Platen moving pair for full-automatic printing machine

A technology of printing machine and moving pair, applied in the field of moving pair of automatic printing machine platen, can solve the problem that the horizontal direction adjustment mechanism cannot smoothly transfer the printing platen, and the vertical feeding mechanism cannot be fully adjusted, structural reliability and stability. problems such as major problems, to achieve the effect of improving printing efficiency, improving reliability and stability, and prolonging drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

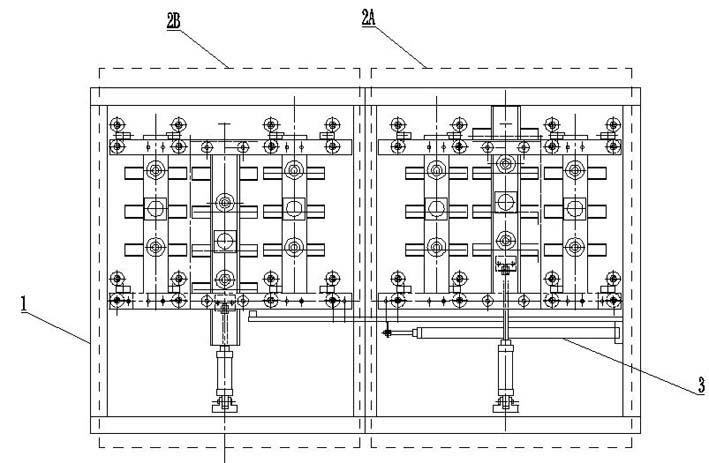

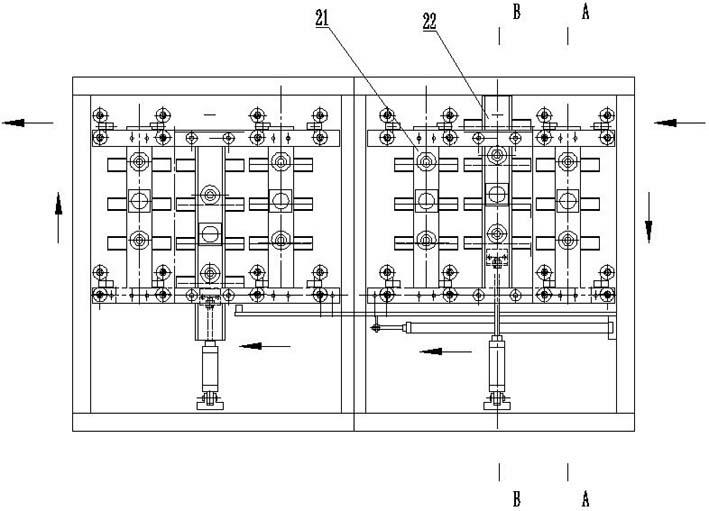

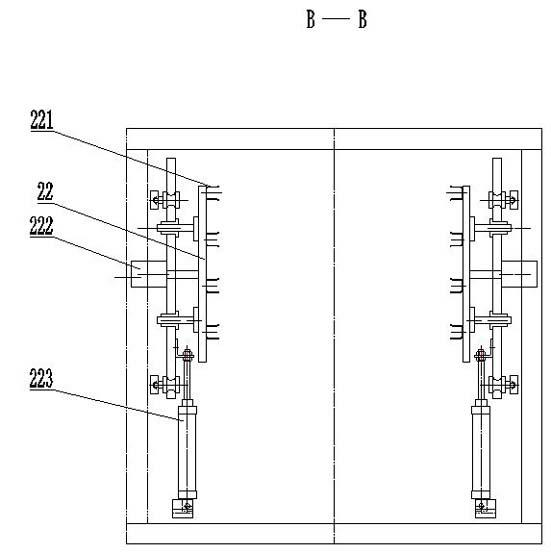

[0022] Such as figure 1 , 2 , 3, and 4, including the frame 1, the feeding side lifting and conveying mechanism 2A, the discharging side lifting and conveying mechanism 2B, the horizontal conveying mechanism 3, the lifting and supporting bracket 21, the platen support Ⅰ211, and the clamping drive mechanism Ⅰ212 , Lifting transfer bracket 22 , platen support II 221 , clamping drive mechanism II 22 , transfer drive mechanism 223 .

[0023] The above-mentioned frame 1 is equipped with a side-by-side lifting and conveying mechanism 2A on the feeding side and a lifting and conveying mechanism 2B on the discharging side, and a horizontal conveying mechanism for its cohesive function is set between the lifting and conveying mechanism 2A on the feeding side and the lifting and conveying mechanism 2B on the discharging side. Mechanism 3, the horizontal conveying mechanism 3 is used to transfer the printing table 4 between the lifting conveying mechanism 2A on the feeding side and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com