Tension self-adjusting multi-strand twister and thread twisting method thereof

A self-adjusting and twisting machine technology, used in textiles and papermaking, etc., can solve the problems of easy yarn quality problems and inability to adjust tension by itself, and achieve the effect of reducing tension changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

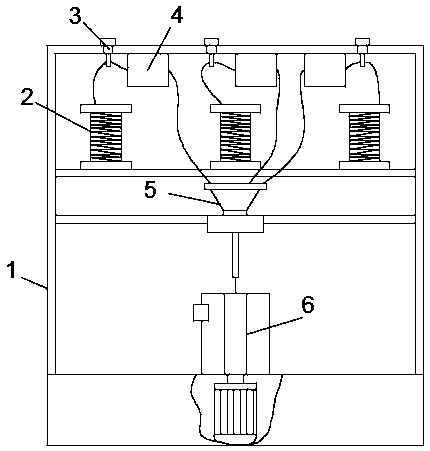

[0026] see Figure 1-Figure 8 , the tension self-adjusting multi-strand twisting machine in the present embodiment comprises a frame 1, a bobbin 2, a yarn guiding device 3, a tension fine-tuning device 4, a twisting device 5 and a winding device 6; the bobbin 2 is fixed on the machine On the frame 1; the winding device 6 is installed on the frame 1.

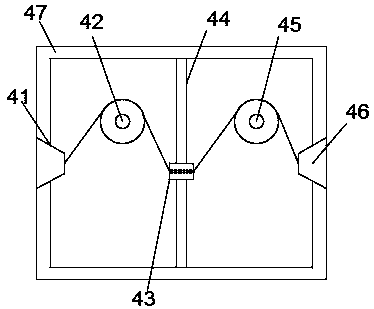

[0027] The yarn guiding device 3 in the present embodiment comprises a yarn guiding wheel 31, a connecting piece 32, a lock nut 33, and a pulley 34; the yarn guiding wheel 31 is fixed on the connecting piece 32; the connecting piece 32 is provided with a through hole 321; the pulley 34 Rotationally connected with the connecting piece 32; the lock nut 33 is threadedly connected with the connecting piece 32; the connecting piece 32 is slidably connected with the frame 1; the frame 1 is provided with a pulley guide rail matched with the pulley 34. In this embodiment, the position of the yarn guide device 3 can be adjusted according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com