Threshing roller with rotatable toothed bar

A technology of threshing drum and gear bar, which is applied in threshing equipment, application, agricultural machinery and implements, etc. It can solve the problems of incomplete threshing, short threshing distance of cross-flow drum, and increasing the size of combine harvester models. Achieve the effect of smooth handover and high grain removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This specific implementation description is an explanation of the present invention, not a limitation of the present invention. Those skilled in the art can make creative contribution modifications to the implementation description after reading this description.

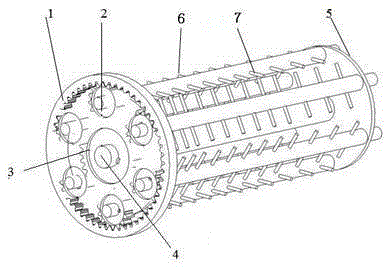

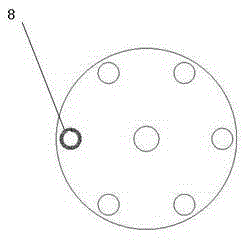

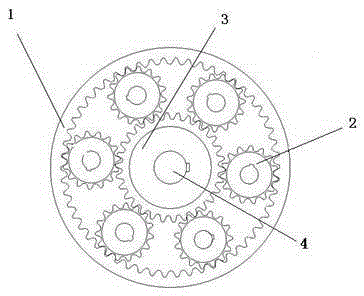

[0015] Such as figure 1 and image 3 As shown, a threshing cylinder with a rotatable tooth bar is composed of: a web 5 and a planetary gear train structure, and the planetary gear train includes a planetary gear carrier 1, several planetary gears 2 and a large central gear 3, and the planetary gear The inside of the gear carrier 1 meshes with the planetary gears 2, and each of the planetary gears 2 meshes with the center bull gear 3 ( figure 2 As shown), the central bull gear 3 is keyed to the main shaft 4, and the other end of the main shaft 4 is keyed to the auxiliary disc 5; each of the planetary gears 2 is keyed to the pinion shaft 6, and each of the The other end of the rack shaft 6 is fixed on the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com