Low-torque-ripple high-efficient permanent magnetic motor stator and rotor structure

A torque pulsation, permanent magnet motor technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit static parts, etc., can solve the inherent performance degradation of the motor, air gap waveform distortion, magnetic leakage and other problems, to achieve the effect of improving efficiency and power density, increasing the width of the yoke, and reducing the eddy current loss and iron loss of the stator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below by specific embodiment:

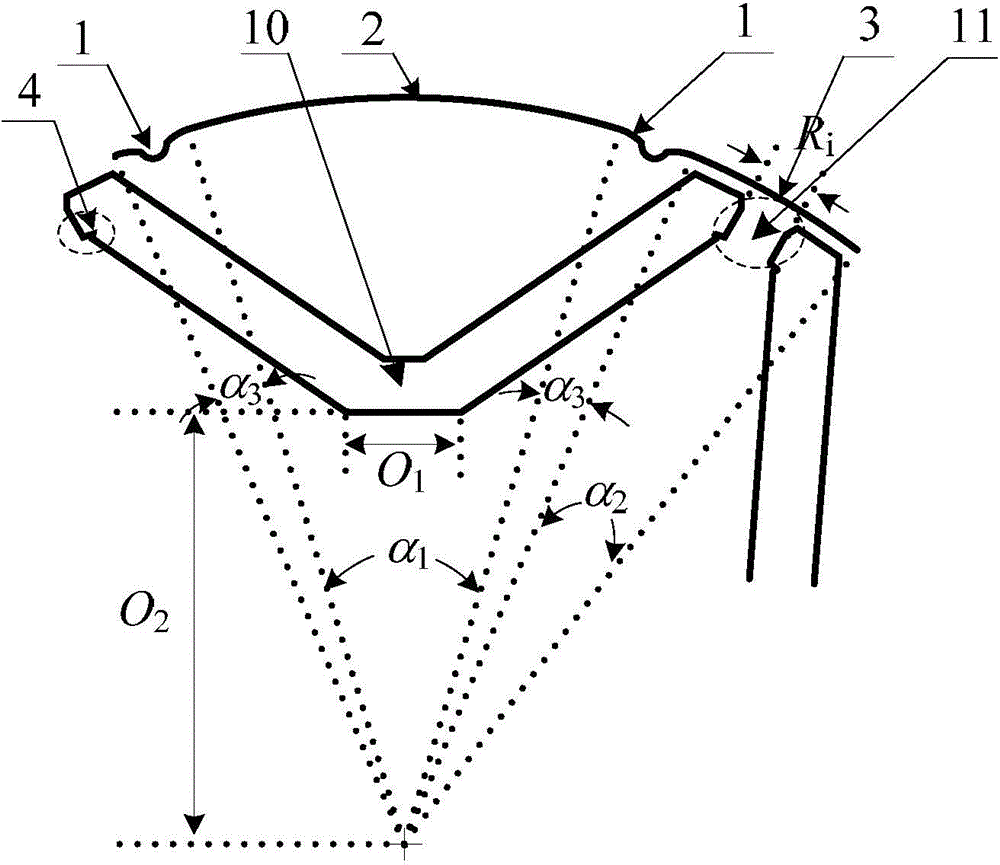

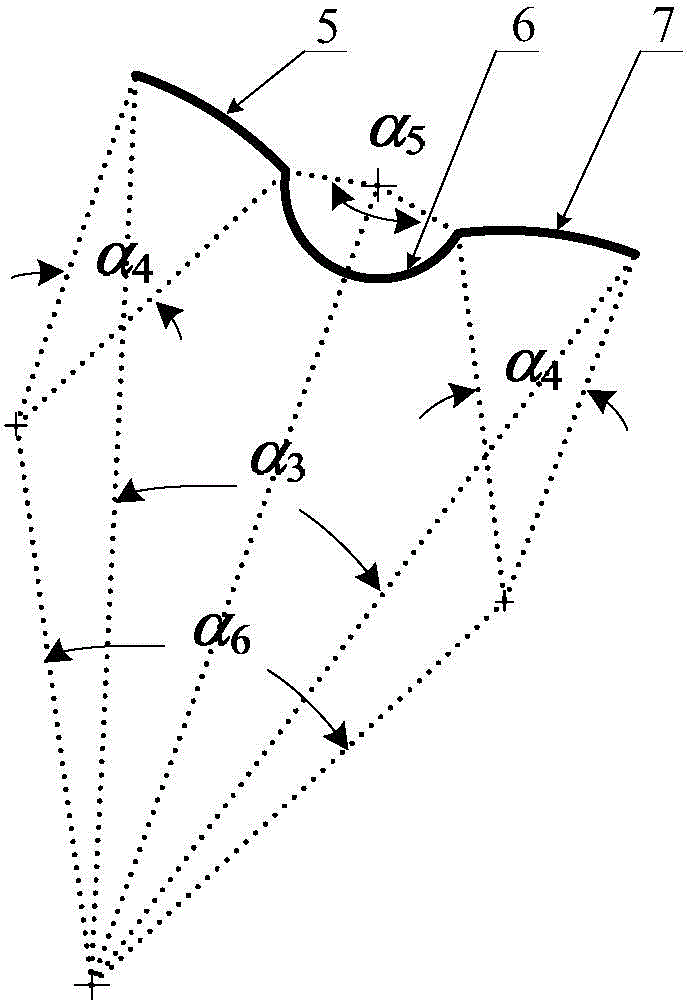

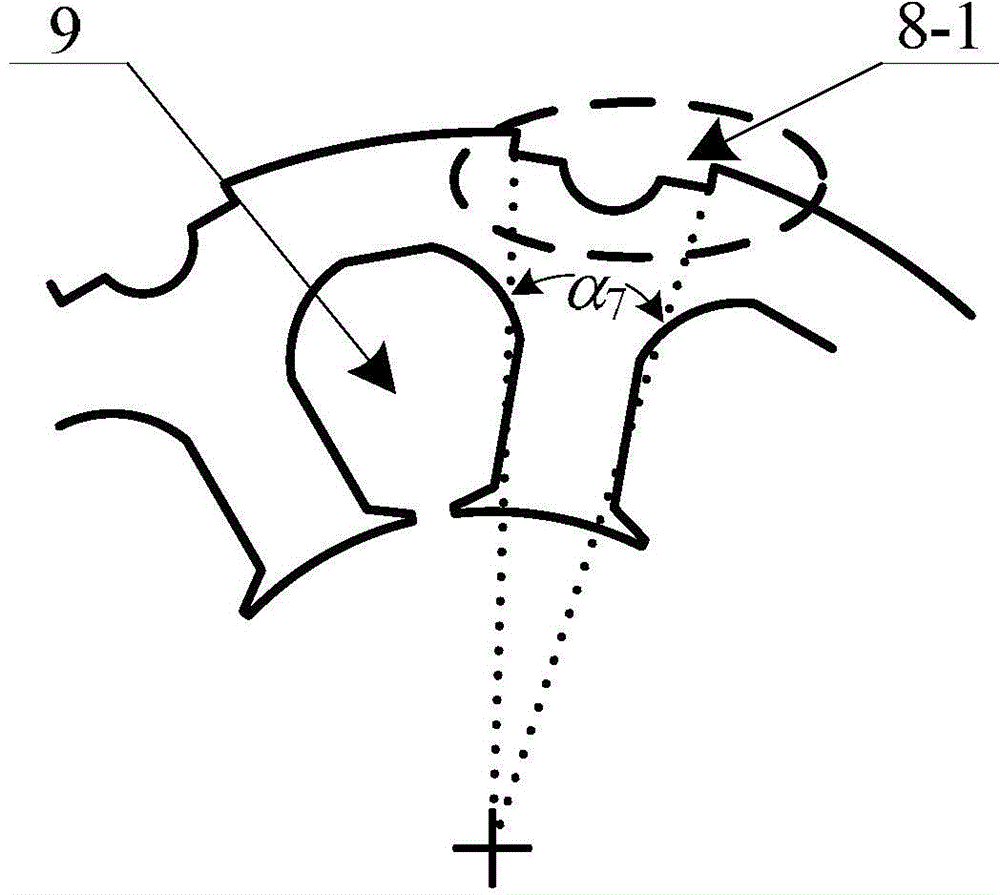

[0021] The invention relates to a stator-rotor structure of a low-torque pulsation high-efficiency permanent magnet motor. The outer circle of the rotor is composed of several four-segment circular arcs connected end to end, and the rotor is provided with a corresponding number of slots for embedding permanent magnets. A number of stator slots 9 are arranged near the stator on the rotor, and stator teeth are formed between every two stator slots. The slot type of the stator slot 9 is a pear-shaped flat-bottomed semi-closed slot. Flatten the bottom of the pear-shaped groove to increase the width of the yoke and reduce hysteresis and eddy current loss.

[0022] The four sections of arcs are two sections of the first arc 1 sunken inward, and the angle they occupy on the outer circle of the rotor is α 3 ; A long second arc 2 that protrudes outward, and the angle it occupies on the outer circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com