Multifunctional intelligent drying system and drying process

A drying system and multi-functional technology, applied in drying safety systems, drying, dryers, etc., can solve the problems of unstable temperature, no automatic control, unstable dry humidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

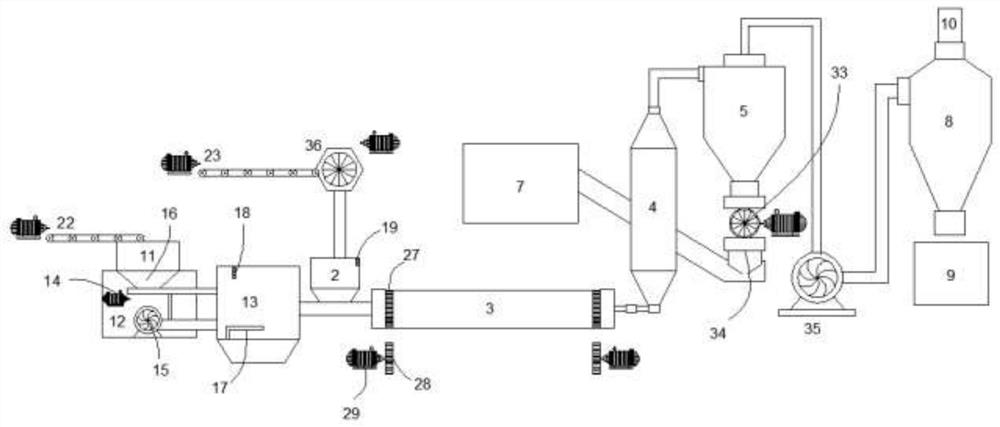

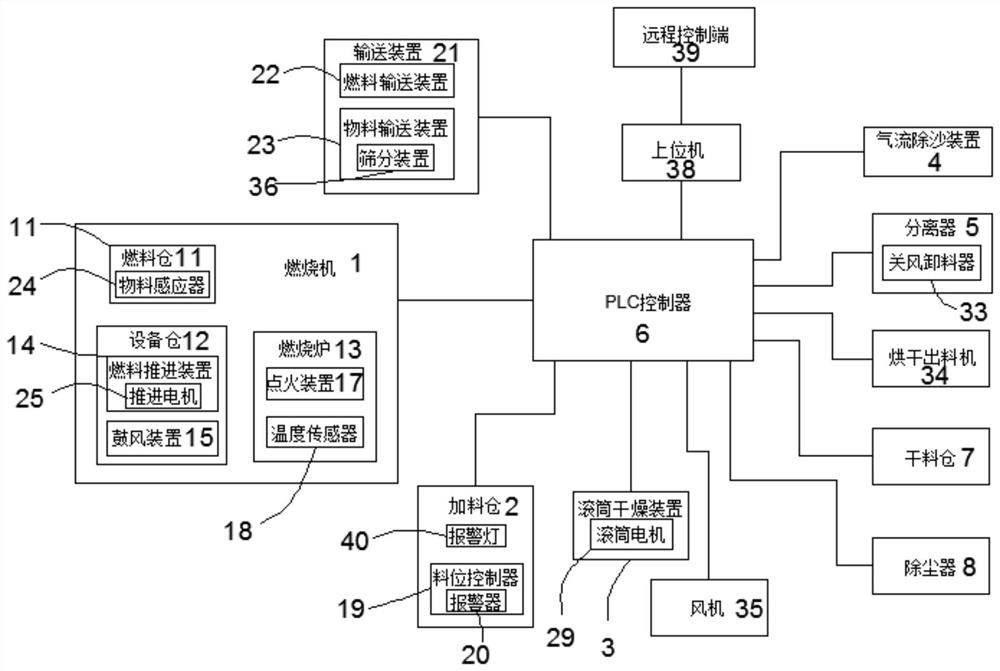

[0038] Such as figure 1 and 2 As shown, this embodiment provides a multifunctional intelligent drying system, which includes a burner 1, a feeding bin 2, a drum drying device 3, an airflow desanding device 4, a separator 5 and a PLC controller 6 connected in sequence. The separator 5 is connected to a dry storage bin 7 and a dust collector 8 respectively. The PLC controller 6 is respectively connected with the burner 1, the feeding bin 2, the drum drying device 3, the airflow desanding device 4, the separator 5, the dry material bin 7, the Dust collector 8 is connected.

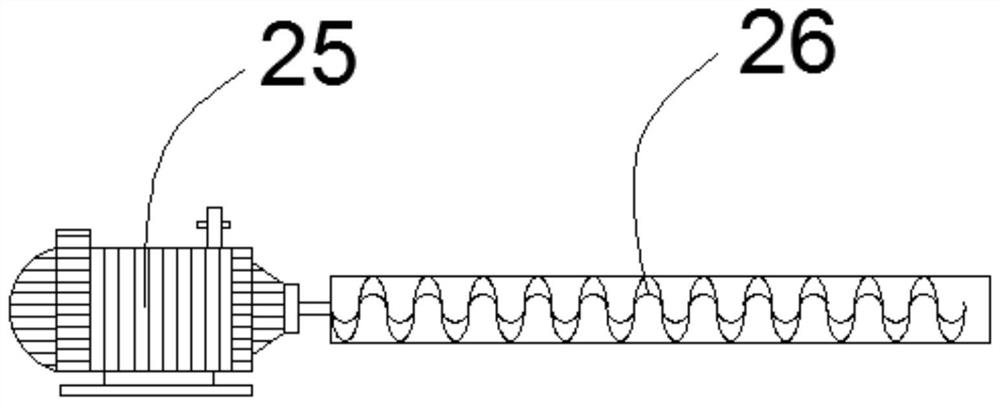

[0039]The drying system also includes a conveying device 21, the conveying device 21 includes a fuel conveying device 22 and a material conveying device 23, the fuel conveying device 22 is connected to the fuel bin 11, and the material conveying device 23 and the material conveying device 23 are connected to each other. The feeding bin 2 is connected to each other, and the fuel conveying device 22 and the ...

Embodiment 2

[0050] This embodiment provides a multifunctional intelligent drying system. The difference from Embodiment 1 is that the drying system also includes a host computer 38 and a remote control terminal 39 connected to the host computer 38 through a communication device. The upper computer 38 is connected with the PLC controller 6 . The communication device includes at least one of a 2G / 3G / 4G / 5G network module, a PLC power line carrier module, NB-IoT, and a LoRa low-power wide-area network module. This kind of remote operation method can be implemented in areas with stable network. According to the temperature and moisture content of raw materials in various places, simple programming can truly realize one-button fool-like operation.

Embodiment 3

[0052] The invention provides a drying process of a multifunctional intelligent drying system. The material to be dried is a biomass stick, which is also a good fuel, and its moisture content is generally controlled at 6-12%, and controlled at 8 -9% is the best, so the fuel used in this embodiment except for the first time is directly dried biomass sticks, and the drying process is as follows:

[0053] Step 1. The fuel is delivered to the burner through the fuel delivery device for combustion to generate heat energy, and the heat energy is delivered to the drum drying device; other fuels need to be added to the burner during the first operation, and the biomass sticks are dried and put into the dry storage bin Finally, the fuel delivery device is directly connected to the dry storage bin, and the biomass sticks in the dry storage bin are transported to the burner as the fuel for the subsequent drying process;

[0054] Step 2, transport the biomass sticks to be dried to the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com