Iron core plate annealing clamp

An iron core sheet and annealing technology, which is applied in the field of transformer production, can solve the problems of annealing, difficulty in annealing operation, and inability to stack iron core sheets into piles, etc., and achieve the effect of guaranteeing the technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. A preferred embodiment of the invention is shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

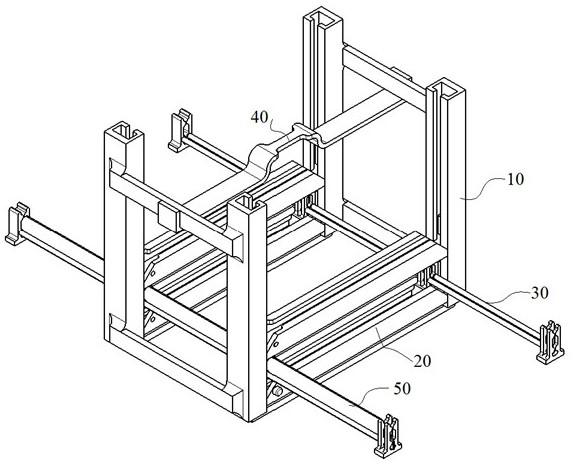

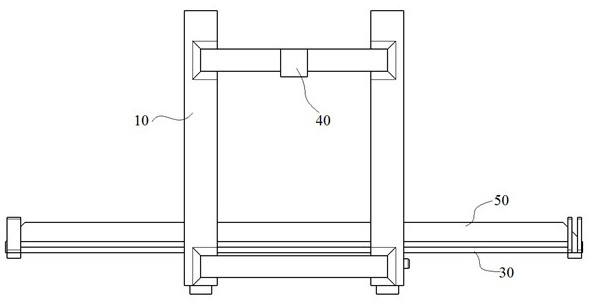

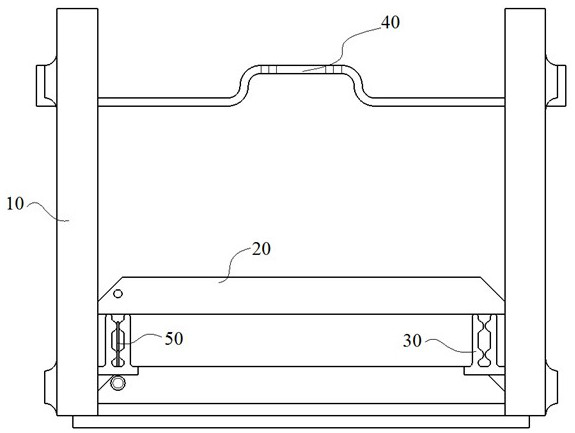

[0018] see Figure 1-Figure 4 The iron core piece annealing jig shown includes frame 10 , beam 20 , bracket 30 and handle 40 , beam 20 is installed on frame 10 , bracket 30 is installed on beam 20 , and handle 40 is installed on top of frame 10 .

[0019] Frame 10 comprises column 11, vertical T groove 12, bottom beam 13 and side beam 14, and column 11 has four, and column 11 center has vertical T groove 12, and a pair of bottom beam 13 and four side beams 14 combine four Uprights 11 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com