Straight line type bottle washing machine

A bottle washing machine, linear technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that the rough washing area and the fine washing area cannot be completely isolated or separated, the bottle feeding method and the cleaning quality Unsatisfactory, high difficulty in sanitation and cleaning inside the box, to achieve the effect of convenient operation and maintenance, small footprint and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

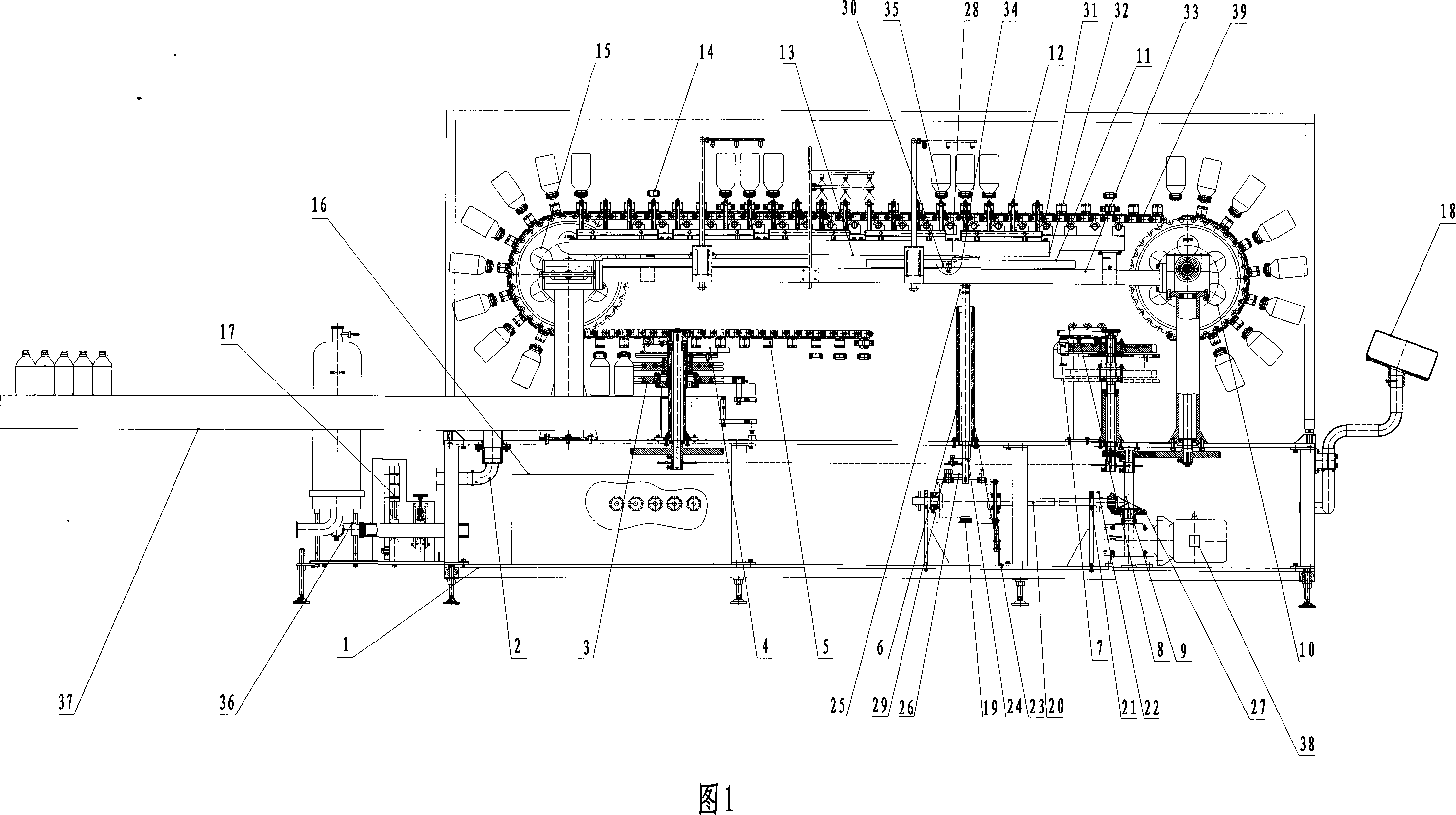

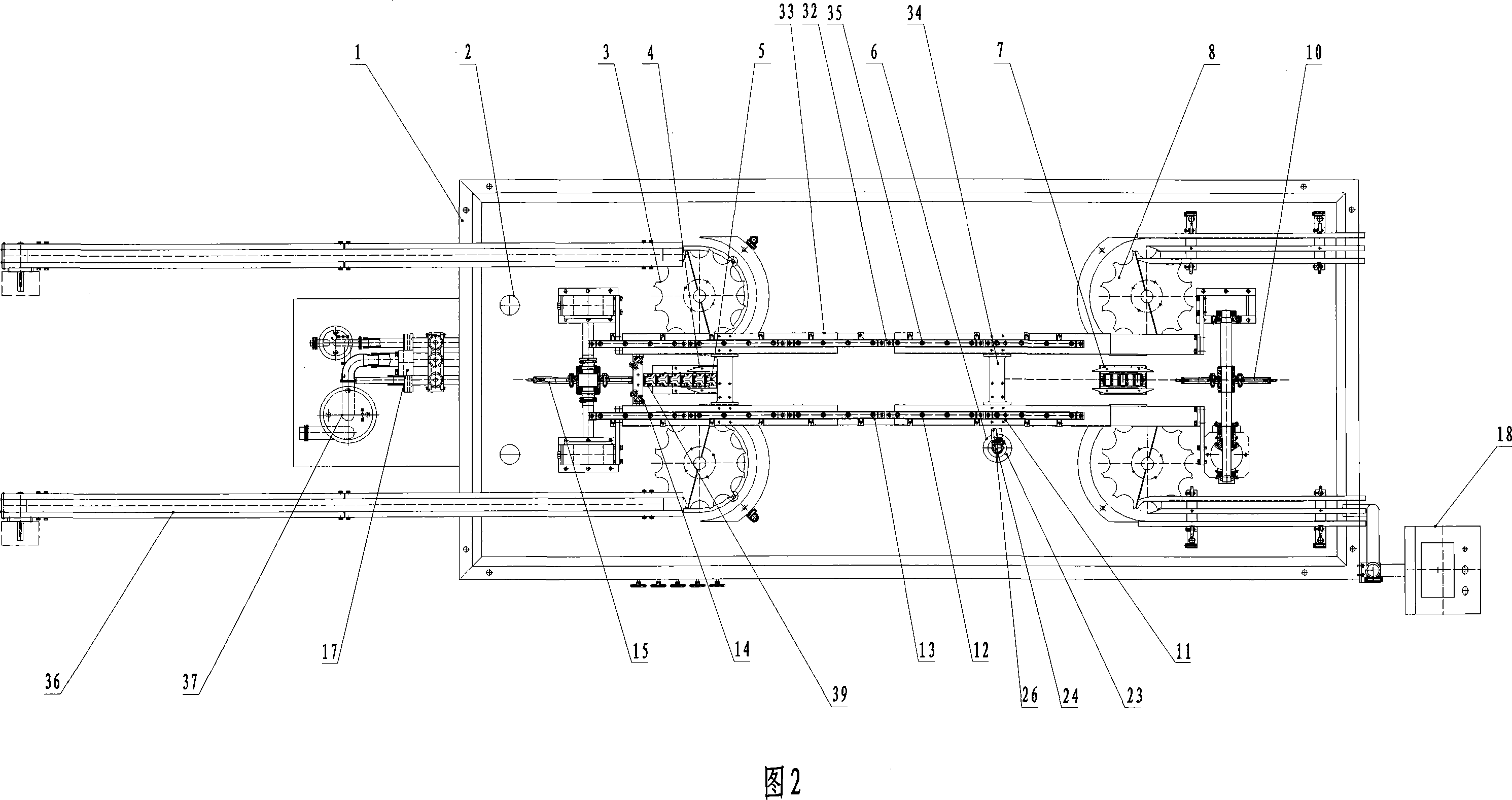

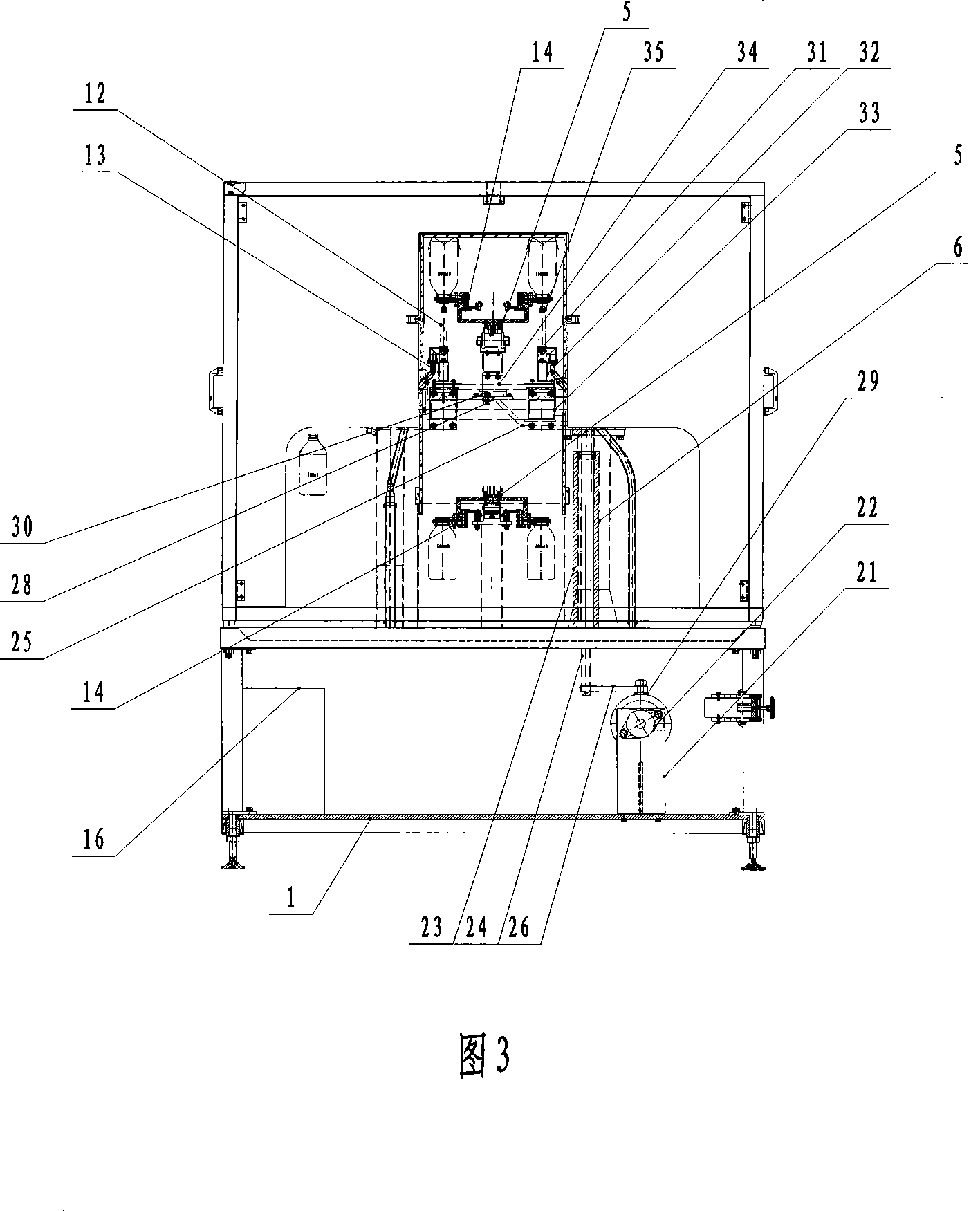

[0026] As shown in Figure 1, Figure 2 and Figure 3, a linear bottle washing machine of the present invention includes a frame 1, a water and air supply device 36, and a bottle feeding mechanism 37 installed on the frame 1. Wheel mechanism 3, circular conveying mechanism 5, reciprocating tracking mechanism 6, bottle outlet wheel mechanism 8, tracking and washing mechanism 13, electric control box 16 and power unit 38, electric control box 16 is connected with control box 18, bottle feeding mechanism 37 Connected with the bottle feeding wheel mechanism 3, one part of the bottle feeding track on the circular conveying mechanism 5 is connected with the bottle feeding wheel mechanism 3, and the other part is matched with the bottle outlet wheel mechanism 8, and is connected with the reciprocating tracking mechanism 6. The tracking flushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com