Tension control device for fiber tows

A tension control and fiber tow technology, which is applied in the field of fiber tow tension control devices, can solve the problems of increased error, tension change, inapplicable fields, etc., and achieves the effects of broad application prospects, good economic benefits, and low improvement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

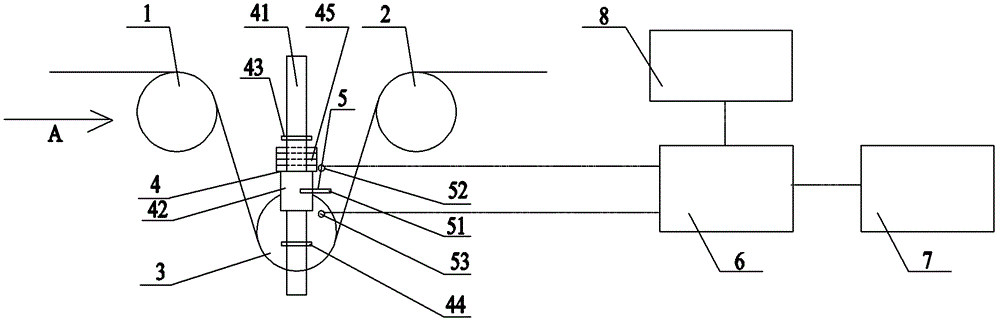

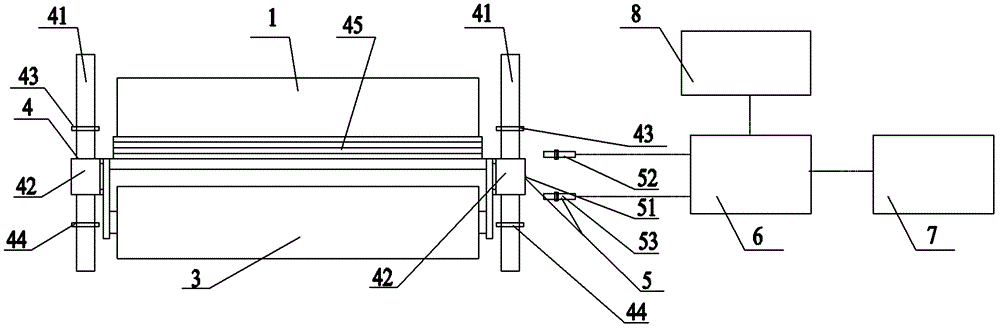

[0036] Such as figure 1 with figure 2 Shown is the fiber tow tension control device of the present invention, including a first positioning roller 1, a second positioning roller 2, a tension roller 3, a guide device 4 for guiding the movement of the tension roller 3, and a guide device 4 for detecting the tension roller 3 position change detection device 5, controller 6 and motor governor 7; the tension roller 3 is located in the area between the first positioning roller 1 and the second positioning roller 2, and the tension roller 3, the first positioning roller 1 and the second positioning roller The axes of the two positioning rollers 2 are parallel to each other. The axes of the first positioning roller 1, the second positioning roller 2 and the tension roller 3 are connected together to form an inverted triangle. The tension roller 3 and the two rollers of the first positioning roller 1 The center distance and tension roller 3 are equal to the center distance between th...

Embodiment 2

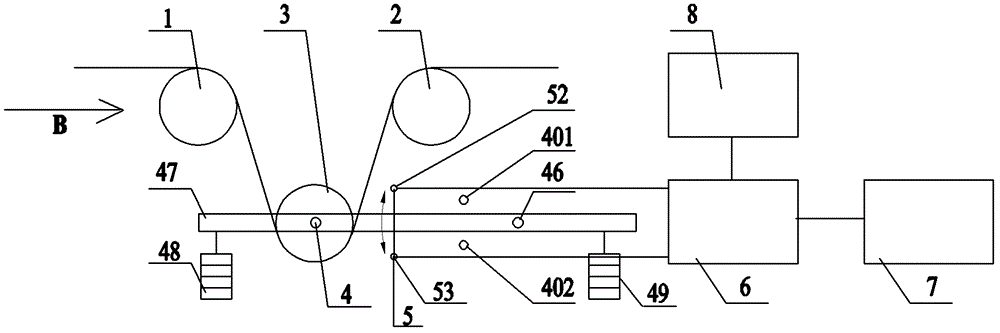

[0055] Such as image 3 , Figure 4 As shown, the fiber tow tension control device of another structure of the present invention includes a first positioning roller 1, a second positioning roller 2, a tension roller 3, a guide device 4 for guiding the movement of the tension roller 3, Detecting device 5, controller 6 and motor governor 7 for detecting the position change of tension roller 3; tension roller 3 is positioned at the area between the first positioning roller 1 and the second positioning roller 2, and tension roller 3, the first The axes of the positioning roller 1 and the second positioning roller 2 are parallel to each other, the axes of the first positioning roller 1, the second positioning roller 2 and the tension roller 3 are connected together to form an inverted triangle, and the tension roller 3 is aligned with the first positioning roller. The center distance between the two rollers of the roller 1 and the center distance between the two rollers of the ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com