Substrates treating device

A substrate processing device and substrate technology are applied in the directions of transportation and packaging, lighting and heating equipment, cleaning methods and appliances, etc., which can solve problems such as increased floor space, high cost, and complex mechanisms, and achieve reduced floor space, Effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

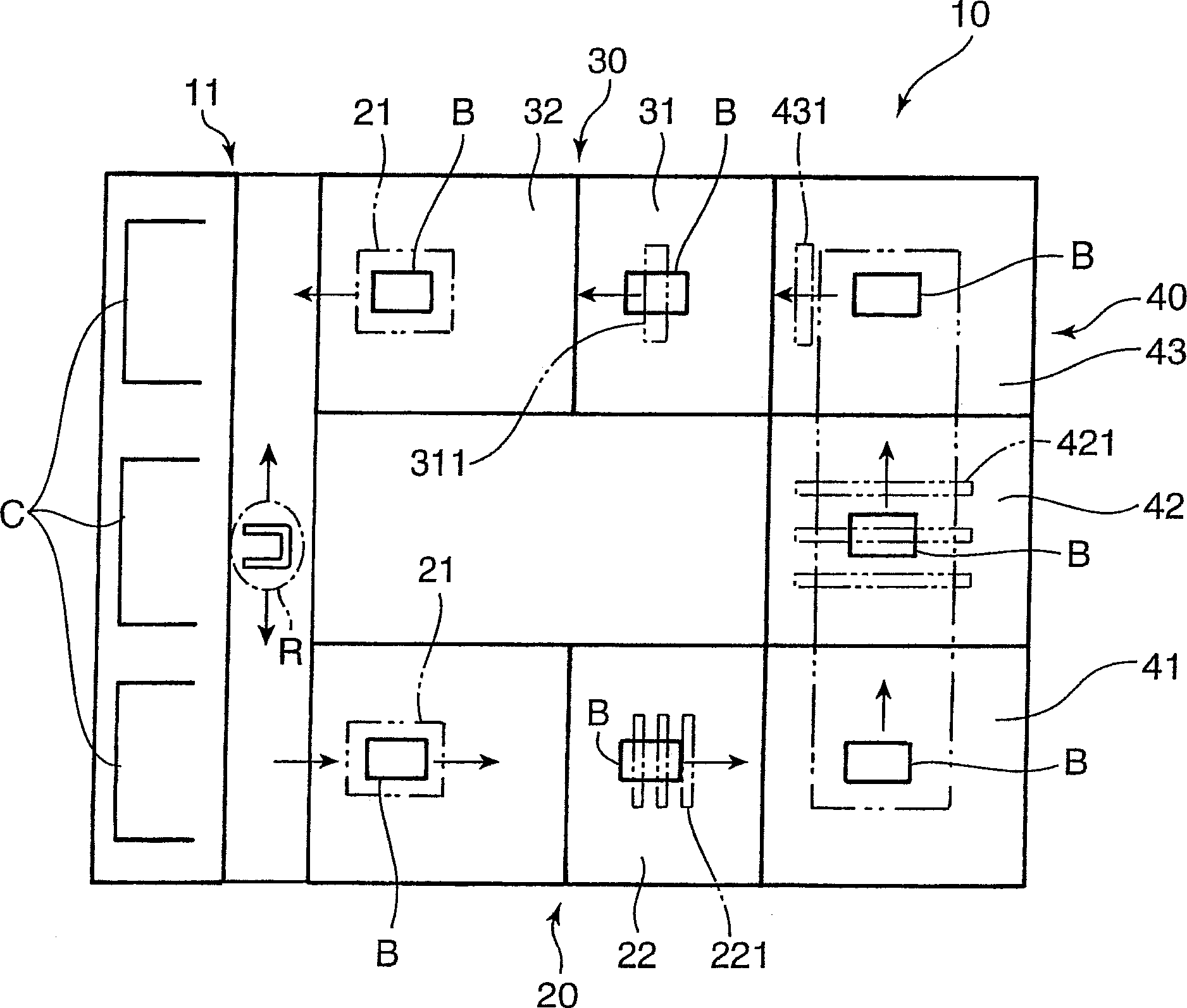

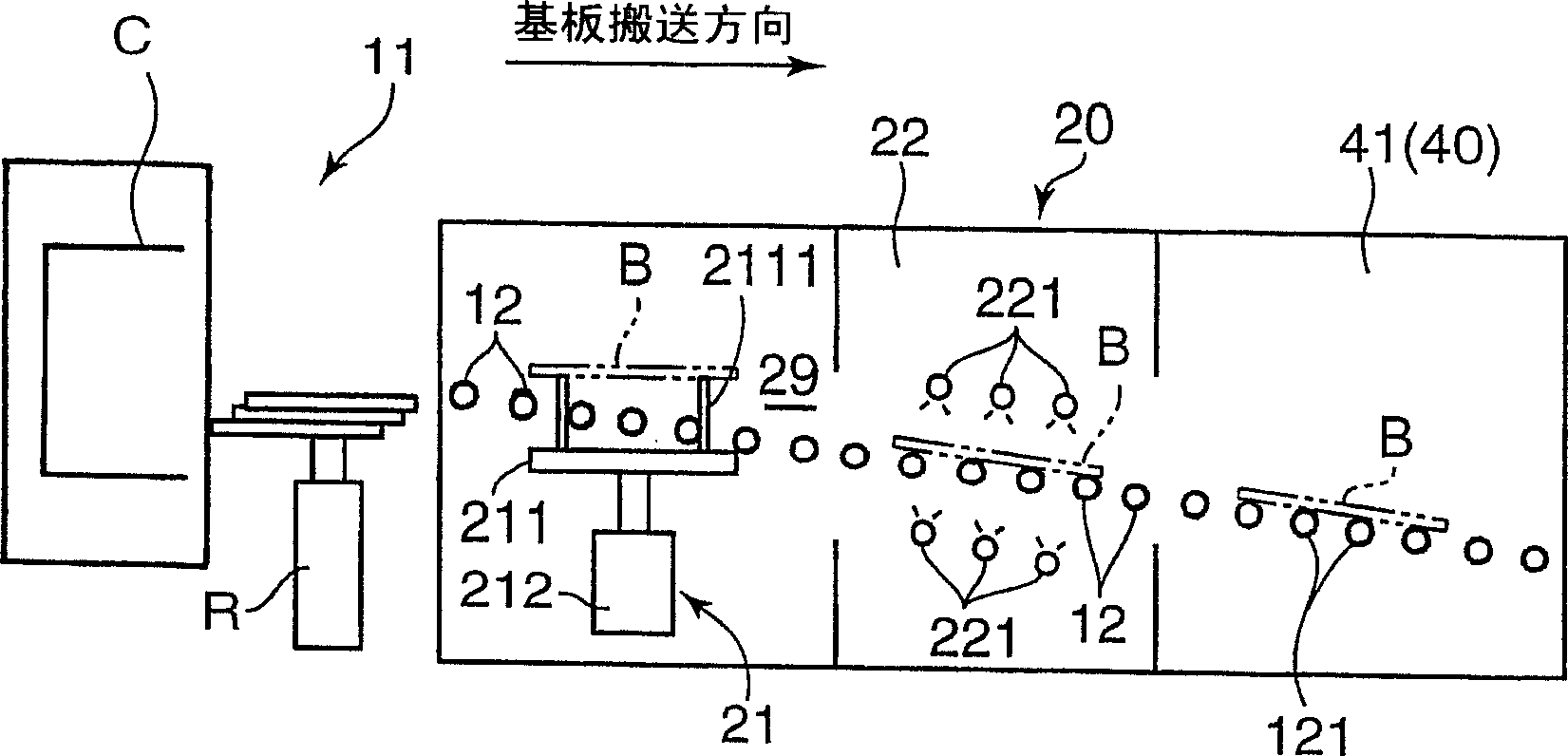

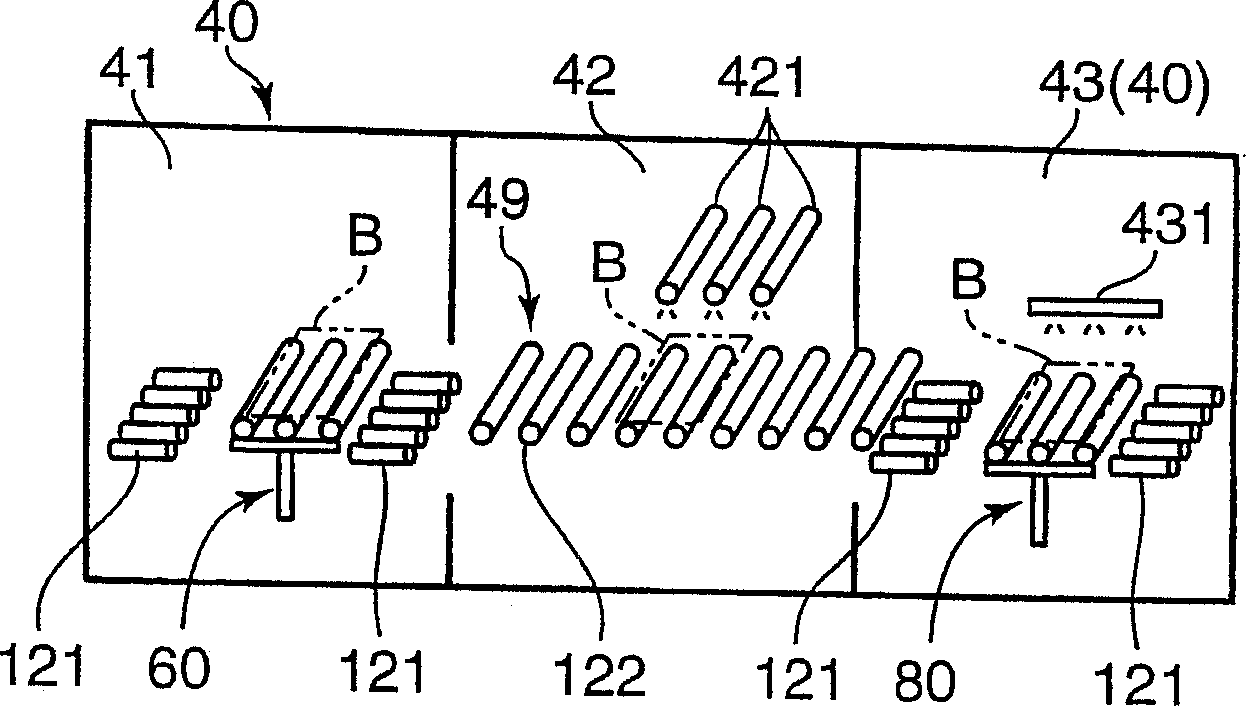

[0035] figure 1 It is a plan view schematically showing the substrate processing apparatus according to the first embodiment of the present invention. Figure 2 is a representation seen from all sides figure 1 A schematic diagram of the substrate processing apparatus shown, Figure 2A It is a side view showing the conveying direction changing part starting from the first processing part, Figure 2B It is a side perspective view of the conveying direction changing part, Figure 2C It is a side view showing the conveyance direction changing part from the 2nd processing part.

[0036] The substrate processing apparatus 10 according to this embodiment is an apparatus for performing a series of preset processes on a substrate B, such as figure 1 As shown, there are: in the direction of the substrate B to be carried out from the substrate storage box C figure 1 The first processing unit 20 that implements a series of processes on the substrate B while being transported in the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com