Rasp bar mechanism and edible bean threshing cylinder applying rasp bar mechanism

The technology of strip rod and sleeve is applied in the field of edible bean threshing drum, which can solve the problems of poor bean pod threshing effect and the like, and achieve the effect of facilitating the adjustment of the amount up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

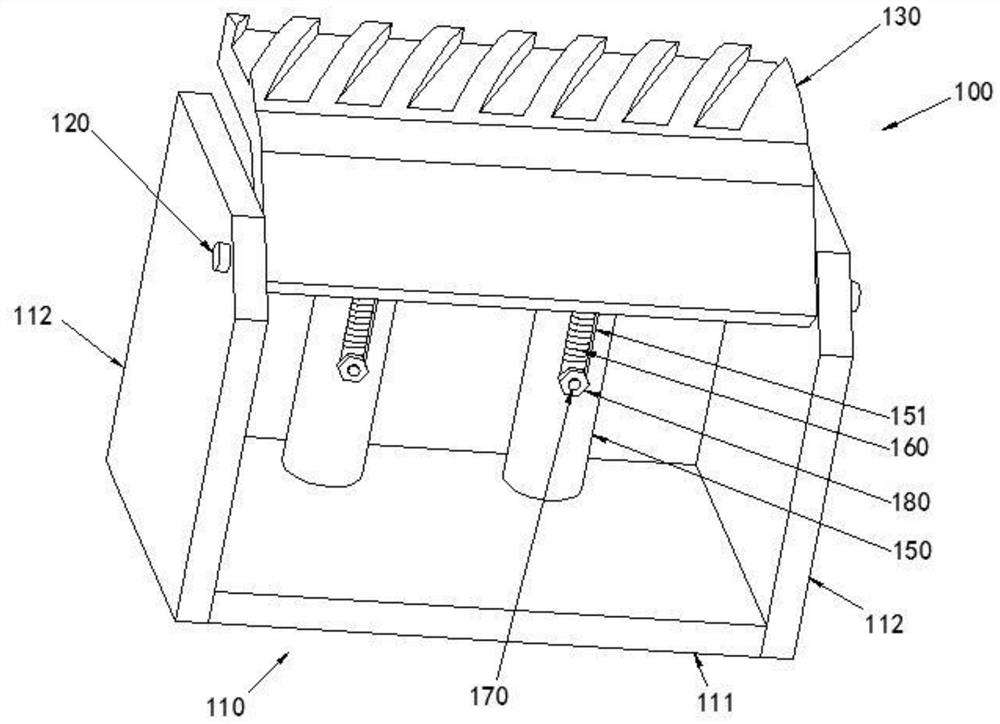

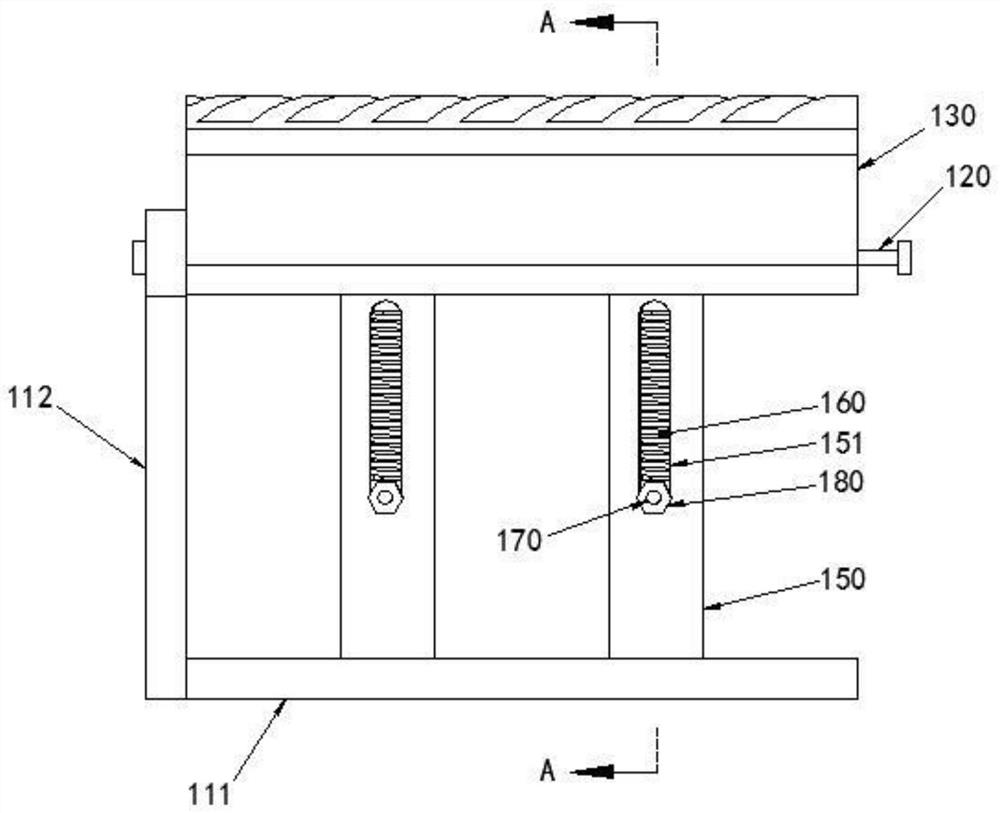

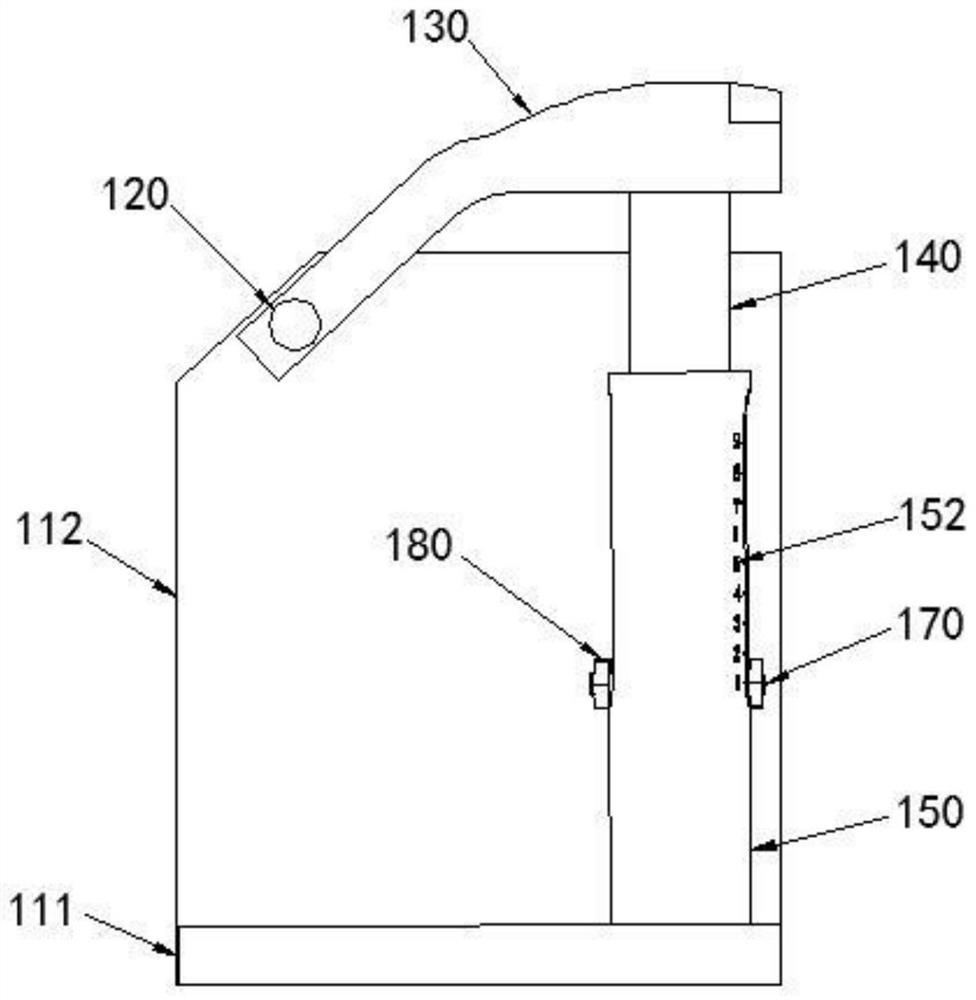

[0029] Such as Figure 1 to Figure 5 As shown, the threaded rod mechanism 100 of this embodiment includes a base 110, a first rotating shaft 120, a threaded rod block 130, an upper adjustment column 140, a sleeve 150, a spring 160, a bolt 170, a nut 180 and a lower adjustment column 190;

[0030] The base 110 is U-shaped with a horizontal bottom, including a bottom plate 111 and side plates 112 erected on both sides of the bottom plate 111. The two ends of the first rotating shaft 120 are respectively connected to the two side plates 112, and the threaded rod block 130 is connected to the first rotating shaft 120. The threaded rod block 130 can rotate around the first rotating shaft 120, and the surface of the threaded rod block 130 is provided with a chute;

[0031] The sleeve 150 is vertically installed on the bottom plate 111, and the surface of the sleeve 150 is provided with a pair of axial long grooves 151, and a scale mark 152 is arranged beside the long grooves 151, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com