Production technology of nylon 6 fine denier network stretch yarn suitable for hydraulic loom

A technology of water jet loom and production process, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of a large amount of short plush on the yarn guide, poor fabric flatness, and easy to cause broken ends, etc., and achieve uniform deformation and reduced tension changes. , low fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

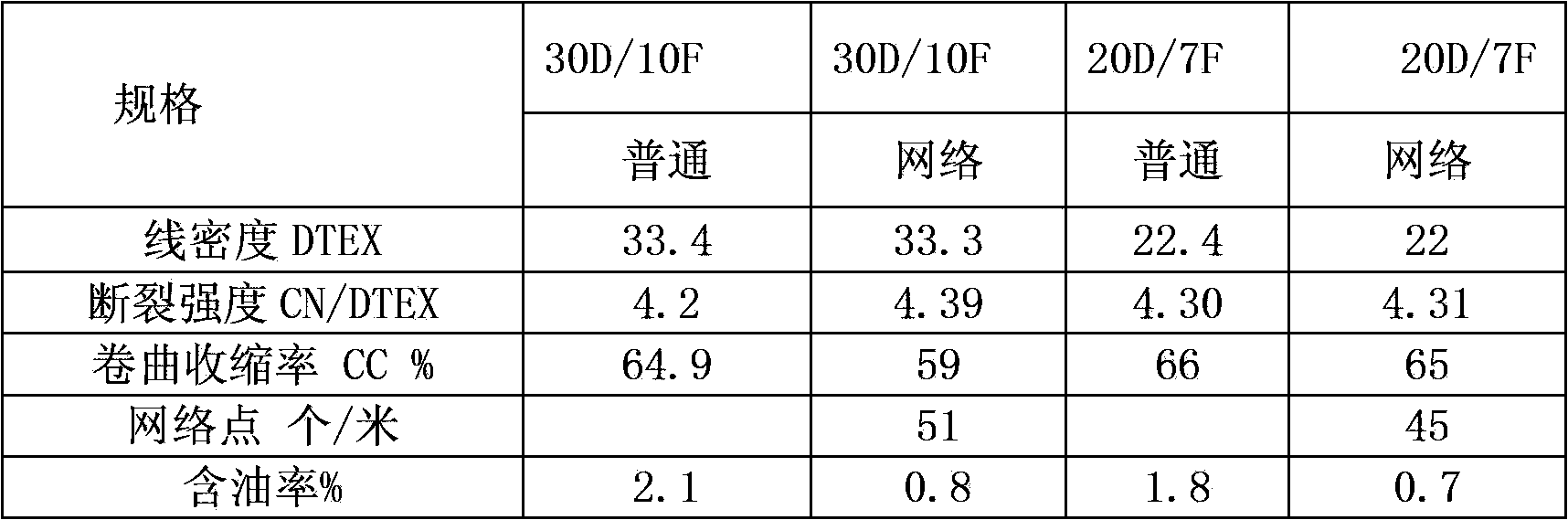

Embodiment 1

[0018] Put the 30D / 10F or 20D / 7F POY raw yarn on the raw yarn rack, lead it out from the raw yarn rack, and pass through the first roller (also called feeding roller), hot box, cooling plate, false twisting Roller, second roller (also called traction roller), netter (select Haberly p203 model), auxiliary second roller, oiling device, winding roller, and obtain nylon 6 fine denier network elastic yarn after winding. Wherein, the distance between the auxiliary second roller and the second roller is 0.2 meters, the linear speed of the auxiliary second roller is less than the linear speed of the second roller, the draft ratio between the first roller and the second roller is 1.4, and the heating box The temperature is 145°C, the ratio of the linear speed of the friction disk of the false twister to the linear speed of the second roller is 1.8, the network pressure of the network device is 0.25Mpa, the linear speed of the first roller is 500m / min, the second roller The line speed i...

Embodiment 2

[0020] Put the 30D / 10F or 20D / 7F POY raw yarn on the raw yarn rack, lead it out from the raw yarn rack, and pass through the first roller (also called feeding roller), hot box, cooling plate, false twisting Roller, second roller (also called traction roller), netter (select Haberly p203 model), auxiliary second roller, oiling device, winding roller, after winding, nylon 6 fine-denier network elastic yarn is obtained, and the auxiliary second roller The distance between the second roller and the second roller is 0.4 meters, the linear speed of the auxiliary second roller is lower than that of the second roller, the draft ratio between the first roller and the second roller is 1.2, and the temperature of the hot box is 160°C. The ratio of the linear velocity of the friction disc of the false twister to the linear velocity of the second roller is 2.2, the network pressure of the network device is 0.35Mpa, the linear velocity of the first roller is 666m / min, and the linear velocity...

Embodiment 3

[0022] Put the 30D / 10F or 20D / 7F POY raw yarn on the raw yarn rack, lead it out from the raw yarn rack, and pass through the first roller (also called feeding roller), hot box, cooling plate, false twisting Roller, second roller (also called traction roller), netter (select Haberly p203 model), auxiliary second roller, oiling device, winding roller, after winding, nylon 6 fine-denier network elastic yarn is obtained, and the auxiliary second roller The distance between the second roller and the second roller is 0.3 meters, the linear speed of the auxiliary second roller is lower than that of the second roller, the draft ratio between the first roller and the second roller is 1.3, and the temperature of the hot box is 150°C. The ratio of the linear velocity of the friction disc of the false twister to the linear velocity of the second roller is 2.1, the network pressure of the network device is 0.31Mpa, the linear velocity of the first roller is 577m / min, and the linear velocity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com