Patents

Literature

57results about How to "With gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-degree-of-freedom nanometer positioning platform

InactiveCN102998899AWith active adjustmentRealize proactive adjustmentPhotomechanical apparatusElectricityLithographic artist

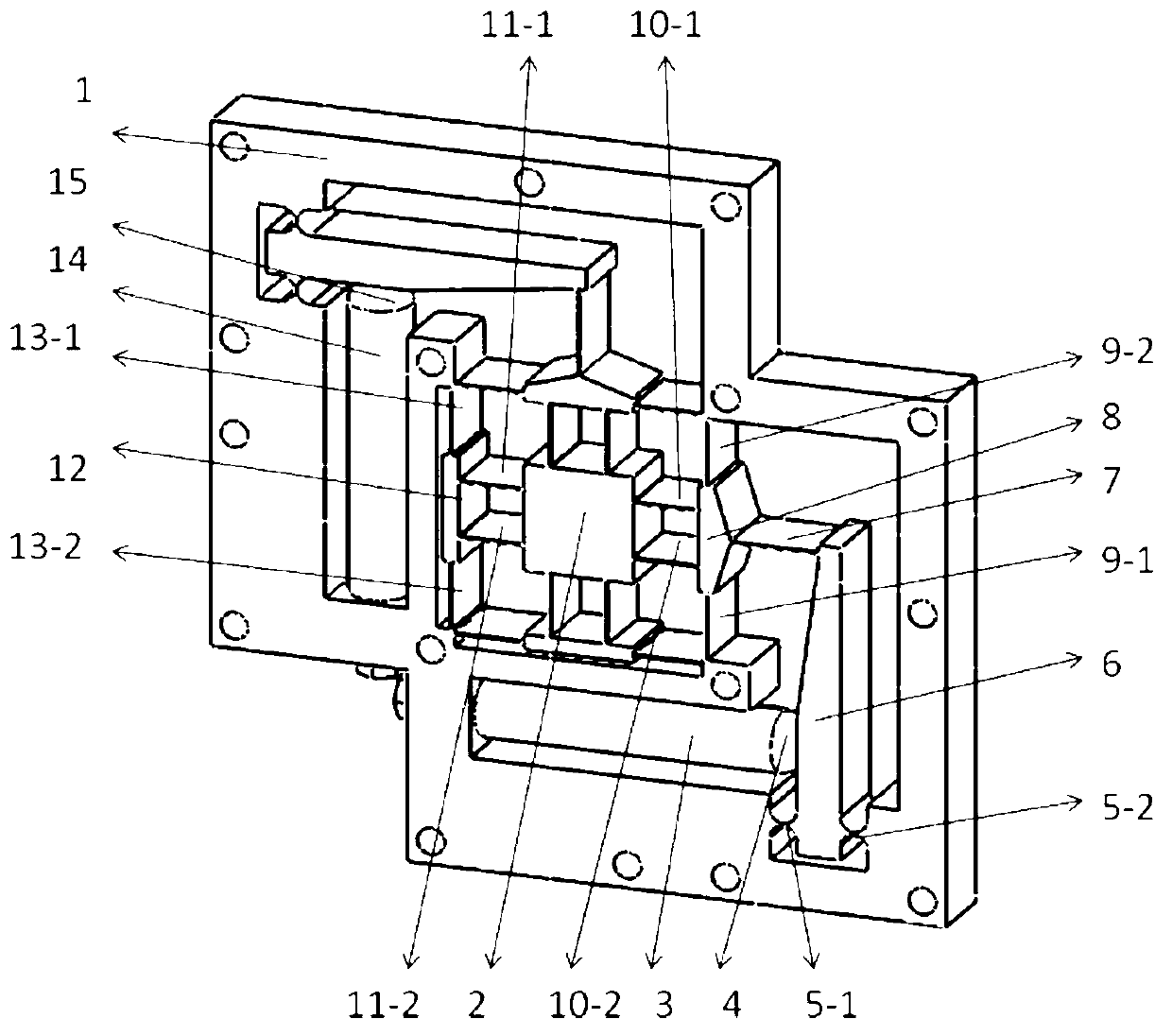

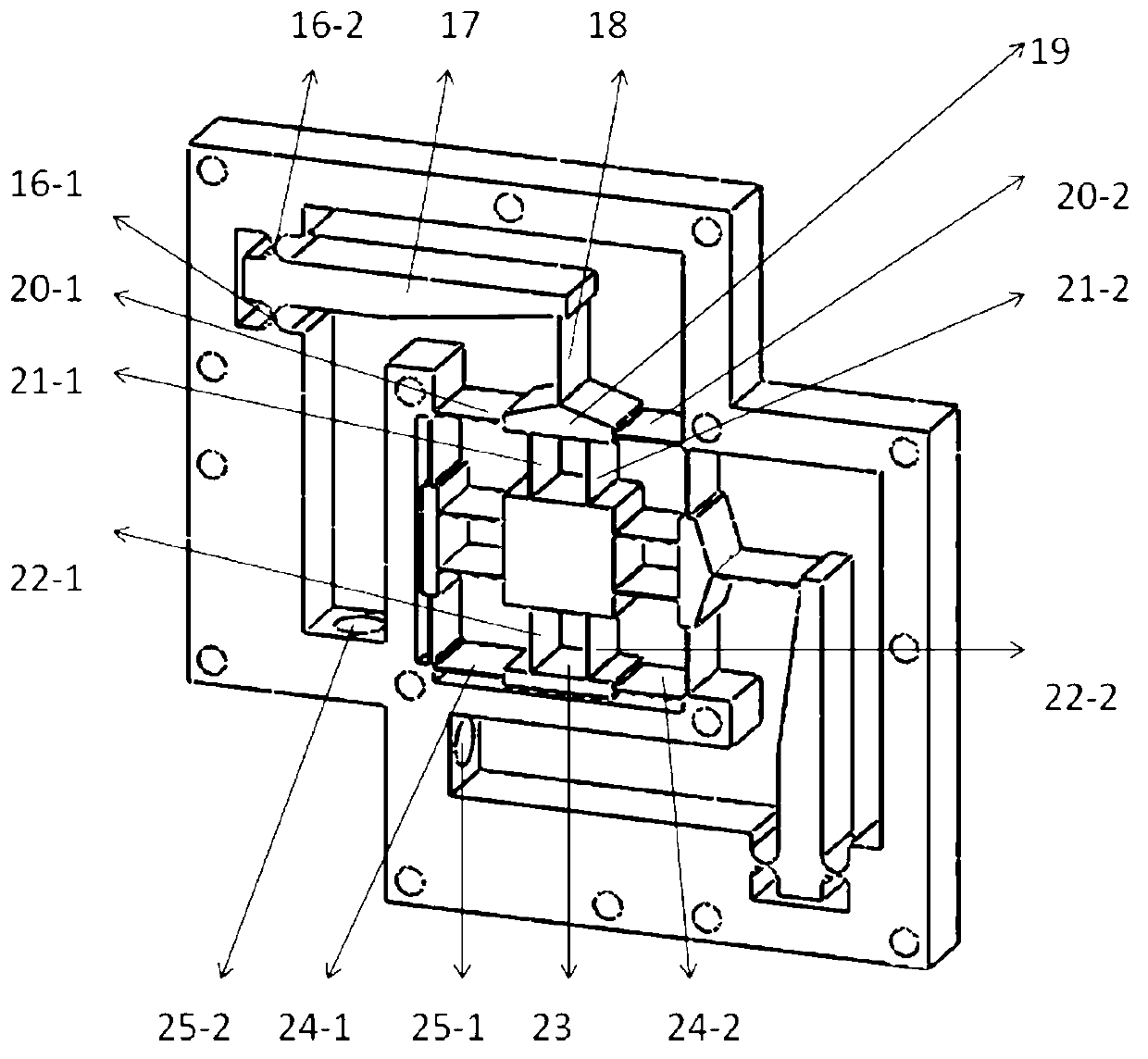

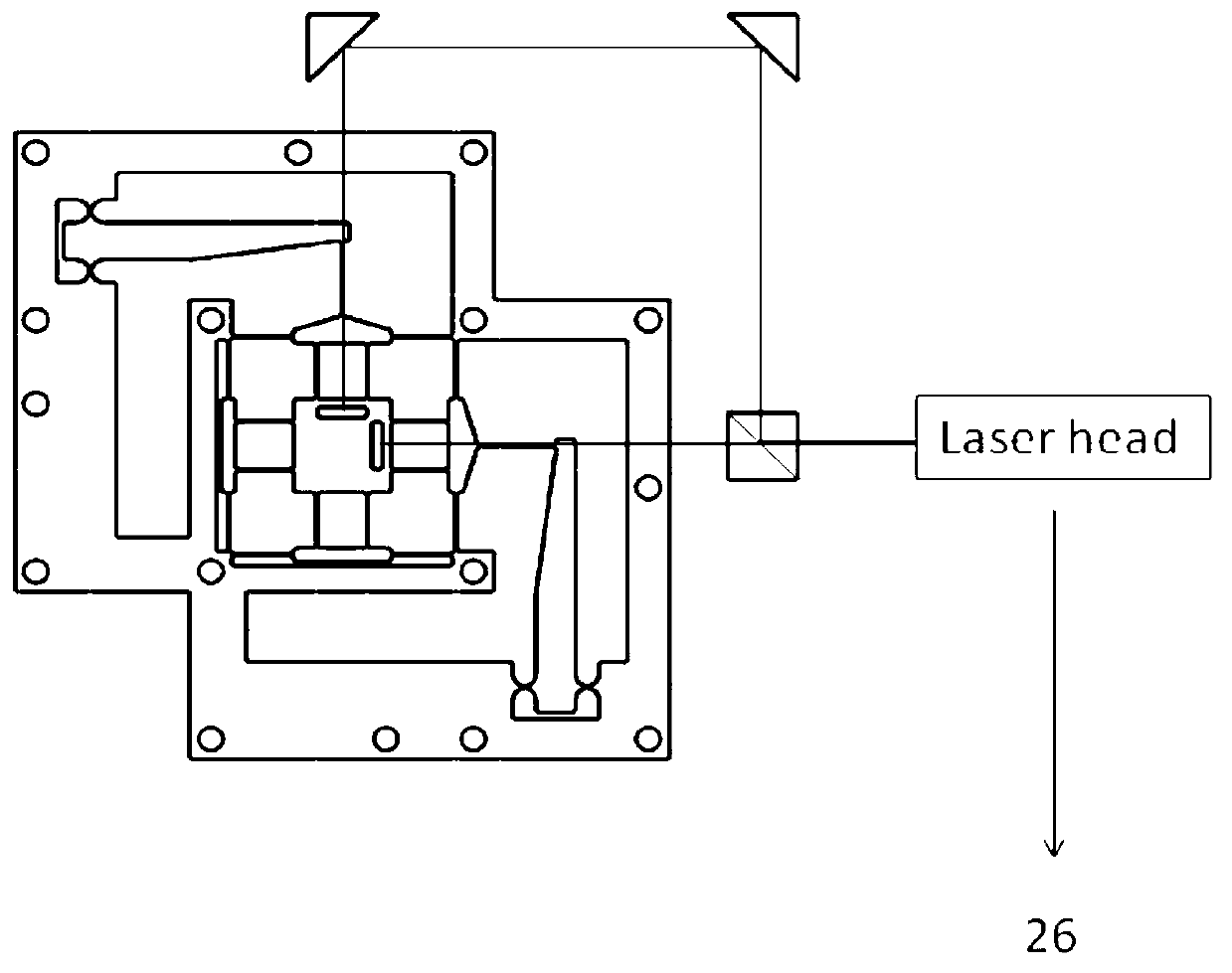

The invention discloses a two-degree-of-freedom nanometer positioning platform. The nanometer positioning platform comprises a movable platform and a base which are connected with each other through a flexible branched chain in an x-axis direction and a flexible branched chain in an y-axis direction. As adopting a flexible parallel connection structure, the nanometer positioning platform has the advantages of high rigidity, high precision, low inertia, compact structure, no error accumulation and the like; and as adopting a flexible plate spring as a transmission component, the nanometer positioning platform has the advantages of no mechanical friction and no gap. Furthermore, based on the elastic deformation of materials, the tiny deformation generated by the flexible plate spring and a tiny working space at the tail end of an actuator, the nanometer positioning platform can effectively eliminate the defects of non-linearity and the like of a parallel connection mechanism; and two piezoelectric ceramic drivers are used for respectively driving the two flexible branched chains, so that a relative position of a template and a substrate in an imprint lithography process can be initiatively adjusted. The two-degree-of-freedom nanometer positioning platform provided by the invention can be taken as an auxiliary positioning platform of a nanometer imprint lithography positioning system, and can implement micro-scale feeding and precise positioning.

Owner:TIANJIN UNIV

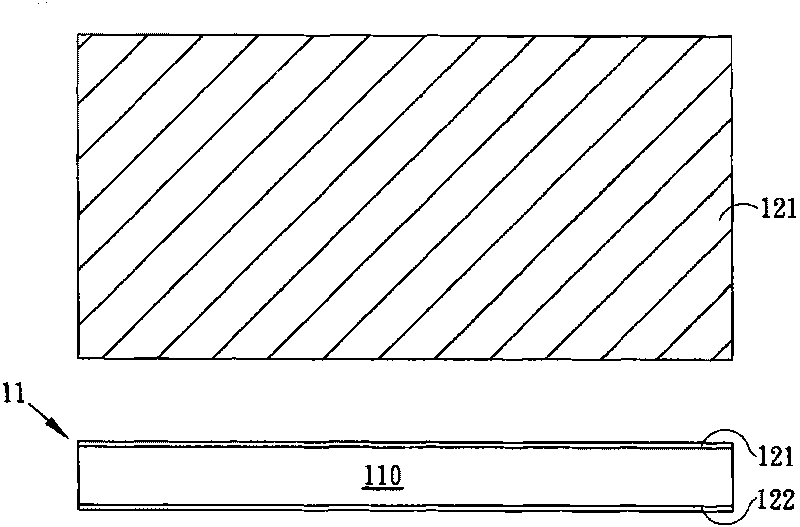

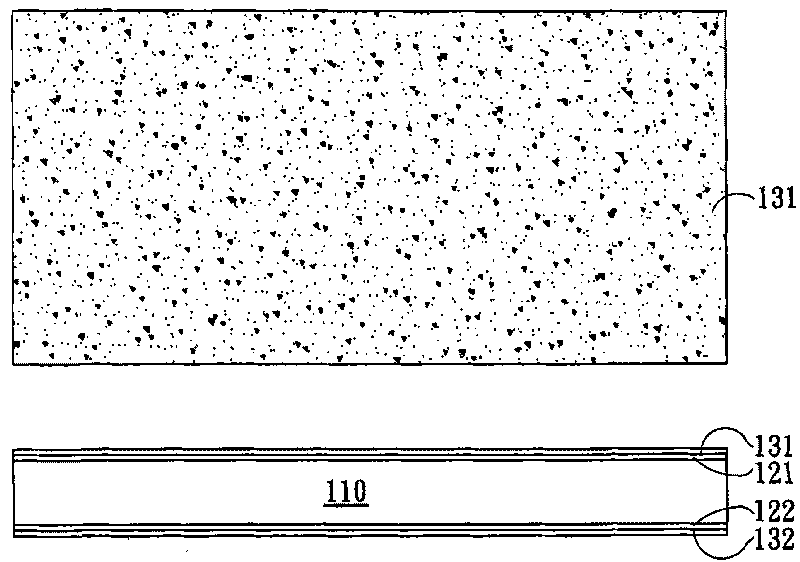

Overvoltage protection element and manufacturing method thereof

InactiveCN101752790AImprove verticalityImprove featuresOvervoltage arrestors using spark gapsOvervoltageEngineering

The invention relates to an overvoltage protection element and a manufacturing method thereof. The overvoltage protection element comprises a basal plate and a pair of electrode layers, wherein a clearance is arranged between electrode layers, a shade layer is arranged above the clearance and part of the electrode layers, and the shade layer and the clearance are covered by a sealing layer. The invention also provides the manufacturing method of the overvoltage protection element, which comprises the following steps: providing the basal plate; forming a first light obstruction layer on the basal plate; forming a patterning metal layer on the first light obstruction layer; taking the patterning metal layer as an exposure light cover and exposing and developing the first light obstruction layer so as to expose part of the basal plate; removing the patterning metal layer; forming a pair of electrode layers on the exposed basal plate, wherein the clearance is arranged between the electrode layers; and forming the sealing layer covering the clearance. The metal electrodes of the invention have end faces with better verticality, and the condition that substances except for air is remained in the clearance between the two metal electrodes can be effectively avoided so as to obtain a better product property, so that the invention is more suitable for practical use.

Owner:CYNTEC

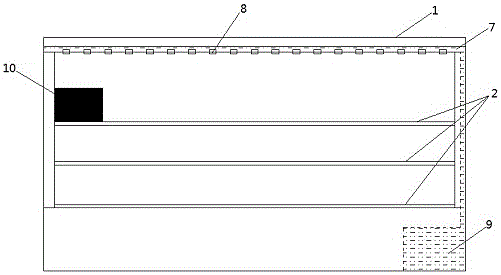

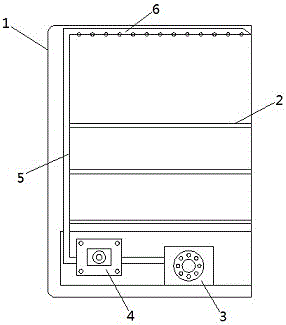

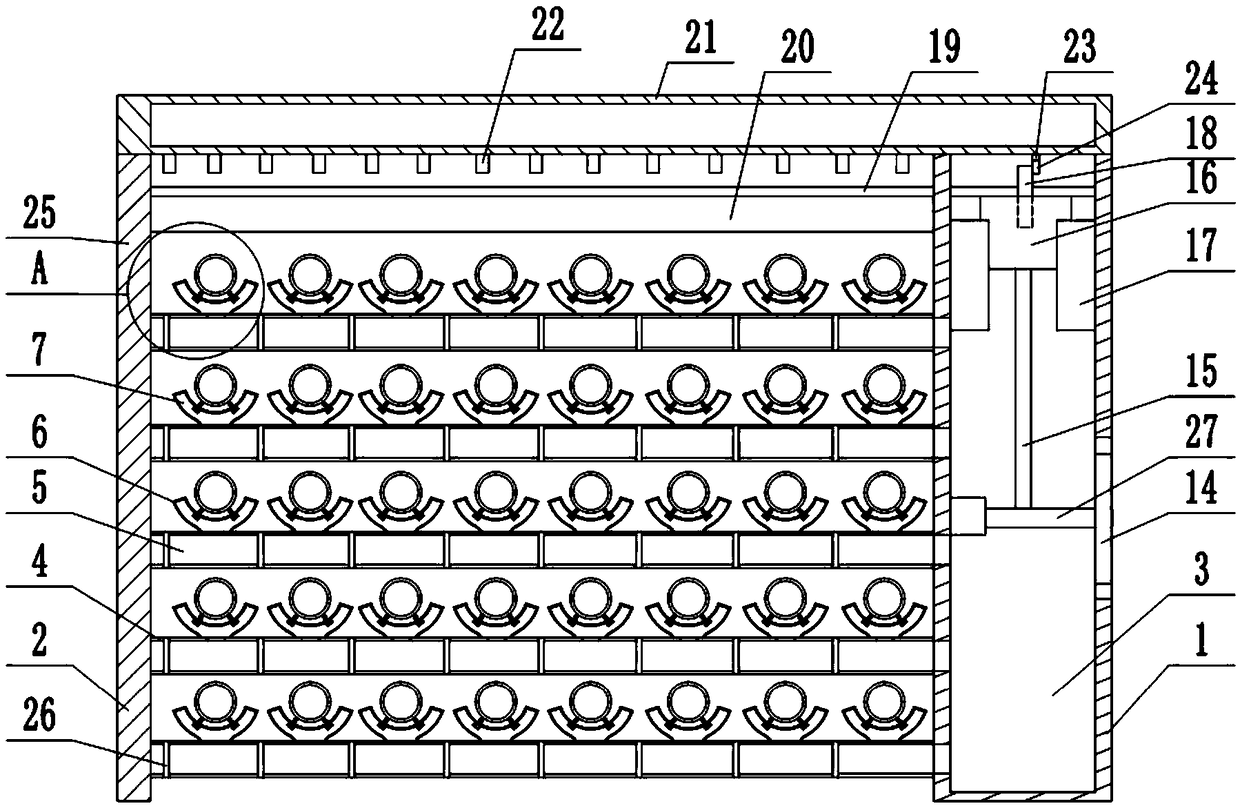

Intelligent supermarket preservation cabinet

InactiveCN106152664AKeep warm and keep freshReduce dependenceLighting and heating apparatusDomestic refrigeratorsCold airAgricultural engineering

The invention discloses an intelligent supermarket preservation cabinet. The intelligent supermarket preservation cabinet comprises a cabinet body; a fruit and vegetable display table is arranged on the cabinet body; an LED lamp panel is arranged in the fruit and vegetable display table; an exhaust fan is arranged in the bottom of the fruit and vegetable display table; a refrigerator is arranged behind the exhaust fan; a cold air conveying pipe extends out from the refrigerator, and is communicated with an exhaust pipe arranged on the top wall of the fruit and vegetable display table; a water spraying pipe and a ultrasonic spraying head are arranged in the top of the cabinet body; a water tank is positioned in the bottom of one side surface of the cabinet body; a water pump in the water tank is connected with the water spraying pipe through a pipeline; and a display screen is arranged on the frontal surface of the cabinet body. The intelligent supermarket preservation cabinet can keep living activity of fruits and vegetables, improves the fruit and vegetable storage quality, prolongs the fruit and vegetable preservation time, enables the fruits and the vegetables to always locate in a fresh state, and can prevent mutual pollution between the fruits and the vegetables.

Owner:吴杰派

High temperature alloy spring for steam turbine steam locking and its processing method and detecting installation

InactiveCN1410688AImprove quality levelHigh thermal efficiencyLeakage preventionMachines/enginesQuality levelWorking temperature

The column type helical spring is made from Inconal X-750 (GH4145) alloy wire. The procedures for manufacturing the spring are as following: wrapping the semi-finished product of long coil of spring:cutting the long coil to single springs; washing the springs; carrying out the solid solution heat treatment; cutting end and adjusting the pitch, and carrying out the aging heat treatment. With the tests of rigidity and permangnet deformation in high temperature being completed, the finished springs are obtained. The device for testing rigidity of the spring includes the worktable, the electric stove and dial gauge etc. Testing indicates the performances of the spring: when the working temperature at 550 degree.C, the service life > or =25000 hr. The spring is easy to be assembled in the vapor lock.

Owner:DONGFANG TURBINE CO LTD

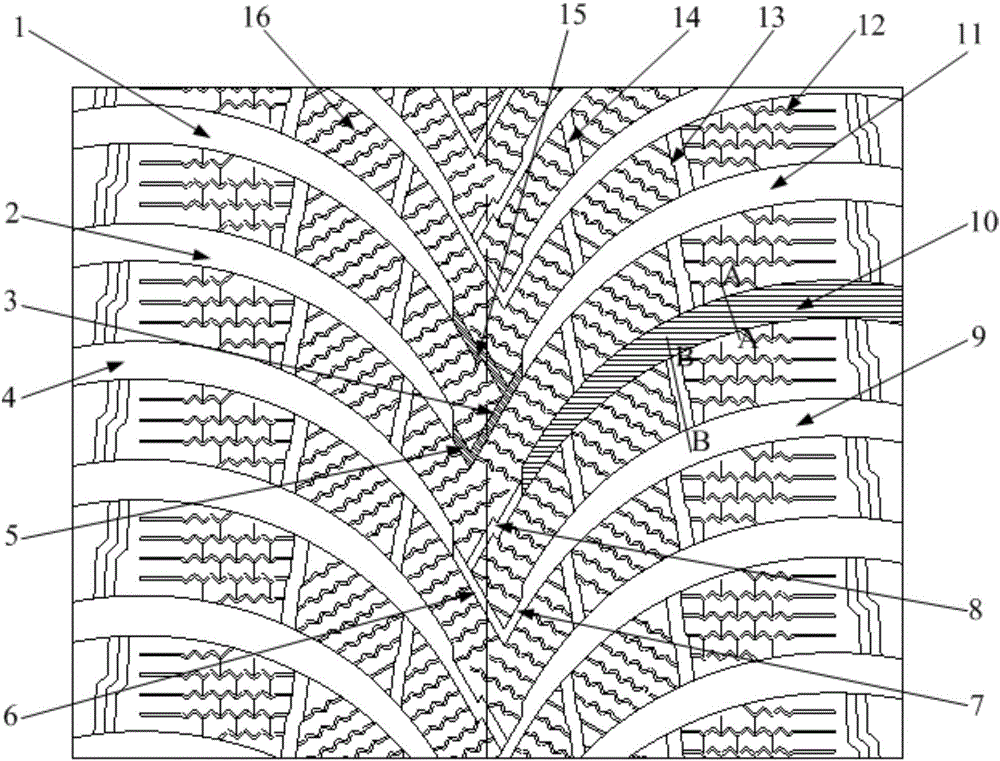

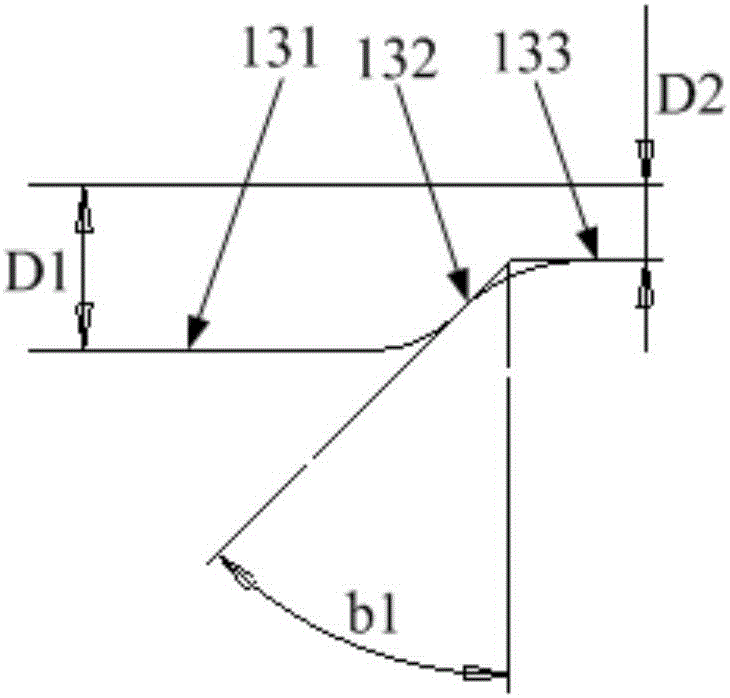

Tire

ActiveCN106142998AWith gapImproved Snow Bite PerformanceRoad vehicle tyresTyre tread bands/patternsMain channelFirst branchial groove

The invention provides a tire. The tire comprises a tire tread and a plurality of tire tread main channel groups which are uniformly arranged on the tire tread along the peripheral direction of the tire; each tire tread main channel group comprises a first transverse channel, a second transverse channel, a third transverse channel, a fourth transverse channel, a fifth transverse channel, a sixth transverse channel, a first central channel and a second central channel; each first central channel is composed of a first branch channel, a second branch channel and a third branch channel; and each second central channel is composed of a fourth branch channel, a fifth branch channel and a sixth branch channel. By setting the plurality of tire tread main channel groups, the plurality of first central channels and second central channels, which are alternately arrayed, are arranged at the central line of the tire tread; the first central channels and the second central channels are independently sealed to form snowfield anti-slipping patterns, so that the snow occlusion property of the tire is improved; and furthermore, the snowfield manipulation property and the braking property of the tire in winter are improved.

Owner:CHENG SHIN RUBBER CHINA

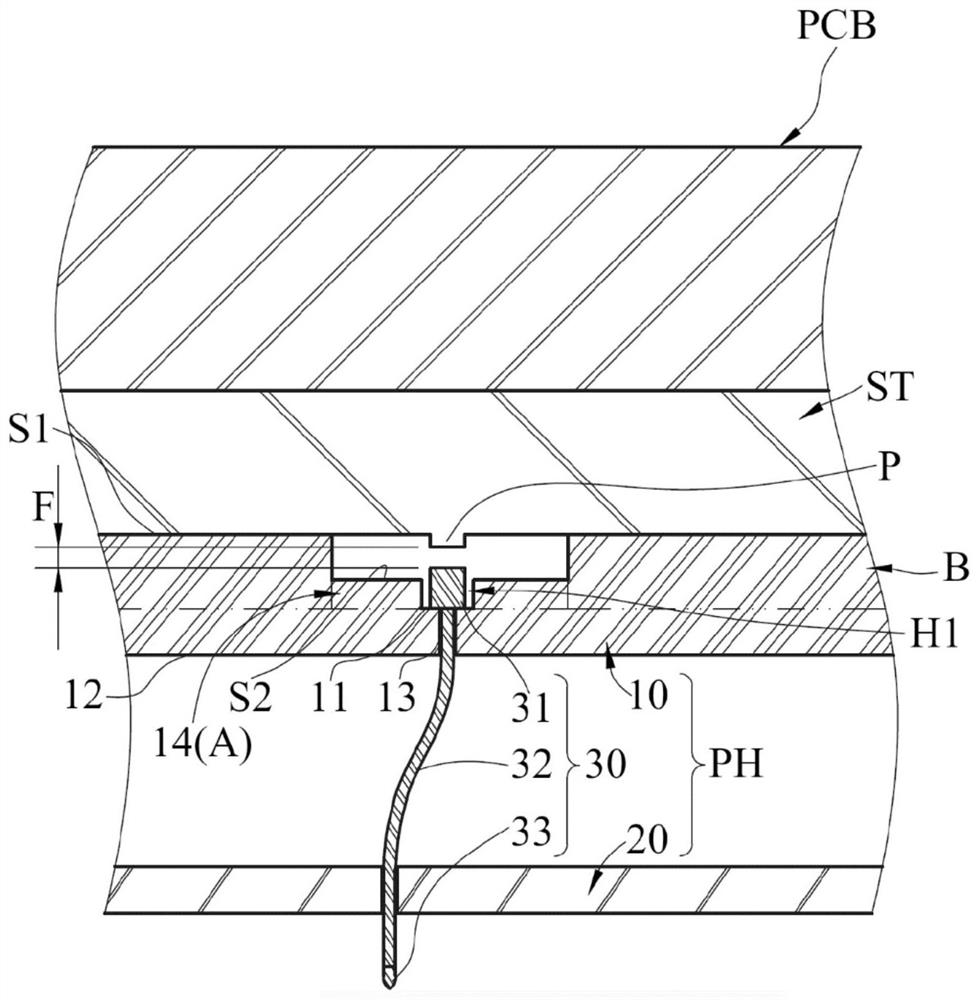

Easily-adjustable toner cartridge and adjustment method thereof

The invention discloses an easily-adjustable toner cartridge, which comprises a shell, a photosensitive drum, a charge roller, anti-pollution filling pieces and a cleaning scraper, wherein the shell consists of a toner hopper plastic piece and a waste toner hopper plastic piece which are combined together; the photosensitive drum and the charge roller are arranged in the waste toner hopper plastic piece side by side; two ends of the charge roller are provided with the anti-pollution filling pieces respectively; and the cleaning scraper is arranged on the lower side of the charge roller. The toner cartridge is characterized in that parts of the shell corresponding to each anti-pollution filling piece are provided with adjusting holes directly communicated with the outside respectively. The invention also discloses a method for adjusting the toner cartridge. Because the parts of the shell corresponding to each anti-pollution filling piece are provided with the adjusting holes directly communicated with the outside respectively, the easily-adjustable toner cartridge has a simple structure and is easy to manufacture. The distance between the charge roller and the photosensitive drum can be adjusted without opening the toner cartridge. The method for adjusting the toner cartridge can ensure the effectiveness of detecting the toner cartridge and the product quality, saves the process steps of opening the shell and assembling the shell, and is favorable for improving the production efficiency.

Owner:周明华

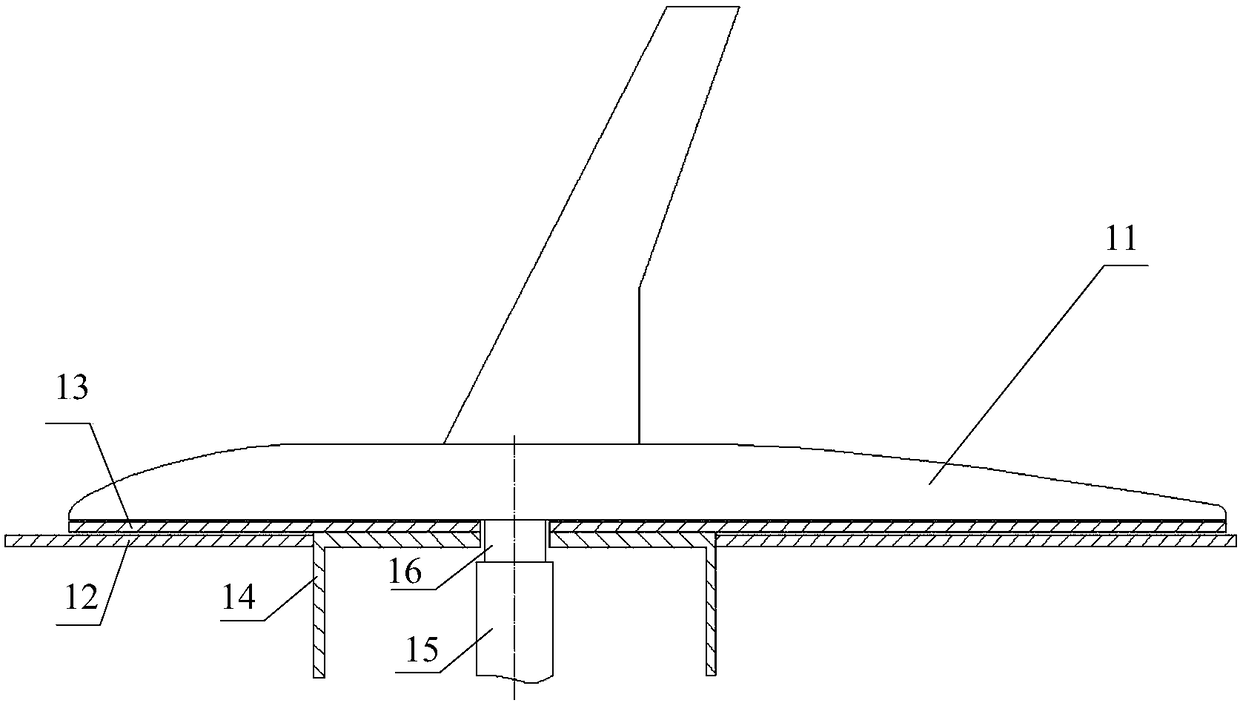

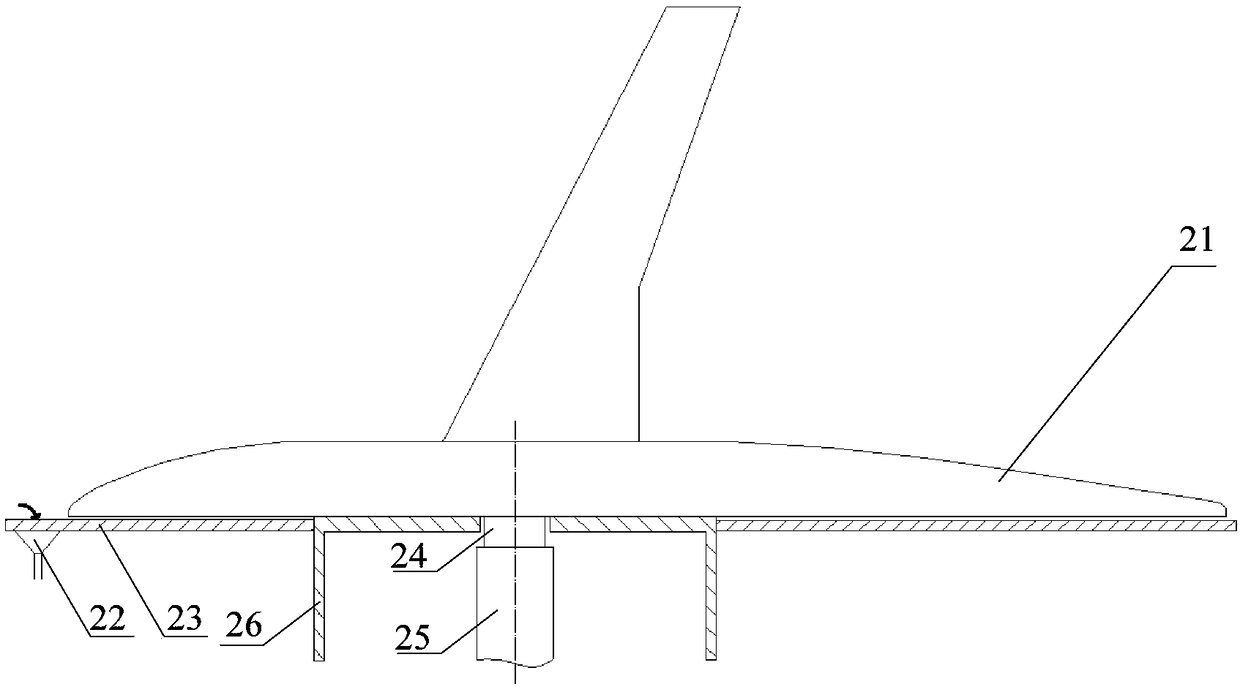

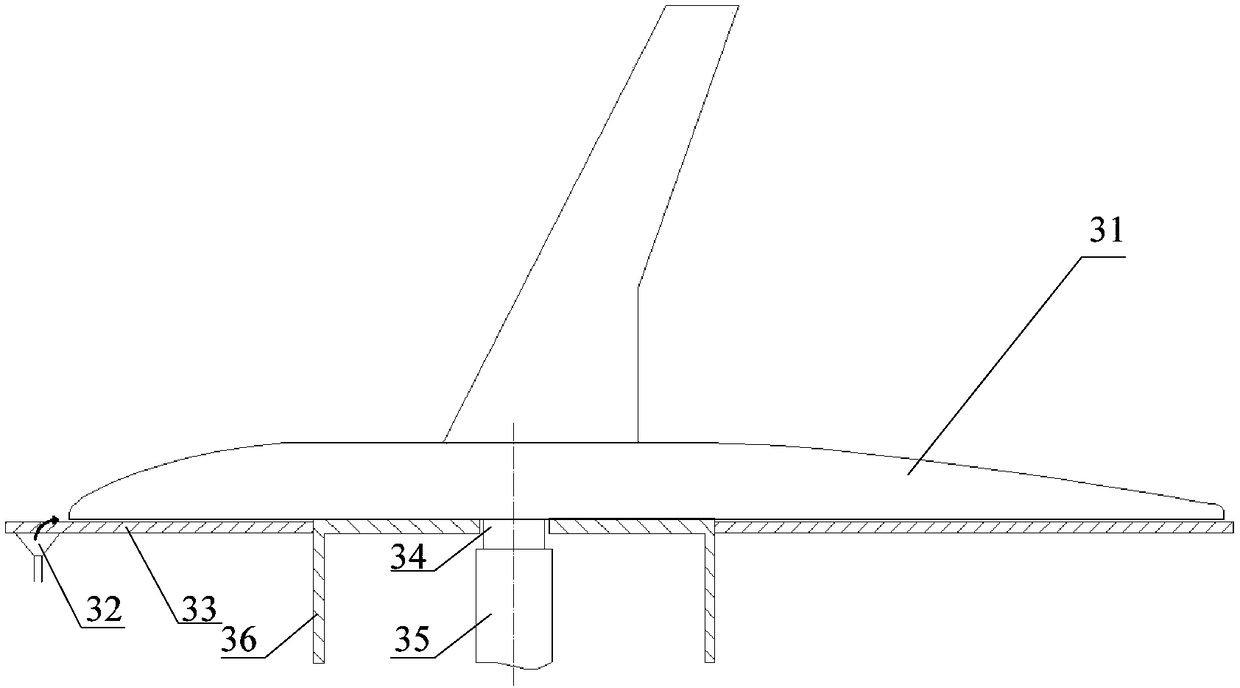

Static aeroelasticity wind tunnel test half-model system and test method

The invention provides a static aeroelasticity wind tunnel test half-model system and test method. The static aeroelasticity wind tunnel test half-model system comprises a half-model arranged in a wind tunnel and a measuring device arranged at the outside of a wind tunnel wallboard; the half-model comprises a main body and a pneumatic airfoil; the main body is provided with a thickening portion atone side, towards the wind tunnel wallboard, of a symmetric plane; the thickening portion is closely adjacent to the wind tunnel wallboard; the thickening portion is used for enabling the distance between the symmetric plane and the wind tunnel wallboard to be greater than or equal to the thickness of a boundary layer of the wind tunnel; and the measuring device is used for measuring the static aeroelasticity effect on the pneumatic airfoil. According to the static aeroelasticity wind tunnel test half-model system and test method, the aerodynamic interference with the half-model by the boundary layer on a tunnel wall and gap fluid channeling can be effectively and respectively isolated and eliminated, and the practicality and the economic property are high.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Multifunctional electric heater

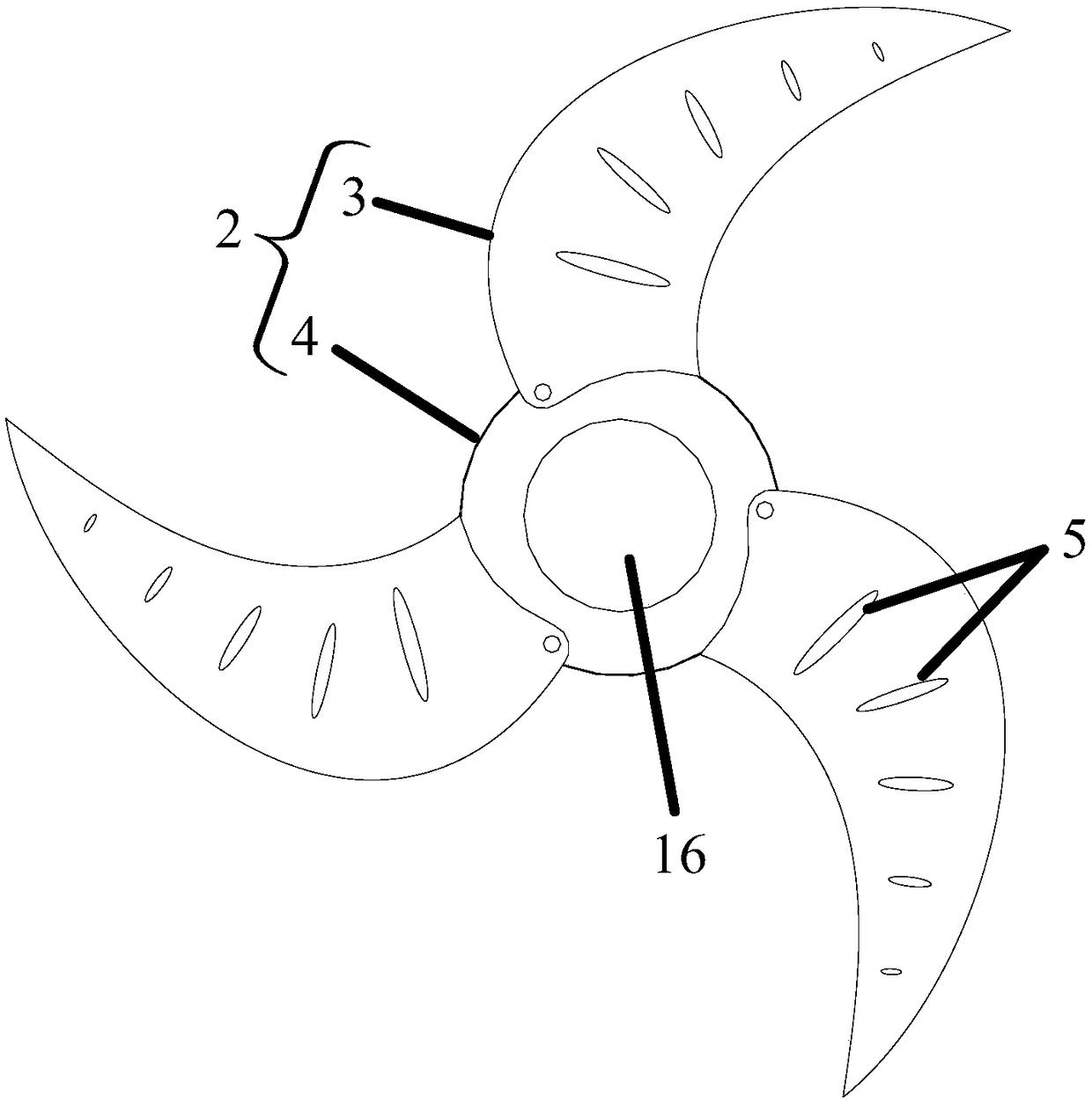

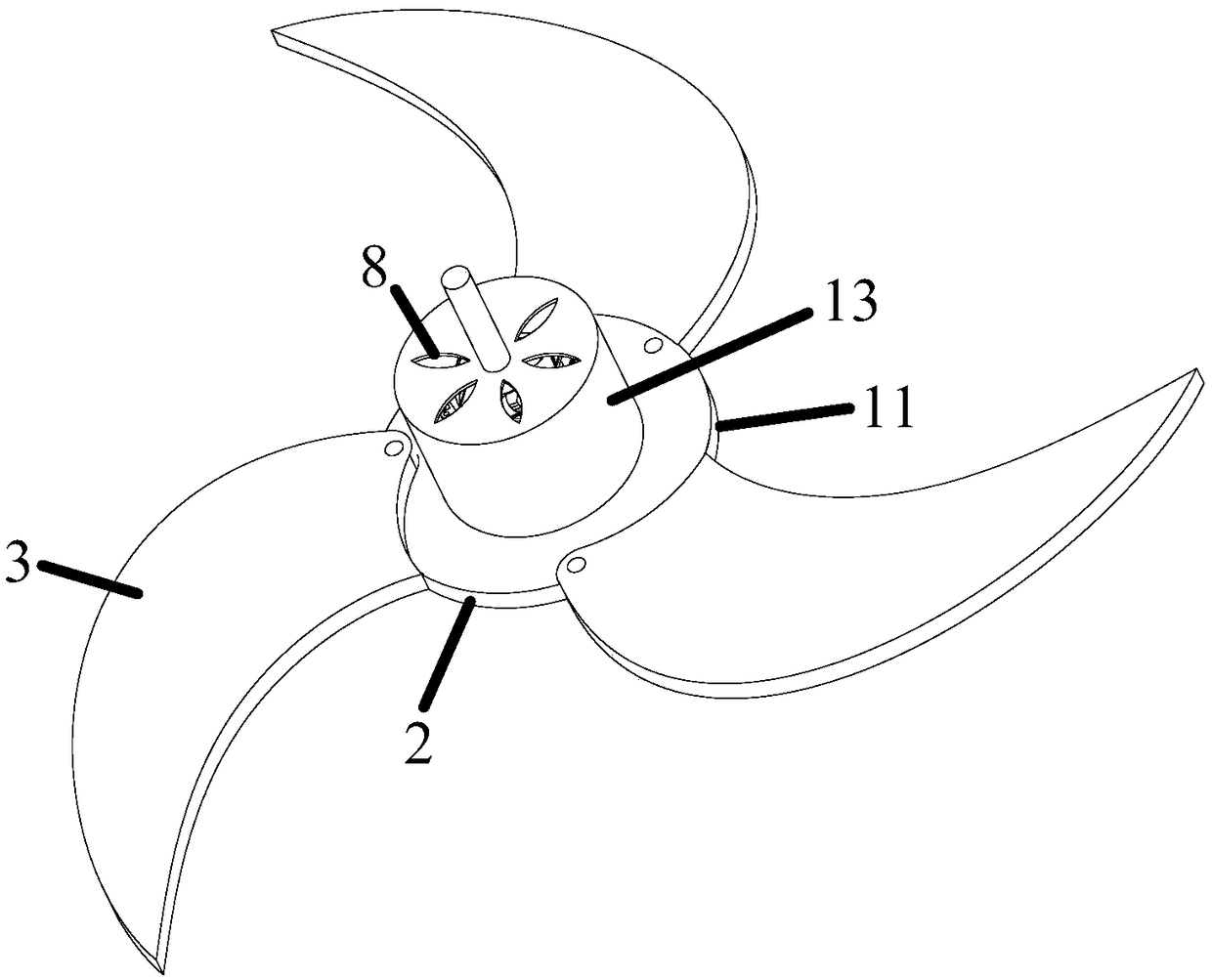

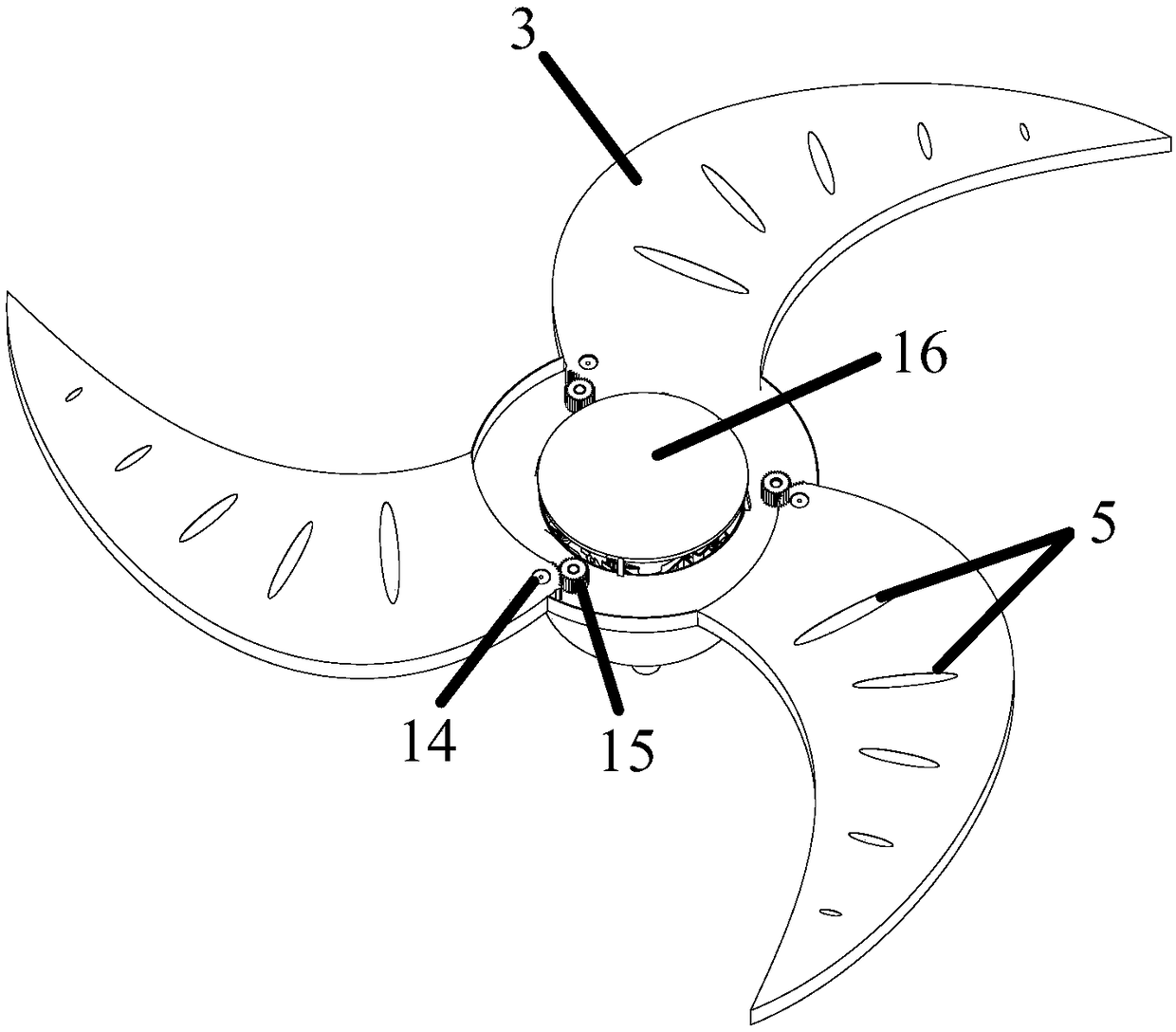

InactiveCN108980972AIncrease profitImprove cooling effectLighting and heating apparatusElectric heating systemEngineeringFan blade

The invention discloses a multifunctional electric heater. The multifunctional electric heater comprises a heating element assembly and a fan blade assembly, wherein the fan blade assembly comprises hollow fan blades, a fan blade fixing frame and fan blade driving parts; an installing cavity is formed inside the fan blade fixing frame; the hollow fan blades are arranged in the circumferential direction of the fan blade fixing frame; cavities of the hollow fan blades communicate with the installing cavity; air outlets communicating with the cavities of the hollow fan blades are also formed in the surfaces of the hollow fan blades; the heating element assembly is arranged in the installing cavity; and air passes through the heating element assembly, enters the cavities of the hollow fan blades through the installing cavity and finally is blown out from the air outlets. The multifunctional electric heater has a heating function and a blowing refrigeration function at the same time so as to solve the problem that as an electric heater in the prior art has a single function, the utilization rate of the product is low, and the family space needs to be occupied all the time.

Owner:GREE ELECTRIC APPLIANCES INC

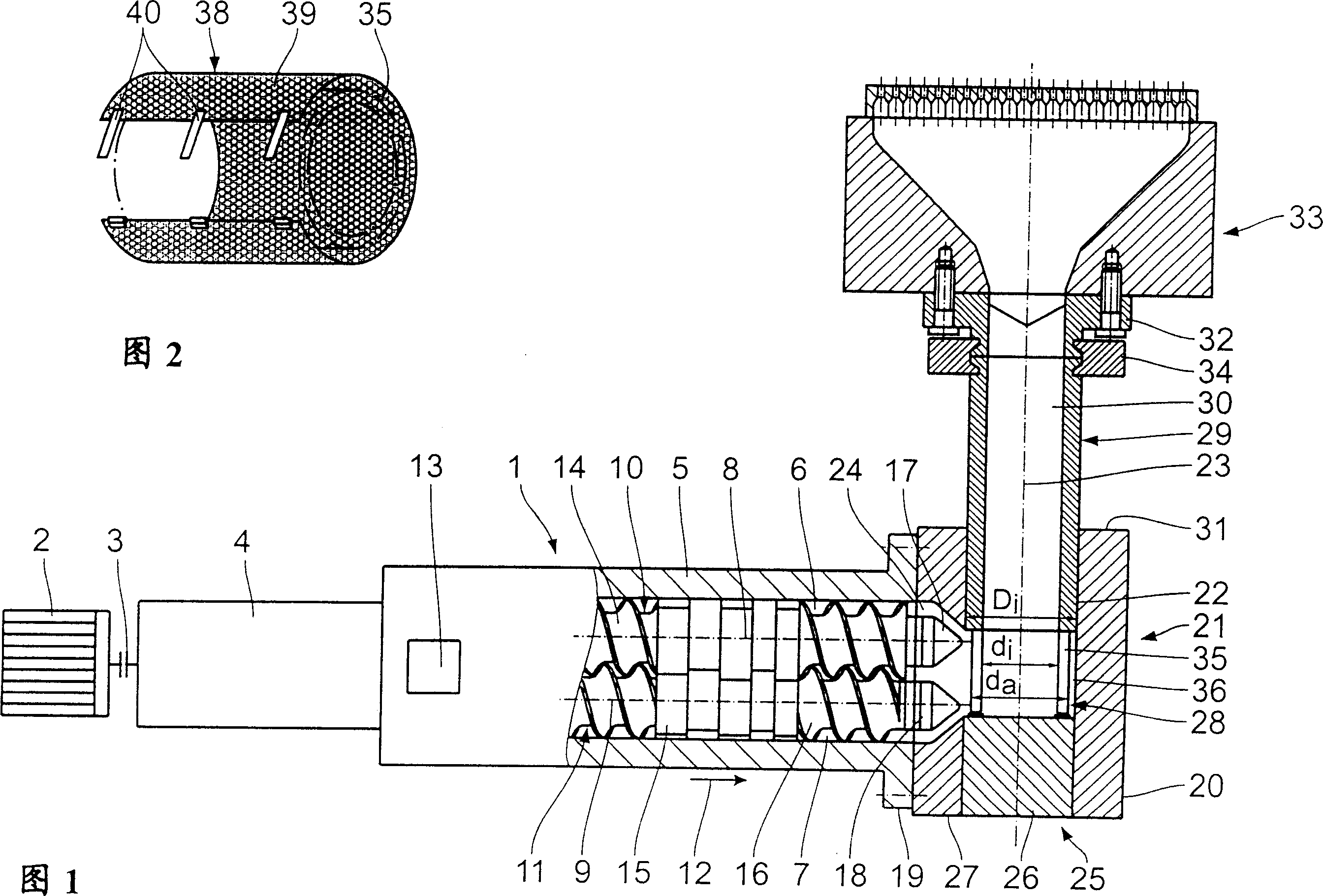

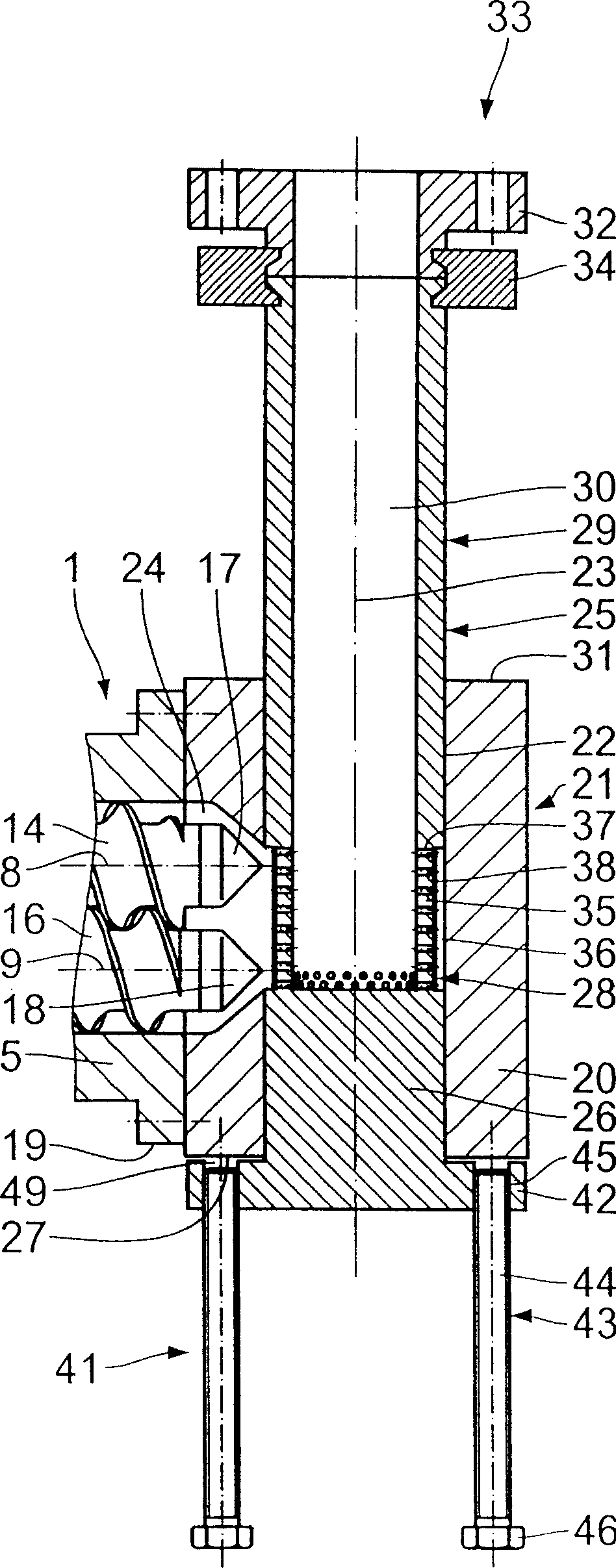

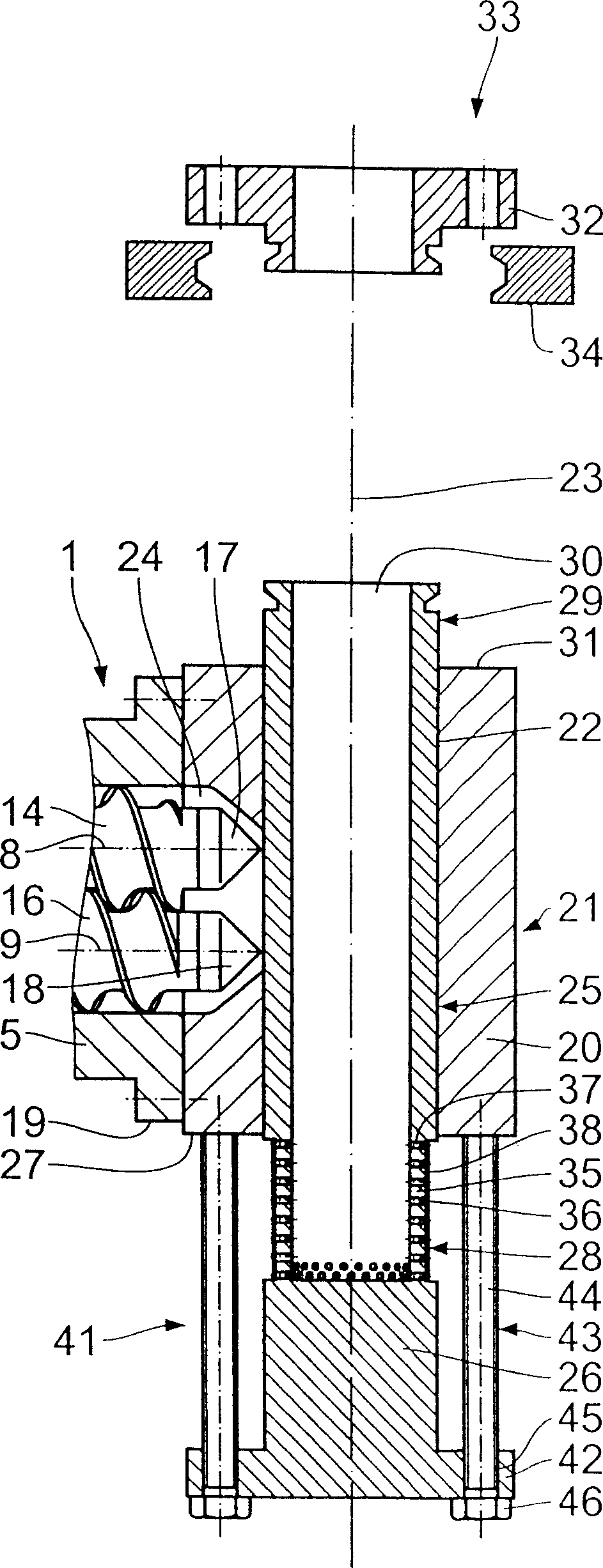

Filter for processing machines, specially extruders

InactiveCN1575961AEasy to cleanEasy to processMembrane filtersStationary filtering element filtersIndustrial engineeringMaterial flow

The invention relates to a material preparation machine, which is characterized in that a screening device (21) of an extruder (1) is provided with a casing (20), wherein the casing is provided with an extending through hole (22) which is vertical to the axis (8, 9) of the extruder (1); a screening rod (25) is arranged in the hole, which can be shifted along the axis (23) direction of the hole. A screening section (28) is tightly connected in the screening rod (25), which forms a pipe section (29); the screened material flows out though the pipe section along the direction of axis (23) of the through hole (22).

Owner:COPERION

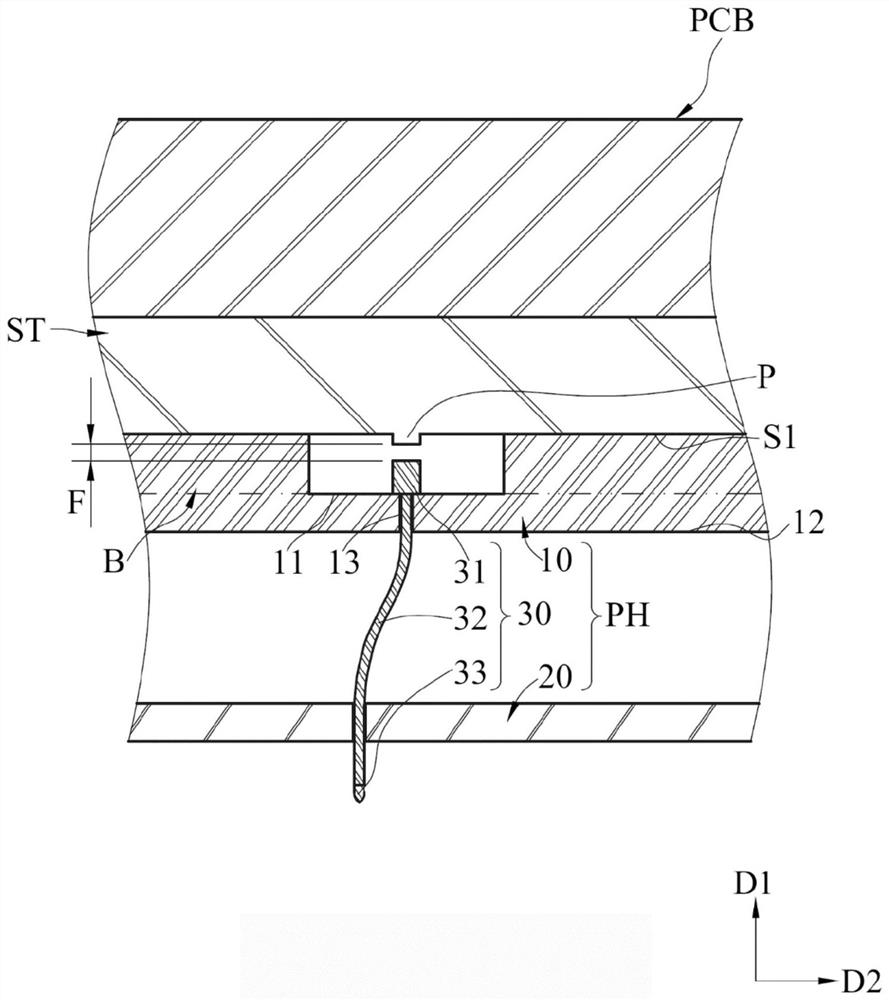

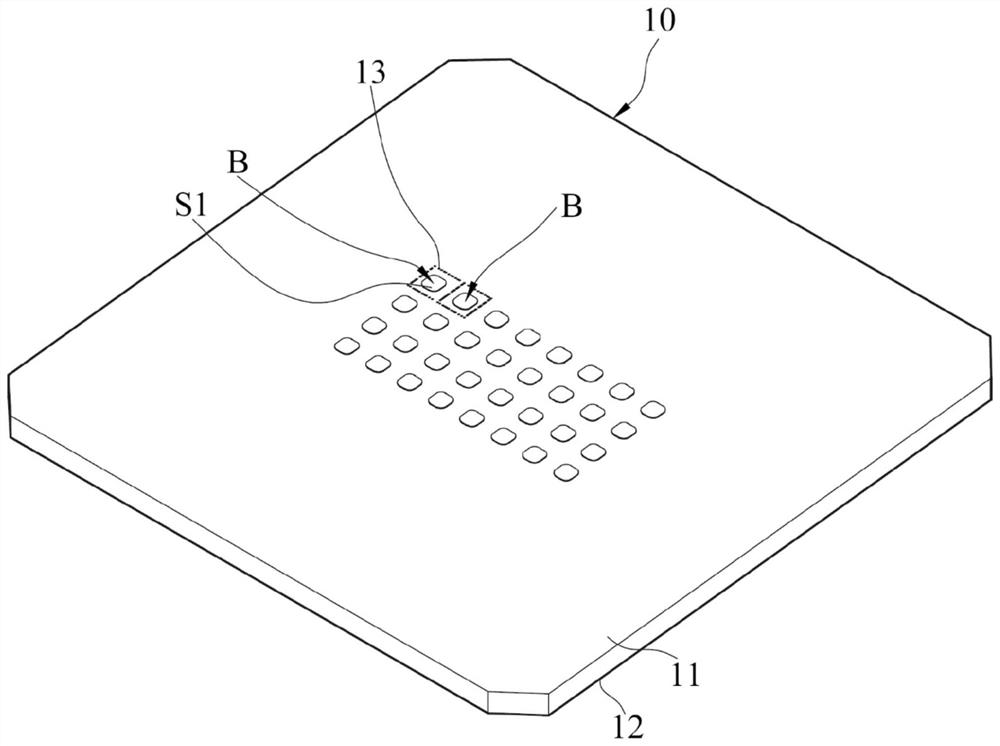

Probe head and probe card

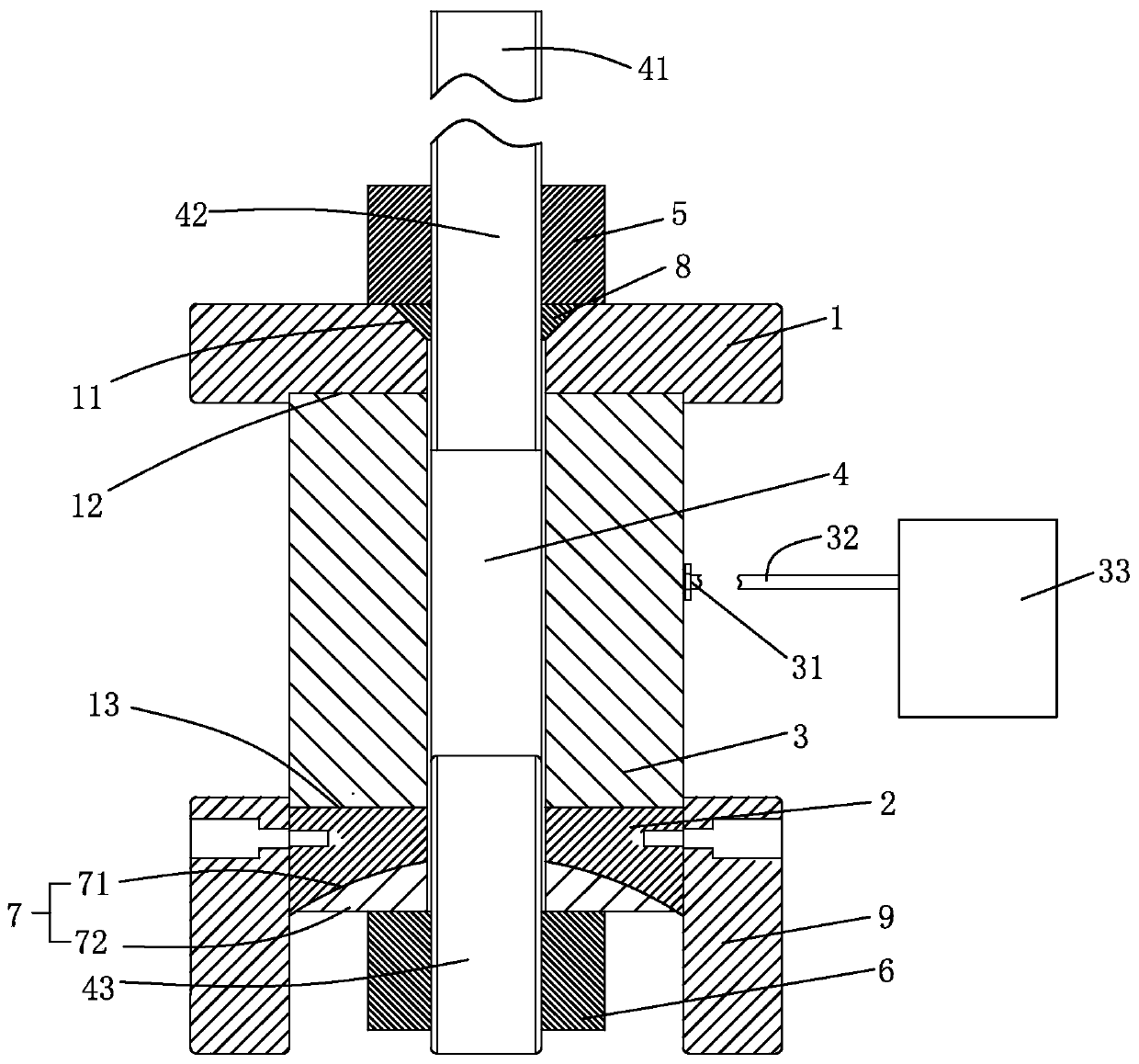

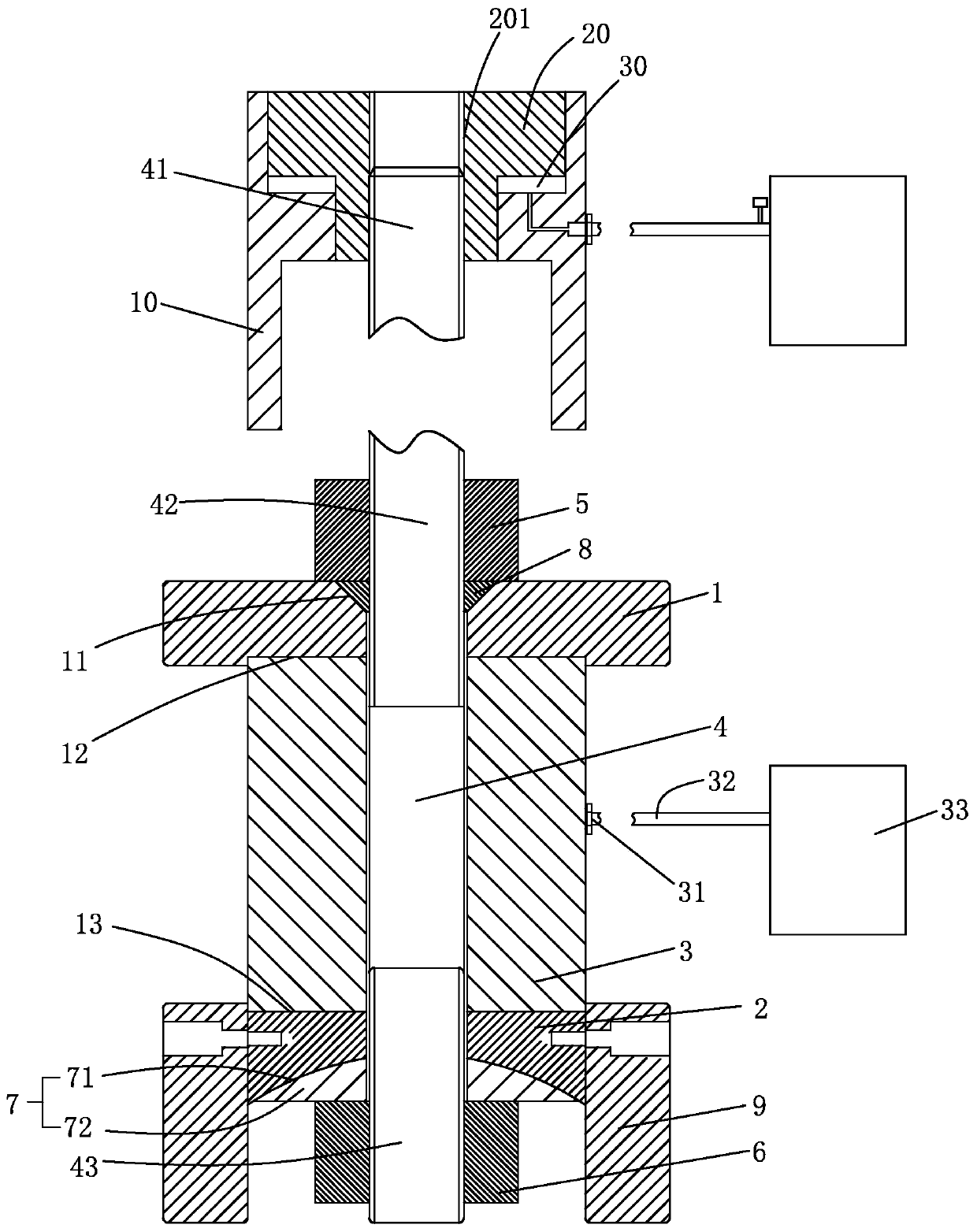

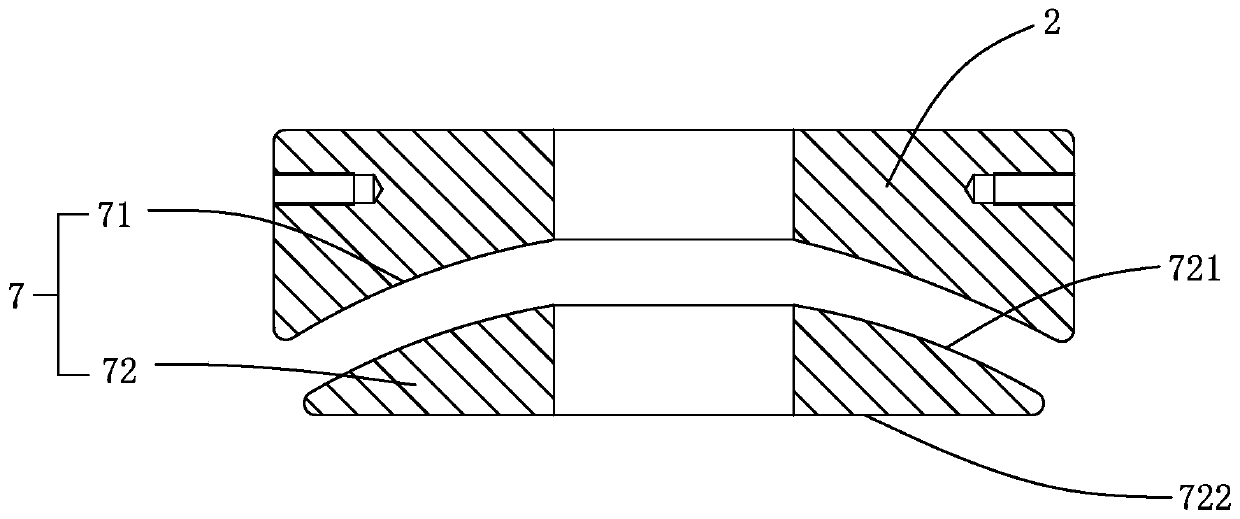

ActiveCN111751583AAvoid damageReduce deformationElectrical testingMeasurement instrument housingConvertersProbe card

Owner:MPI CORP

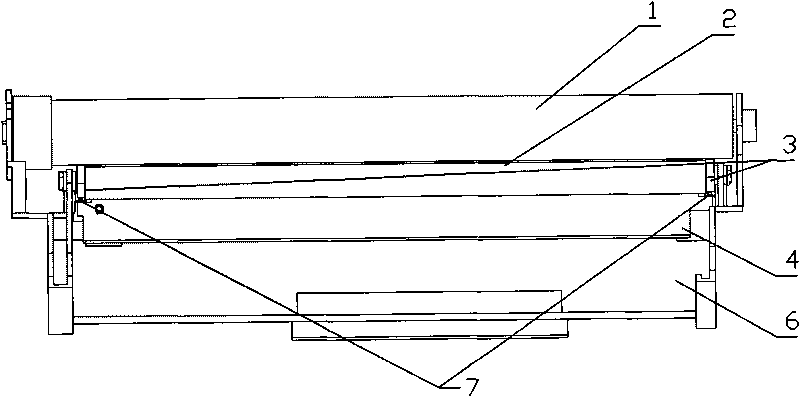

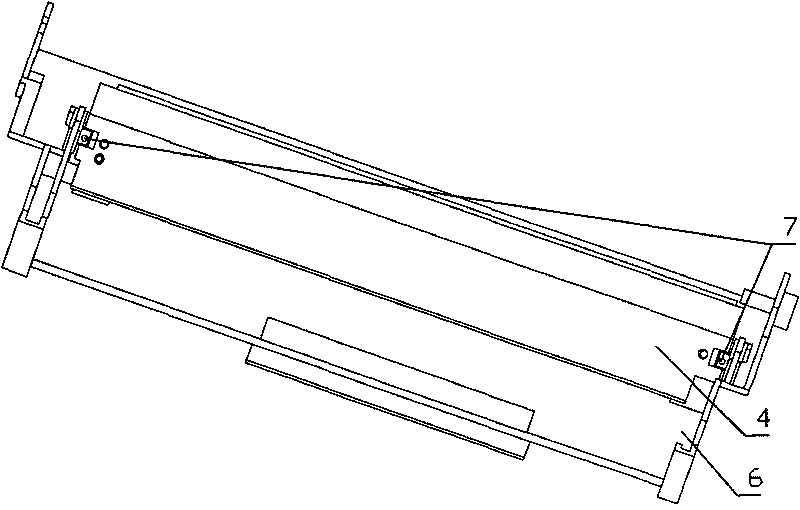

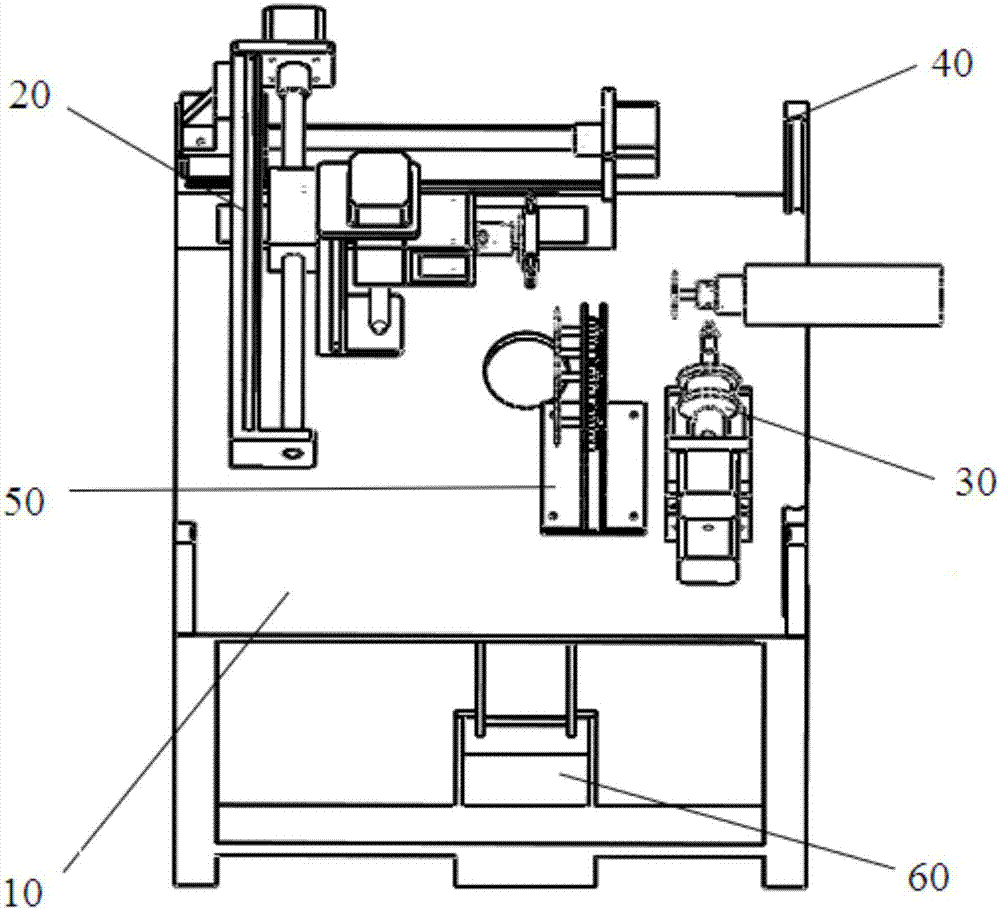

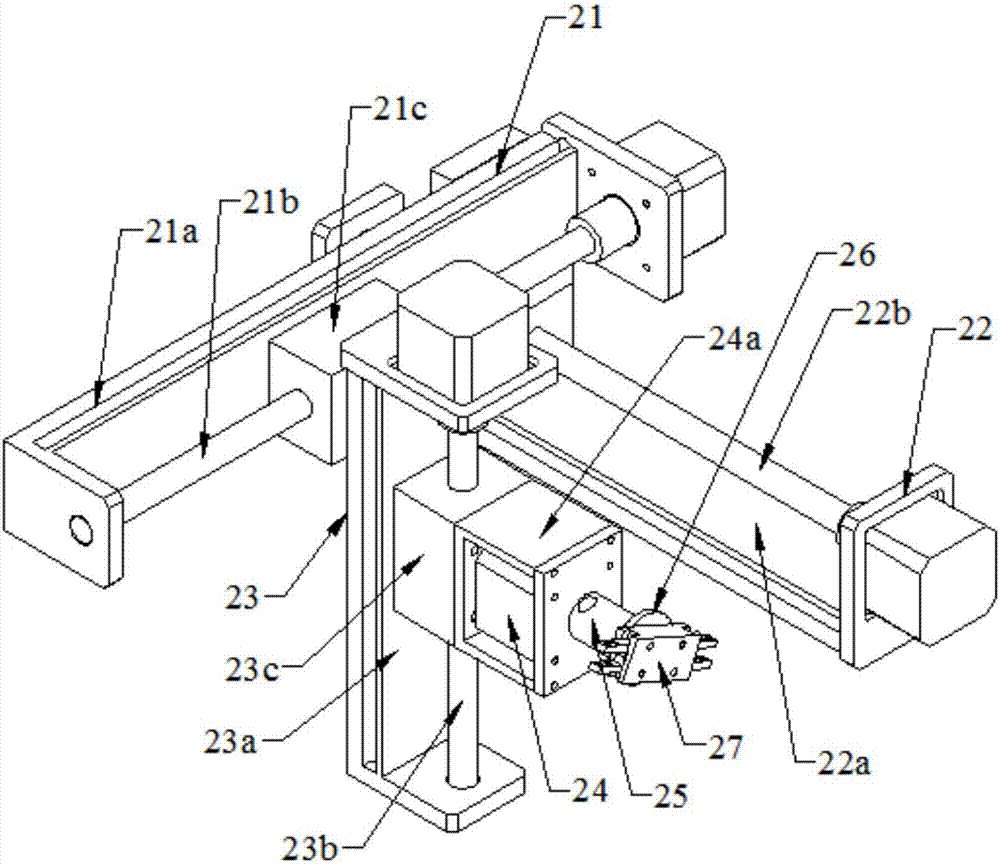

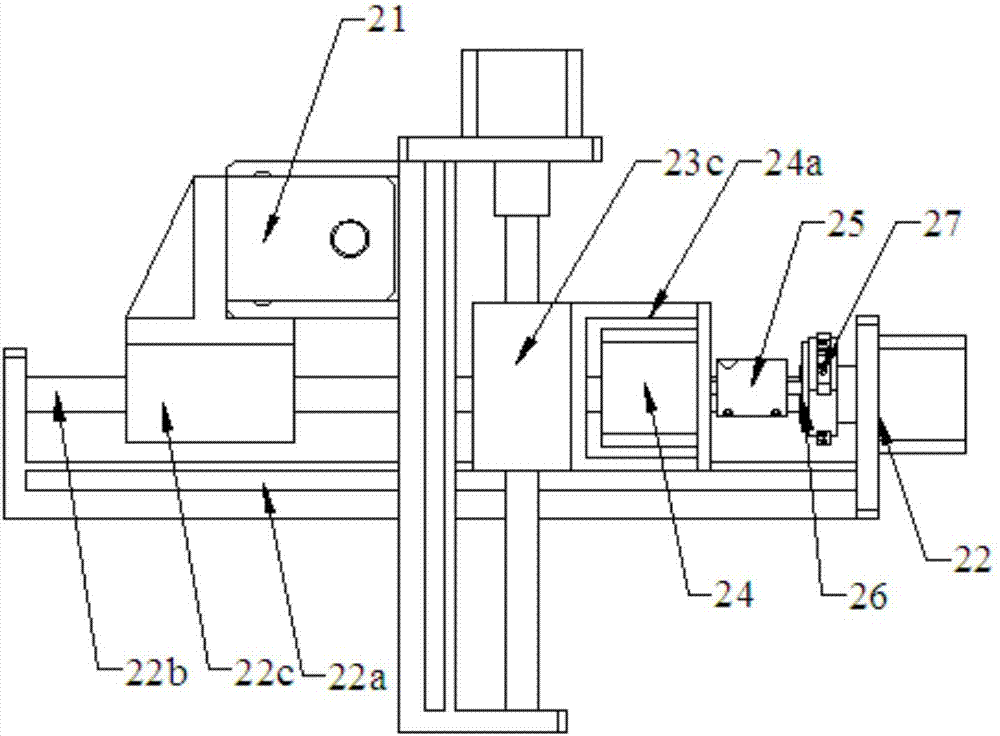

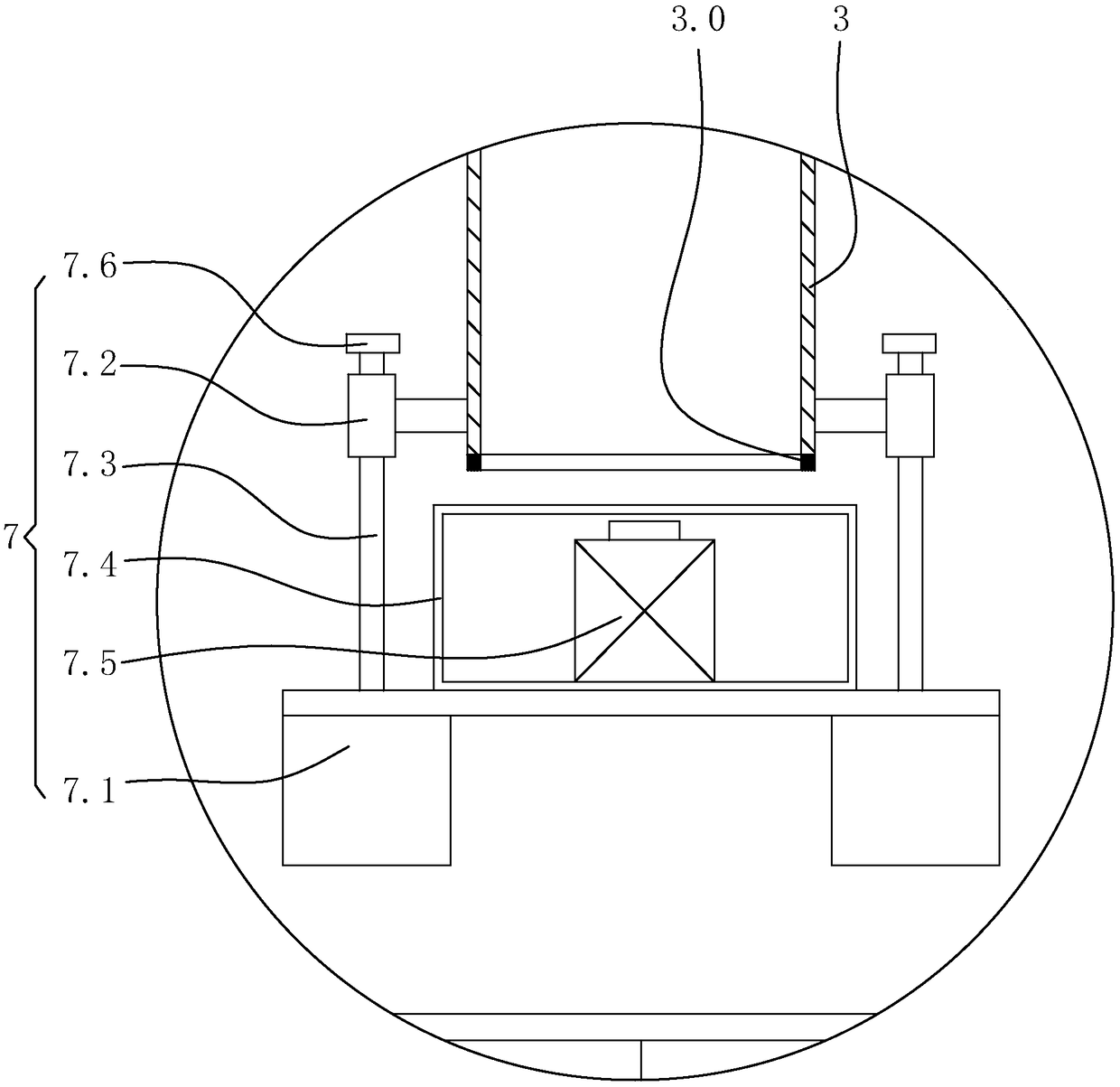

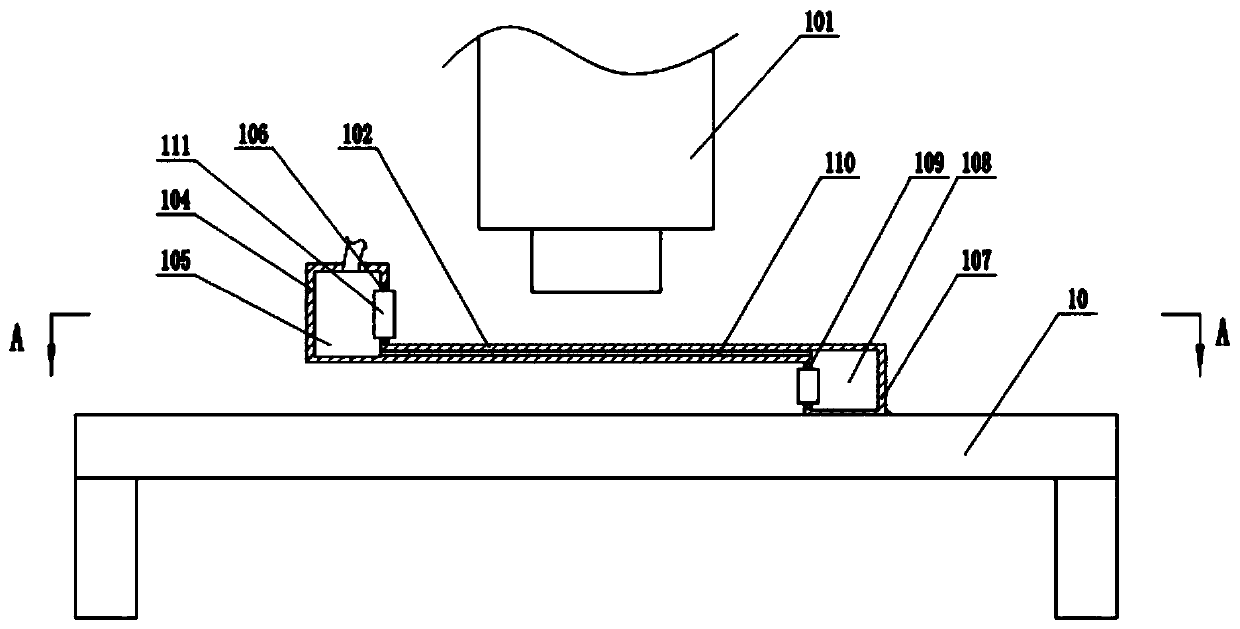

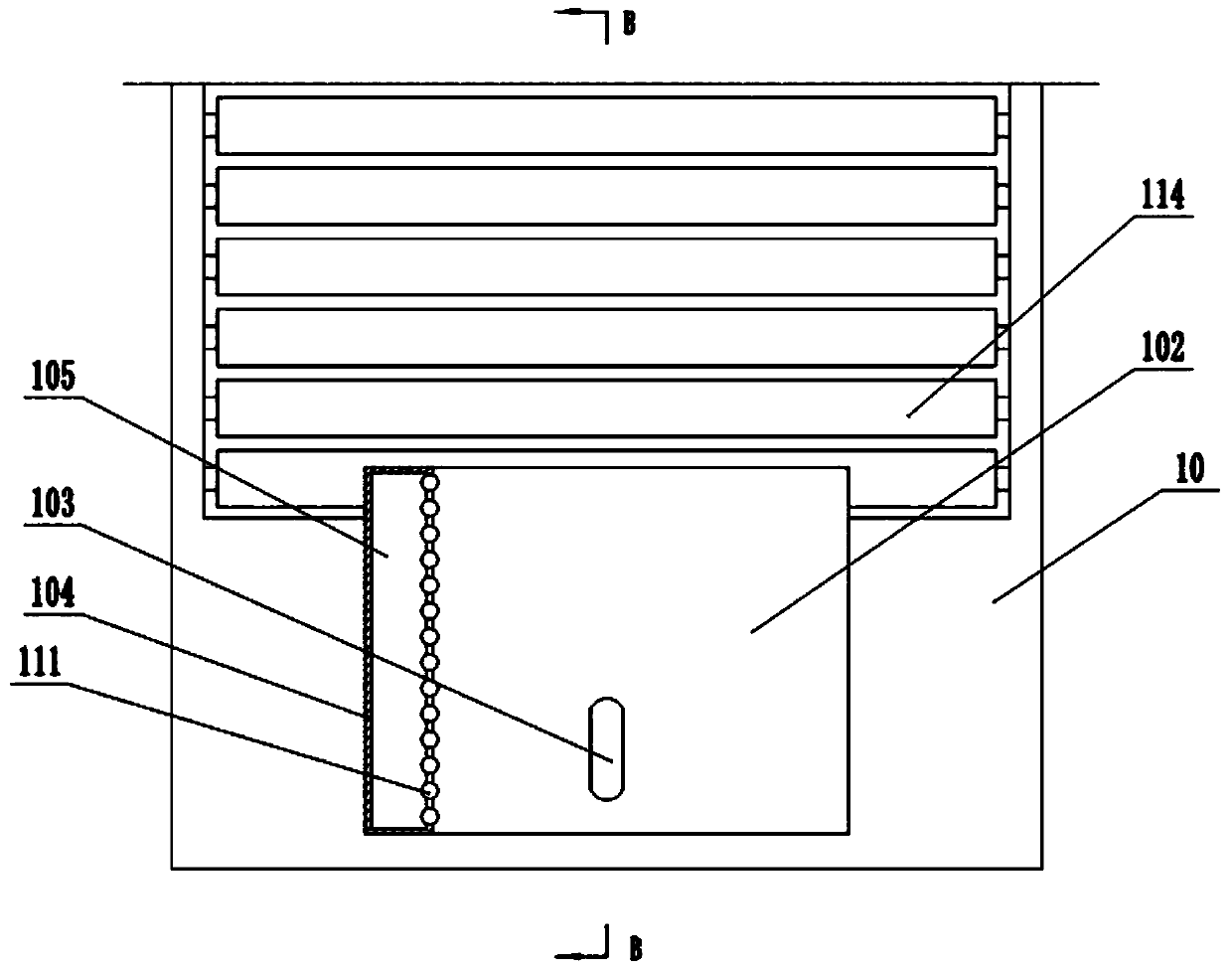

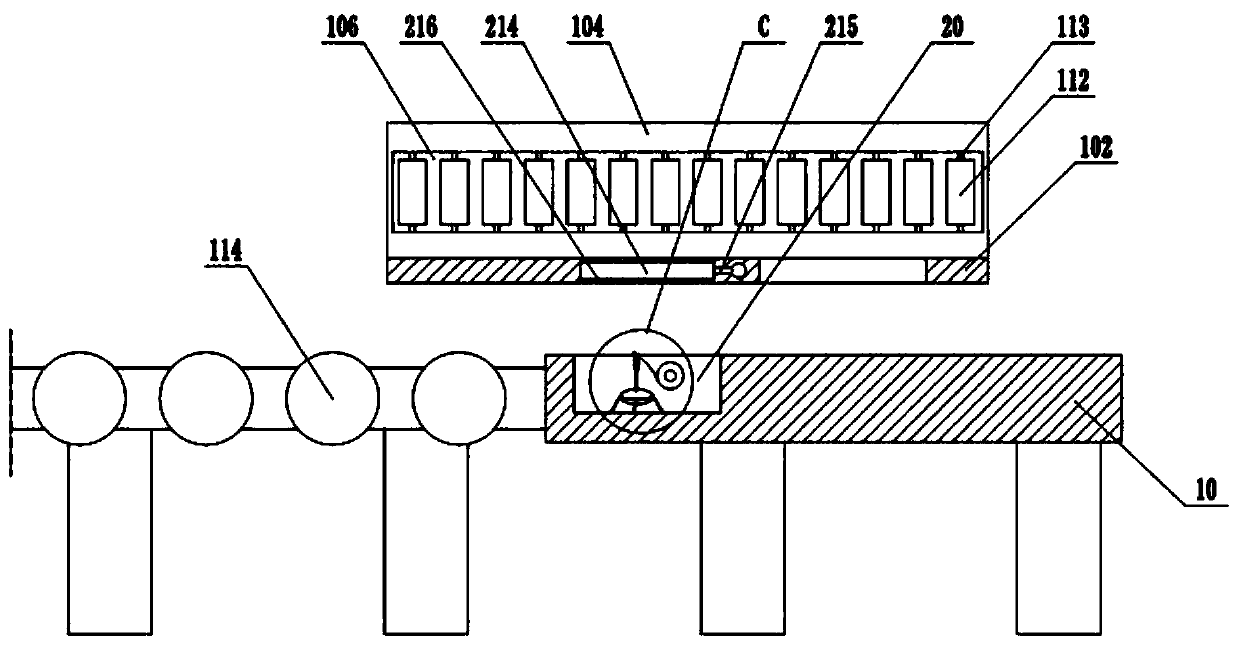

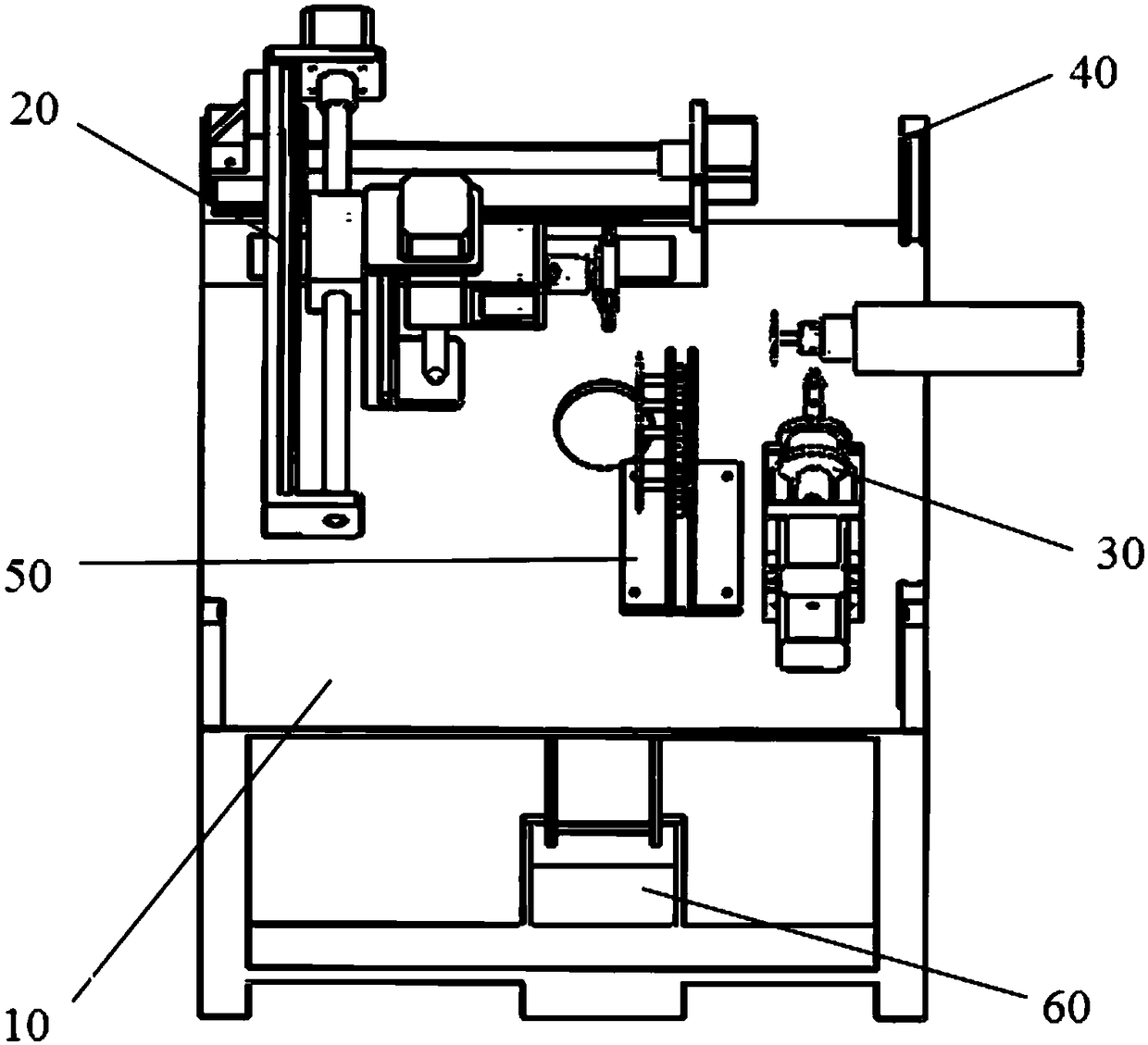

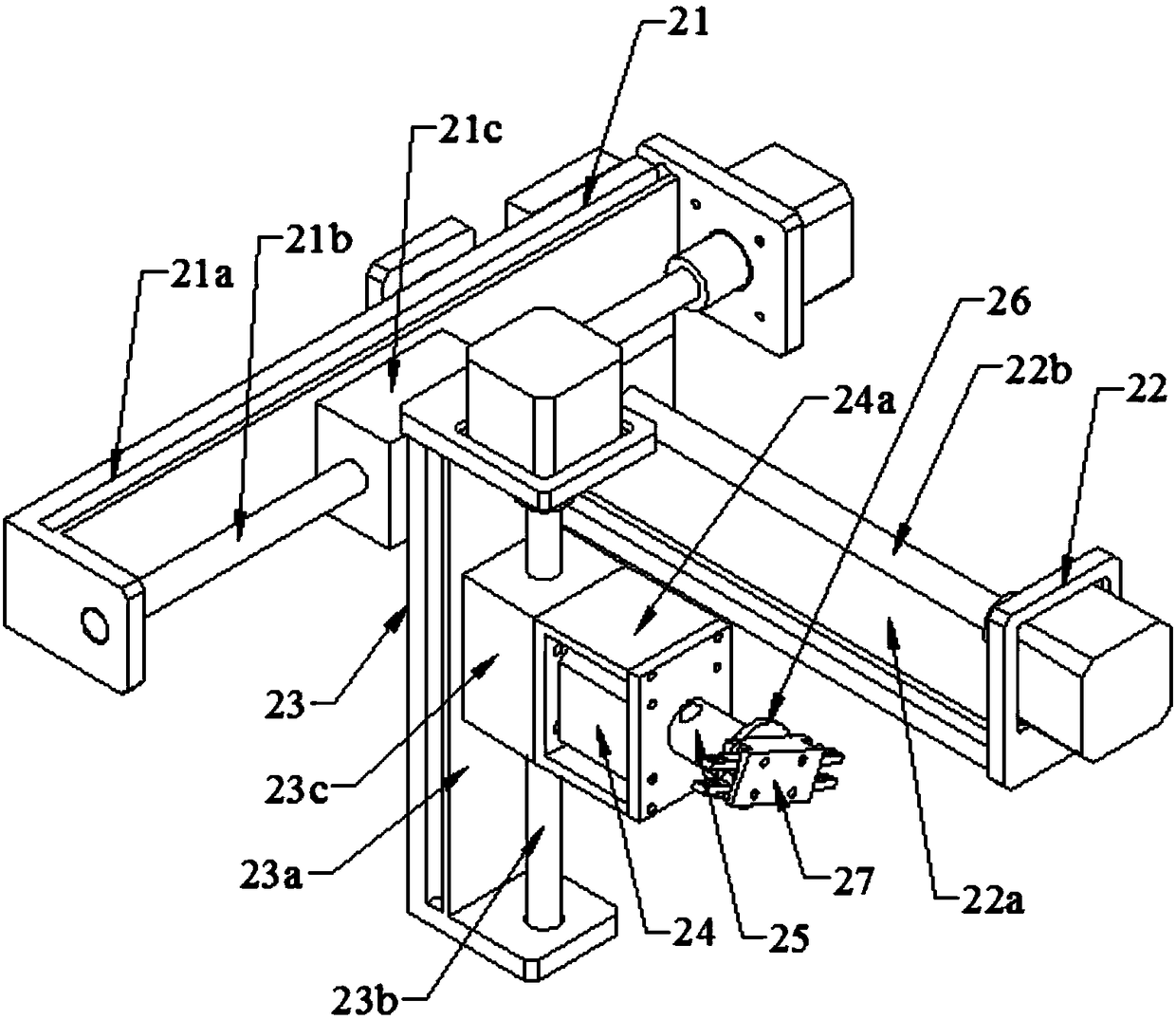

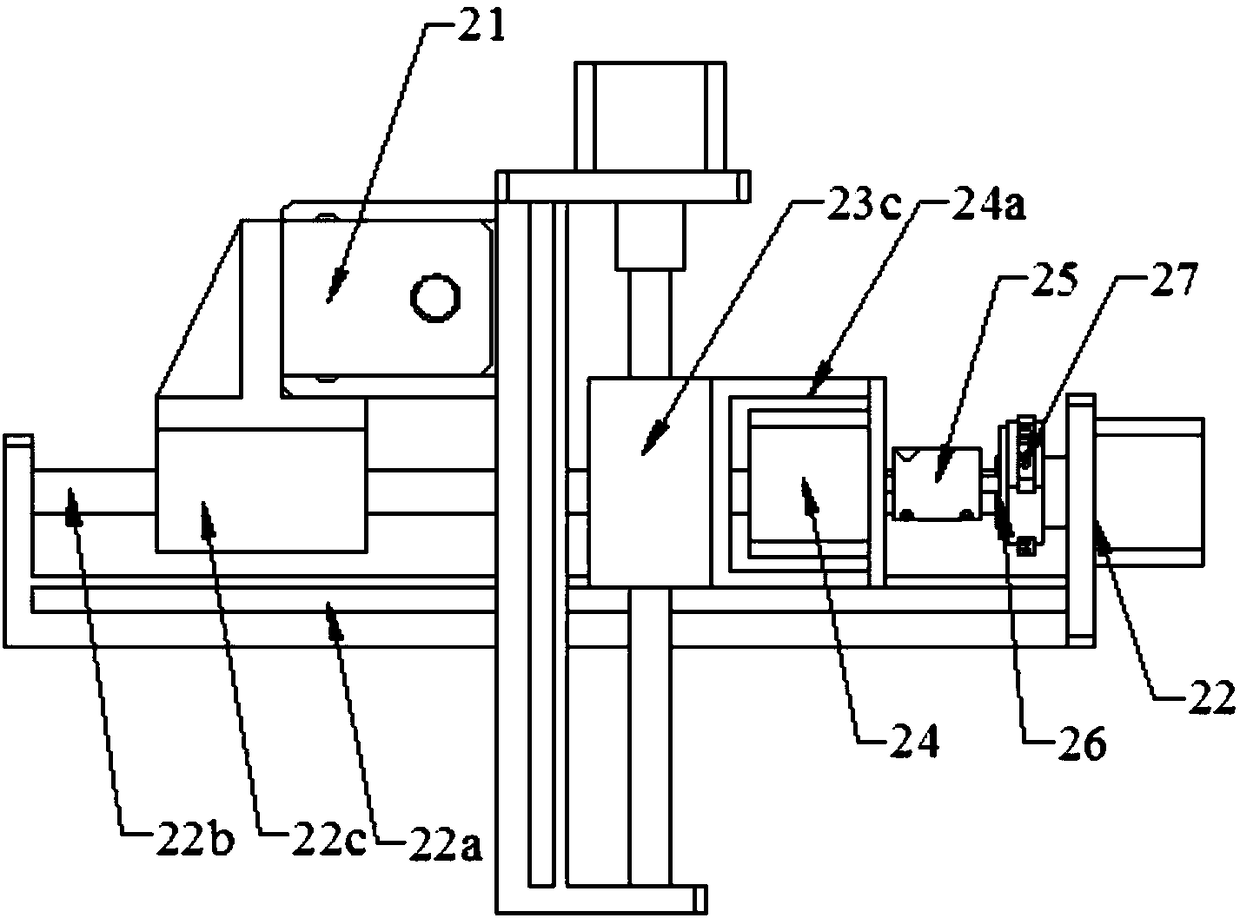

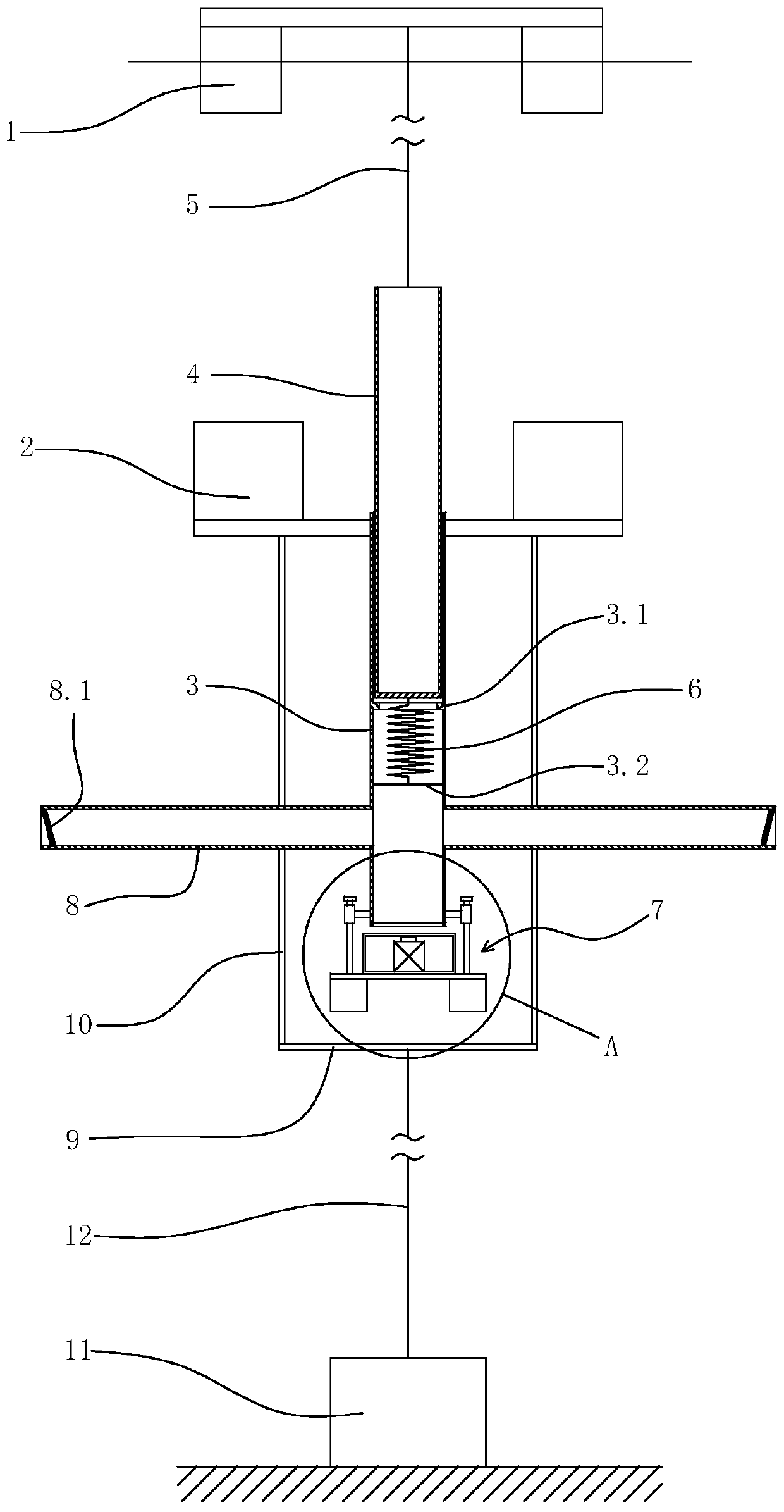

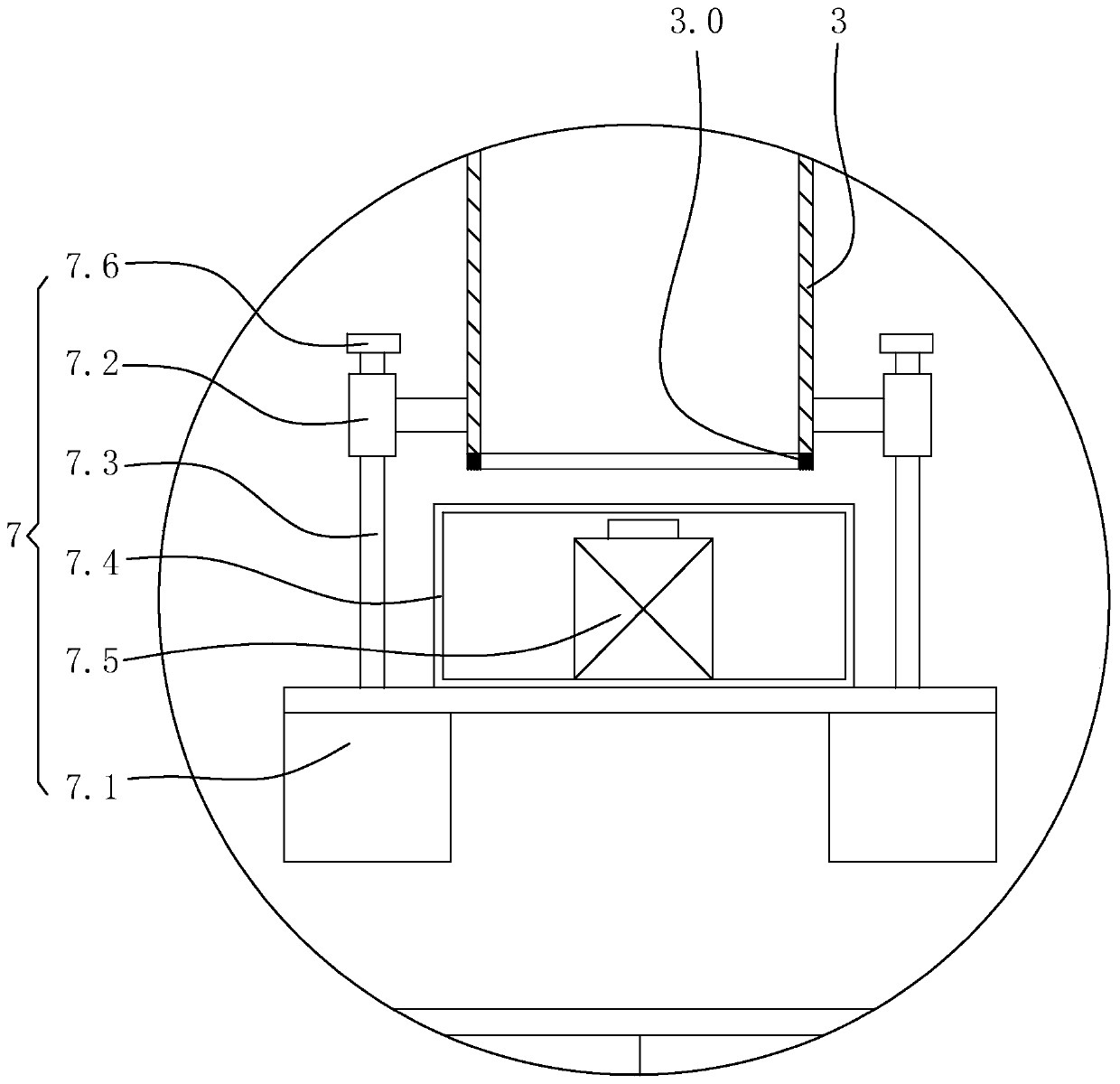

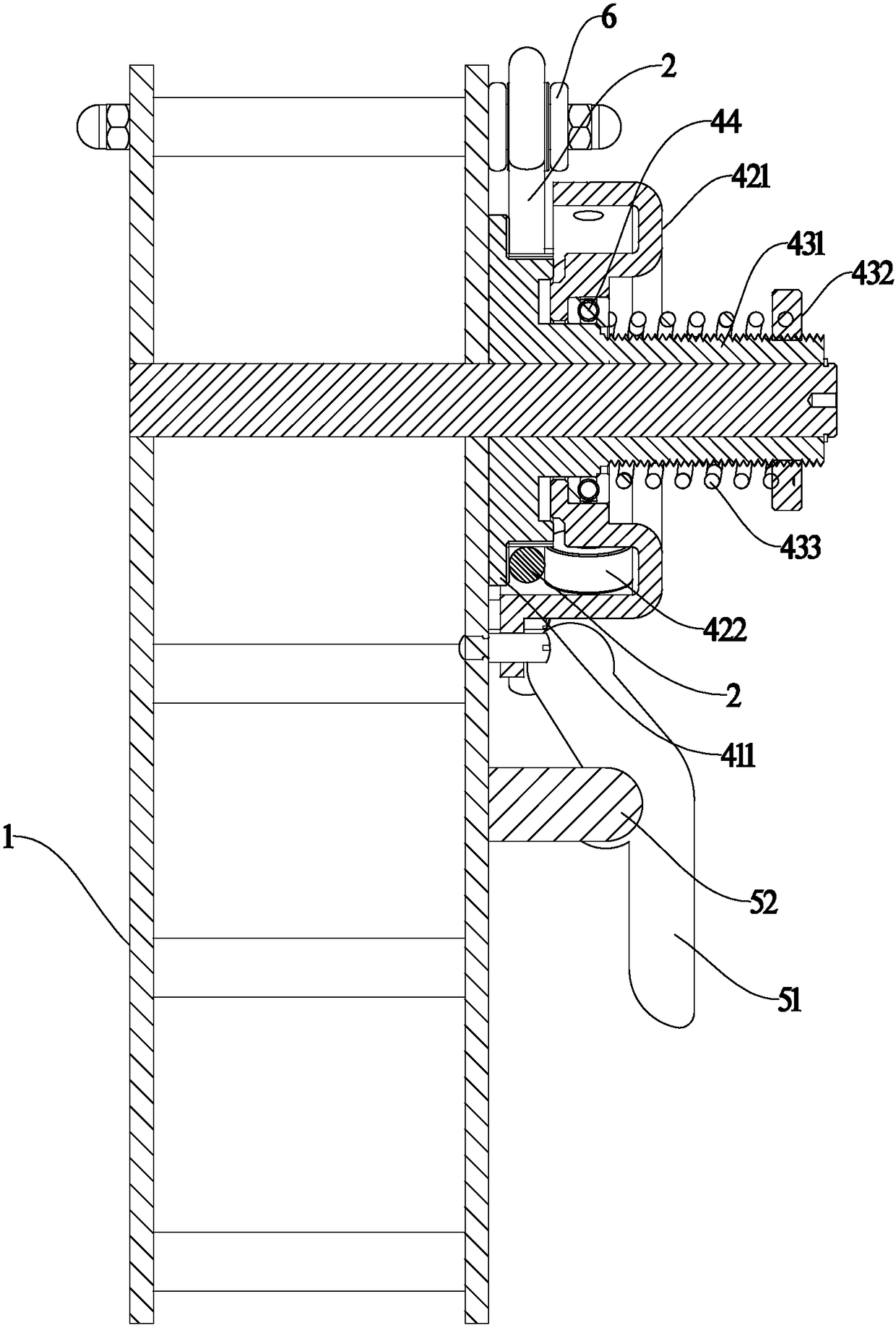

Device for automatically replacing grinding head

ActiveCN106985069AWith gapIngenious structural designGrinding wheel securing apparatusGrinding machinesEngineeringManipulator

The invention discloses a device for automatically replacing a grinding head. The device comprises a rack as well as a three-dimensional manipulator mechanism, an electric drill key driving device and a grinding head storeroom mechanism which are arranged on the rack, wherein the three-dimensional manipulator mechanism is fixed at the upper left corner of the rack through an X-axis linear sliding table, and used for clamping grinding heads in the grinding head storeroom mechanism; the electric drill key driving device is fixed at the middle of the rack through a driving device mounting frame, and used for tightening or loosening an electric drill bit; and the grinding head storeroom mechanism is fixed at the middle of the rack through a magnet provided with a switch, positioned on the left side of the electric drill key driving device, and used for providing the grinding heads. The device is ingenious in structural design and reasonable in layout; the electric drill grinding head replacement quality and speed can be effectively improved; the application range is broad; and the widespread popularization and application are facilitated.

Owner:深圳市有控技术有限公司

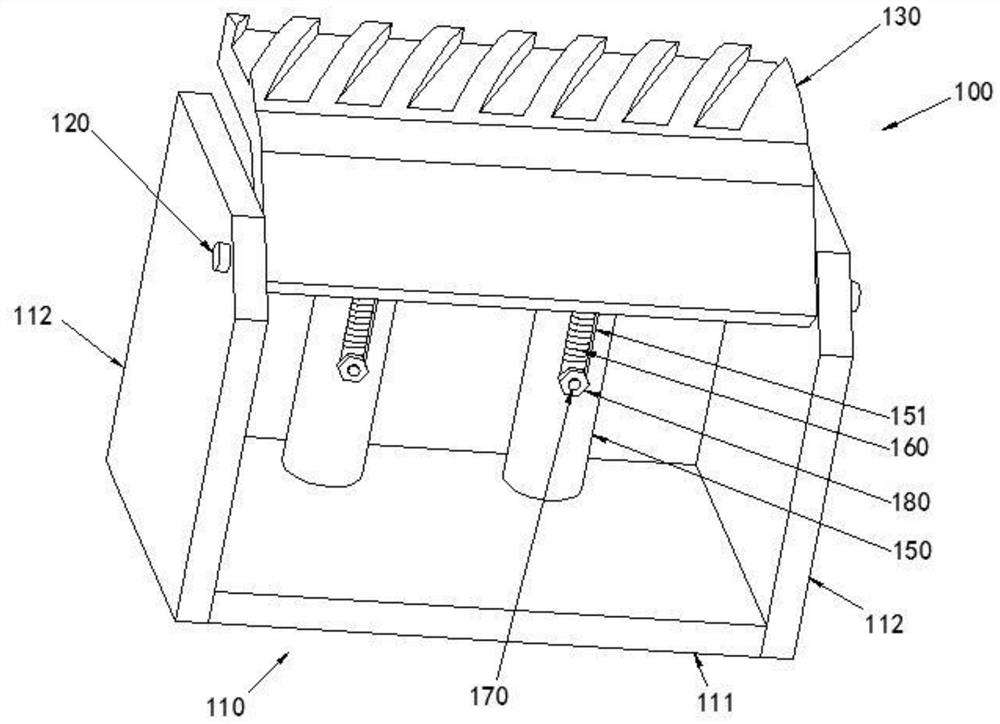

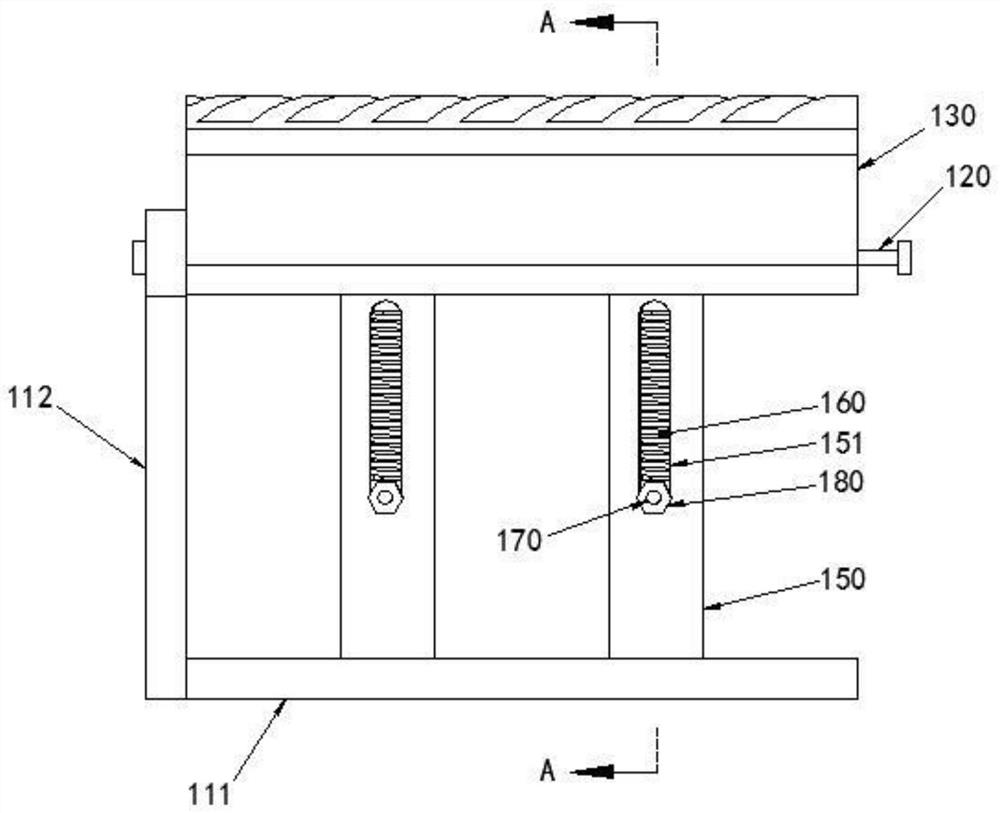

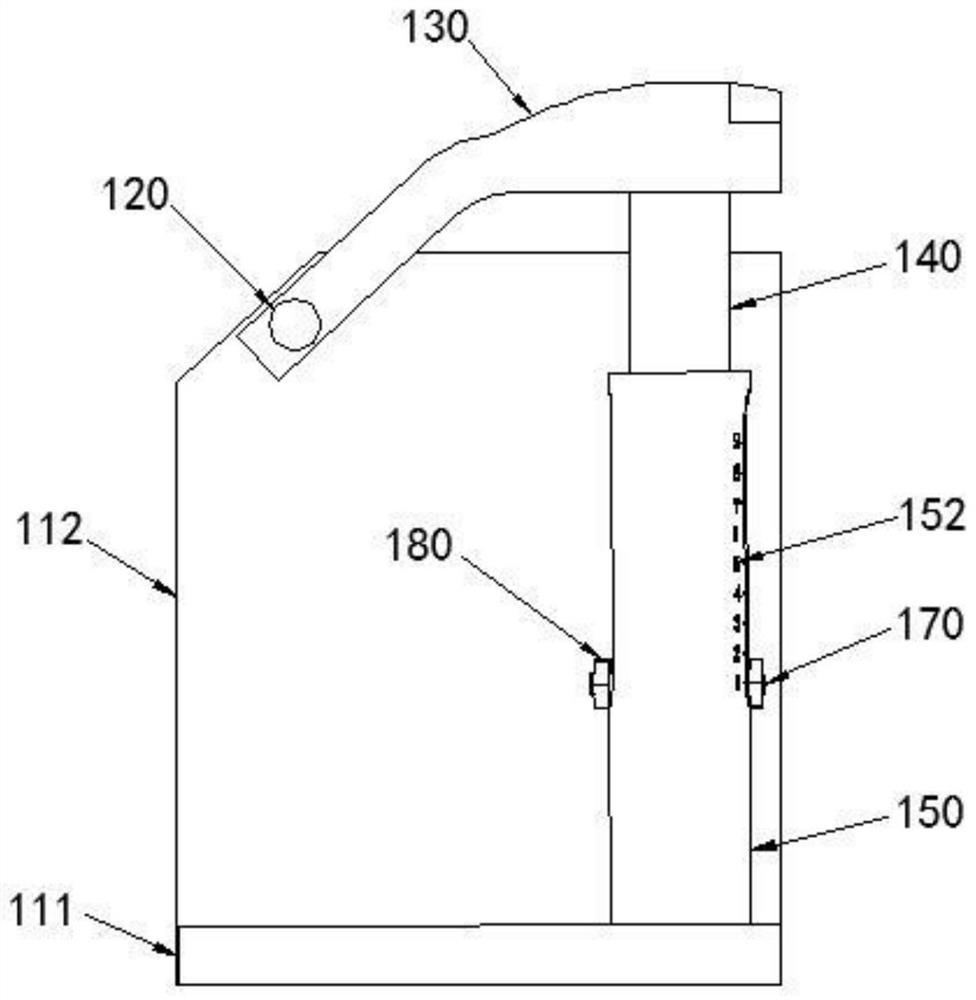

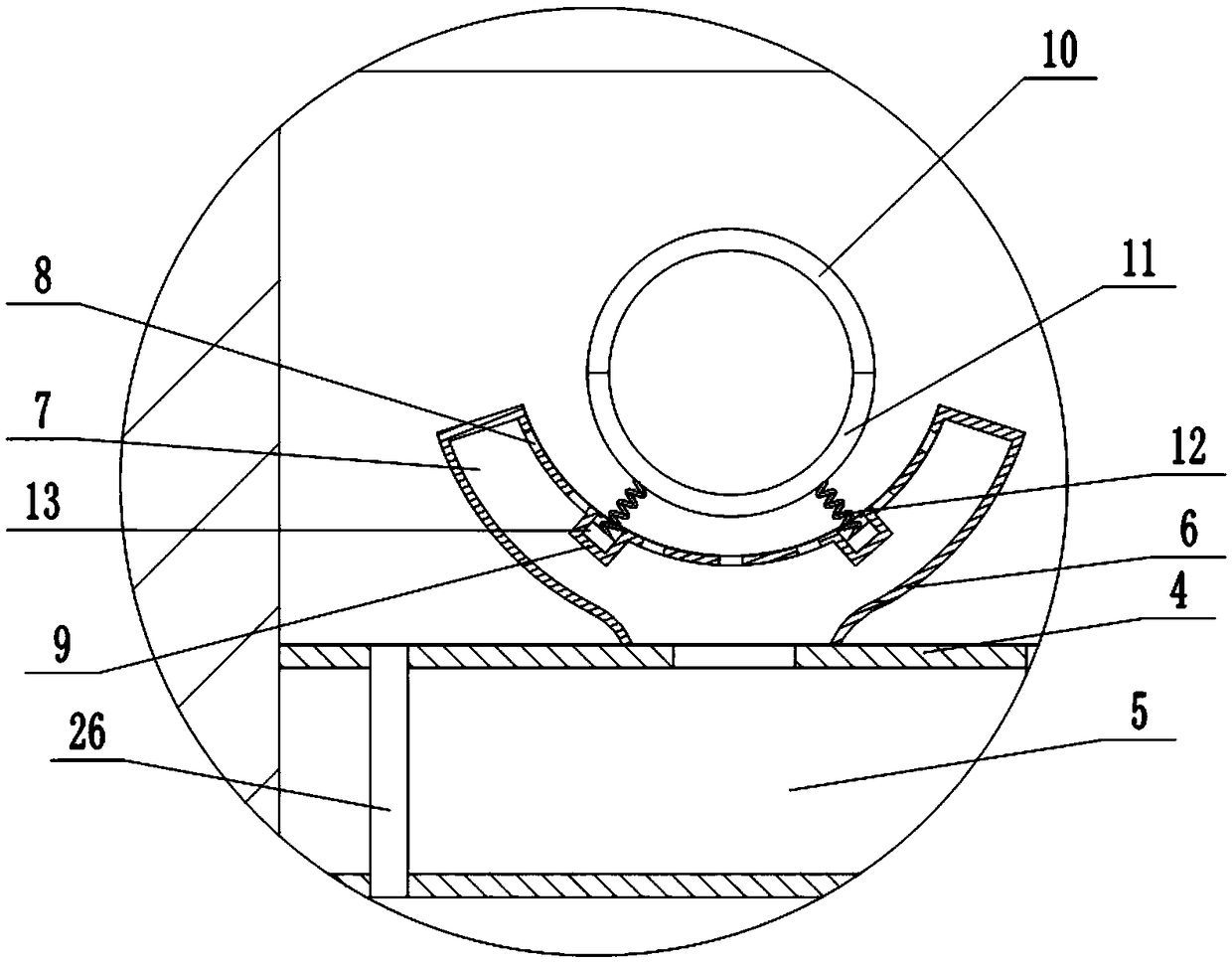

Rasp bar mechanism and edible bean threshing cylinder applying rasp bar mechanism

The invention discloses a rasp bar mechanism. The rasp bar mechanism comprises a base, a first rotating shaft, a rasp bar block, an upper adjusting column, a sleeve and an elastic body. The surface ofthe rasp bar block is provided with inclined grooves. The rasp bar block is installed on the base through the first rotating shaft. The rasp bar block can rotate around the first rotating shaft. Thesleeve is installed on the base. The elastic body is located in the sleeve. The upper adjusting column is connected with the rasp bar block. The upper adjusting column is inserted into the sleeve andlocated above the elastic body. According to the rasp bar mechanism, the rasp bar block is used to configure the first rotating shaft and the elastic body, so that the gap between the rasp bar block and a sieve cylinder can adaptively change with the change of the size of bean pods when the rasp bar mechanism is used. The rasp bar block is always in contact with the bean pods and applies basicallythe same pressure on the bean pods, thereby ensuring that both large and small bean pods can be threshed normally without damaging seeds.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

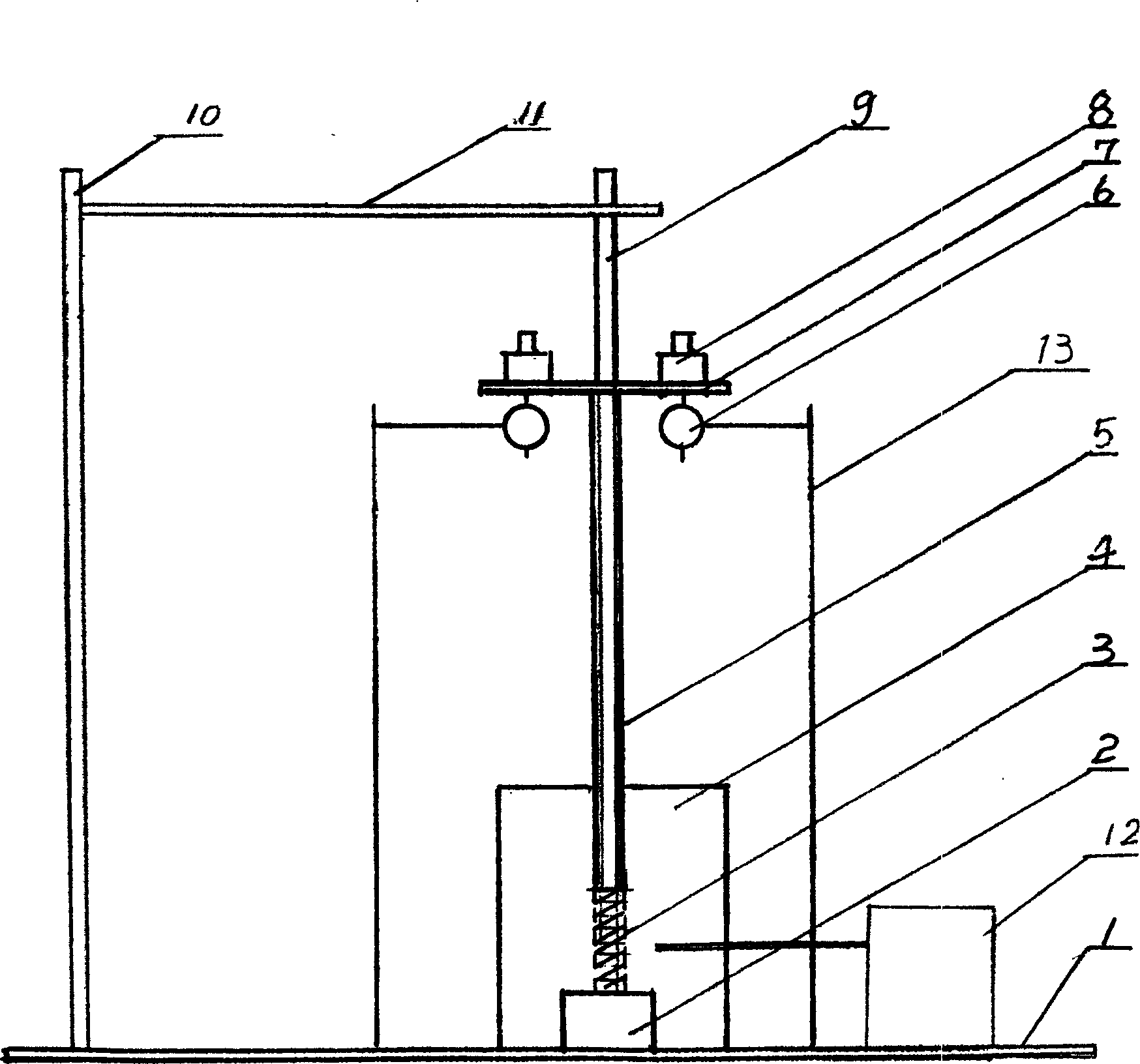

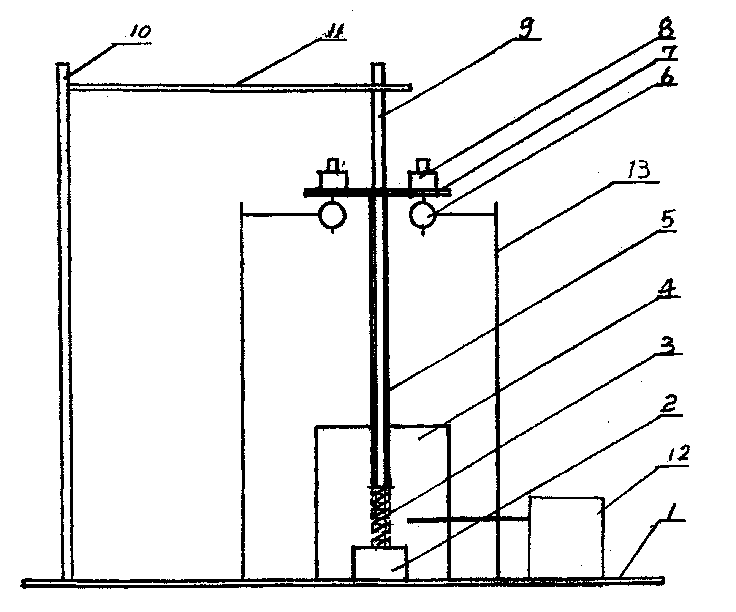

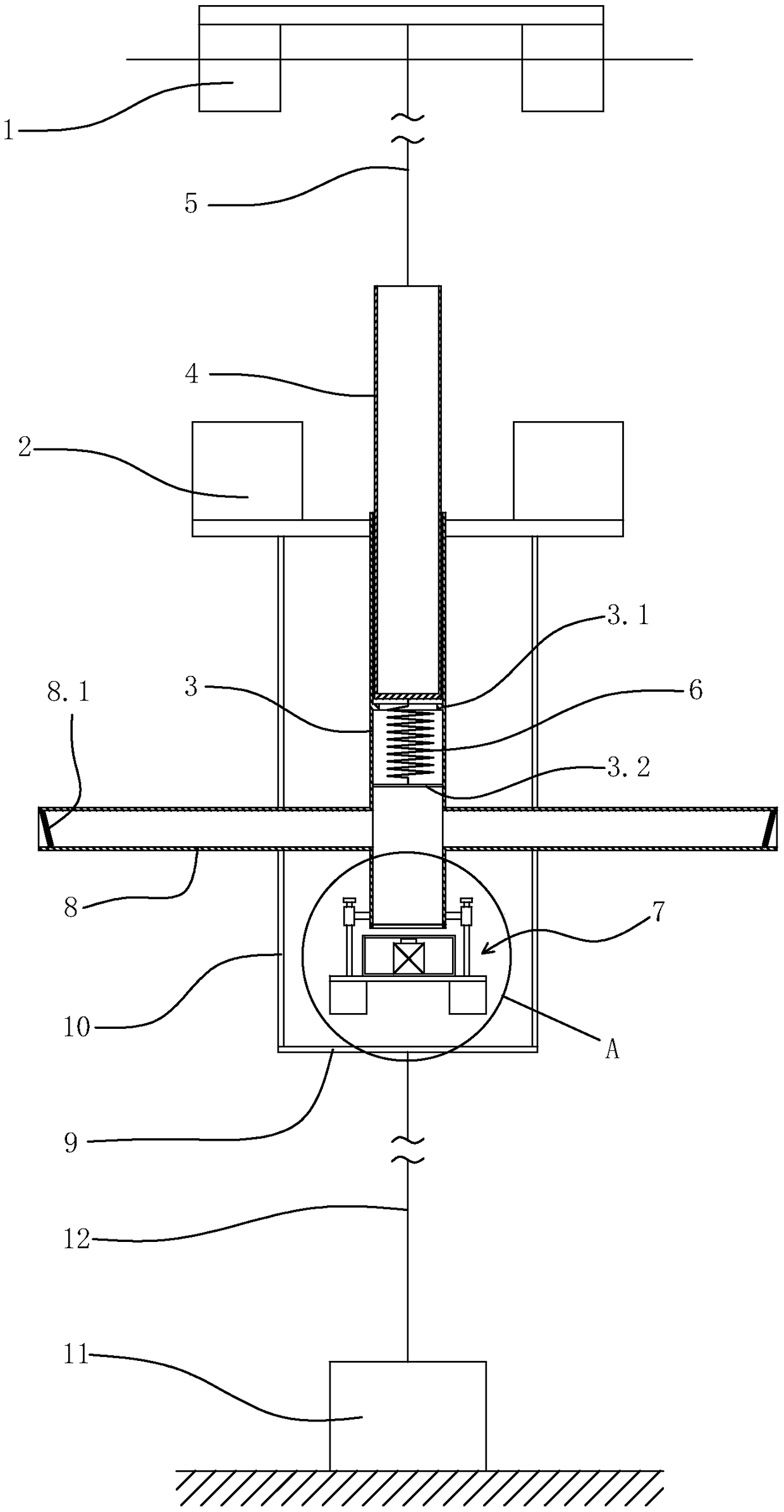

Fishery resource monitoring system for sea area restoration area

ActiveCN108931234AImprove the effective monitoring areaSolve the problem that affects the clarity of the shootingWaterborne vesselsPhotogrammetry/videogrammetryOcean bottomMonitoring system

The invention discloses a fishery resource monitoring system for a sea area repairing area. The invention aims at providing the fishery resource monitoring system for the sea area repairing area in order to effectively enlarge the effective monitoring area of floating fish eggs in water and effectively solve the problem of influences of accumulation or adhesion of sediments and the like on the shooting sharpness. The system comprises a floating frame floating on the sea, a balancing weight settling to the seabed, a suspending frame suspending in seawater, a fixed vertical pipeline arranged atthe upper opening and lower opening of the suspending frame, a mobile vertical pipeline slidably arranged at an upper opening and a lower sealing in the fixed vertical pipeline, a plurality of lateralwater feeding pipelines arranged at the lower part of the fixed vertical pipeline, an upper connecting rope for connecting the upper end of the floating frame with the mobile vertical pipeline, a tension spring positioned in the fixed vertical pipeline, a transverse rod positioned below the fixed vertical pipeline, a vertical connecting rod for connecting the transverse rod with the suspending frame, a lower connecting rope for connecting the transverse rod with the balancing weight, and a floating detector arranged on the fixed vertical pipeline.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Nailing device for packaging carton

InactiveCN111070786AReduce frictionImprove stabilityPaper-makingBox making operationsCartonPaperboard

The invention relates to the technical field of carton production equipment and particularly disclose a nailing device for packaging a carton. The nailing device comprises a working table, a rack anda nailing machine, wherein a horizontal plate is fixed on the working table; a strip-shaped groove right below the nailing machine is formed in the horizontal plate; a first paper retaining box and asecond paper retaining box are fixed on the two sides of the horizontal plate and are positioned on the upper and lower sides of the horizontal plate separately; a first cavity is formed in the firstpaper retaining box; a second cavity is formed in the second paper retaining box; a flow guidance channel communicating with the first cavity and the second cavity is arranged in the horizontal plate;a first adsorption groove communicating with the first cavity is formed in the side wall of the first paper retaining box; a second adsorption groove communicating with the second cavity is formed inthe side wall of the second paper retaining box; the first adsorption groove and the second adsorption groove are oppositely formed; and a vacuum pump communicating with the first cavity and the second cavity is further arranged on the rack. With adoption of the technical scheme, the paperboard nailing precision is improved to further improve the paperboard quality.

Owner:重庆皖渝纸制品有限公司

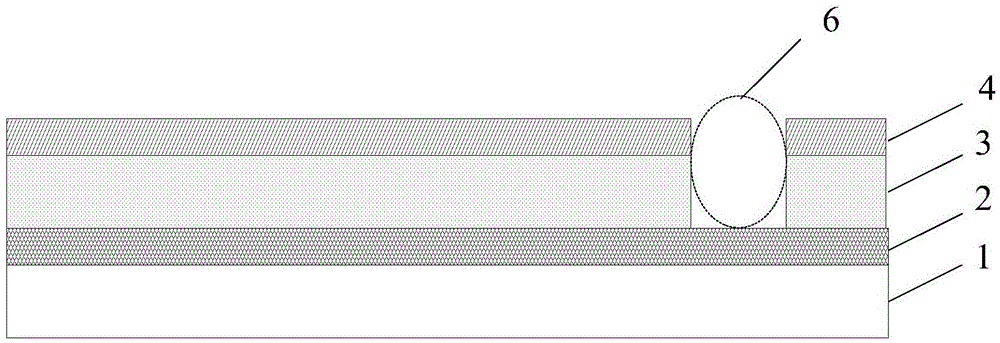

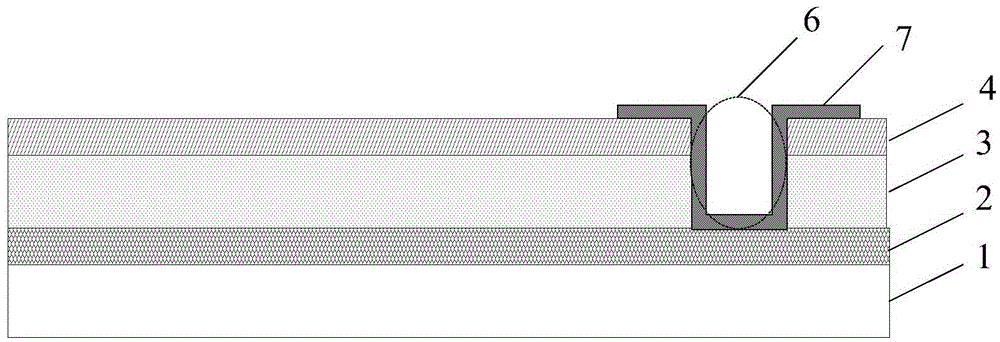

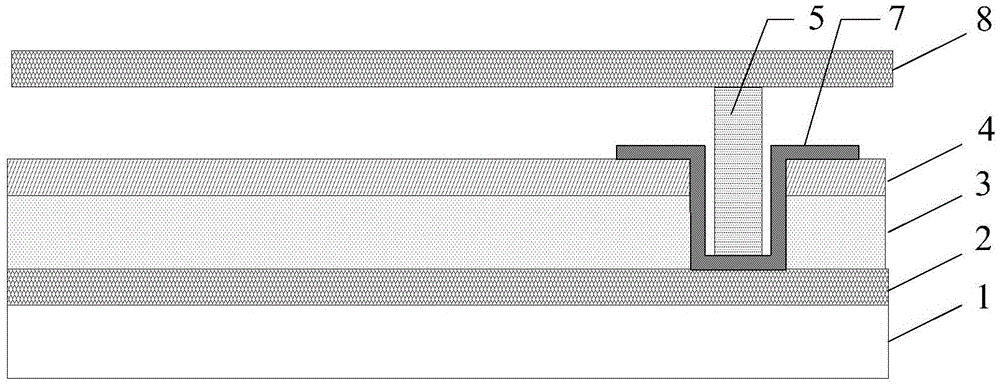

Array substrate, display panel, methods for preparing array substrate and display panel, and display device

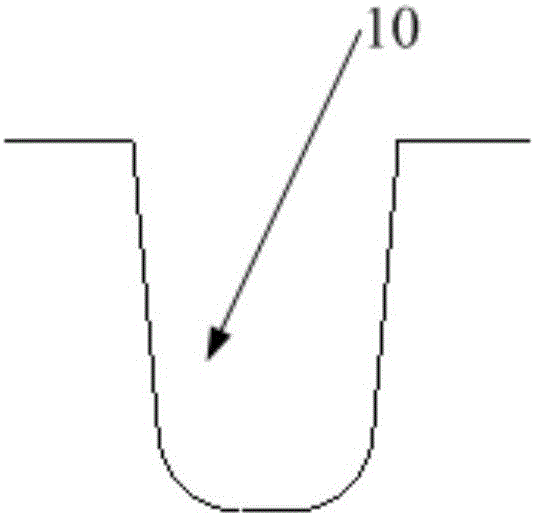

ActiveCN105549250AGood sealing performanceAvoid Adhesive ForcesSolid-state devicesNon-linear opticsEngineeringHigh pressure

The invention aims to provide an array substrate, a display panel, methods for preparing the array substrate and the display panel, and a display device to solve the problem that when an organic membrane under a seal agent is affected by high temperature, high pressure and high humidity, sealing property between the seal agent the membrane adhering to the seal agent becomes poor. The array substrate comprises a substrate body, a grid protection layer, an organic membrane and an insulating layer, wherein the grid protection layer, the organic membrane and the insulating layer are sequentially formed on the substrate body. A groove structure used for accommodating a seal agent is formed in the array substrate and extends towards the grid protection layer from the insulating layer in the direction perpendicular to the substrate, and the grid protection layer is exposed.

Owner:BOE TECH GRP CO LTD +1

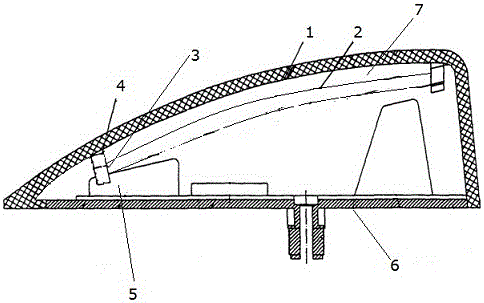

Radio signal receiving antenna for vehicle and ship

InactiveCN105789834AHigh sensitivityComprehensive signal receptionAntenna adaptation in movable bodiesRadio receptionAudio power amplifier

The invention discloses a radio signal receiving antenna for a vehicle and a ship. The radio signal receiving antenna for the vehicle and the ship comprises an antenna shell, wherein a radio receiving antenna is arranged in the antenna shell; an antenna signal output end is arranged at one end of the radio receiving antenna and is connected with an antenna amplifier signal input end through a wireless connection element; a mounting base plate is mounted at the bottom of the antenna shell; the upper end face of the antenna shell is arc-shaped, the radio receiving antenna is located at the upper part of the inner side of the antenna shell and is distributed in a longitudinal direction of the arc-shaped surface of the antenna shell, and an interval is reserved between the radio receiving antenna and the antenna shell. According to the radio signal receiving antenna for the vehicle and the ship, the upper end face of the antenna shell is set to be the arc-shaped surface, thereby strengthening omnidirectional receiving of antenna signals; furthermore, the existence of the interval, which is reserved between the radio receiving antenna and the antenna shell, is used for improving signal receiving intensity; due to the existence of the interval, after reflected and superposed for multiple times, the signals are reinforced.

Owner:WUXI NANLIGONG TECH DEV

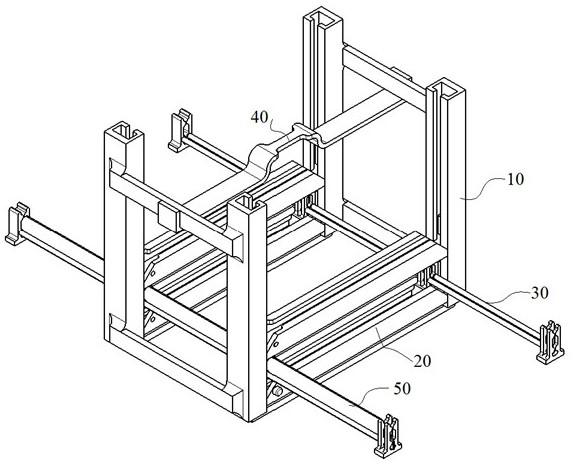

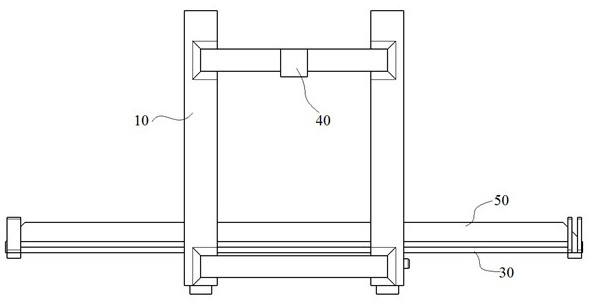

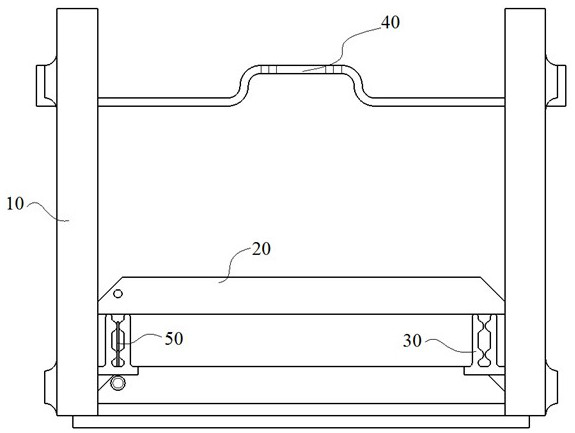

Iron core plate annealing clamp

ActiveCN112029982AEasy to holdGuaranteed clearanceFurnace typesHeat treatment furnacesTransformerStructural engineering

The invention discloses an iron core plate annealing clamp and belongs to the field of transformer production. The iron core plate annealing clamp comprises a frame, cross beams, supports and a handle, the cross beams are mounted on the frame, the supports are mounted on the cross beams, and the handle is mounted at the top of the frame. The frame comprises stand columns, vertical T-shaped grooves, bottom beams and side beams, the number of the stand columns is four, the vertical T-shaped grooves are formed in the centers of the stand columns, and the four stand columns are connected to form the whole frame through the pair of bottom beams and the four side beams. The cross beams comprise beam bodies, horizontal T-shaped grooves, gaps, sliding grooves and side tables, the horizontal T-shaped grooves are formed in the middles of the beam bodies, the supports are installed in the horizontal T-shaped grooves, the gaps are formed in one ends of the beam bodies and used for being embedded into the supports, the sliding grooves are formed in the two ends of the beam bodies, and the side tables are arranged at the outer ends of the sliding grooves. Each support comprises a connecting rod,vertical grooves, round heads and sliding blocks, the connecting rod of each support is connected with the multiple vertical grooves, and the corresponding sliding blocks are arranged at the bottomsof the two vertical grooves in the middle of each support and installed in the corresponding horizontal T-shaped grooves. The handle comprises a transverse rod, side hooks and a hand shank, the handleis installed on the side beams at the top of the frame, the side hooks are arranged at the two ends of the transverse rod and hook the side beams, and the hand shank is arranged in the middle of thetransverse rod.

Owner:JIANGXI GANDIAN ELECTRIC

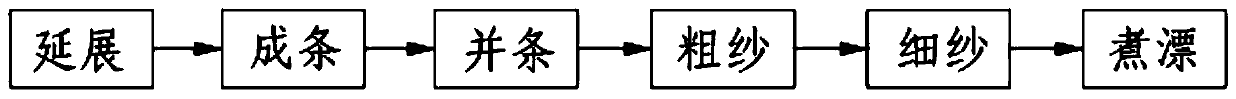

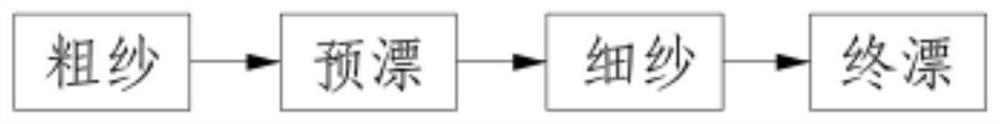

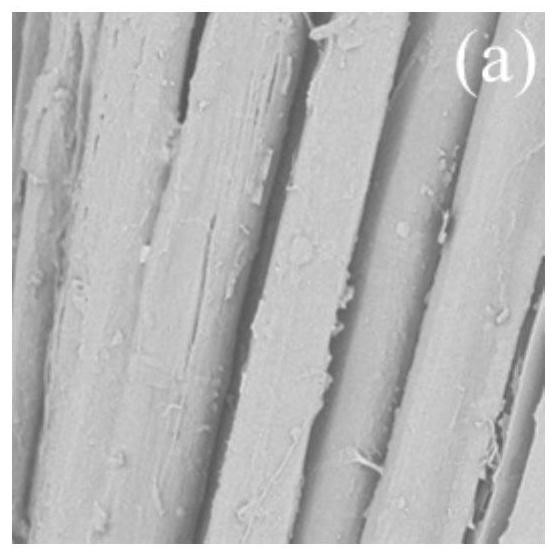

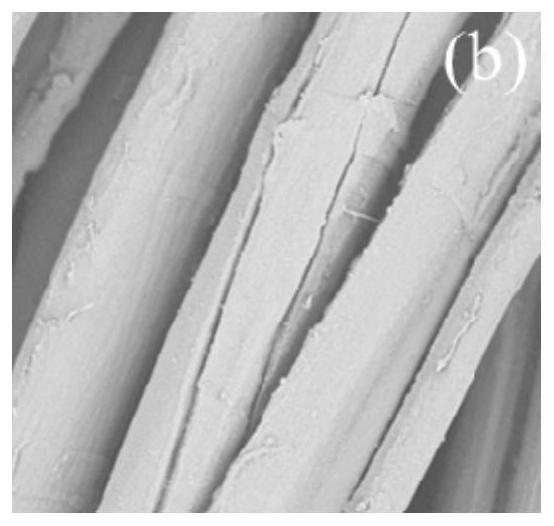

Novel linen yarn wet spinning process based on long linen

ActiveCN110257979AIncrease cohesionIncreased strength and uniformityLiquid/gas/vapor removalYarnYarnEngineering

The invention discloses a novel linen yarn wet spinning process based on long linen. The long linen is used as a raw material. The process includes following steps: (1), extending; (2), forming strips; (3), drawing; (4), roving; (5), spinning; (6), scouring and bleaching. Resultant yarn is high in quality, end breakage rate is lowered greatly, gaps exist among obtained linen fine yarn fiber, and hand feeling is softener. The problem in conventional scouring and bleaching and spinning processes is divided into rough yarn pre-bleaching-fine yarn final-bleaching, and the problem that conventional rough yarn scouring and bleaching degree is difficult in control is divided into two steps, so that controllability of the process is realized, and high resultant yarn quality of linen fine yarn is ensured.

Owner:YUYUE HOME TEXTILE +1

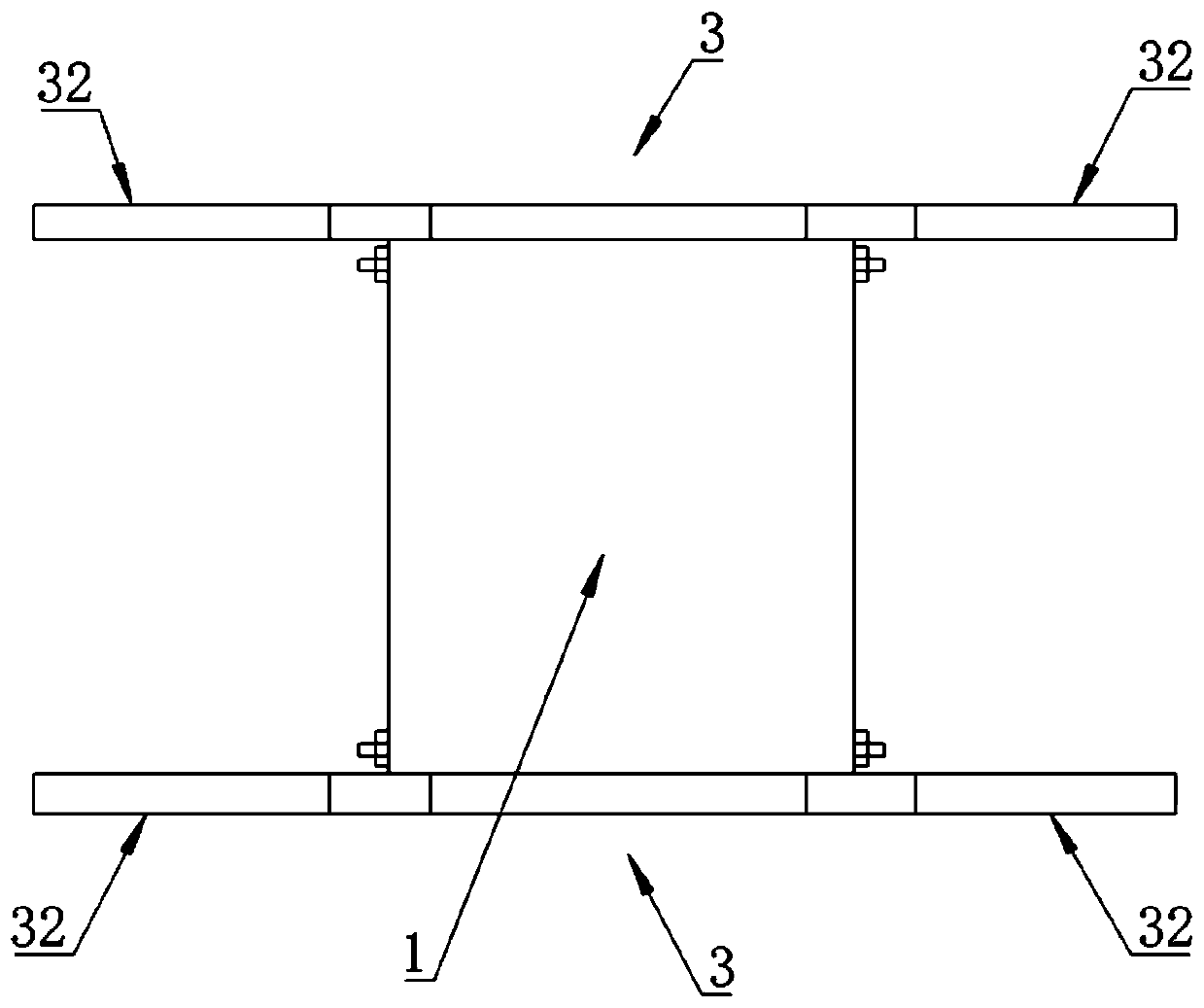

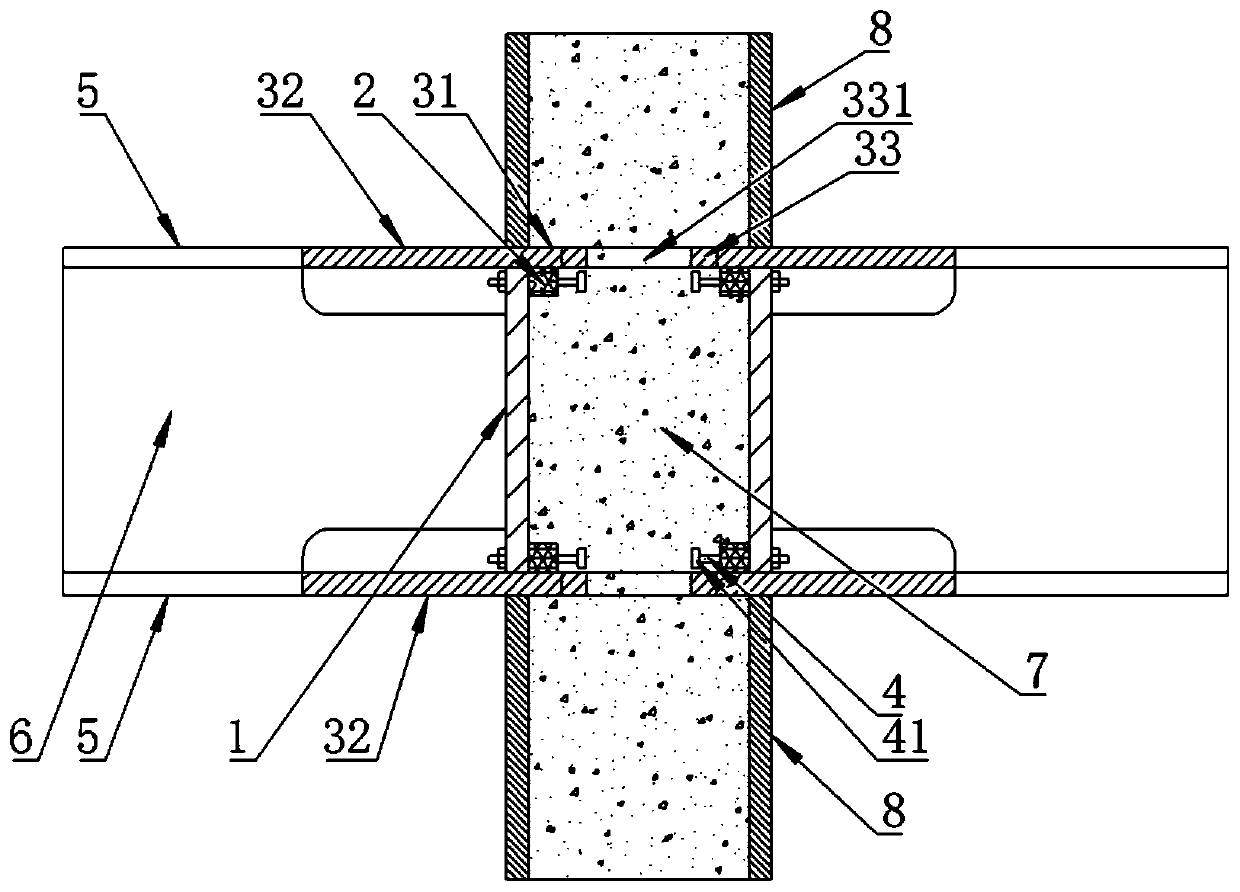

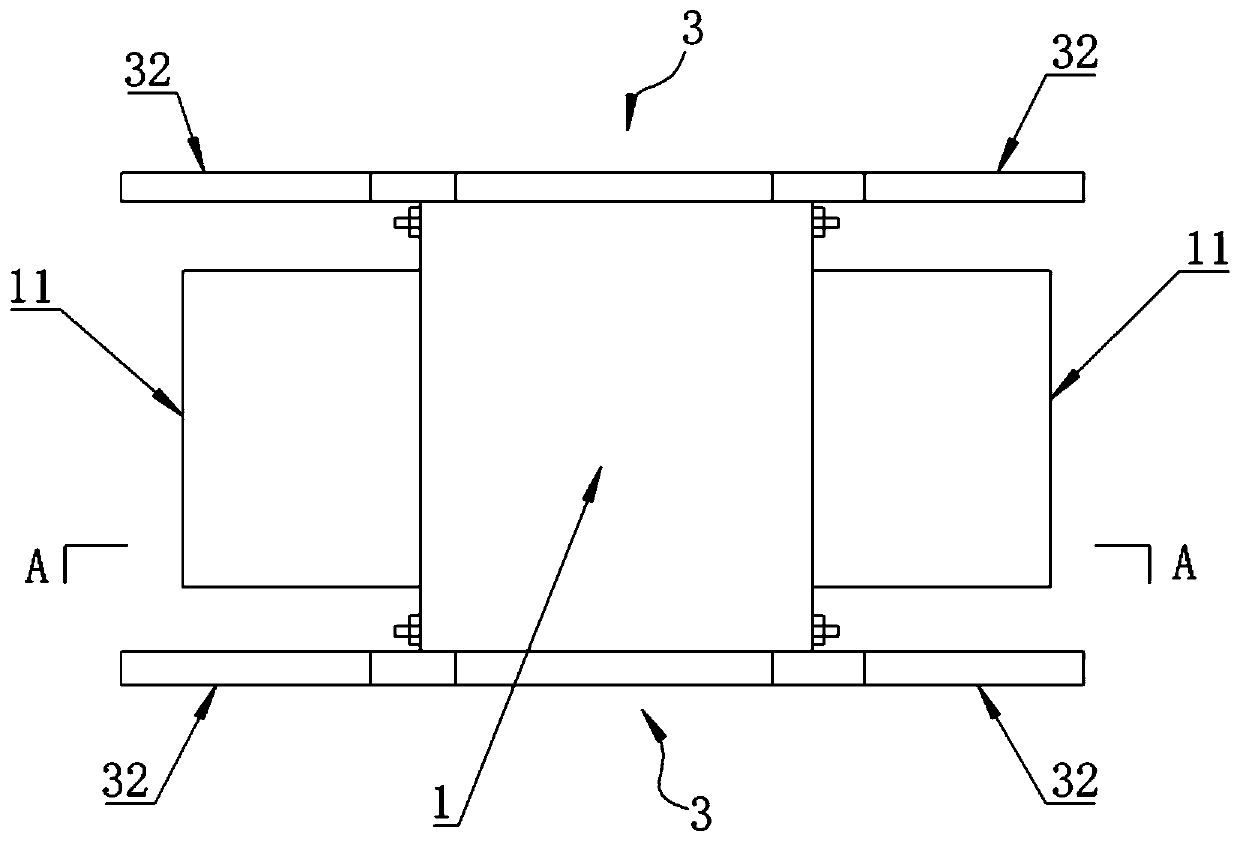

Through diaphragm type joint assembly, through diaphragm type beam column joint and building

PendingCN109914613AImprove deformation abilityImprove energy consumptionShock proofingEnergy consumptionBeam column

The invention provides a through diaphragm type joint assembly, a through diaphragm type beam column joint and a building, and belongs to the field of constructional engineering. The through diaphragmtype joint assembly comprises a joint core tube, diaphragms and damping blocks, wherein the interior of the joint core tube is used for pouring concrete, the outer wall of the joint core tube is usedfor being connected to a cross beam, the diaphragms are connected to the end parts of the joint core tube, each diaphragm comprises connecting portions located on the outer side of the joint core tube and an abutting portion located on the inner side of the joint core tube, the abutting portions are arranged along the inner side wall of the joint core tube and are connected to the connecting portions, and the damping blocks are arranged at included angles between the abutting parts and the inner side wall of the joint core tube. The through diaphragm type beam column joint adopts the throughdiaphragm type joint assembly. The building adopts the through diaphragm type joint assembly or the through diaphragm type beam column joint. According to the through diaphragm type joint assembly, the through diaphragm type beam column joint and the building, when the cross beam is deformed relative to the joint core tube, the abutting portions and the inner side wall of the joint core tube can extrude the damping blocks, the damping blocks absorb the deformation energy, so that the deformation capability and the energy consumption capability of the through diaphragm type joint are improved,and the brittle failure of the through diaphragm type joint is avoided.

Owner:INST OF ECONOMIC & TECH STATE GRID HEBEI ELECTRIC POWER +1

An automatic grinding head replacement device

ActiveCN106985069BWith gapIngenious structural designGrinding wheel securing apparatusGrinding machinesEngineeringManipulator

The invention discloses a device for automatically replacing a grinding head. The device comprises a rack as well as a three-dimensional manipulator mechanism, an electric drill key driving device and a grinding head storeroom mechanism which are arranged on the rack, wherein the three-dimensional manipulator mechanism is fixed at the upper left corner of the rack through an X-axis linear sliding table, and used for clamping grinding heads in the grinding head storeroom mechanism; the electric drill key driving device is fixed at the middle of the rack through a driving device mounting frame, and used for tightening or loosening an electric drill bit; and the grinding head storeroom mechanism is fixed at the middle of the rack through a magnet provided with a switch, positioned on the left side of the electric drill key driving device, and used for providing the grinding heads. The device is ingenious in structural design and reasonable in layout; the electric drill grinding head replacement quality and speed can be effectively improved; the application range is broad; and the widespread popularization and application are facilitated.

Owner:深圳市有控技术有限公司

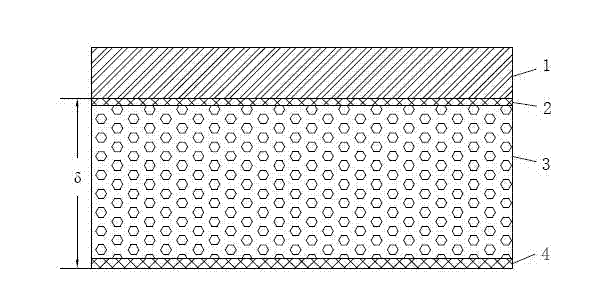

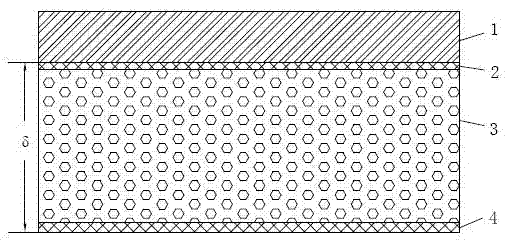

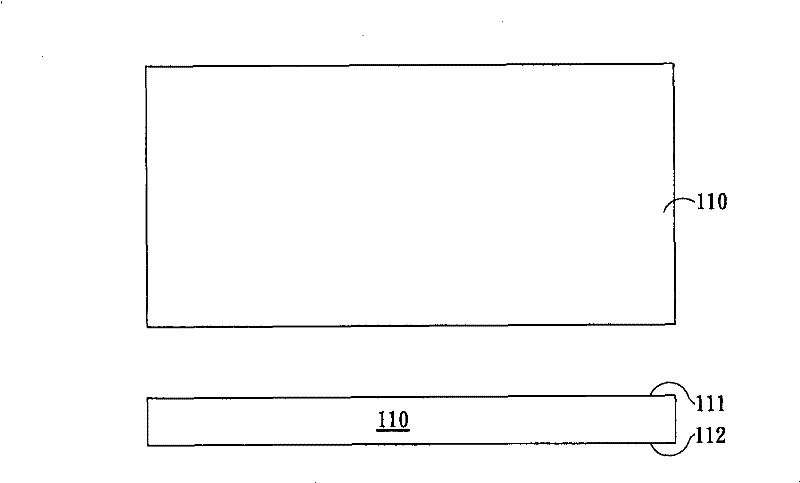

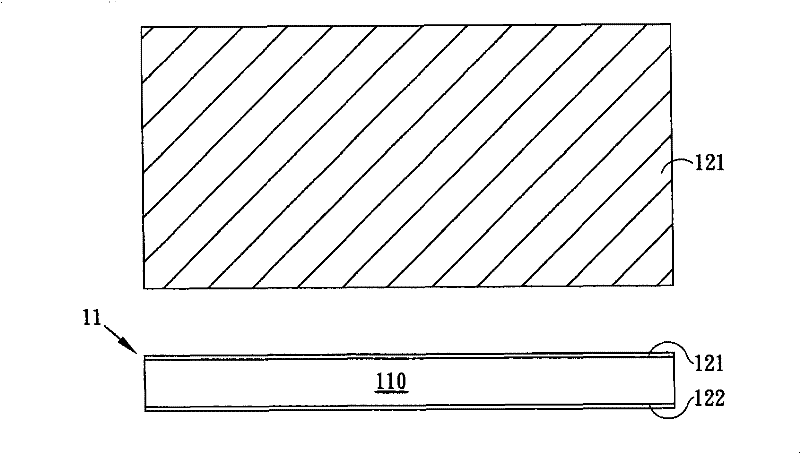

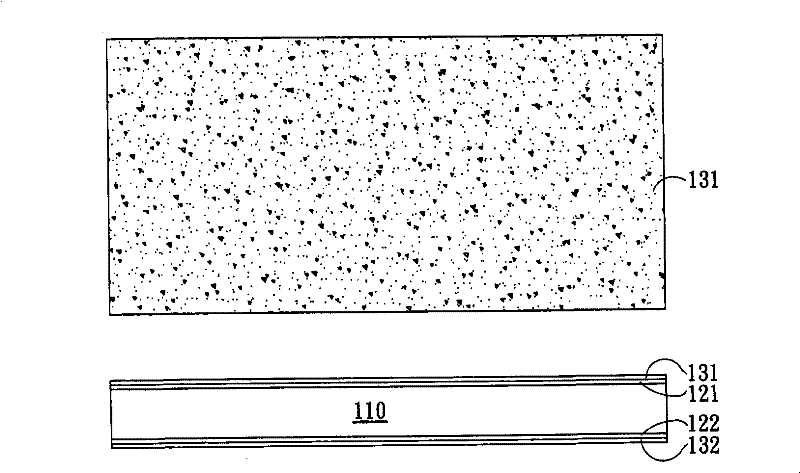

Composite board

ActiveCN101818538AHigh strengthFireproofConstruction materialCovering/liningsFiberglass meshGlass fiber

The invention discloses a composite board, which is formed by adhering a substrate and a wooden panel. The substrate is formed by bonding an upper fiberglass mesh fabric layer, a ceramsite concrete layer and a lower fiberglass mesh fabric layer, wherein the ceramsite concrete layer is formed by adding water and concrete stiffeners in quick-dry concrete, ceramsite and polyvinyl chloride foaming particles, stirring and condensing at the normal temperature, wherein the weight ratio of the quick-dry concrete, the ceramsite and the polyvinyl chloride foaming particles is 1:0.60-0.74:0.018-0.022; and the particle diameter of the polyvinyl chloride foaming particles is not more than 2.5mm. The composite board has the advantages of high intensity, fire prevention, insulation, weather resistance and light weight.

Owner:江苏长青艾德利装饰材料有限公司

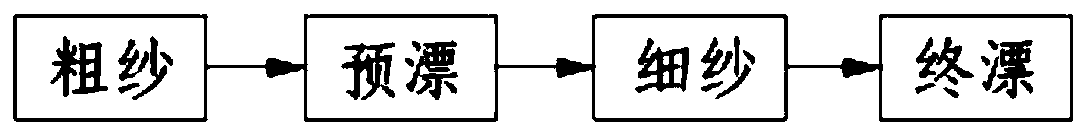

Novel scouring and bleaching technology for pure flax yarn

ActiveCN110284316AIncrease cohesionIncreased strength and uniformityLiquid/gas/vapor removalLiquid/gas/vapor yarns/filaments treatmentFlax fiberChemistry

The invention discloses a novel scouring and bleaching technology for a pure flax yarn. The technology comprises the following steps of 1, roving; 2, prebleaching; 3, spinning; 4, final bleaching. Cheese sleeves a creel and is placed in a scouring and bleaching pot. The steps of acid pickling, neutralization, primary bleaching, secondary bleaching and washing with water are implemented in sequence. According to the novel scouring and bleaching technology, it is guaranteed that a spun yarn is more even after being subjected to final bleaching, the strength of the spun yarn is guaranteed, the yarn formation quality is good, the final bleaching is greatly lowered, obtained spun flax yarn fibers have gaps, and the hand feeling is softer. According to the novel scouring and bleaching technology, the problem of traditional scouring and bleaching and spinning technologies is solved through thick yarn prebleaching-spun yarn final bleaching, the problem that the degree of traditional thick yarn scouring and bleaching is not easily controlled is solved through two steps, the controllability of the technology is achieved, and the high yarn formation quality of the flax fiber spun yarn is guaranteed.

Owner:YUYUE HOME TEXTILE +1

A Fishery Resource Monitoring System in Sea Area Restoration Area

ActiveCN108931234BImprove the effective monitoring areaSolve the problem that affects the clarity of the shootingWaterborne vesselsPhotogrammetry/videogrammetryMonitoring systemSeawater

The invention discloses a fishery resource monitoring system for a sea area repairing area. The invention aims at providing the fishery resource monitoring system for the sea area repairing area in order to effectively enlarge the effective monitoring area of floating fish eggs in water and effectively solve the problem of influences of accumulation or adhesion of sediments and the like on the shooting sharpness. The system comprises a floating frame floating on the sea, a balancing weight settling to the seabed, a suspending frame suspending in seawater, a fixed vertical pipeline arranged atthe upper opening and lower opening of the suspending frame, a mobile vertical pipeline slidably arranged at an upper opening and a lower sealing in the fixed vertical pipeline, a plurality of lateralwater feeding pipelines arranged at the lower part of the fixed vertical pipeline, an upper connecting rope for connecting the upper end of the floating frame with the mobile vertical pipeline, a tension spring positioned in the fixed vertical pipeline, a transverse rod positioned below the fixed vertical pipeline, a vertical connecting rod for connecting the transverse rod with the suspending frame, a lower connecting rope for connecting the transverse rod with the balancing weight, and a floating detector arranged on the fixed vertical pipeline.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Hydraulic elongator calibration device

PendingCN110208021AImprove unbalanced load phenomenonReduce connectorsStructural/machines measurementApparatus for force/torque/work measurementEngineeringForce sensor

The invention relates to the technical field of mechanical metering detection, in particular to a hydraulic elongator calibration device, comprising a first support plate, a load cell, a second support plate, a test pull rod, a first fastener and a second fastener, wherein the test pull rod is sequentially disposed on the first support plate, the load cell and the second support plate in a penetration manner, and the first fastener and the second fastener are respectively located on both ends of the test pull rod and are relatively locked; the first end of the test pull rod extends out from the first fastener to form an elongator connecting portion for connecting the hydraulic elongator, and a force eccentric load elimination structure for correcting an acting force applied by the second support plate to the second fastener is further arranged between the second fastener located at the second end of the test pull rod and the second support plate. The hydraulic elongator calibration device provided by the invention has fewer connecting pieces, is convenient to carry, can realize onsite measurement and calibration, and greatly improves the eccentric load phenomenon between the secondfastener and the second support plate through the force eccentric load elimination structure.

Owner:广东省中山市质量计量监督检测所

Planting method for Pleurotus citrinopileatus

ActiveCN109122019APromote growthQuality improvementCultivating equipmentsMushroom cultivationBiologyFresh air

The invention relates to the field of mushroom planting, and discloses a planting method for Pleurotus citrinopileatus. The planting method comprises the following steps: A, preparation of a culture material; B, preparation of mushroom bags; C, inoculation; D, transportation of the mushroom bags; E, culturing with the mushroom bags; F, fruiting; and G, harvesting. According to a scheme of the invention, sufficient fresh air is supplied for the sporocarp of the Pleurotus citrinopileatus; the growth of the sporocarp is greatly promoted; and the fruiting quality and yield of the Pleurotus citrinopileatus are improved. In addition, water mist sprayed from atomizing nozzles can be more dispersed through rotation of a rotating plate, so the humidity of the surrounding air of the mushroom bags during fruiting is increased; growth of the sporocarp is further promoted; and the fruiting quality and yield of the Pleurotus citrinopileatus are improved.

Owner:遵义新蓝图休闲农业发展有限公司

Overvoltage protection element and manufacturing method thereof

InactiveCN101752790BImprove verticalityImprove featuresEmergency protective arrangements for limiting excess voltage/currentOvervoltage arrestors using spark gapsOvervoltageEngineering

The invention relates to an overvoltage protection element and a manufacturing method thereof. The overvoltage protection element comprises a basal plate and a pair of electrode layers, wherein a clearance is arranged between electrode layers, a shade layer is arranged above the clearance and part of the electrode layers, and the shade layer and the clearance are covered by a sealing layer. The invention also provides the manufacturing method of the overvoltage protection element, which comprises the following steps: providing the basal plate; forming a first light obstruction layer on the basal plate; forming a patterning metal layer on the first light obstruction layer; taking the patterning metal layer as an exposure light cover and exposing and developing the first light obstruction layer so as to expose part of the basal plate; removing the patterning metal layer; forming a pair of electrode layers on the exposed basal plate, wherein the clearance is arranged between the electrode layers; and forming the sealing layer covering the clearance. The metal electrodes of the invention have end faces with better verticality, and the condition that substances except for air is remained in the clearance between the two metal electrodes can be effectively avoided so as to obtain a better product property, so that the invention is more suitable for practical use.

Owner:CYNTEC

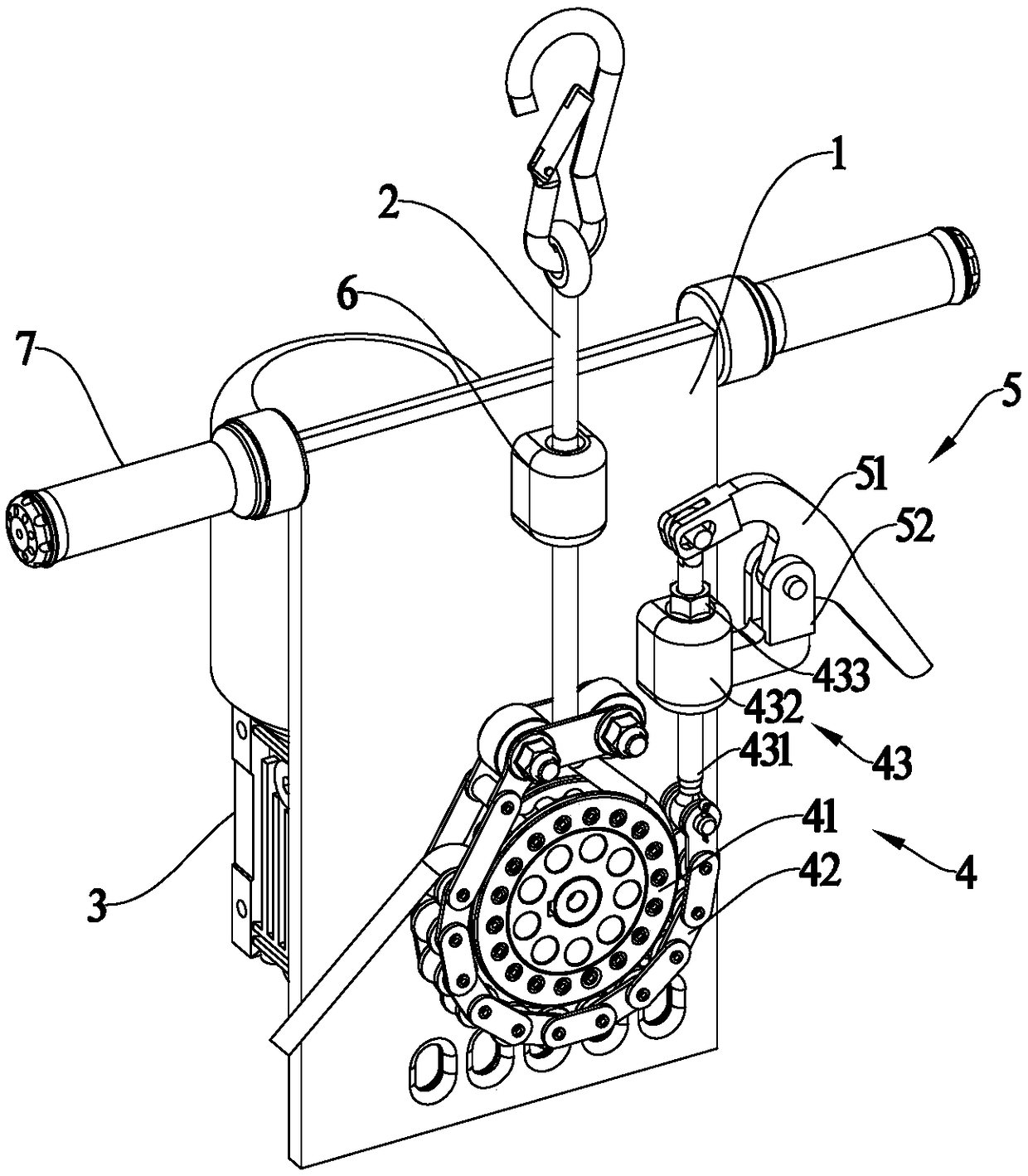

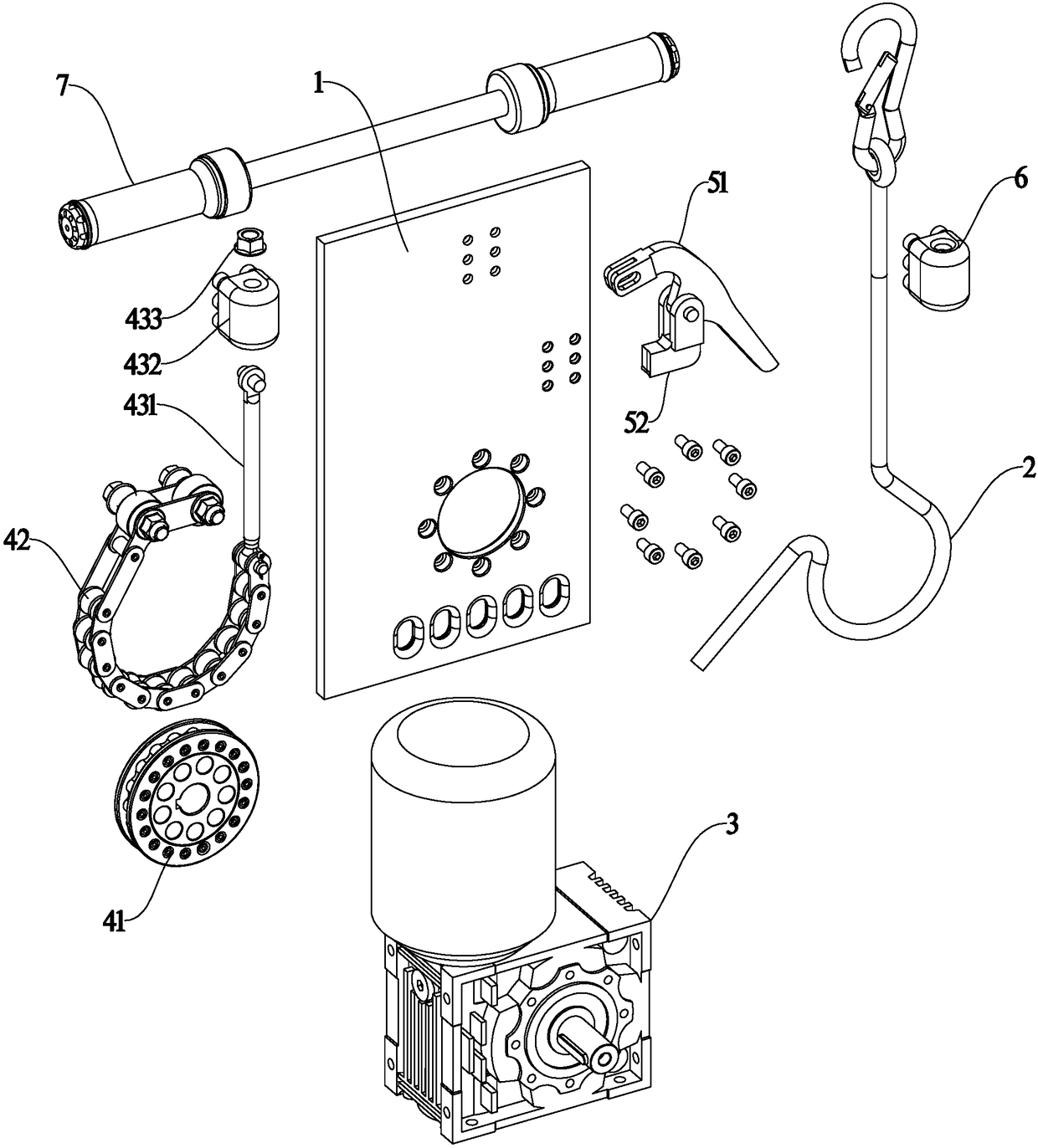

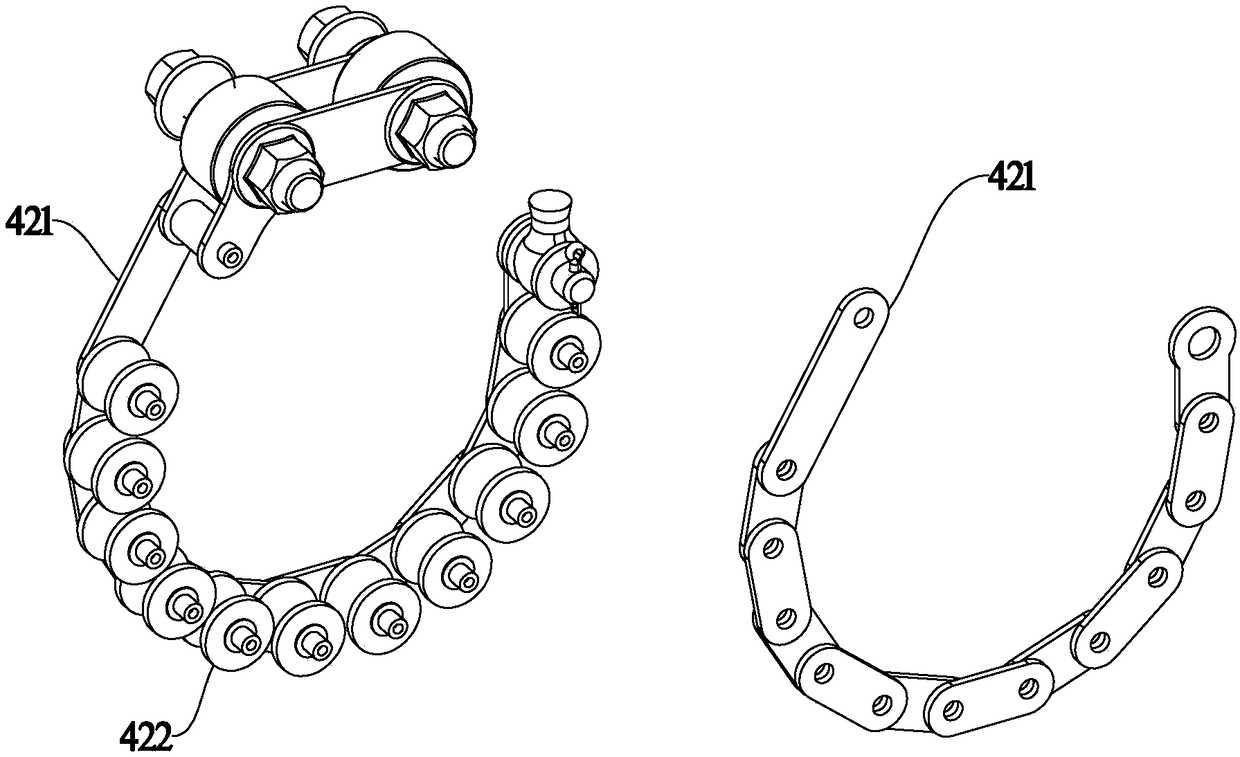

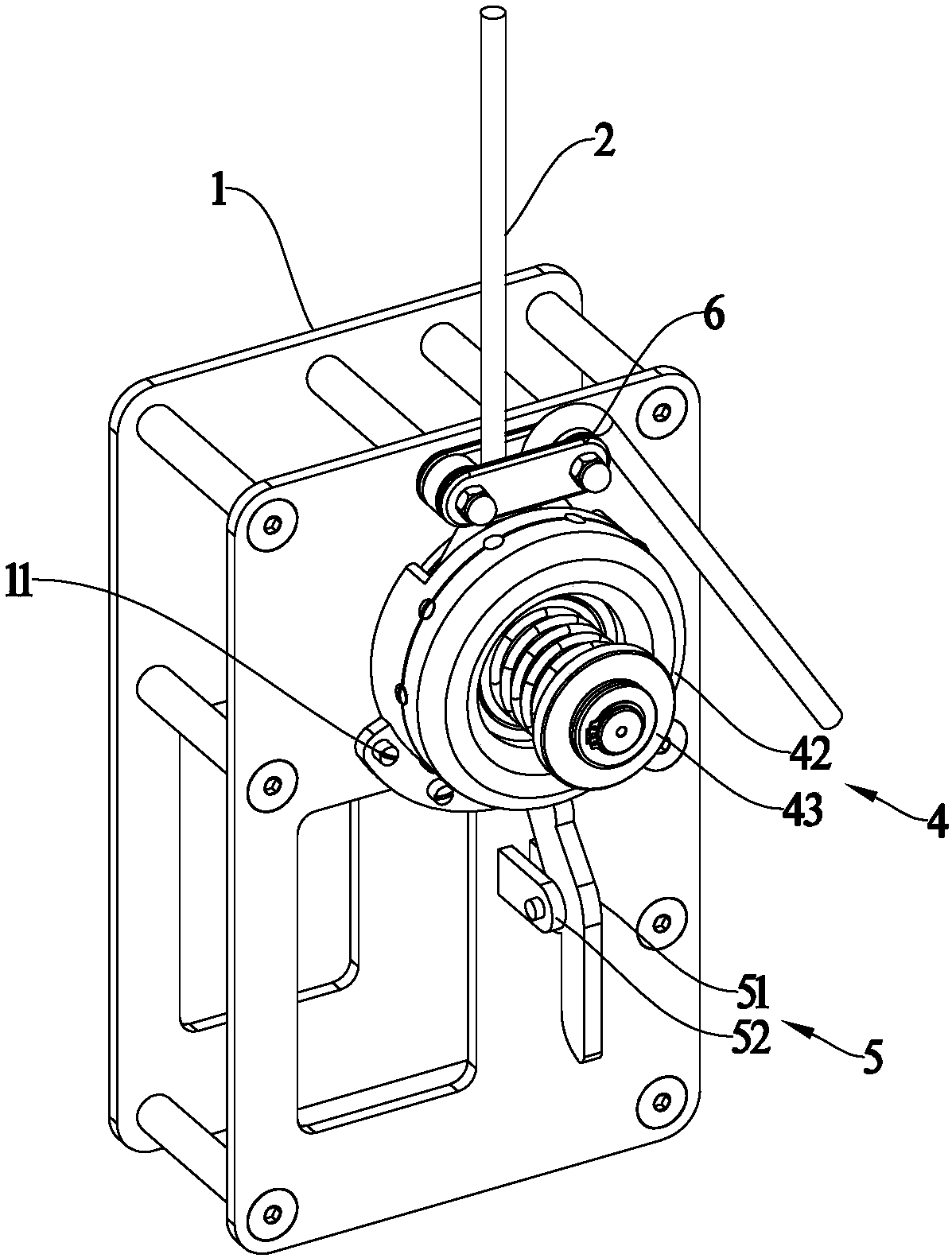

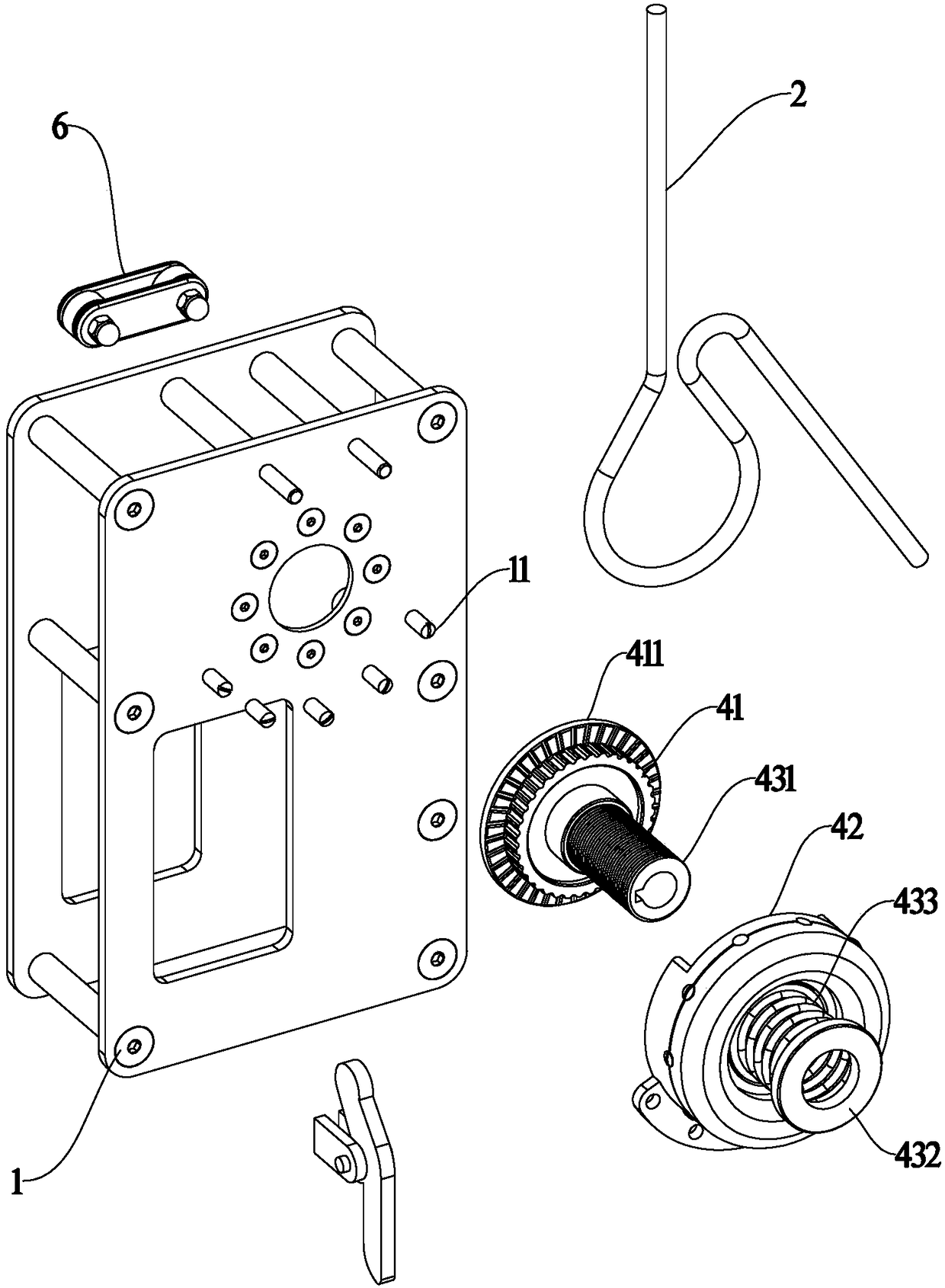

Radial pressing mechanism and lifting device comprising same

The invention provides a radial pressing mechanism. The radial pressing mechanism comprises a rotating disc and a pressing part; the pressing part is of a chain structure and comprises chain plates and idler wheels; the chain plates are sequentially articulated; the idler wheels are articulated between the chain plates positioned at the two sides; the two ends of the pressing part are fixed and are arranged at the periphery of the rotating disc; a rope penetrates through the position between the rotating disc and the pressing part; the rope is pressed by the idler wheels so as to make contactwith the rotating disc; when the rotating disc runs on the rope, the rope is used for driving the idler wheels to rotate; the invention also provides a lifting device; the lifting device comprises a frame, the rope, a power mechanism and the radial pressing mechanism; the radial pressing mechanism has the advantages of simple structure, small abrasion, little generated heat, long service life andreliable pressing; and the lifting device comprising the radial pressing mechanism has the advantages of being simple in structure, safe, reliable and long in service life.

Owner:浙江弘安智能科技有限公司

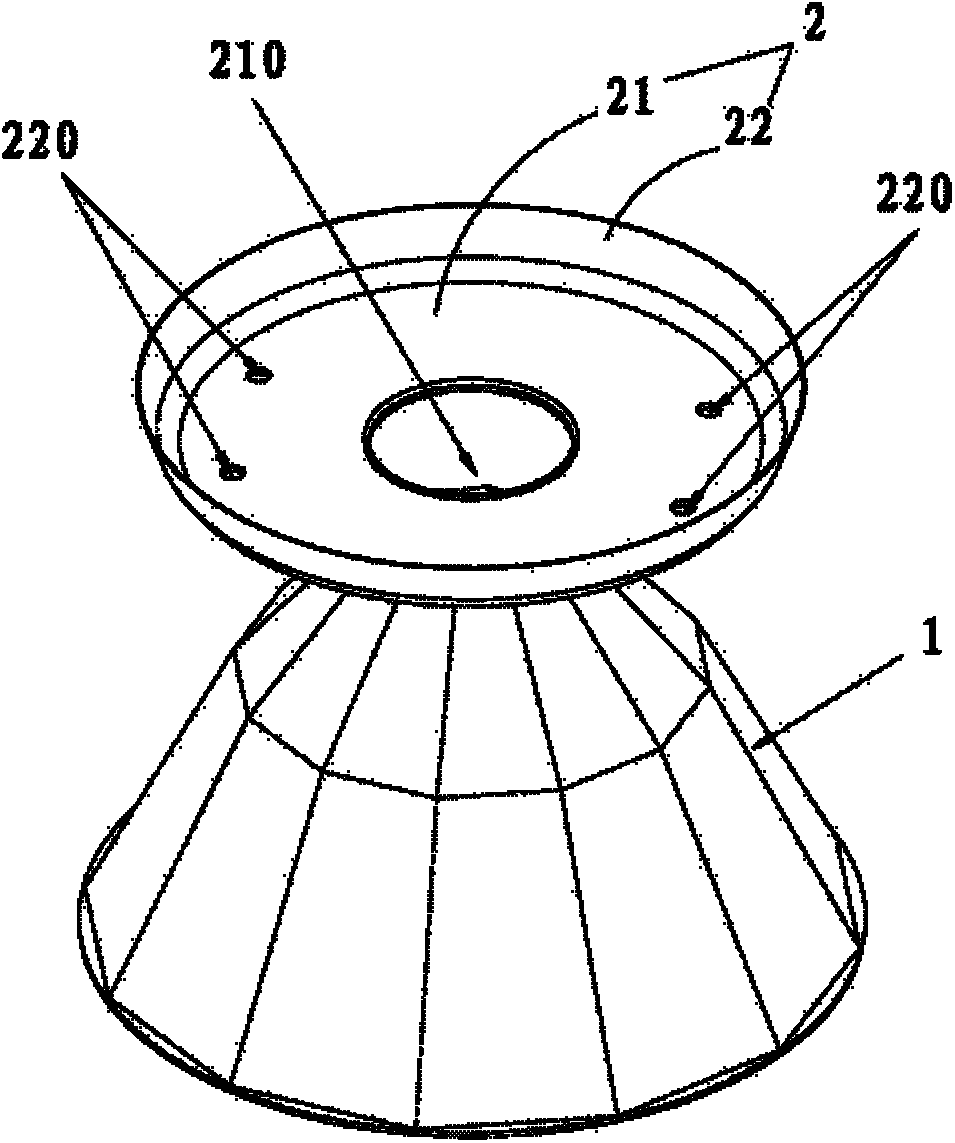

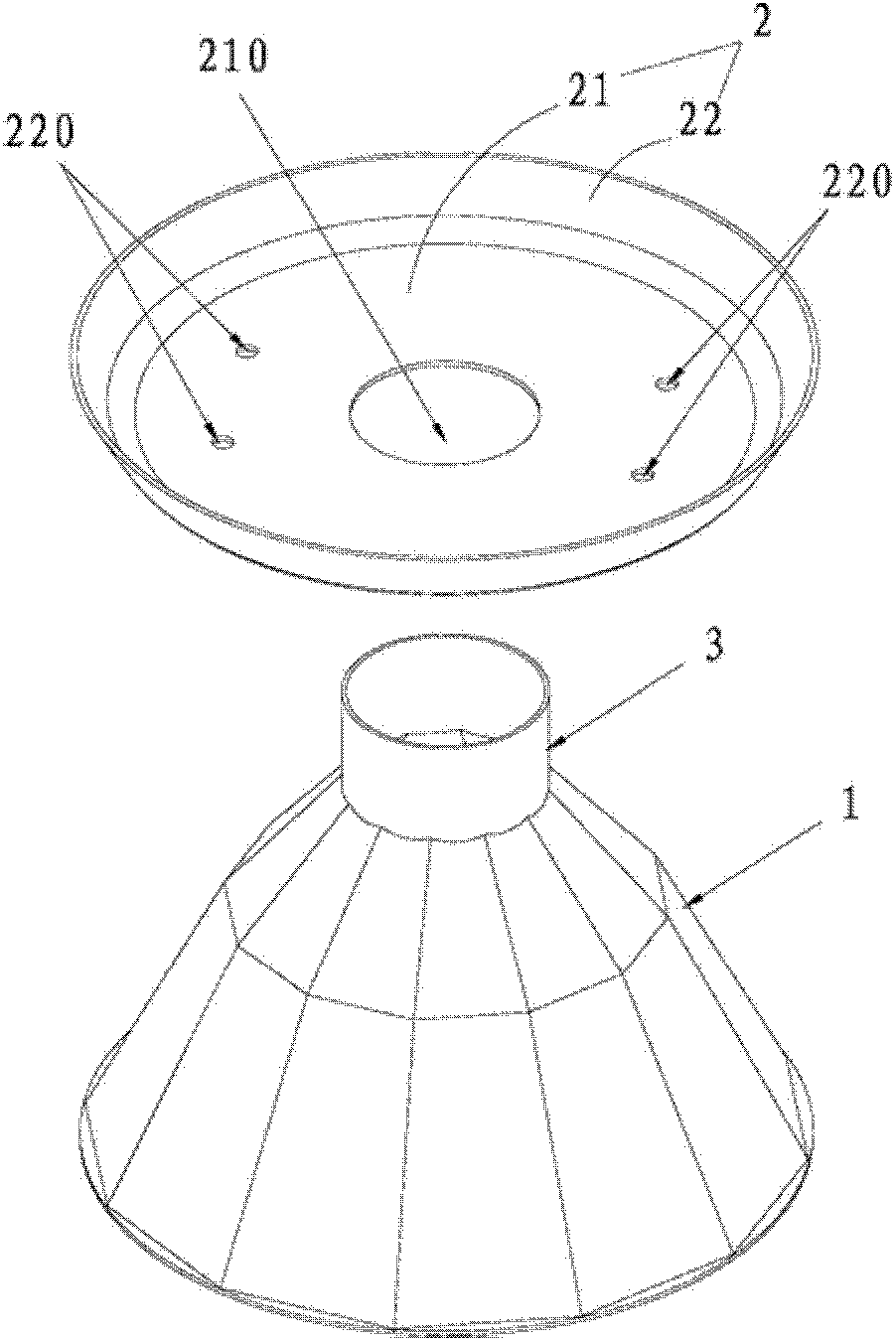

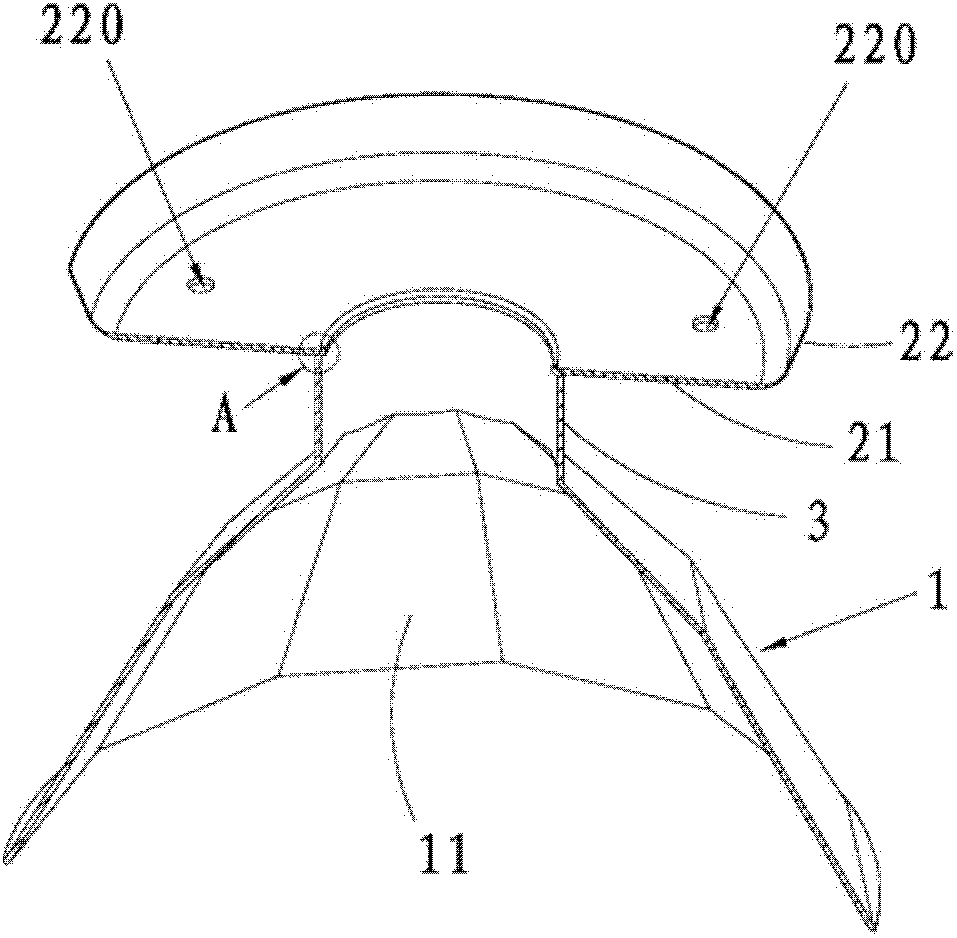

Multifunctional reflector and down lamp

InactiveCN103017087BSimple structureLow costLighting heating/cooling arrangementsGas-tight/water-tight arrangementsLight equipmentHeat conducting

The invention is applicable to the technical field of lighting equipment, and provides a multifunctional reflector and a down lamp. The multifunctional reflector comprises a reflective cup, and a heat insulating plate, wherein the heat insulating plate is arranged at the tail end of the reflective cup and consists of a heat insulating bottom board and heat conducting sheets rolling over along the edge of the heat insulating bottom board, a through hole is arranged in the center of the heat insulating bottom board, a barrel capable of penetrating the through hole in a matching manner is arranged at the tail end of the reflective cup, and the heat insulating plate is sheathed on the barrel through the through hole and is connected with the reflective cup. The down lamp adopts the multifunction reflector. The multifunctional reflector is simple in structure, low in cost and convenient to install, not only has good reflection function, but also has good function of reducing the internal temperature of the down lamp, thereby being capable of effectively playing roles of protecting a light source and a lamp cap, and also greatly reducing the possibilities of causing safety accidents due to ultrahigh temperature in the down lamp.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Axial compression slow descending device

The invention relates to an axial compression slow descending device which is characterized by comprising a rack, a rope and an axial compression mechanism. The rope penetrates the axial compression mechanism, the axial compression mechanism comprises a rotary disc and a compression piece, the rotary disc is rotationally arranged on the rack, the peripheral side of the bottom of the rotary disc extends out of a supporting table, the rope surrounds the periphery of the rotary disc in the peripheral direction of the rotary disc and is arranged on the supporting table, the compression piece comprises a compression shell and a compression roller, the compression roller is rotationally arranged on the compression shell, the compression shell can be fixed in the axial direction of the rotary disc, and the compression roller presses the rope to be in contact with the supporting table in the axial direction of the rotary disc; and when the rotary disc rolls on the rope, the rope drives the compression roller to rotate. The axial compression slow descending device has the beneficial effects of being simple in structure, small in abrasion, less in generated heat, safe, reliable and long in service life.

Owner:浙江弘安智能科技有限公司

A kind of boiling and bleaching process for pure linen yarn

ActiveCN110284316BHigh strengthImprove uniformityLiquid/gas/vapor removalLiquid/gas/vapor yarns/filaments treatmentYarnPulp and paper industry

The invention discloses a novel boiling and bleaching process for pure flax yarn, comprising the following steps: (1), roving, (2), pre-bleaching, (3), spun yarn, (4), final bleaching: the bobbin The yarn is set on the creel, put into the bleaching pot, and carried out in the following order: a, pickling; b, neutralization; c, initial bleaching; d, rebleaching; e, washing. The invention ensures that the final bleaching of the spun yarn is not only more uniform, but also strong, the yarn quality is good, the broken end rate is greatly reduced, and the obtained flax spun yarn has gaps between fibers, and the handle is softer. The present invention divides the problems in the traditional scouring and bleaching and spinning processes into roving pre-bleaching and spun yarn final bleaching, and divides the difficult problem of traditional roving scouring and bleaching into two steps, which realizes the controllability of the process and ensures the hemp fiber spun yarn Higher yarn quality.

Owner:YUYUE HOME TEXTILE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com