Hot-rail deformation hot box

A deformation hot box and hot rail technology, applied in textiles and papermaking, etc., to achieve the effect of controlling broken ends and filaments, reducing maintenance costs, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

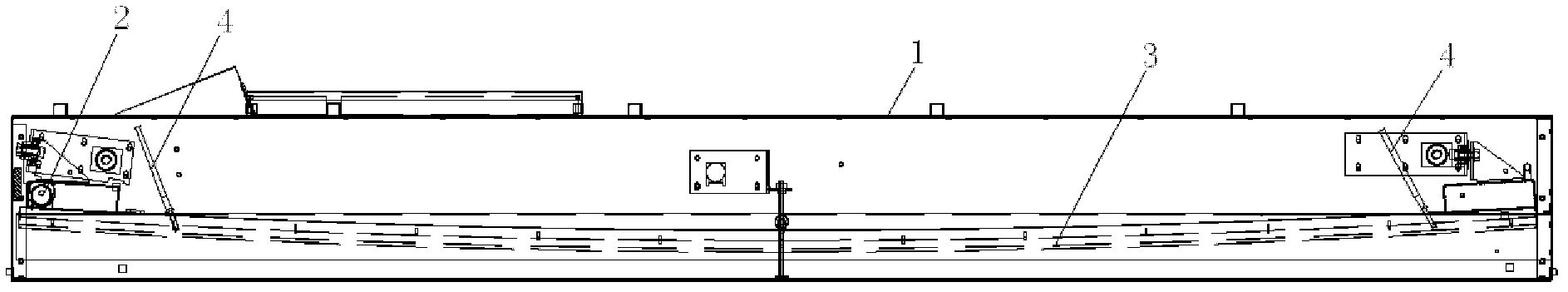

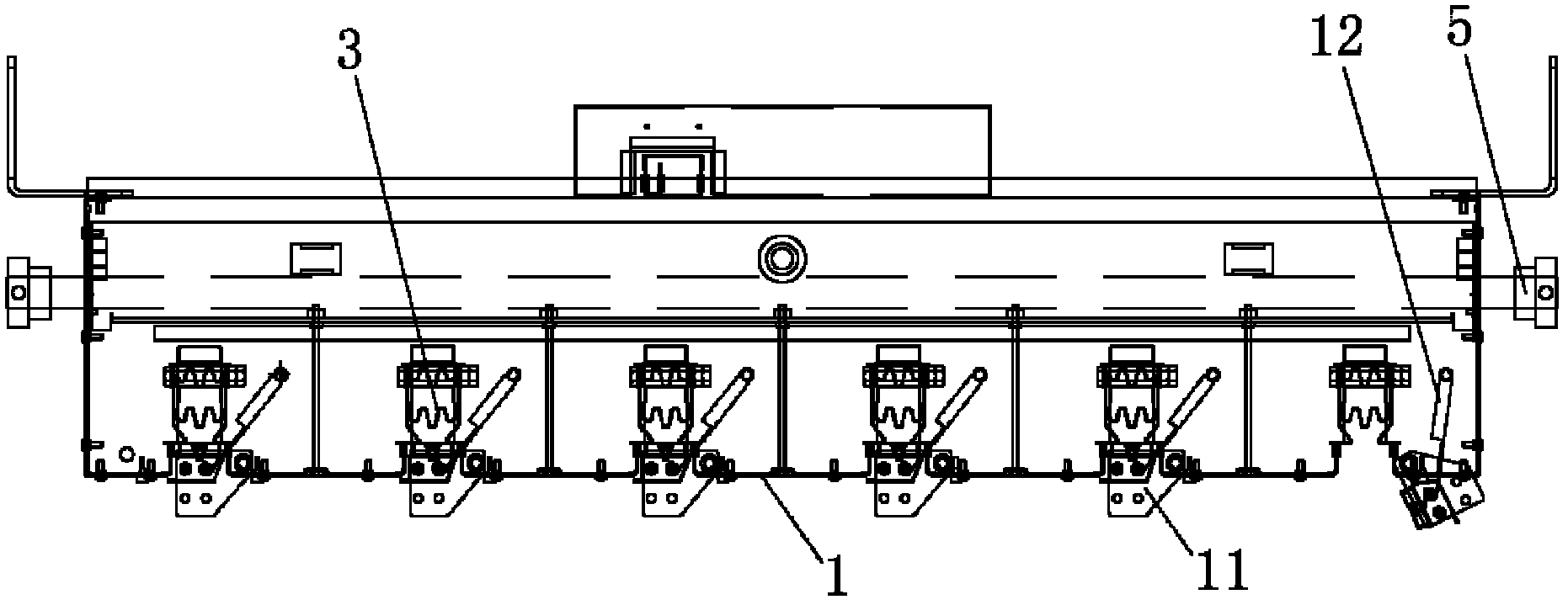

[0030] see figure 1 , This embodiment includes a housing 1, a heating liner 2, a hot rail 3, a temperature sensor 4, and a fume exhaust duct 5.

[0031] The heating inner container 2, the hot rail 3, the temperature sensor 4 and the oil fume exhaust duct 5 are arranged inside the casing 1. The housing 1 is provided with a working status indicator, which can visually display the working status of the hot box. Heat insulation material is filled between the shell 1 and the heating inner liner 2; the heating inner liner 2 is provided with a heating medium, and the heating medium is biphenyl. Biphenyl has the characteristics of good chemical stability, low cost, and stable cycle. The maximum heating temperature can reach 250°C, and its critical temperature is just below the melting point of PET, so it can effectively avoid local overheating. The outer wall of the heating liner 2 is provided with six heating element installation pipes, and the six heating elements are respectively ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com