A Hydraulic Cylinder Type Passive Heave Compensation System Based on Hydraulic Transformer

A passive heave compensation and hydraulic transformer technology, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problem that the passive heave compensation system cannot achieve compensation performance, the ability of load heave movement is poor, and the mother ship The problem of limited deck area can avoid the collision between the piston of the compensation cylinder and the cylinder head, reduce the accuracy requirements, and avoid the back pressure caused by insufficient oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

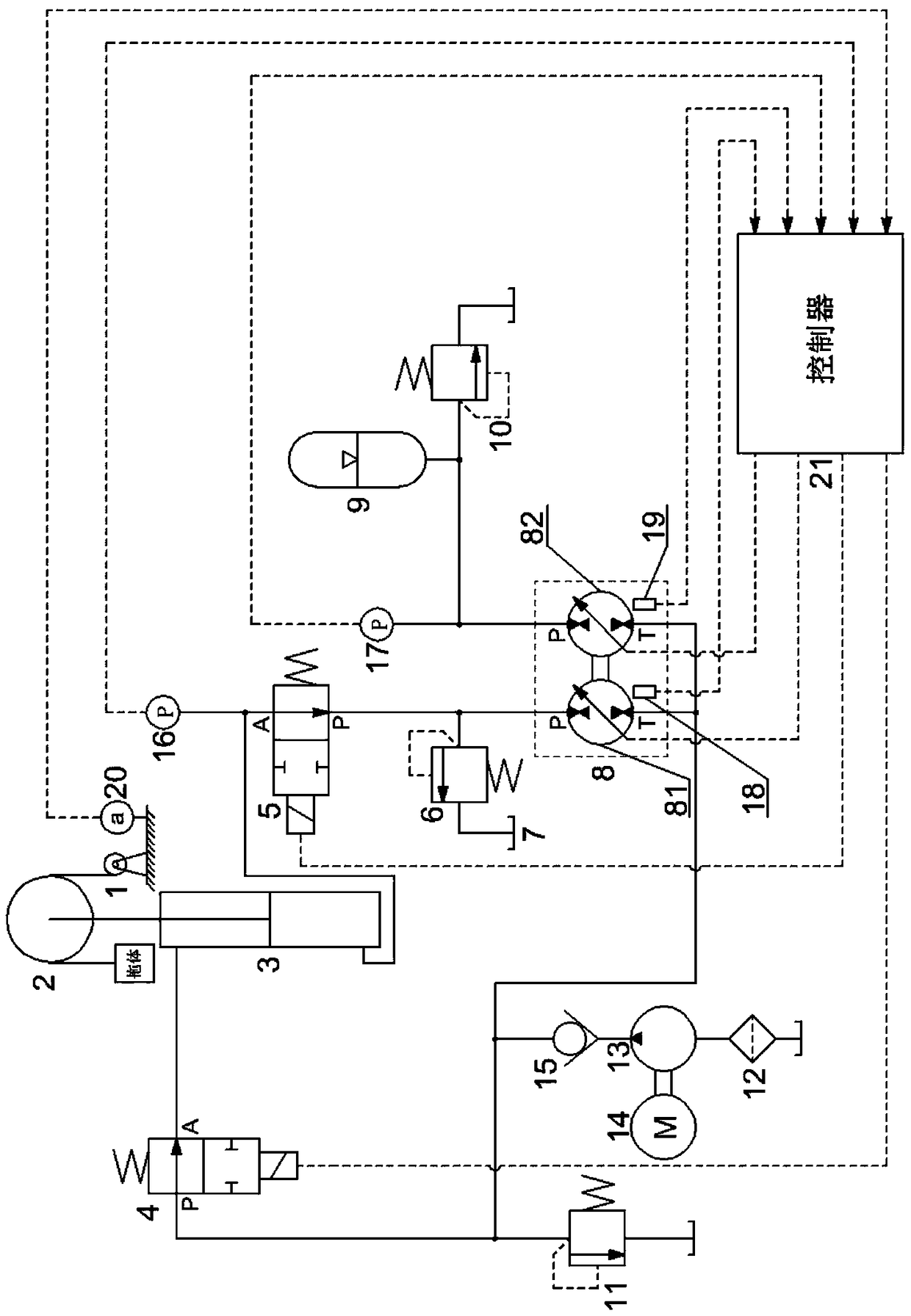

[0022] A hydraulic cylinder passive heave compensation system based on a hydraulic transformer, used to compensate the heave of the towing body, including a winch 1, a compensation cylinder 3, an accumulator 9 and an oil tank 7, the winch 1 is fixed on the mother ship, and the winch 1 is compensated by The oil cylinder 3 is connected with the drag body, and also includes a hydraulic transformer 8, a rod chamber safety control valve 4, a rodless chamber safety control valve 5, a hydraulic motor safety valve 6, an accumulator safety valve 10, an overflow valve 11, an oil inlet Oil filter 12, charge pump 13, electric motor 14, charge check valve 15. Wherein, the hydraulic transformer 8 includes a primary motor 81 and a secondary motor 82 connected to the output shaft, the primary motor 81 and the secondary motor 82 are variable hydraulic motors; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com