Hot rail deformation heating box

A deformation hot box and hot rail technology, applied in textiles and papermaking, etc., to achieve the effect of good finish, easy cleaning, and reduced tension changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

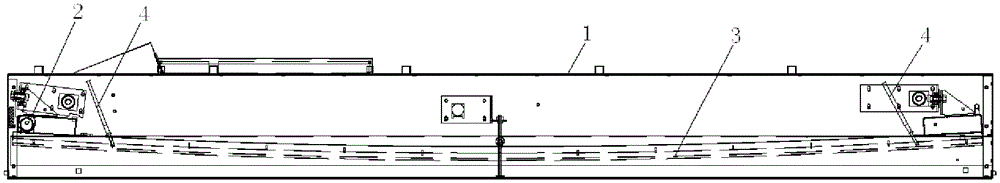

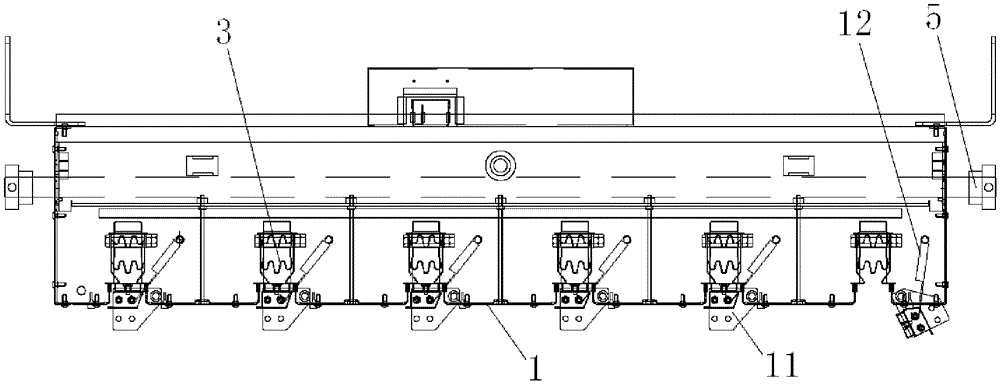

[0030] See figure 1 , this embodiment includes a housing 1 , a heating liner 2 , a heating rail 3 , a temperature sensor 4 and an oil fume exhaust duct 5 .

[0031] The heating liner 2 , the heating rail 3 , the temperature sensor 4 and the oil fume exhaust duct 5 are arranged inside the housing 1 . The housing 1 is provided with a working status indicator light, which can visually display the working status of the heating box. The space between the shell 1 and the heating liner 2 is filled with thermal insulation material; the inside of the heating liner 2 is provided with a heating medium, and the heating medium is biphenyl. Biphenyl has the characteristics of good chemical stability, low cost, and stable cycle. The maximum heating temperature can reach 250°C, and its critical temperature is just lower than the melting point of PET, so it can effectively avoid local overheating. The outer wall of the heating liner 2 is provided with six heating element installation pipes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com