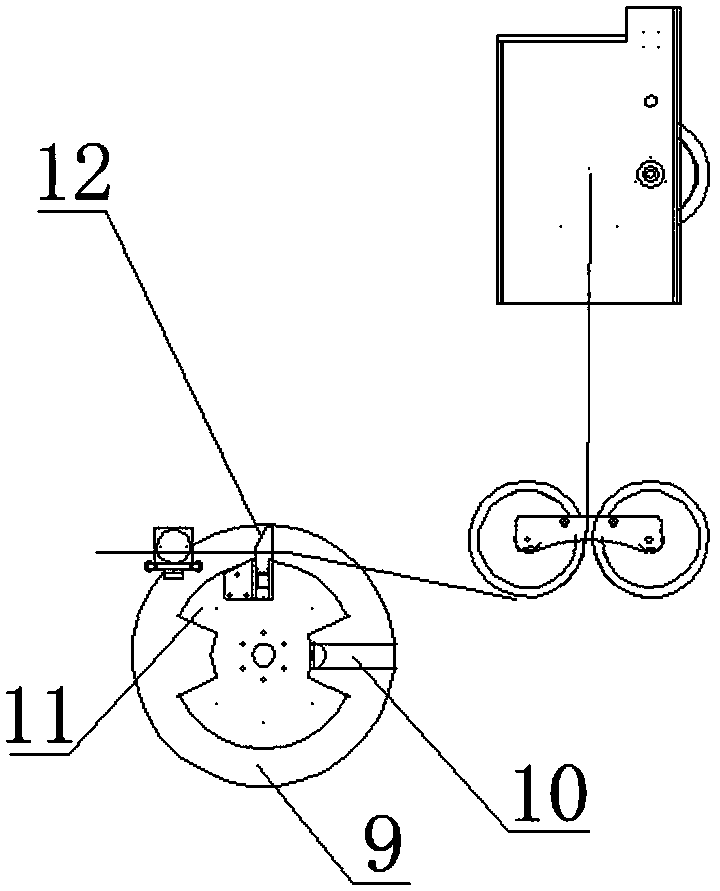

[0028] Step 1: The wire inlet 10 of the reel 9 is placed vertically downward on the reel feeding mechanism 2, and the initial position of the wire clamp 12 on the side of the winding reel 11 is located in the direction of 90° clockwise from the wire inlet 10 of the reel;

[0029] Step 2: The disk 9 is transported to the designated position on the disk feeding mechanism 2, the lifting mechanism 4 and the coil clamping and rotating mechanism 5 lift and clamp the coil 9, and the coil clamping and rotating mechanism 5 drives the coil 9 to rotate clockwise 90° so that the wire clamp 12 is located directly above the winding reel 11;

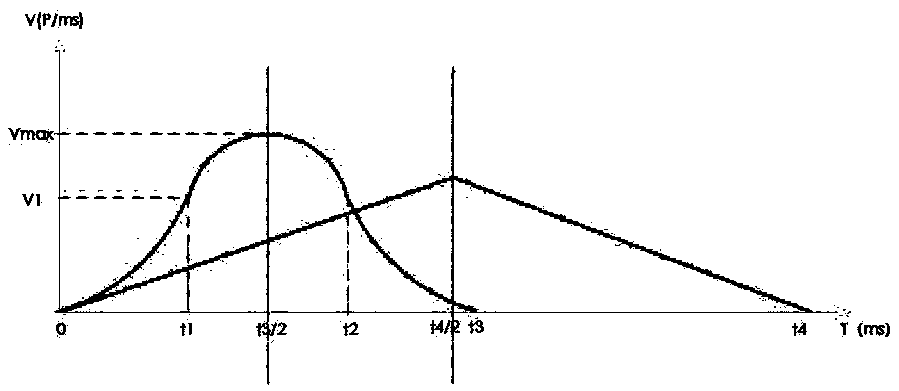

[0030] Step 3: The horizontal cable arrangement mechanism 6 and the wire clamp 12 act to catch the wire, clamp the cable in the wire clamp 12, and then rotate 90°+α, so that the cable is just at the position of the cable inlet 10 of the pan; the rotation angle α The va...

Embodiment 2

[0034] A wire winding method for a leather cable, comprising the following steps:

[0035] Step 1: The wire inlet of the reel is placed vertically downward on the reel feeding mechanism, and the initial position of the wire clip on the side of the reel is located at 90° clockwise from the wire inlet of the reel;

[0036] Step 2: The reel is transported to the designated position on the reel delivery mechanism, the lifting mechanism and the wire reel clamping and rotating mechanism lift and clamp the reel, and the wire reel clamping and rotating mechanism drives the reel to rotate clockwise 90° so that the wire clamp is positioned at the winding The position directly above the reel;

[0037] Step 3: The horizontal cable arrangement mechanism and the wire clamp act to catch the wire, clamp the cable in the wire clamp, and then rotate 90°+α, so that the cable is just at the position of the wire inlet of the pan; the value of the rotation angle α is, The radius of the winding ree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com