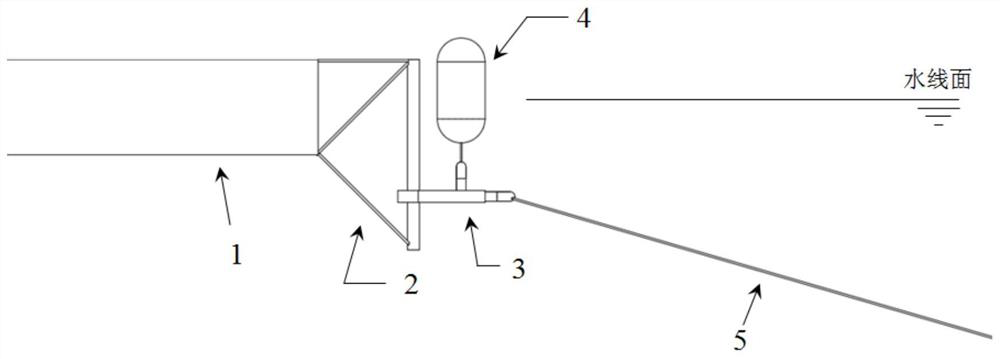

Moorings for large water level changes

A technology of water level changes and mooring devices, which is applied to ships and other directions, can solve the problems of high cost, high processing and material costs, and inconvenient construction, and achieve the effects of small tension changes, simple structure, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

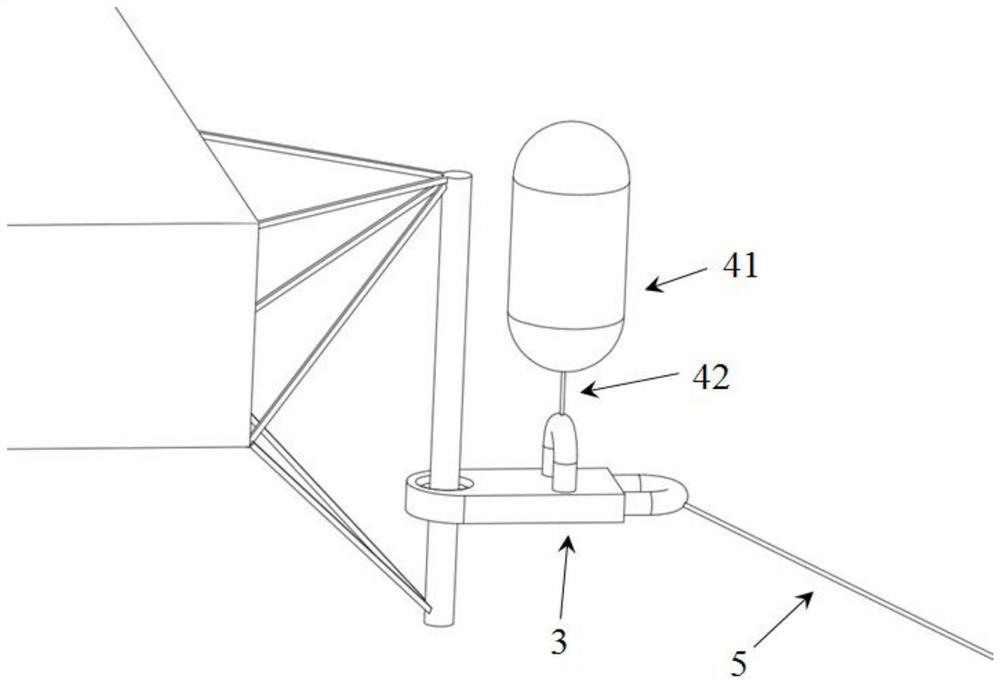

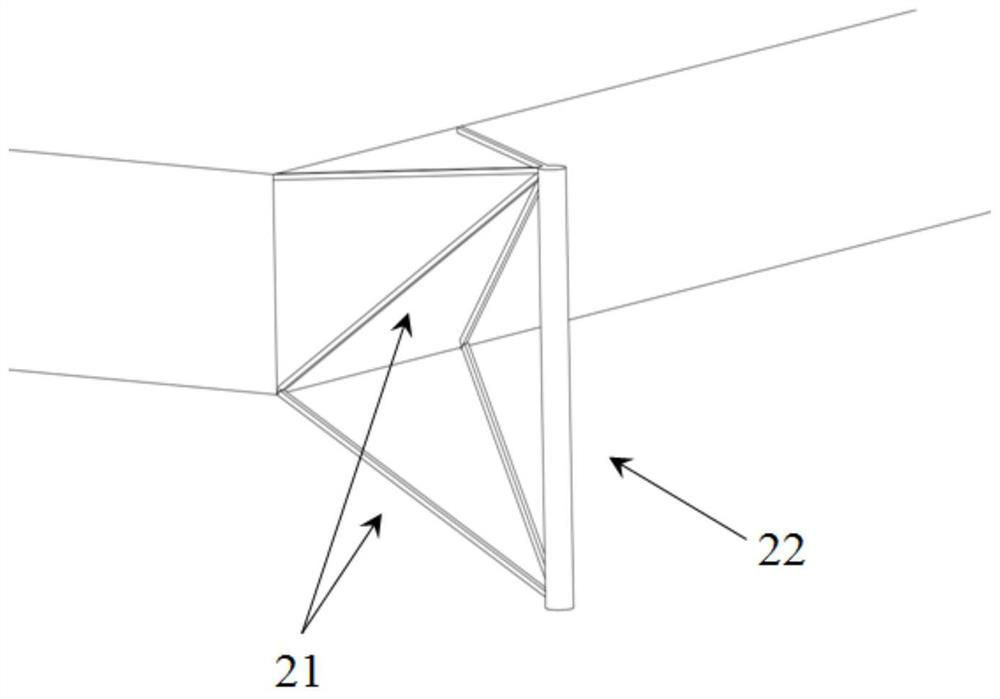

[0032] As shown in Figure 2 and Figure 3, the mooring bracket 2 includes a supporting truss 21 and a vertical sliding rod 22, the supporting truss 21 and the floating

[0035] As shown in FIG. 2, the floating box system 4 includes a floating body unit 41 and a floating body connecting rope 42, and the interior of the floating body unit 41 is hollow,

[0037] The outer wall of the floating body unit 41 is structurally strengthened to avoid collision damage. In conjunction with FIG. 5, the interior of the floating body unit 41 contains many

[0042] The basic principles and main structural features of the present invention have been shown and described above. The present invention is not limited to the above examples

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com