Patents

Literature

71 results about "Flax basis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flax basis is a moth of the Micronoctuidae family. It is found in Laos (Vientiane), in Southeast Asia.

Bleaching work fluid of flax, flax/cotton fabric and low temperature bleaching technology

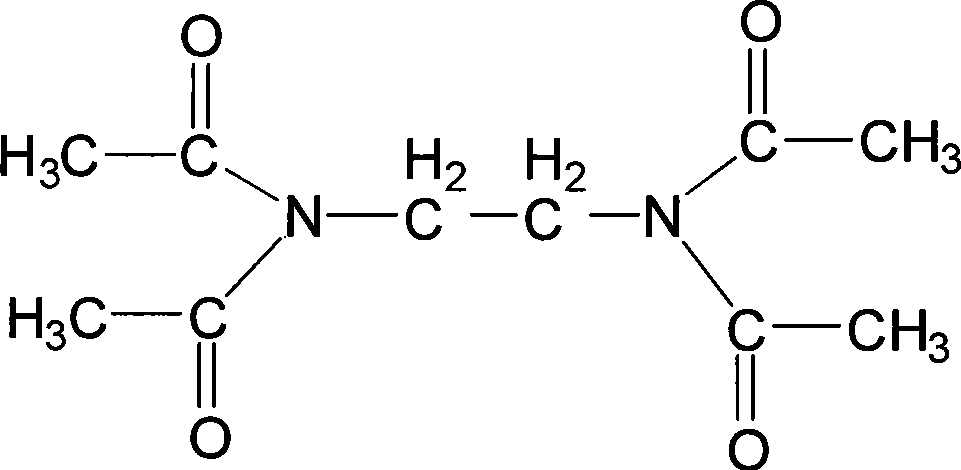

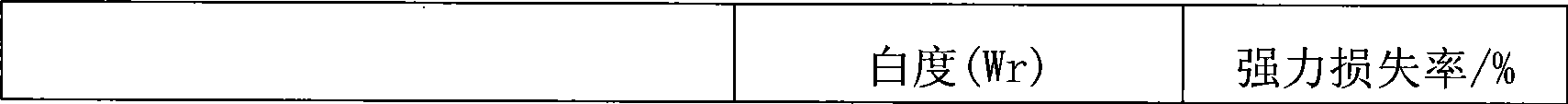

InactiveCN101392453AReduce stacking timeReduce dosageBleaching apparatusEthylene diamineAdditive ingredient

The invention discloses a bleaching working fluid of the flax fabric or flax / cotton fabric and a low-temperature bleaching technology using the working fluid. One formula of the bleaching working fluid is as follows: each liter of the working fluid comprises the following ingredients: 1-20g / L of H2O2 with the concentration of 30 percent, activating agent TAED (Tetra Acetyl Ethylene Diamine) with the mol ratio of 1 / 15:1-1:1 with the H2O2, 0.1-10g / L of stabilizing agent, 0.1-5g / L of penetrating agent and the rest is water. The low-temperature bleaching technology adopting the bleaching working fluid formula is the bleaching technology in low-temperature bath. Another formula of the bleaching working fluid is as follows: each liter of the fluid comprises 10-50g / L of H2O2 with the concentration of 30 percent, activating agent TAED (Tetra Acetyl Ethylene Diamine) with the mol ratio of 1 / 15:1-1:1 with the H2O2, 0.1-10g of stabilizing agent and the rest is water. The low-temperature bleaching technology adopting the bleaching working fluid formula is cold pad-batch bleaching technology. The invention adopts the TAED as the activating agent, introduces oxydol / TAED bleaching system, has better bleaching effect, can reduce the damage of the fabrics and improves the production efficiency.

Owner:杭州鑫至投资管理有限公司

Blended yarn of flax and tencel and producing technology thereof

InactiveCN1920138ANo damage to physical and chemical propertiesHygroscopicYarnLiquid/gas/vapor textile treatmentYarnBoiling process

The invention relates to a blended yarn of flax and Tencel fiber, wherein the flax is 50-60%; the Tencel fiber is 40-60%; and its preparation comprises: (1) preparing the flax into blended yarn bar to be mixed with Tencel fiber into bar, and combining the bars into thick yarn; (2) boiling said thick yarn into thin yarn; (3) drying the thin yarn and winding to prepare the blended yarn; and the boiling process in the step (2) comprises: washing with hydric sulphate solution; bleaching with the mixture of sodium chlorite and sodium nitrate; first washing with water; oxygen bleaching with the mixture of sodium carbonate, caustic soda, sodium silicate and hydrogen dioxide solution; second washing with water. The inventive blended yarn has the advantages of two fibers, and the boiling process can increase the spinning number of flax; therefore, the product has crinkle resistance and better brightness, etc.

Owner:XINSHEN GROUP

Preparation method and use of sulfydryl flax

InactiveCN102389778AImprove adsorption capacityLarge adsorption capacityOther chemical processesWater/sewage treatment by sorptionMechanical propertyPollution

The invention discloses a preparation method and use of sulfydryl flax, which is characterized by comprising: adding 45 to 52 mass percent of thioglycolic acid, 35 to 40 mass percent of tetrahydrofuran, 23 to 30 mass percent of degummed flax, 1 to 1.5 mass percent of glacial acetic acid and 0.15 to 0.3 mass percent of concentrated sulfuric acid into a triangular flask with a plug, stirring and refluxing for 4 to 6 hours at 50 to 60 DEG C, washing with deionized water, filtering under vacuum till the filtrate is neutral, washing with a small amount of ethanol, drying in an oven at 35 DEG C, and obtaining the sulfydryl flax. The sulfydryl flax has high metal ion absorbability, has properties of sulfydryl and can be directly use to absorb and elute various metal ions in water, the absorptionefficiency and speed are high, the physical, chemical and mechanical properties of the sulfydryl flax are high, the sulfydryl flax can be used in a wide pH value range, the high regenerability of thesulfydryl flax, makes the repeated use number of the sulfydryl flax 30 percent higher than that of sulfydryl cotton, the waste from flax title is utilized, cost is saved, and environment pollution isavoided.

Owner:UNIV OF JINAN

Wear-resistant cotton, linen and tencel blended fabric

The invention discloses a wear-resistant cotton, linen and tencel blended fabric, which is interwoven by warp yarns and weft yarns. The warp yarns comprises cotton fibers and jute fibers; the jute fibers are flax fibers; the cotton fibers and the jute fibers are low-twist fibers, and have the twist of 300-400T / cm; the warp yarns are prepared by combining and twisting the cotton fibers and the jute fibers; and the weft yarns are tencel. The wear-resistant cotton, linen and tencel blended fabric integrates advantages of the cotton, linen and tencel, and a combining and twisting technology is adopted, so that the fabric has the advantages of a little fuzz, smooth appearance, high strength, high wear resistance, and high drapability, and has the characteristics of moisture absorption, heat dissipation, health care and bacteria resistance.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

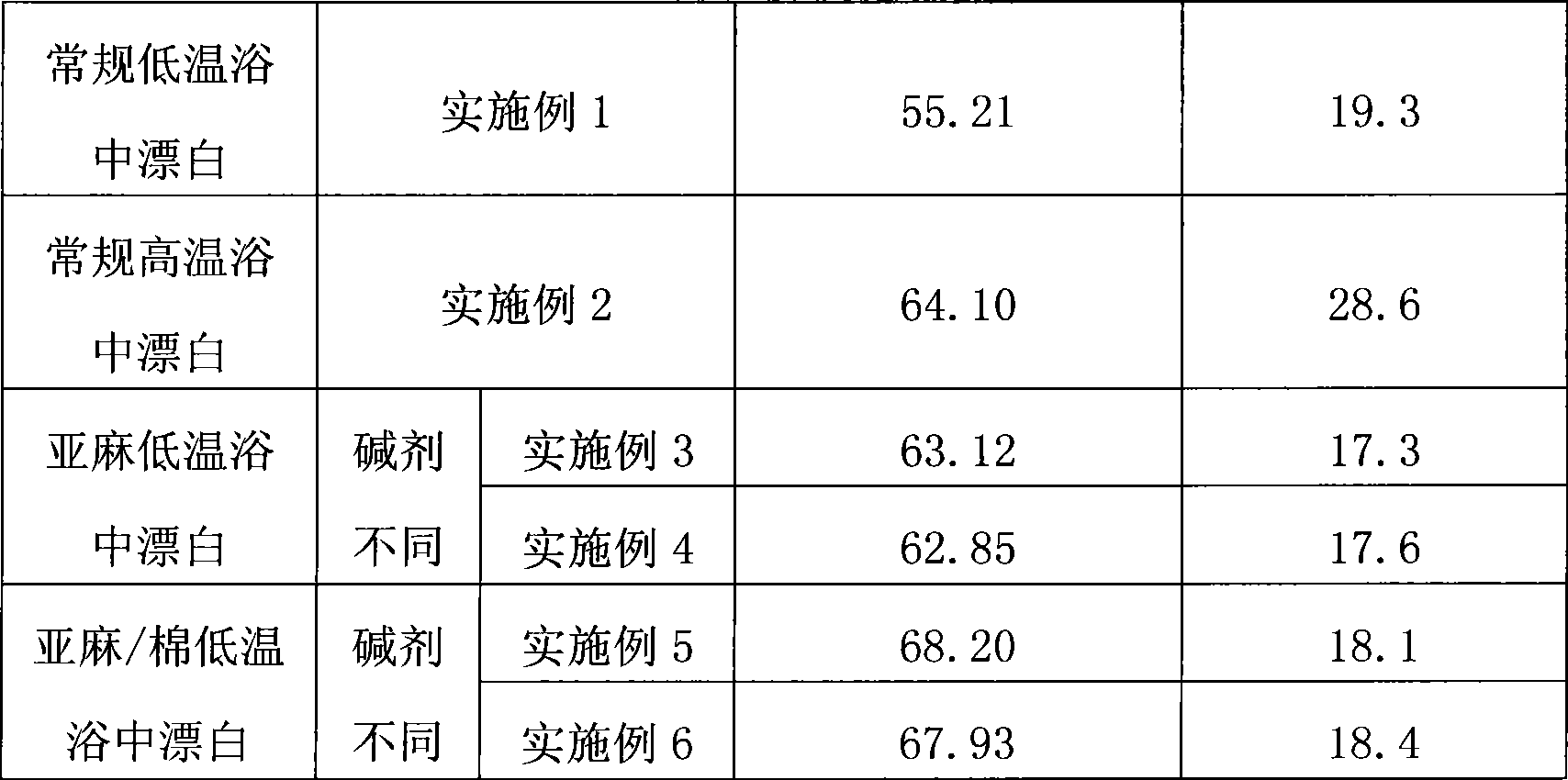

Flax fiber and tencel fiber blended yarn and preparation method thereof

The invention provides a flax fiber and tencel fiber blended yarn and a preparation method thereof. The flax fiber and tencel fiber blended yarn comprises 35 to 40 weight percent of flax fiber and 60 to 65 weight percent of tencel fiber, wherein the twist degree of the blended yarn is 21.32 to 23 T / inch; the average strength of the blended yarn is 300 g; and the elongation percentage of the blended yarn is 14.1 percent. The flax fiber and tencel fiber blended yarn combines moisture absorption, perspiration, antibacterial effect and the like of the flax fiber and the healthy environmentally-friendly characteristic of the tencel fiber, has the advantages of natural environmental friendliness, cooling performance and antibacterium, and can be applied to clothing fabrics and other industries.

Owner:SHANGHAI FEILONG TEXTILE

Bioplastics, monomers thereof, and processes for the preparation thereof from agricultural feedstocks

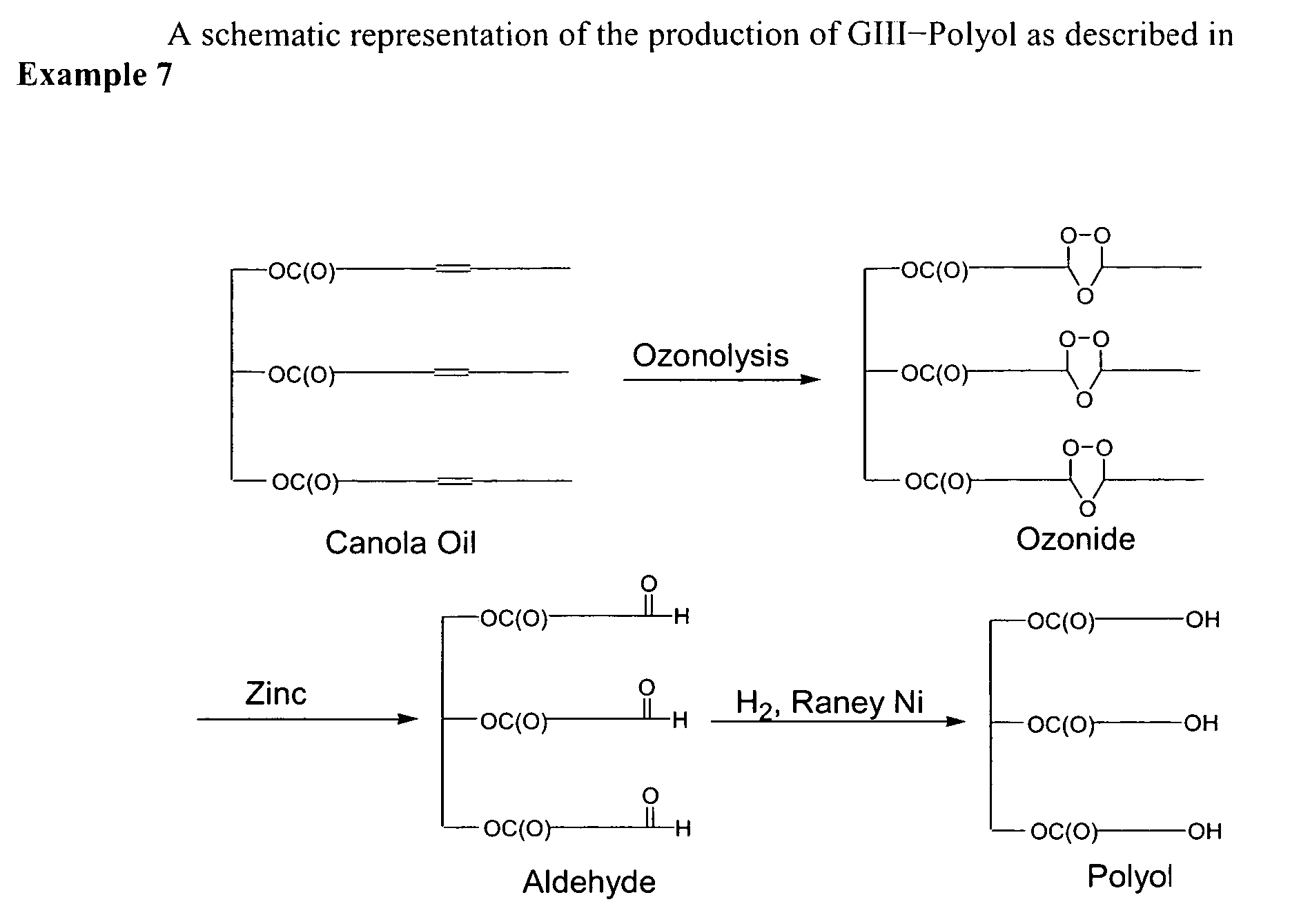

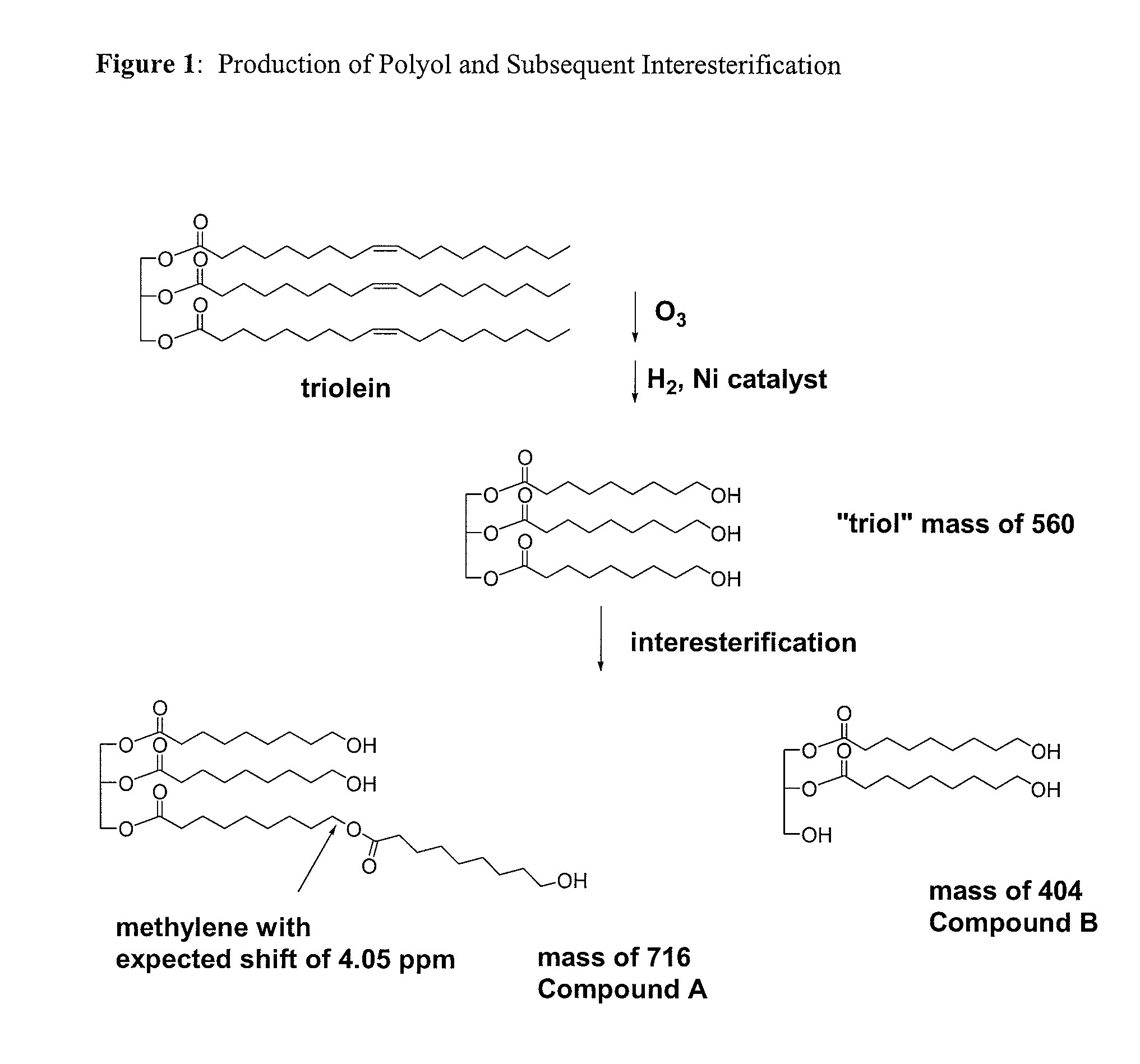

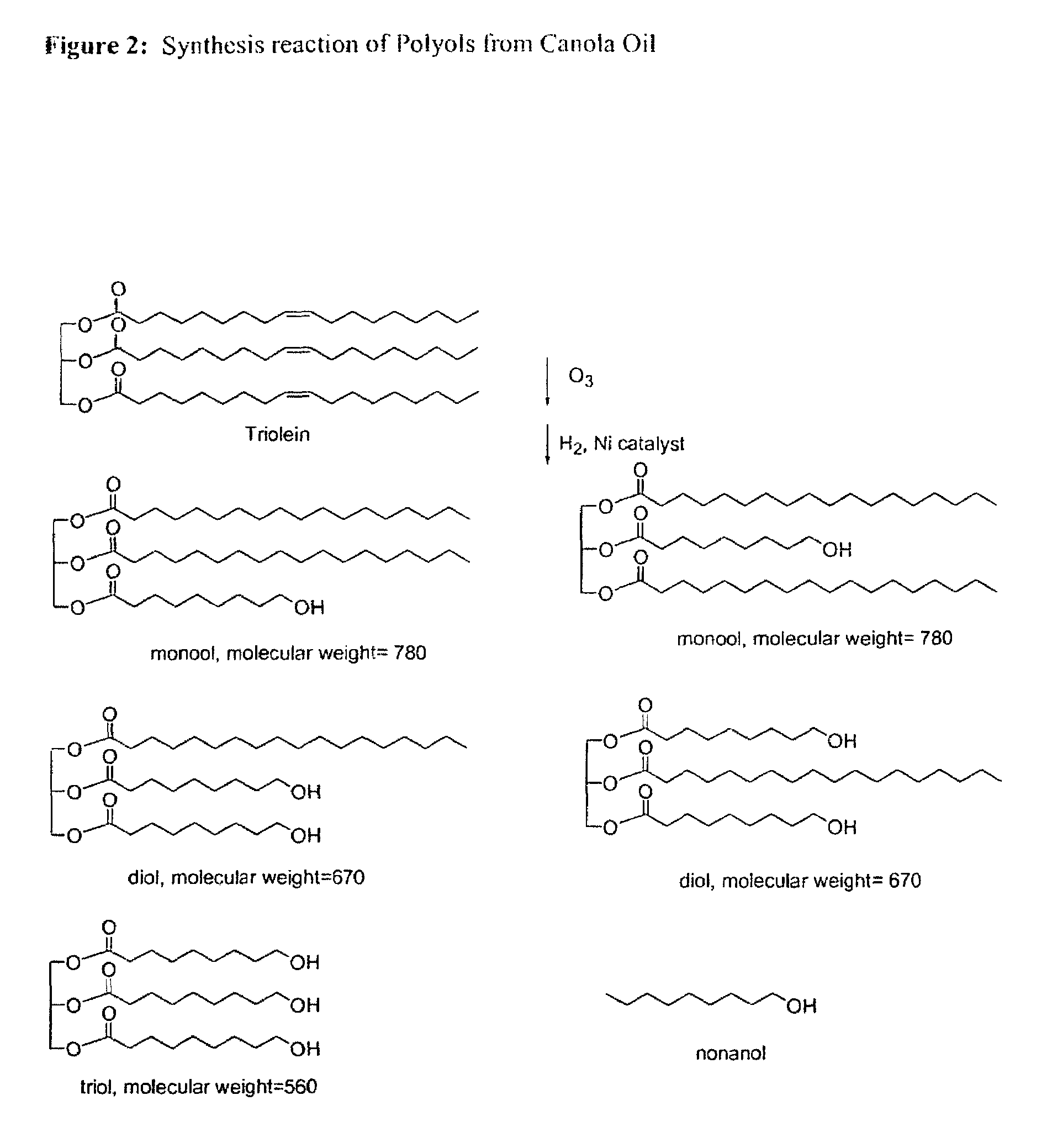

InactiveUS7538236B2Reducing steric hindrance to crosslinkingProduce some attenuationFatty acid hydrogenationCoke ovensAlcoholWax ester

The present invention relates generally to polymers and monomers derived from agricultural feedstocks, and more particularly to methods for the production of monomers from renewable agricultural resources such as feedstocks, for example canola, flax and tallow, and polymers, in particular polyurethanes produced from monomers derived from such feedstocks. The present invention also relates to novel processes for the production of short-chain alcohols, as well as hydroxyl wax esters, from renewable feedstocks. An improved apparatus for carrying out ozonolysis reactions is also disclosed.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Complex enzyme generated by aspergillus niger and application thereof in boiling-off of flax roving

InactiveCN101805725ANo toxicityStrong pectinase activityHydrolasesBiochemical fibre treatmentYarnFiltration

The invention discloses a complex enzyme generated by aspergillus niger. The complex enzyme is prepared by taking aspergillus niger HYA4 with the preserving number of CGMCCNo.1897 as a strain through incline preservation and culture, solid fermentation and culture and leaching filtration and preparation, wherein a culture medium for the solid fermentation comprises bran, straw powder and ammonium sulfate; and the invention has the advantages that the used aspergillus niger HYA4 strain is at a food safety level and has no toxicity, large enzyme yield, complete enzyme system and more extensive culture condition. The cultured complex enzyme not only has very strong pectinase activity but also has very strong cellulase activity. The used complex enzyme can enhance the split degree of flax fibre, reduces nep and hair feather obviously, lowers the strength loss of yarn, also solves injuries caused by a chlorine bleach process to a worker and the environment thoroughly and has multiple advantages of saving water and electricity, reducing the treatment cost of sewage, lowering the production cost and the like.

Owner:QIQIHAR UNIVERSITY

Flax SSR molecular marker and application thereof

InactiveCN109517925AEfficient constructionStable amplificationMicrobiological testing/measurementDNA/RNA fragmentationHigh densityBiology

The invention relates to the technical field of plant variety identification and breeding, in particular to a building method of flax SSR fingerprint chromatography. According to the method, through MISA software, a flax genome is searched for to obtain 28751 SSR sites, Primer 5.0 is used for designing 71184 pairs of primers, and 26 flax genetic resources are used for screening out the 11 pairs ofSSR markers rich in polymorphism: RM4-5, RM4-7, RM6-2, RM6-6, RM6-7, RM7-1, RM7-3, RM8-1, RM9-4, RM13-5 and RM15-1. The SSR primers which are developed based on the flax genome have the advantages ofbeing stable in amplification, clear in electrophoretic band, rich in polymorphism and the like, and the building method of the flax SSR fingerprint chromatography can be effectively used for the study fields of flax genetic resource genetic diversity analysis, high-density chromatography building, variety purity and authenticity identification, molecular marker-assisted breeding and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Doubled haploid production and genetic transformation

Development of an efficient and cost-effective doubled haploid production system and genetic transformation system are the prerequisite to initiate haploid breeding and genetic modification in flax respectively. Pre-culturing anthers on a high osmotic, high auxin and high mineral salt concentration for a period of time before transfer to a low osmotic, low auxin and low salt concentration significantly increased the overall efficiency of regeneration or anther efficiency than directly culturing anthers on a low osmotic, low auxin and low salt concentration medium. This culture procedure also dramatically reduced the frequency of shoot regeneration from somatic cells in anther culture. Using this procedure, a highly efficient anther culture-derived callus based transformation system was developed. The transformation efficiency of anther culture-derived callus based transformation system was four times higher than the best reported transformation efficiency using hypocotyls as the ex-plants in Agrobacterium tumefaciens based transformation system or particle bombardment based transformation system. The frequency of escape in anther culture-derived callus based transformation system was one third of that in hypocotyl-based transformation system using A. tumefaciens or one half using particle bombardment. This very high efficient transformation system will prove to be very valuable in basic research for gene discovery and practical applications in genetic engineering for improved traits.

Owner:AGRICORE UNITED

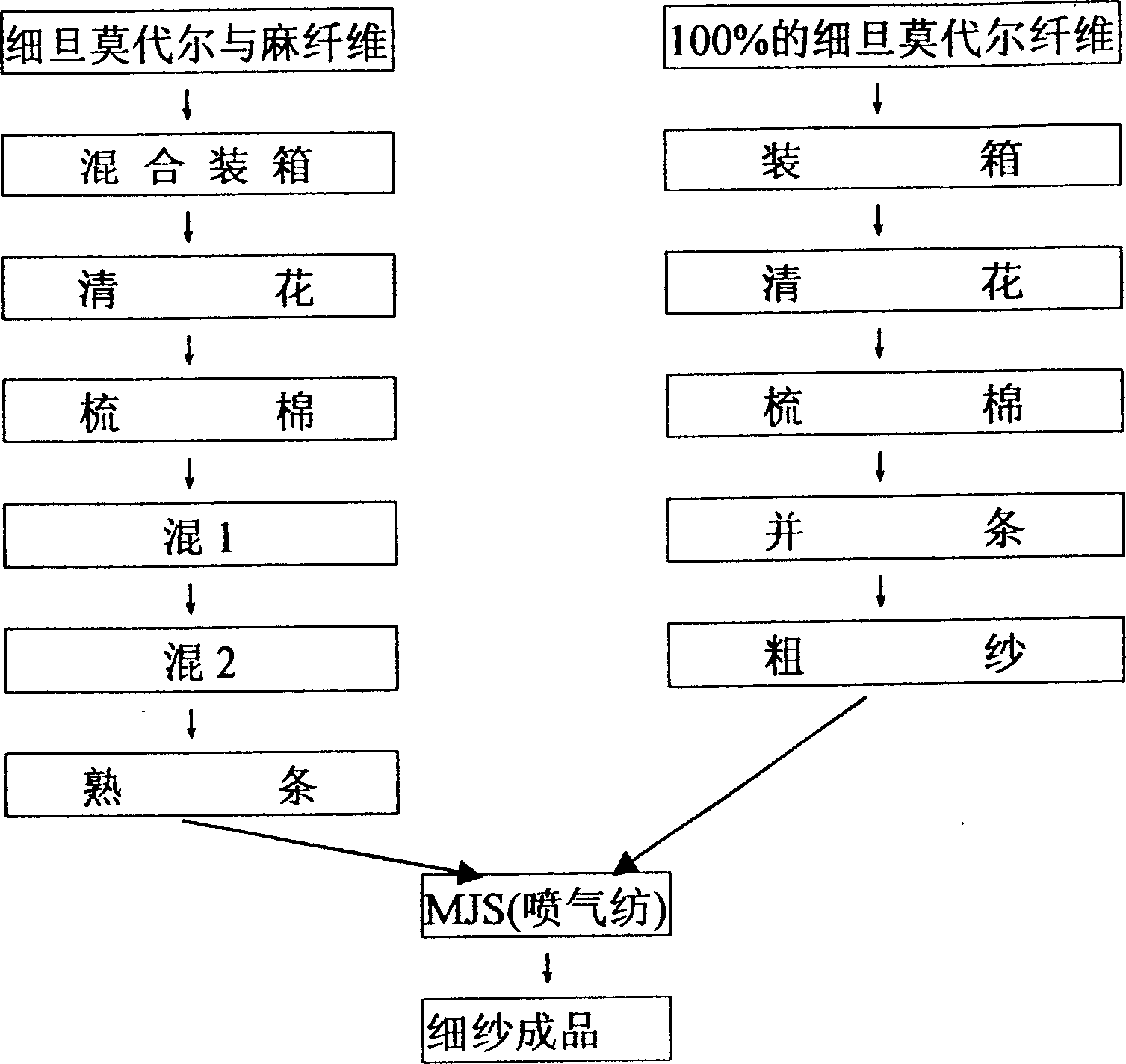

Blended yarn of fine denier modal with hemp and its blow spinning process

The present invention is blended yarn of fine denier modal fiber and hemp fiber and its jet spinning process. The blended yarn consists of fine denier modal fiber and hemp fiber in the ratio of 20-80 to 20-80, the fine denier modal fiber is short fiber of 1 d or below, and the hemp fiber is flax fiber or ramie fiber. The jet spinning producing process of the blended yarn includes the following steps: mixing fine denier modal fiber and hemp fiber and producing mixed sliver of 2.0-2.8 g / m; producing fine denier modal fiber in 100 % into roving of 2.4-3.2 g / 10m, feeding the mixed sliver and the roving in required ratio into the same nozzle of one jet spinning machine to form the blended yarn. The said technological process can produce blended yarn in the structure of hemp fiber coating fine denier modal fiber core homogeneously.

Owner:SHANGHAI NO 17 COTTON TEXTILE MILL

Synthetic method of flax fabric finishing agent

InactiveCN101328683AMild reaction conditionsSimple and fast operationVegetal fibresSynthesis methodsFiltration

The invention discloses a method for synthesizing a linen cloth finishing agent. The method takes citric anhydride as a modified compound for degraded chitosan and comprises the following steps: firstly, the degraded chitosan is added into a medium according to a certain proportion and then stirred and swelled for 0.5 hour; secondly, the citric anhydride is added into the mixture according to the mass ratio of the degraded chitosan to the citric anhydride is 1 to 2-5; thirdly, a catalyst of 1 to 2 percent against the total mass is added into the mixture and reacted for 16 to 24 hours at a normal temperature; and fourthly, after the reaction is stopped, the pH value is adjusted to neutrality and the mixture undergoes pump filtration and decompression concentration, is added with 60 milliliters of ethanol, stands overnight, and then undergoes pump filtration and vacuum drying. The method has the advantages that: the synthesis method has mild reaction condition and simple and convenient operation; and the synthesized citric acylated degraded chitosan is an environment-friendly product, not only contains chitosan molecules with the antibacterial performance but also contains polybasic carboxylic acid radicals with wrinkle resistance, can simultaneously give play to the dual function of antibacterium and wrinkle resistance when used for linen cloth finishing, and is a multifunctional environment-friendly linen cloth finishing agent.

Owner:HARBIN INST OF TECH +1

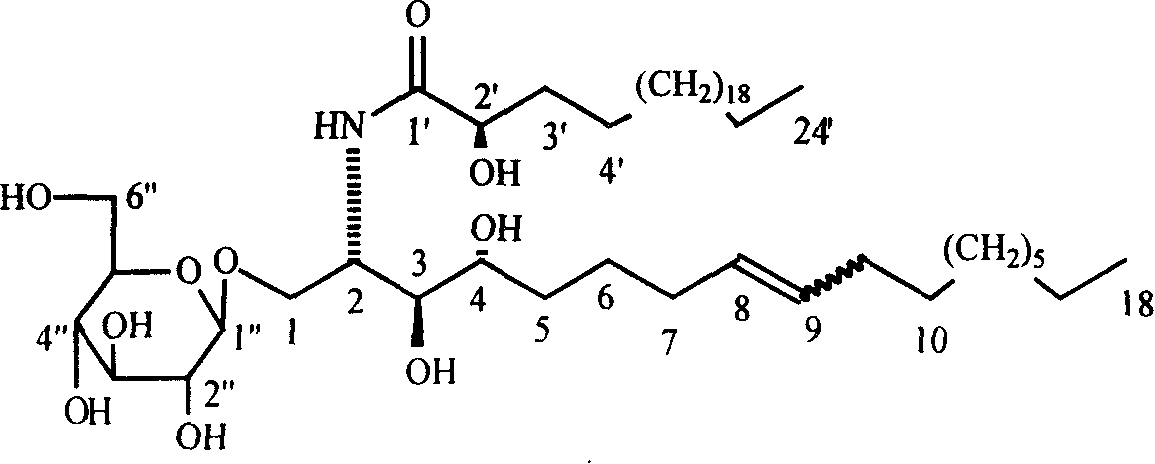

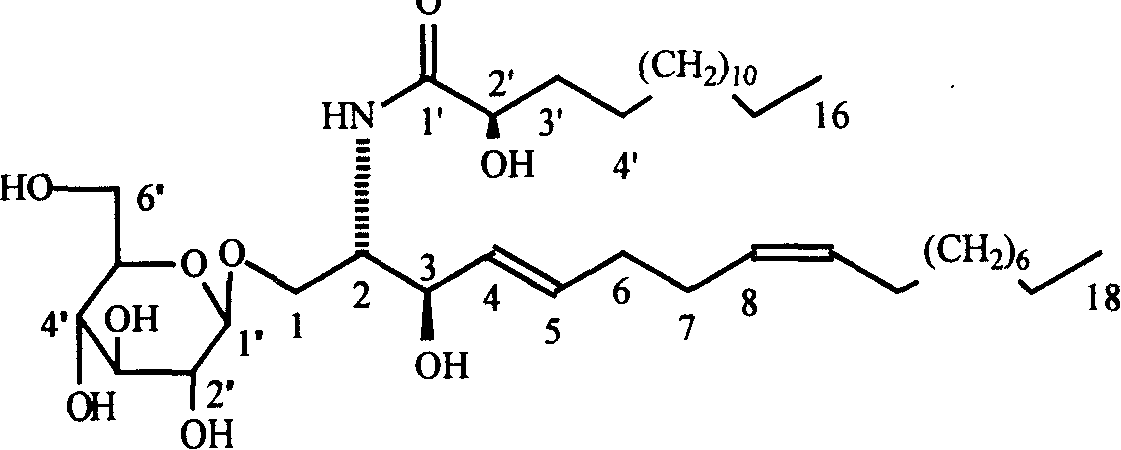

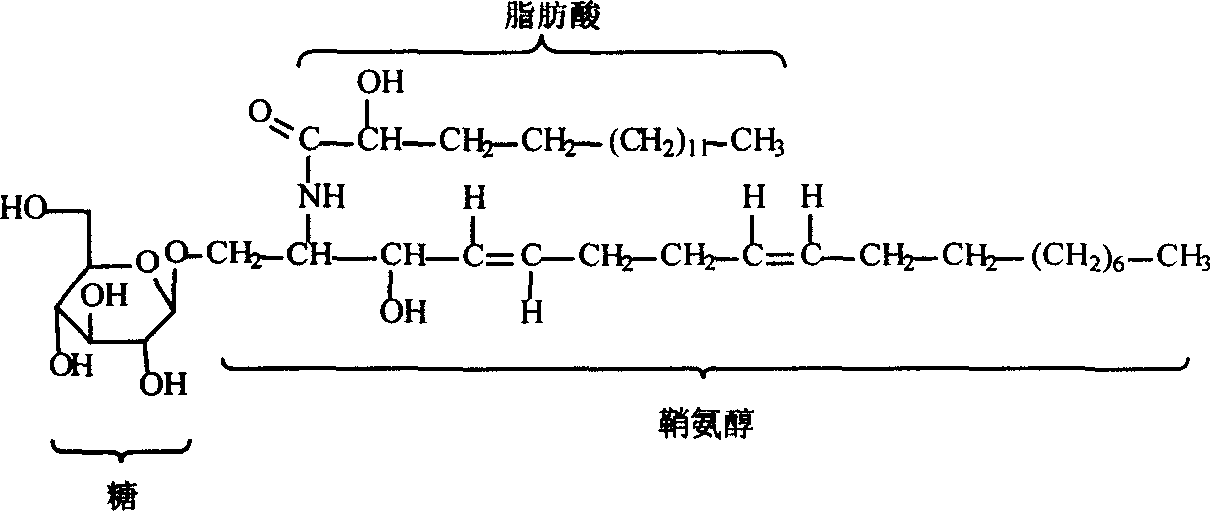

Method of preparing cerebroside compound from flax root

InactiveCN1718583ARealize comprehensive utilizationSugar derivativesSugar derivatives preparationCrystallizationChemistry

A process for preparing the cerebroside compounds including beta-daucosterin from the root of flax includes such steps as extracting separation and recrystallizing.

Owner:龙井民康生物制品厂

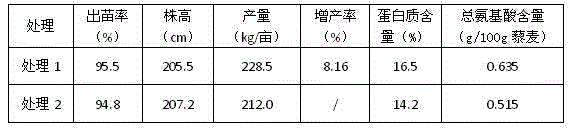

Special fertilizer for chenopodium quinoa and preparation method thereof

ActiveCN104446984AMeet growth needsIncrease productionAlkali orthophosphate fertiliserExcrement fertilisersAmmonium sulfateNitrogen fertilizer

The invention provides a special fertilizer for chenopodium quinoa. The special fertilizer is prepared by mixing 10-30 parts of dried sheep manure, 10-20 parts of flaxseed flake, 10-30 parts of nitric phosphate fertilizer, 10-30 parts of ammonium sulfate, 10-30 parts of urea, 10-30 parts of diammonium phosphate, 10-30 parts of potassium sulfate, 1-10 parts of zinc sulfate, 1-10 parts of manganese sulfate and 1-5 parts of a granulation binder. The ratio of nitrogen phosphorus and potassium nutrients, namely N: P2O5: K2O, in the special fertilizer is 1: (0.4-0.7): (0.3-0.5); the weight ratio of different forms of nitrogen, namely nitrate nitrogen: ammonium nitrogen: amide nitrogen, is 4: 3: 3; the nitrogen phosphorus and potassium macroelements and microelements are matched reasonably, and the ratio of the nitrate nitrogen: ammonium nitrogen: amide nitrogen is reasonably set, and therefore, the nutritional requirements of chenopodium quinoa in the growth period are fully satisfied, the yield of chenopodium quinoa is increased, the quality of chenopodium quinoa is improved, and the content of proteins and amino acids in the chenopodium quinoa is remarkably increased.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Health fragrant tipping paper with mango leaves and preparation method thereof

InactiveCN104195875AKeep freshReasonable formulaNon-fibrous pulp additionMetabolism disorderPolyvinyl alcoholPapermaking

The invention discloses health fragrant tipping paper with mango leaves. The health fragrant tipping paper is prepared from the following raw materials in parts by weight: 120-145 parts of hardwood pulp, 65-80 parts of bamboo pulp, 1-2 parts of polyvinyl alcohol, 1-2 parts of sodium carboxymethylcellulose, 2-3 parts of 75% ethyl alcohol, 2-3 parts of polyvinyl butyral resin, 1.5-2.5 parts of maltodextrin, 0.4-0.7 part of linolenic acid, 0.4-0.6 part of citric acid, 3-4 parts of torreya grandismerrillii, 4-5 parts of folium rubi suavissimi, 2-3 parts of mango leaves and 3-4 parts of a spice mixture. The crushed torreya grandismerrillii, mango leaves, torreya grandismerrillii and the like are added during papermaking, so that the tipping paper has the functions of relieving cough and reducing sputum, improving digestion and invigorating stomach, reducing blood sugar, inhibiting bacteria, relieving the discomfort caused by smoking, etc., and also has the health function; with the spice mixture, the pungent smoke and the peculiar smell of cigarettes are alleviated, and thus the mouth remains fresh and cool; base paper of the tipping paper prepared by the method is reasonable in preparation, high in wet strength and air permeability, and high in quality.

Owner:ANHUI SANHUAN PAPER GRP

Naturally-degraded disposable tableware and manufacturing method thereof

Owner:GUANGXI TEACHERS EDUCATION UNIV

Flowable flax bast fiber and flax shive blend useful as reinforcing agent

InactiveUS6833399B2Small average aspect ratio valueEasy compoundFibre mixingSynthetic resin layered productsThermoplastic compositesMaterials science

This invention relates to free flowing fiber reinforcing material which includes a blend of flax bast fibers and flax shives with a specific distribution of particle sizes and aspect ratios, thermoplastic pellets which include such reinforcing fiber blend, thermoplastic composites which include such reinforcing fiber blend and method for making such pellets and composites.

Owner:OMNISWEET

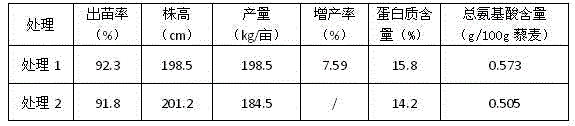

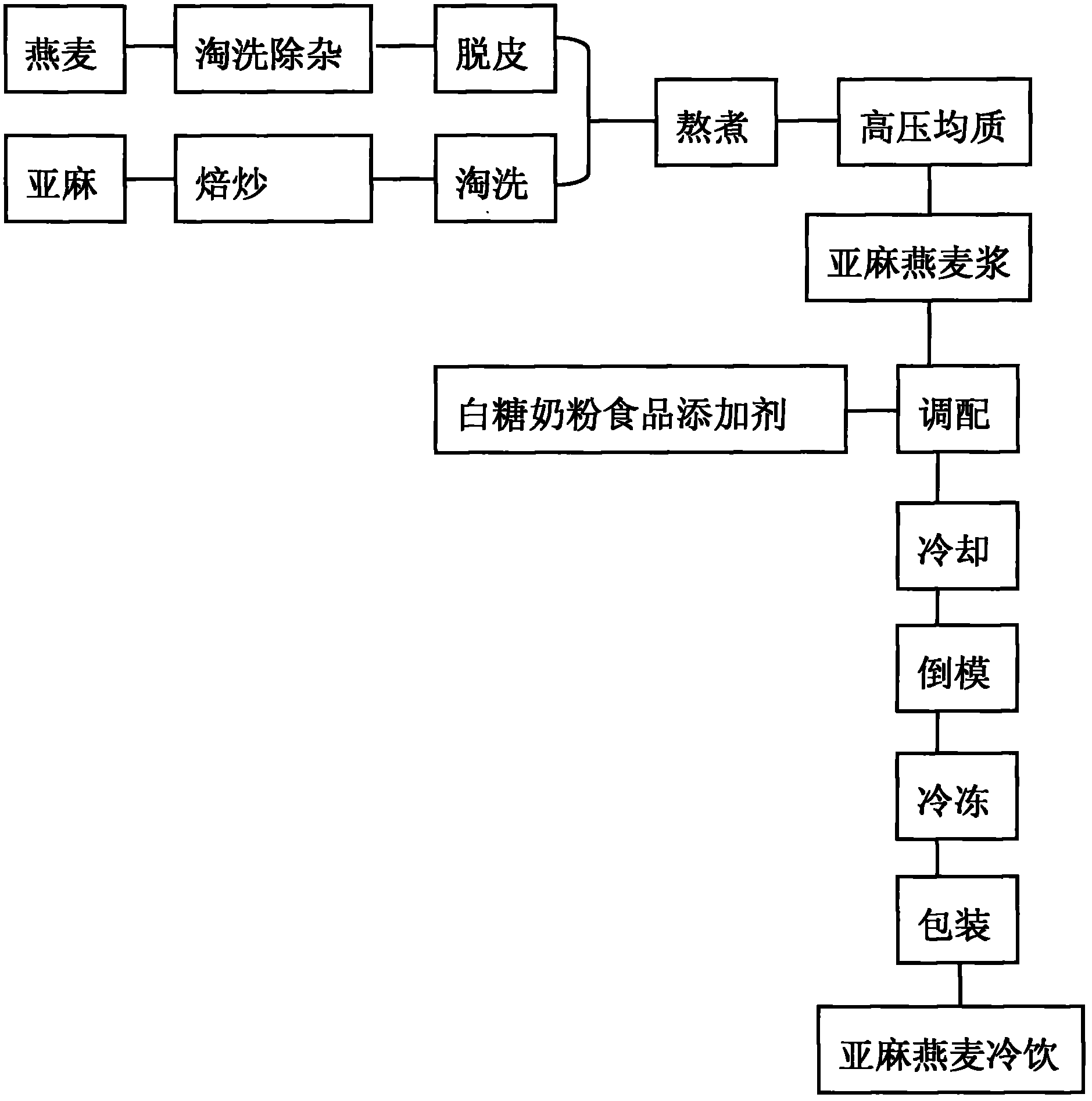

Method for producing flax oat cold drink

InactiveCN102187933AGive full play to nutritional valueDifferent ways to eatFrozen sweetsFood additiveNutritive values

The invention relates to a method for producing a flax oat cold drink, and belongs to the technical field of food processing. The method comprises the following steps of: mixing flax oat starch serving as a main raw material and white sugar, milk powder and a food additive, molding, freezing and packaging to obtain the flax oat cold drink, wherein the flax oat starch is prepared by performing processes of elutriating, impurity removal, decocting and high-pressure homogenizing on flax and oats. The method aims to give full play to the nutritive value of the oats and flax seeds (linseed), and the oats and the flax seeds are combined organically to provide oat and flax seed (linseed) nutritional food which is easy and convenient to eat. By the method, the problem of single edible method of the oats and the flax is solved, and the edible method of the oats and the flax is enriched while nutritional ingredients of the oats and the flax are maintained fully.

Owner:甘肃省农业科学院作物研究所

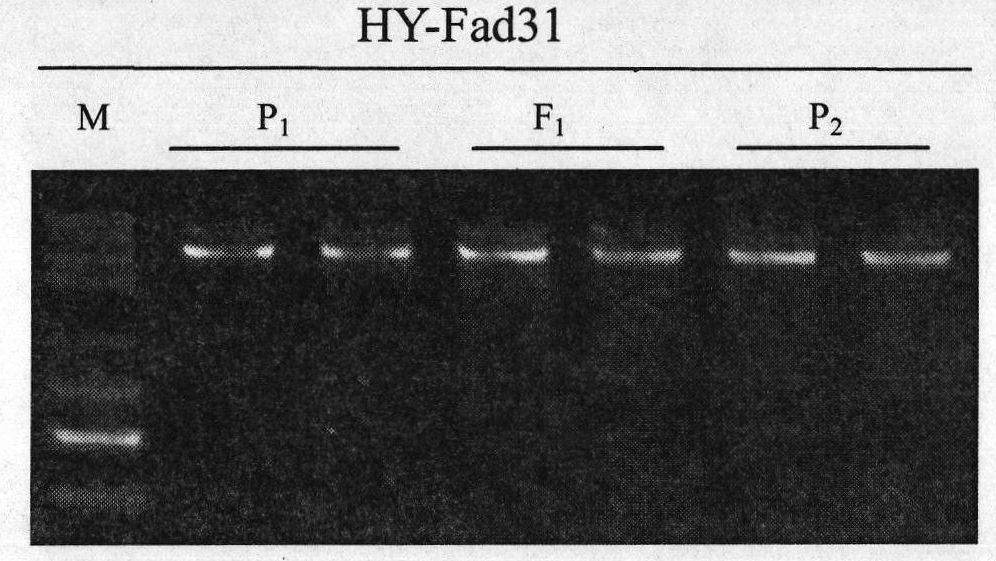

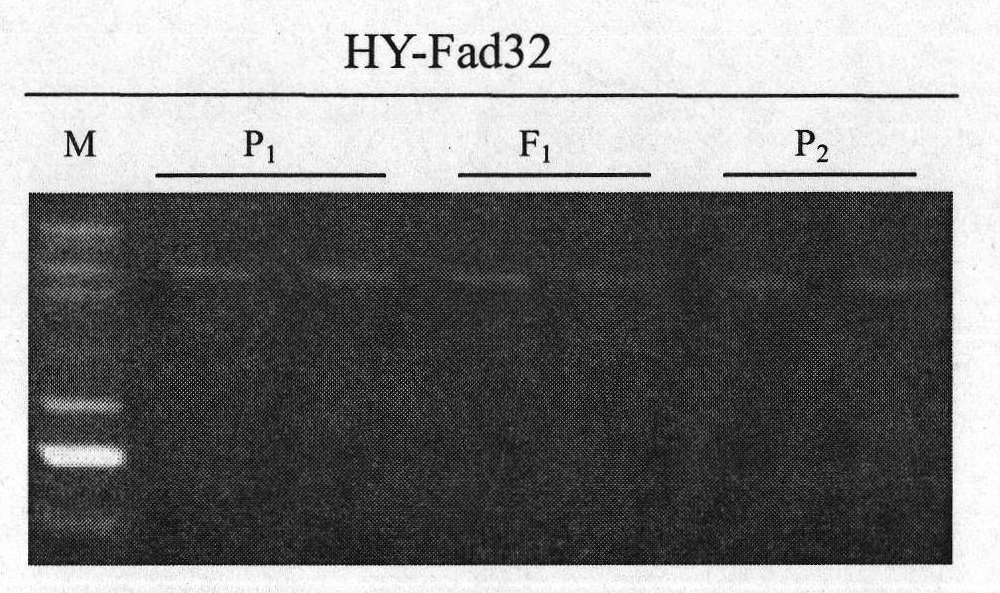

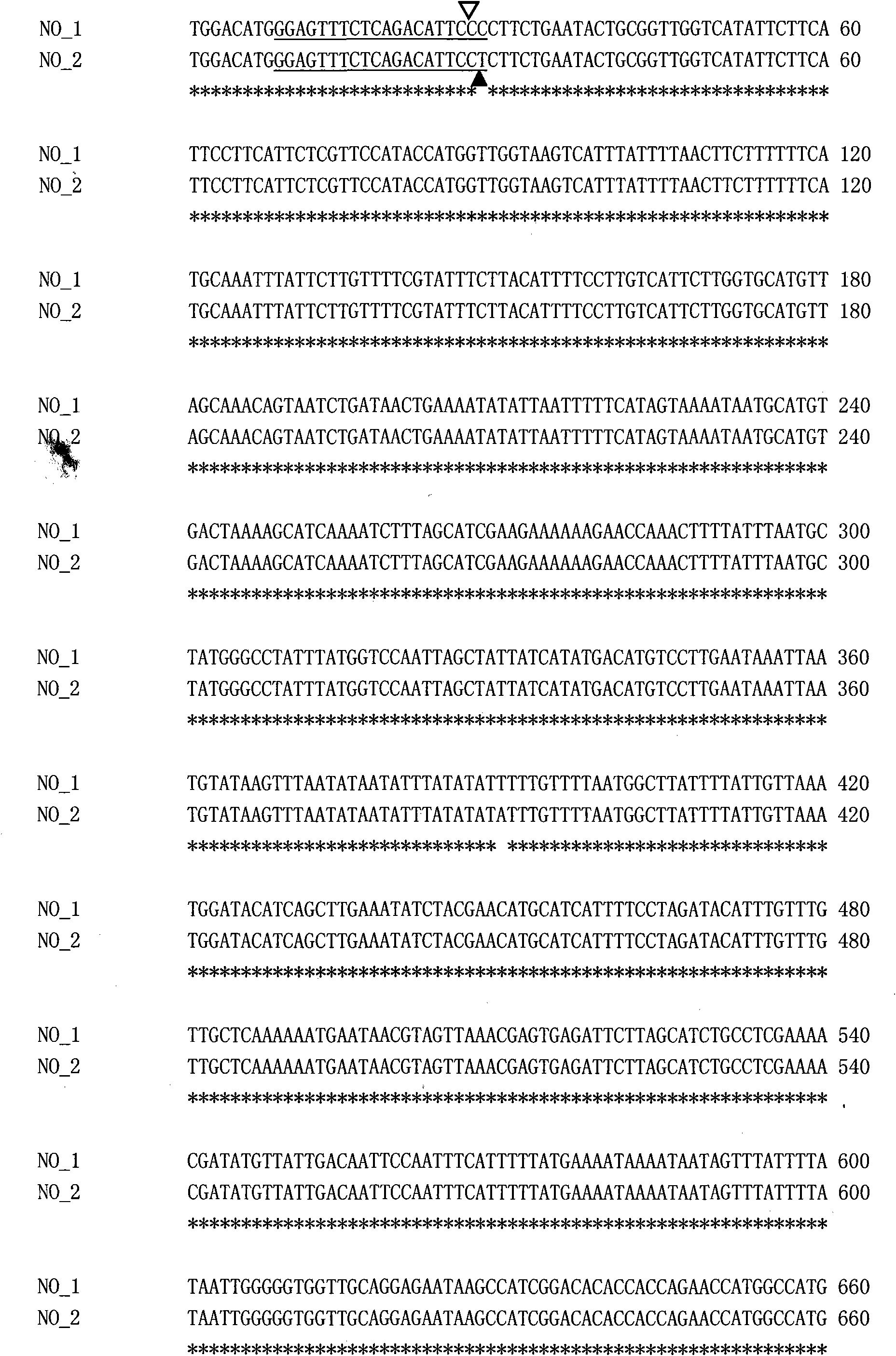

Molecular marker for low linolenic acid of cabbage type rape, preparation method and application thereof

InactiveCN101818196AReduce breeding workloadShorten the breeding periodMicrobiological testing/measurementFermentationHeterologousForward primer

The invention belongs to the technical field of rape molecular breeding, in particular relates to a preparation method of a codominant SNP (Single Nucleotide Polymorphism) molecular marker closely linked with the linolenic acid content of a cabbage type rape and application thereof as the marker in the auxiliary selection of the low linolenic acid cabbage type rape. The low linolenic acid cabbage type rape strain A254 and high linolenic acid cabbage type rape strain A177 genomes DNA are amplified by using primers to respectively obtain two DNA amplified fragments, then cloning, sequencing and nucleotide sequences comparison are carried out on the four DNA amplified fragments; according to the difference of the sequences, the second bases at 3'-end of a forward primer and a reverse primer are mispaired, primer pairs of YQ-fad31-1, YQ-fad31-2, YQ-fad32-1 and YQ-fad32-2 are designed, the PCR (Polymerase Chain Reaction) amplification is carried out on the primer pairs of YQ-fad31-1, YQ-fad31-2, YQ-fad32-1 and YQ-fad32-2, and the PCR amplification and group detection effects are analyzed to obtain the codominant SNP molecular marker linked with low linolenic acid genes of the cabbage type rape. The invention provides a new marker for the rape molecular breeding. In the invention, a mispairing strategy of the 3'-end of the primer is firstly applied to the development and the detection of the SNP polymorphic marker of the cabbage type rape, and a means of synchronously mispairing the forward primer and the reverse primer is firstly adopted to develop the SNP marker based on the PCR amplification and an agarose gel electrophoresis in the cabbage type rape of an allopolyploid crop. The invention synchronously discloses a method for preparing the molecular marker and the application thereof.

Owner:HUAZHONG AGRI UNIV

Method for preparing fiber and flax blended yarn

The invention discloses a preparation method of fiber and flax blended yarn. The weight content of the flax fiber is 45-75%, and the rest is elastic polyester fiber. The preparation includes: pretreatment, cleaning, carding, drawing and roving , degumming, bleaching, pickling, washing and spinning. The production method provided by the invention can prepare the elastic polyester fiber and flax fiber blended yarn with hygroscopicity, lightness, glossiness, air permeability, antibacterial property and anti-mite property. The blended yarn of elastic polyester fiber and flax fiber of the present invention has high spinnability and good elasticity, and the cloth woven with it is soft, comfortable, breathable, sweat-absorbing, antibacterial and elastic, and has a novel and fashionable appearance. The invention blends elastic polyester and flax fiber, which can make up for the low elasticity of the hemp fiber, and makes the fabric feel comfortable and elastic, and can improve the style and feel of the blended yarn.

Owner:江阴市博帆化纺有限公司

Method for producing viscose/flax fiber blending knitting yarns through rotor spinning

InactiveCN101858000AFeel comfortableHigh glossContinuous wound-up machinesOpen-end spinning machinesYarnPulp and paper industry

The invention discloses a method for producing viscose / flax fiber blending knitting yarns through rotor spinning, which comprises the following steps of: opening and scotching flax fibers and viscose which are used as raw materials respectively; dewing the flax fibers; mixing the flax fibers and the viscose in a ratio of 15:85; making the mixed flax fibers and viscose on a carding machine to form cotton slivers; and finally, making the knitting yarns through rotor spinning. Due to the adoption of the technical scheme, the flax fibers are blended with the viscose with comfortable, smooth and soft feel and good glossy, moisture absorption, drapability and skin compatibility, so that the performance of the flax fibers and the viscose is combined. The viscose / flax fiber blending knitting yarns can improve the defect of the performance of the pure flax fibers, maintains the advantages of the flax fibers such as nice and cool wearing, moisture absorption, air permeability and the like, and expands the new field of the rotor spinning knitting yarns.

Owner:徐士琴

Disease-resisting fertilizer capable of resisting disease and providing nutrient to plant

InactiveCN1970509AStrong disease resistanceImprove disease resistanceNitrate fertilisersFertilizer mixturesNicotiana tabacumHordeum vulgare

The invention discloses a disease-resistant fertilizer, which is characterized by the following: setting the rate of cupric nitrate, zinc nitrate and notoginseng escin at 1:5:0.1-0.5; protecting plant from powdery mildew, late blight, downy mildew, macrophyric disease and aphid without pollution or toxicity; providing nourishment and microelement for crop; accelerating the growth of crop; improving crop quality.

Owner:YUNNAN ACAD OF AGRI SCI

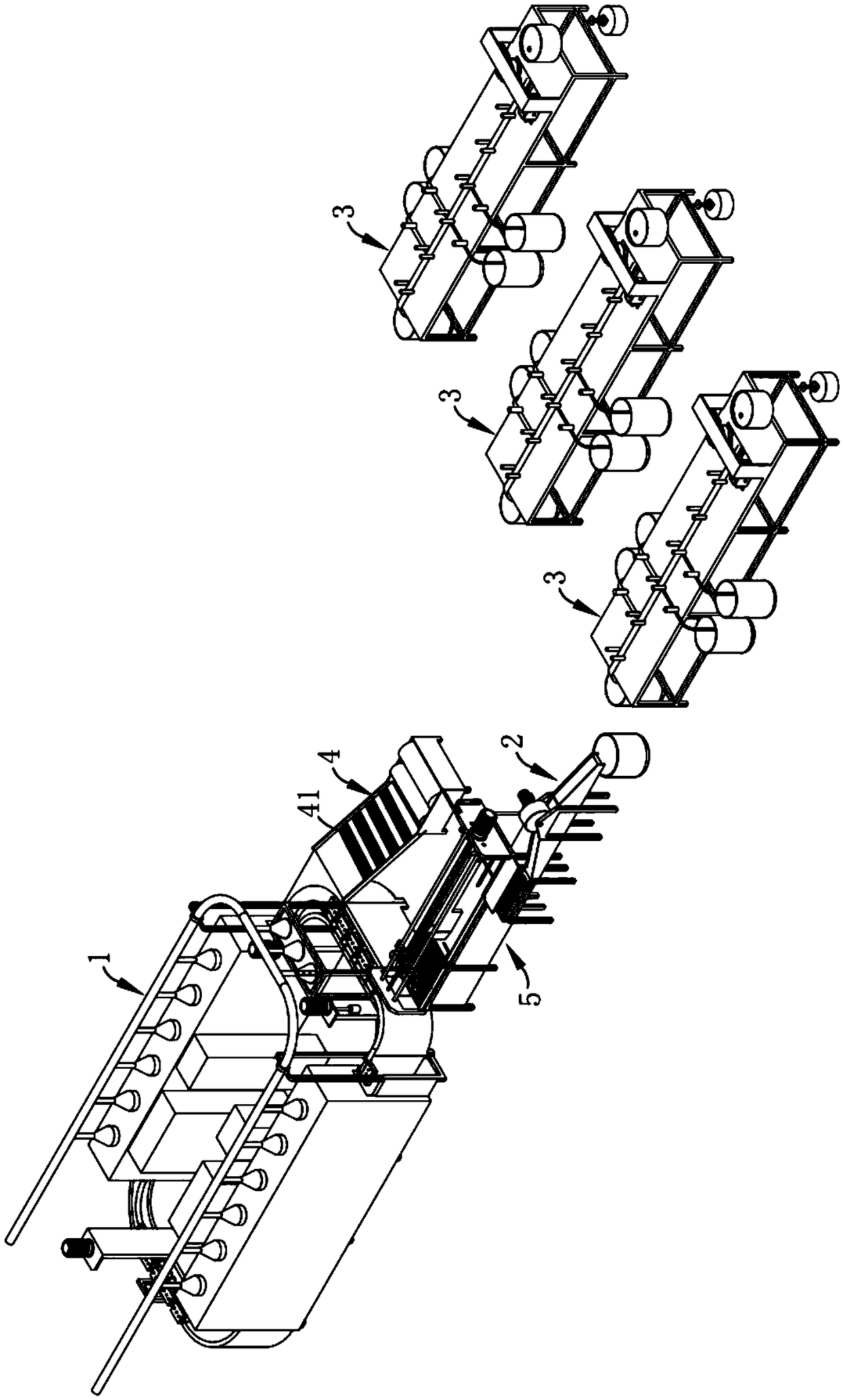

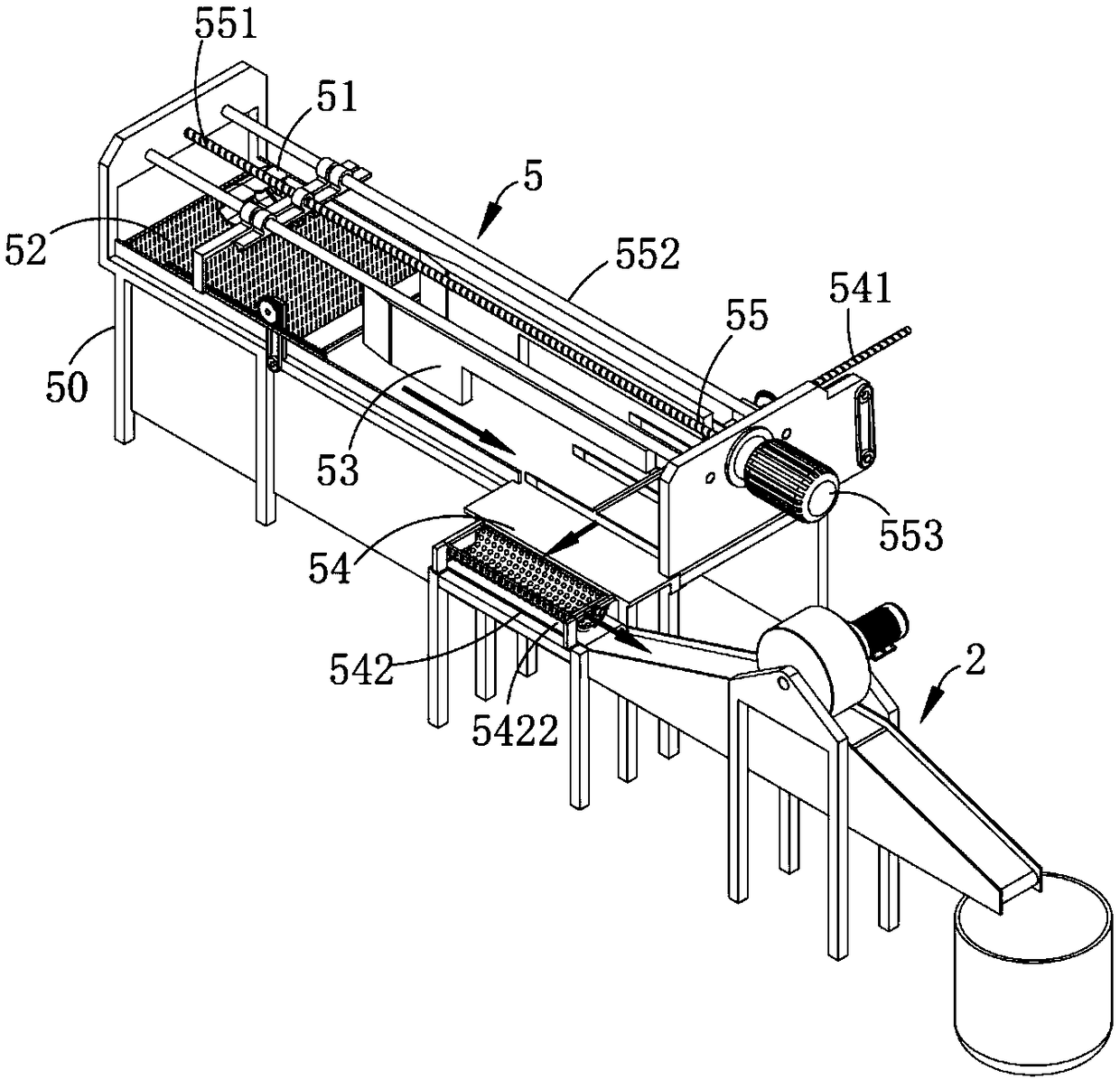

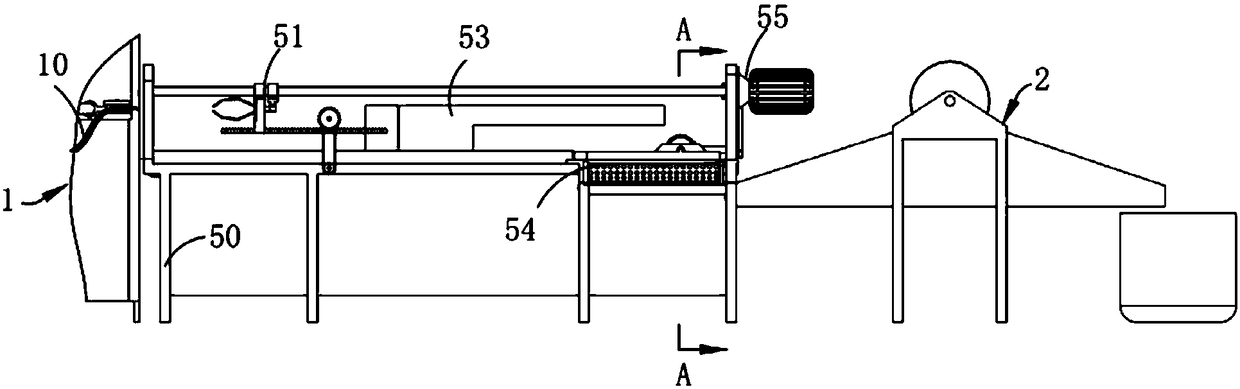

Continuous automatic production line for flax yarn

InactiveCN108950750AAutomate the connectionImprove reliabilityPiercing arrangementsContinuous processingState of artYarn

The invention relates to the technical field of flax yarn production, in particular to a continuous automatic production line for flax yarn. The production line comprises a raw material pretreatment device, a hackling machine, an automatic flax fiber material adding device, a drawing frame and a yarn mixing machine; the automatic flax fiber material adding device comprises a traction mechanism, asplitting mechanism and a material adding mechanism; a fiber bundle obtained after overlapping and winding is transferred into the drawing frame, a fiber rod is formed, and the fiber rod is made intorough yarn through the yarn mixing machine; by means of the traction mechanism, in the process of conducting directional transfer o the flax yarn, short fiber removing and fiber bundle separation areconducted on the flax yarn by cooperating with a carding mechanism and the splitting mechanism respectively, by combining the transmission connection characteristic of a lap joint mechanism and a driving mechanism, automatic winding in the end-to-end lapping process of the fiber bundle is achieved, high-quality automatic production of flax splitting and lapping is achieved, and the technical problem that in the prior art, due to the fact that manual splitting it not uniform, the yarn quality is not stable is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

Production method of flax/cotton blended yarns

The invention provides a production method of flax / cotton blended yarns, which comprises the following steps of: 1, carrying out flax fiber pre-processing, i.e., firstly, carrying out flax rolling processing and flax carding processing on flax fibers, then spraying a softener to carry out softening, then sealing for 24h to enable the fibers to be softened, and packaging to obtain performance-improved flax fibers; 2, after mixing the flax fibers and cotton fibers, by sequential machining thorugh a disk plucker, a cotton blender machine, a porcupine opener, a multimixer, a card wire roller cotton slitting machine, a vibrating cotton feeding machine, a single beater scutcher, a carding machine, a three-pass drawing frame, a roving frame, a siro spinning frame and a winding machine, obtaining the flax / cotton blended yarns. According to the method provided by the invention, the produced flax / cotton blended yarns have the advantages of yarn evenness, small single yarn strength CV value, high strength and the like, can meet function requirements of consumers for a fabric, and have excellent development prospect.

Owner:NANTONG DOUBLE GREAT TEXTILE

Special pesticide for flax and preparation method of special pesticide for flax

InactiveCN104430566APromotes robust growthIncrease productionBiocideArthropodicidesPumpkin seedInsect pest

The invention discloses a special pesticide for flax and a preparation method of the special pesticide for flax. The special pesticide comprises the following components in parts by weight: 18-20 parts of carbendazim, 15-17 parts of triadimefon missible oil, 11-13 parts of pumpkin seed powder, 10-12 parts of pulveris fructus cnidii, 7-9 parts of deltamethrin, 6-8 parts of beauveria bassiana, 5-7 parts of aliette, 4-6 parts of trifloxystrobin, 3-5 parts of folpet, 2-4 parts of antimycoin, 1-3 parts of amino-oligosaccharin and 30-50 parts of water. The special pesticide for the flax is simple to prepare, is low in cost, has a universal poisonous property on common plant diseases and insect pests existing on the flax, and can be used for improving the stress resistance of flax plants, guaranteeing the vigorous growth of the flax, increasing the yield of the flax greatly and improving quality of the flax greatly.

Owner:张爱丽

Method for extracting flax glue from flax seed husk

InactiveCN101130664AImprove leaching rateImprove product qualityNatural resin processFood preparationSlagHusk

The invention discloses a method to extract flax glue from flax seed shell, which comprises the following steps: (1) cleaning raw material; de-stoning; (2) separating seed peel; (3) proceeding shell gumming; (4) separating the glue and peel shell slag; (5) condensing; (6) sprayed-drying. This invention can keep the getting ratio and quality of the flax seed, which possesses advanced craft, low cost and high quality.

Owner:北京市粮食科学研究院有限公司

Flax crisp cake and preparation method thereof

The invention relates to the food field, in particular to a flax crisp cake and a preparation method thereof. The flax crisp cake is composed of the following raw materials (parts by weight): 100 parts of low gluten flour, 13-15 parts of milk butter, 25-30 parts of flax seed oil, 25-30 parts of soybean oil, 50-60 parts of sugar powder, 0.5-1 part of salt, 13-15 parts of eggs, 1-3 parts of soda powder, 0.5-1 part of baking powder, 5-8 parts of flax instant powder, 5-8 parts of roasted flax seeds and 0.1-0.3 parts of sodium dehydroacetate. The prepared flax crisp cake has a crisp, fragrant and delicious taste which is not easy to go bad with time, and can not only expand the application scope of flax seeds, but also increase people's choice of flax food and improve the consumption of flax food by people.

Owner:杭州思味王食品有限公司

Jute/flax/cotton blended yarn

A jute / linen / cotton blended yarn comprises three types of fiber of jute, linen and cotton and is characterized in that the weight of the linen fiber accounts for 10-40 percent by weight of the total weight of the jute, the linen and the cotton fiber. The fineness difference between the linen fiber and the jute fiber and the fineness difference between the linen fiber and the cotton fiber are both small. When being blended, the linen fiber of the blended yarn can be cohered with the jute fiber and can also be cohered with the cotton fiber, thereby enhancing the cohesion among different types of fiber; and the spun blended yarn has better breaking strength. The invention discloses the content range of the added linen fiber which can lead the breaking strength of the yarn to be more satisfactory during the blending of the jute fiber / cotton fiber with different weight percentages.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

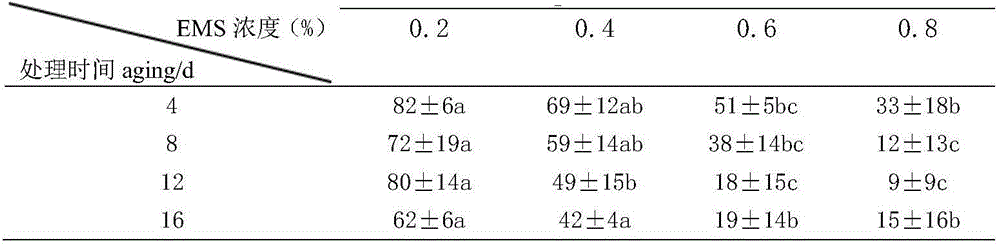

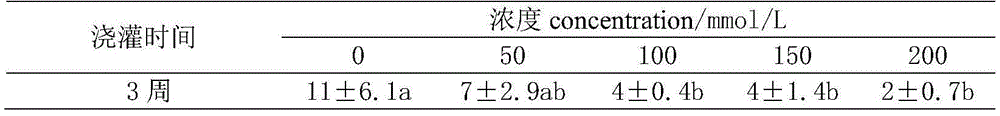

Method for mutagenizing flax seeds and screening salt-tolerance mutants

InactiveCN105638454AImprove use valueProcess conditions are easy to controlPlant genotype modificationEthylmethane SulfonateRoom temperature

Owner:XINJIANG UNIVERSITY

Chenopodium quinoa willd half-dried noodles with high lysine content and preparation method

InactiveCN106858319AImprove processing qualityImprove developmentFood ingredient as colourFood ingredient as flavour affecting agentFood additiveFlax fiber

The invention relates to chenopodium quinoa willd half-dried noodles with high lysine content. The chenopodium quinoa willd half-dried noodles are made from the following raw materials in percentage by weight: 20-30% of chenopodium quinoa willd flour, 5-15% of dietary flax fiber flour and 55-75% of high-gluten wheat flour. The chenopodium quinoa willd half-dried noodles disclosed by the invention have the advantages of being simple in technology, free from food additives and high in lysine content.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

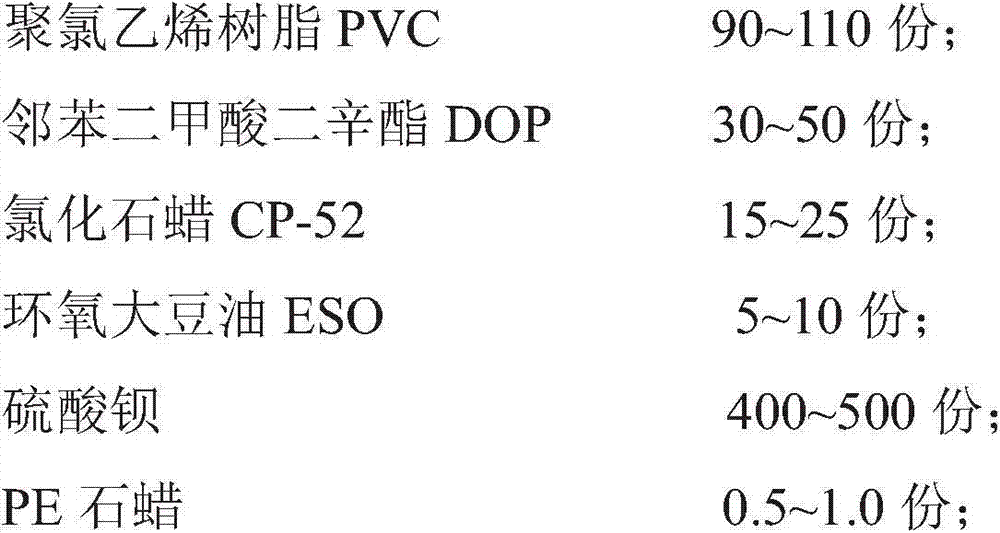

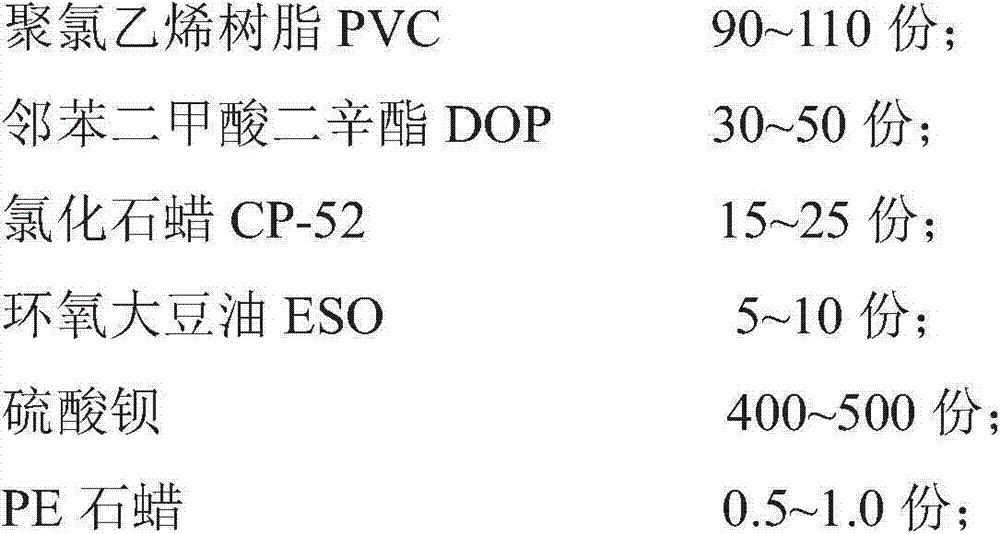

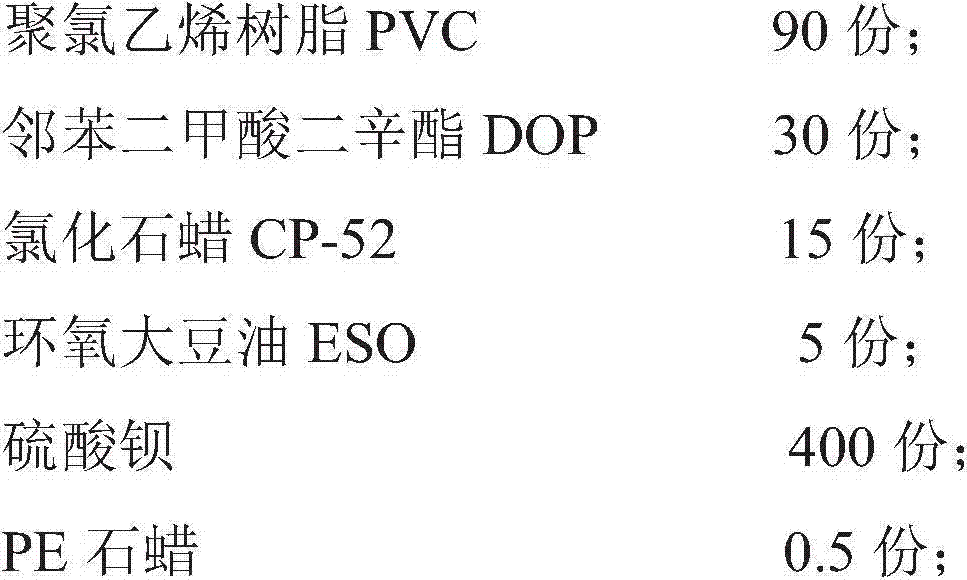

Preparation method of fiber composite material for signal cables and product thereof

ActiveCN104262827AImprove noise immunityMeet reciprocating stretchingPlastic/resin/waxes insulatorsMonocomponent halogenated hydrocarbon artificial filamentPolyvinyl chlorideFlax fiber

The invention discloses a preparation method of a fiber composite material for signal cables, which is characterized by comprising the following steps: (1) preparing polyvinyl chloride (PVC) resin fibers; (2) preparing flax fibers, immersing the prepared flax mixed fibers in a 2% sodium hydroxide solution for 1-2 hours, cleaning with clear water, treating in an acid bath for dealkalization, cleaning with deionized water until the cleaning solution is neutral, finally putting in a baking oven, and baking at 100-120 DEG C for 0.5-1 hour for later use; (3) preparing a fixing solution; and (4) by using the prepared PVC fibers as a base film, fixing the prepared flax fibers to the PVC fibers by using the prepared fixing solution, putting in a baking oven, baking at 100-120 DEG C for 0.5-1 hour, and naturally cooling to obtain the fiber composite material for signal cables. The invention also discloses a product prepared by the method.

Owner:DONGGUAN YINGTONG WIRE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com