Reinforced concrete pipe jacking pipe joint and machining die thereof

A reinforced concrete and mold processing technology, which is applied in the direction of manufacturing tools, sewer pipeline systems, waterway systems, etc., can solve the problems of affecting the service life of pipe jacking, unfavorable pipe jacking construction, and hindering pipe joint jacking construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

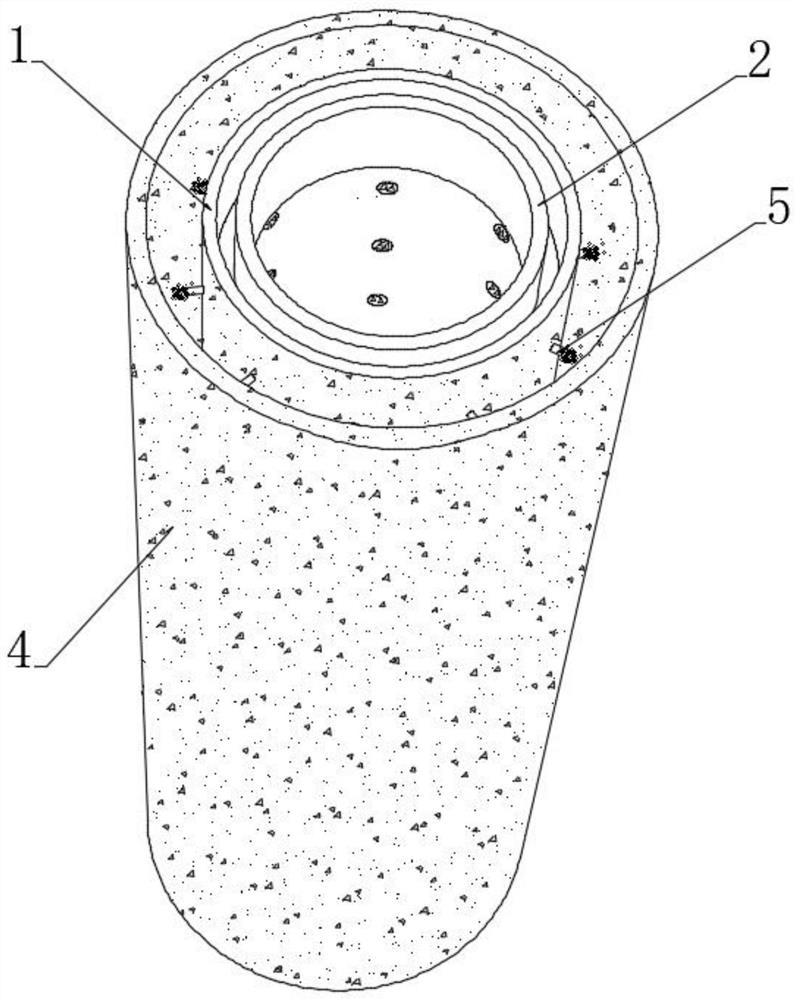

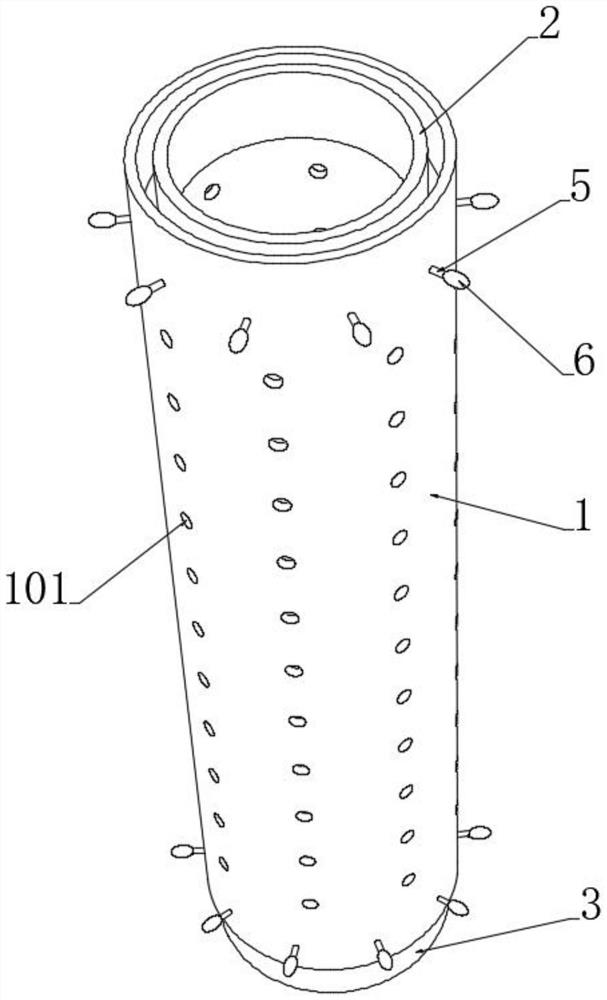

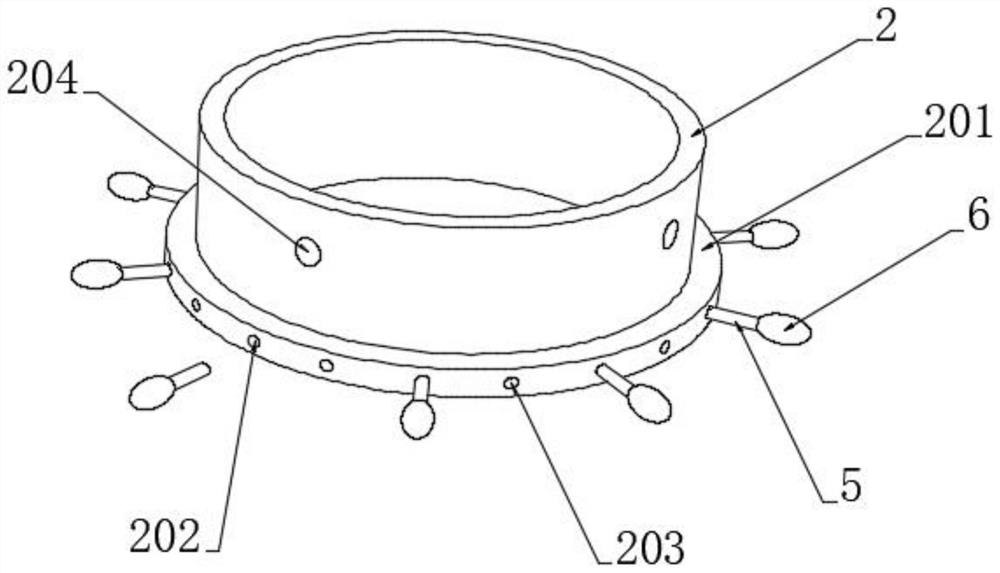

Embodiment 1

[0043] see Figure 1-5 , the reinforced concrete pipe jacking pipe joint, including the thin inner steel bar 1, the upper and lower ends of the inner steel bar thin tube 1 are respectively fixedly connected with the outer connecting tube 2 and the inner supporting tube 3, and the inner supporting tube 3 is exposed at one end of the outer side of the inner reinforcing bar thin tube 1 It is the inner connection part, and the outer side of the outer connection pipe 2 is provided with an outer bearing cavity 201 for matching the inner connection part. When the pipe joints are butted, the inner connecting part on the inner bearing pipe 3 is fastened to the outer bearing cavity 201 of the outer connecting pipe 2. The end walls are connected and embedded to realize the sealing of the connection of the pipe joints. The outer connection pipe 2, the inner support pipe 3 and the inner wall of the thin inner steel tube 1 are connected. One end is the upper joint part and the lower joint p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com