Novel linen yarn wet spinning process based on long linen

A flax yarn and long hemp technology, which is applied in the processing of yarn, textiles, papermaking and textile materials, etc., can solve the problems of reduced spun yarn strength, high cost, restricted production efficiency, etc., and achieves improved strength and uniformity. The effect of reducing and increasing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

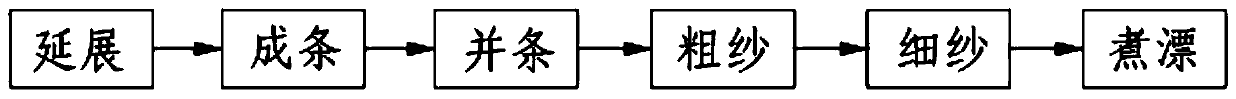

[0038] Such as figure 1 Shown, a kind of novel flax yarn wet-spinning process based on hemp, comprises the following steps:

[0039] (1) Stretching: The long-fiber hemp sheets mixed with fixed weight are combed and blended into a certain length of hemp belt by two stretching machines;

[0040] (2), slivering: the hemp ribbon of gained certain length is made into continuous hemp sliver through needle combing and drafting of sliver making machine;

[0041] (3) Drawing: Merge two or more hemp slivers, and through the needle combing action of the multi-channel drawing frame, the hemp fibers are further straightened and paralleled, mixed evenly, and made into a certain fineness of hemp sliver;

[0042](4), roving: the hemp slivers after drawing and drafting are drawn into roving by roving frame, twisted and processed to make roving, and the roving is wound to form package roving;

[0043] (5), pre-bleaching: the package roving is treated in a water bath, the pH range of the water...

Embodiment 2

[0054] The same parts of this example and Example 1 will not be repeated, and the difference is: step (5), pre-bleaching: the package roving is treated in a water bath, the pH range of the water bath is 3.5, the temperature of the water bath is set to 60 ° C, and the water bath is treated. The time is 30 minutes; the water bath solution for treating the flax roving in a water bath is water or an aqueous solution containing an acidic agent. The aqueous solution containing the acidic agent is an aqueous solution of acetic acid. Pre-soaking the roving in an acidic environment can rapidly expand and soften the pectin on the fiber surface, and strengthen the cohesion between the fibers that make up the flax roving, thereby improving the strength of the flax roving and breaking the spun yarn when spinning The rate is reduced, and the spinning strength is improved. And because the pectin expands and softens, the pectin can be more easily dissolved when the spun yarn is boiled and bl...

Embodiment 3

[0062] The same parts of this embodiment as in Embodiments 1 and 2 will not be repeated. The difference lies in: step (5), pre-bleaching: the packaged roving is treated in a water bath, the pH range of the water bath is 7, and the temperature of the water bath is set to 100°C. The water-bath treatment time is 15 minutes; the water-bath solution for the water-bath treatment of flax roving is water. (6), scouring and bleaching: the cheese is set on the creel, put into the scouring and bleaching pot, and proceed in the following order:

[0063] c. Initial bleaching: prepare the initial bleaching liquid, fill another container with water, and raise the temperature to 32°C, add pectinase and penetrant with a mass concentration of 2.90g / l respectively, stir and mix thoroughly to form the initial bleaching liquid, and then put the initial bleaching Pour the liquid into the blanching pot, raise the temperature to 60°C, keep warm for 40 minutes, and drain the liquid; the penetrating ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com