Reinforced structure of seam tank and large-scale helical double-folded seam tank with this structure

A technology of strengthening structure and double folded edge, applied in the direction of large containers, containers, packaging, etc., can solve the problems of detachment, inability to make large or super large spiral double folded occlusal cans, and reduced sealing of occlusal ribs, etc. Structural strength and distance, the effect of avoiding being pulled apart or even detached, avoiding leakage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

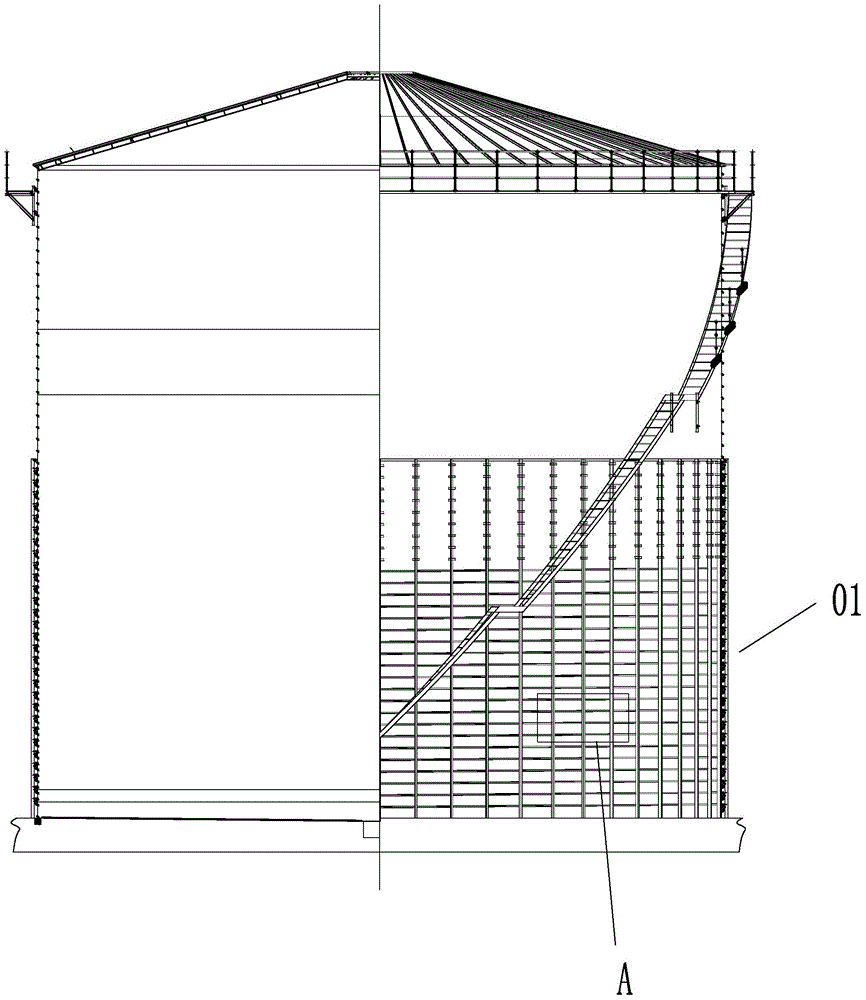

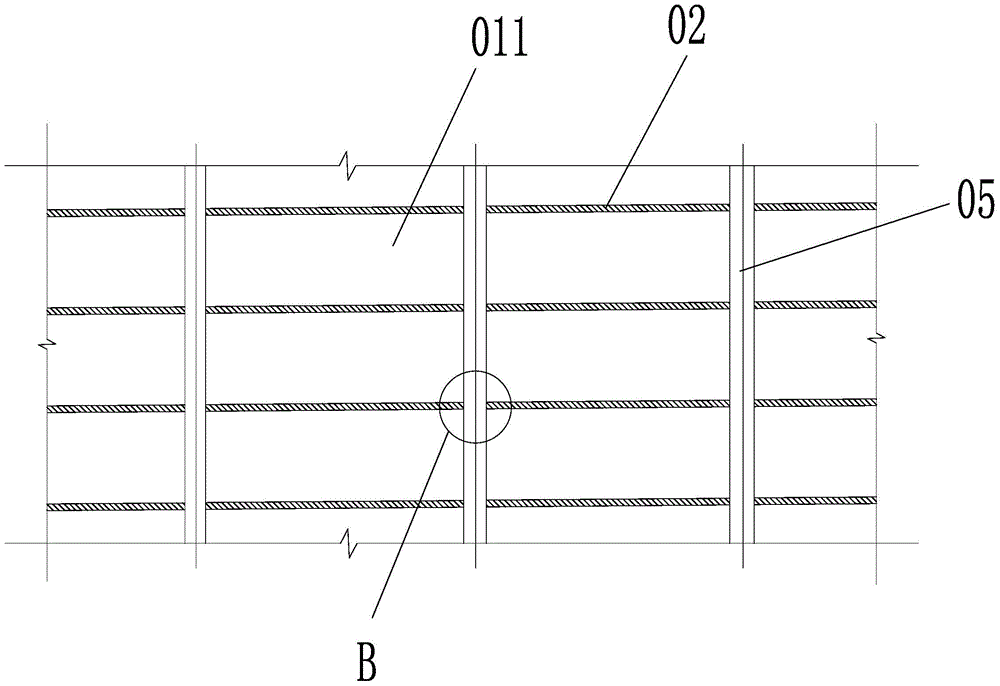

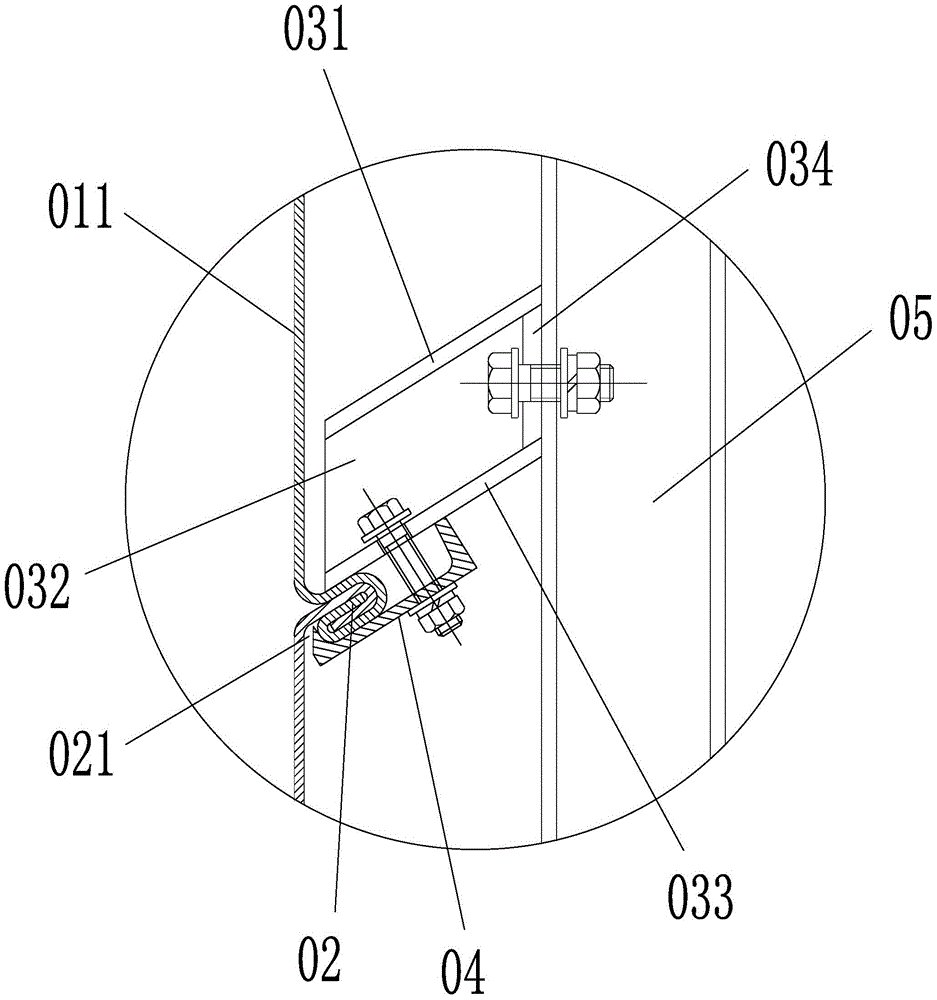

[0026] Embodiment 1: as figure 2 As shown, a helical double-folded seaming tank reinforcement structure includes a seaming rib 02, and an excessive bending angle 021 is formed between the seaming rib 02 and the tank wall 011, and the seaming rib is a spiral double-folding structure. A vertical reinforcing rib 05 is installed on the side of the occlusal rib away from the tank wall, and the reinforcing rib 05 can be made of channel steel. The occlusal rib is provided with a connecting piece that is entangled with the excessively bent angle, and the occlusal rib is fixedly connected with the reinforcing rib through the connecting piece. Such as image 3 As shown, the connector includes a support rib 03 located above the articulation rib and a connecting rib 04 located below the articulation rib. Such as image 3 , 5 As shown, the cross section of the supporting rib is in the shape of "concave". The supporting rib includes an upper rib plate 031, a lower rib plate 033 and a v...

Embodiment 2

[0029] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 6 , 7 As shown, a ring rib 06 is arranged between the upper and lower adjacent occlusal ribs, and the ring rib 06 can be made of channel steel. One side of the ring rib is against the outer surface of the tank wall, and the ring rib is connected with the reinforcing rib by the adjustable bolt 07. The ring ribs can surround the tank body end to end, or surround the tank body in multiple intervals. A ring rib is set between the upper and lower adjacent occlusal ribs. One side of the ring rib is against the outer surface of the tank wall. The ring rib and the reinforcement rib are connected together by adjustable bolts. When the pressure in the tank is exerted from the inside to the outside , the ring rib can withstand the outer surface of the tank wall to ensure that the tank wall is always in a vertical state, avoid the tank wall from bulging...

Embodiment 3

[0030] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 8 , 9 As shown, the connector includes a rectangular rib plate 08, one side of the rectangular rib plate is provided with an engagement groove 081 matching the outer surface of the articulation rib, and the side of the rectangular rib plate away from the articulation rib is attached to the reinforcing rib and fixed with bolts. The connector can also include a rectangular rib plate, one side of the rectangular rib plate is provided with an engagement groove that matches the outer surface of the articulation rib, and the engagement groove can completely fit the outer surface of the articulation rib to limit each point on the outer surface of the articulation rib, When the occlusal rib is under tension, the engagement groove of the rectangular rib plate can prevent the occlusal rib from being pulled apart, and the side of the rectangular rib plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com