Patents

Literature

78 results about "Wax ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

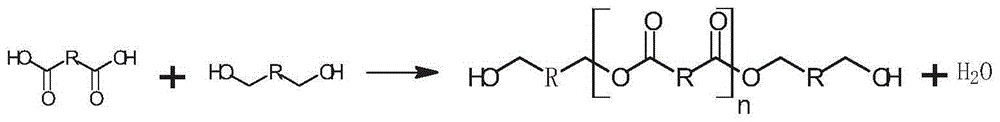

A wax ester (WE) is an ester of a fatty acid and a fatty alcohol. Wax esters comprise the main components of three commercially important waxes: carnauba wax, candelilla wax, and beeswax. Wax esters are formed by combining one fatty acid with one fatty alcohol: RCOOH+RʼOH<=>RCOORʼ+H₂O Various types of wax esters exist. Some are saturated, and others contain unsaturated centers. Saturated wax esters have higher melting points and are more likely to be solid at room temperature.

Wax ester compositions

Blends of wax-esters with beneficial health properties comprise: > / = two different wax-esters in amounts of 5-95% and each having m.pt -10 DEG C. to 80 DEG C. blend displaying m.pt: 15 to 45% while >80 wt % of wax-esters in blend have m.pt 20 to 60 DEG C.; wax-esters derived from linear alcohols and linear carboxyl acids either of them having > / =8 C-atoms.

Owner:LODERS CROKLAAN USA

Impregnating solution for cosmetic cloths

InactiveUS20060039956A1Cosmetic preparationsNon-ionic surface-active compoundsWax esterFatty alcohol

The invention relates to preparations for impregnating cosmetic wipes, characterized in that they contain (a) an emulsifier mixture containing nonionic and amphoteric surfactants in a quantity ratio of 10:1 to 1:1, based on the quantity of emulsifiers, (b) a mixture of wax components containing wax esters, partial glycerides and fatty alcohol ethoxylates and (c) at least one cationic polymer. The preparations containing wax particles lead to optimal foaming and cleansing performance and to a favorable sensorial impression.

Owner:COGNIS DEUT GMBH & CO KG

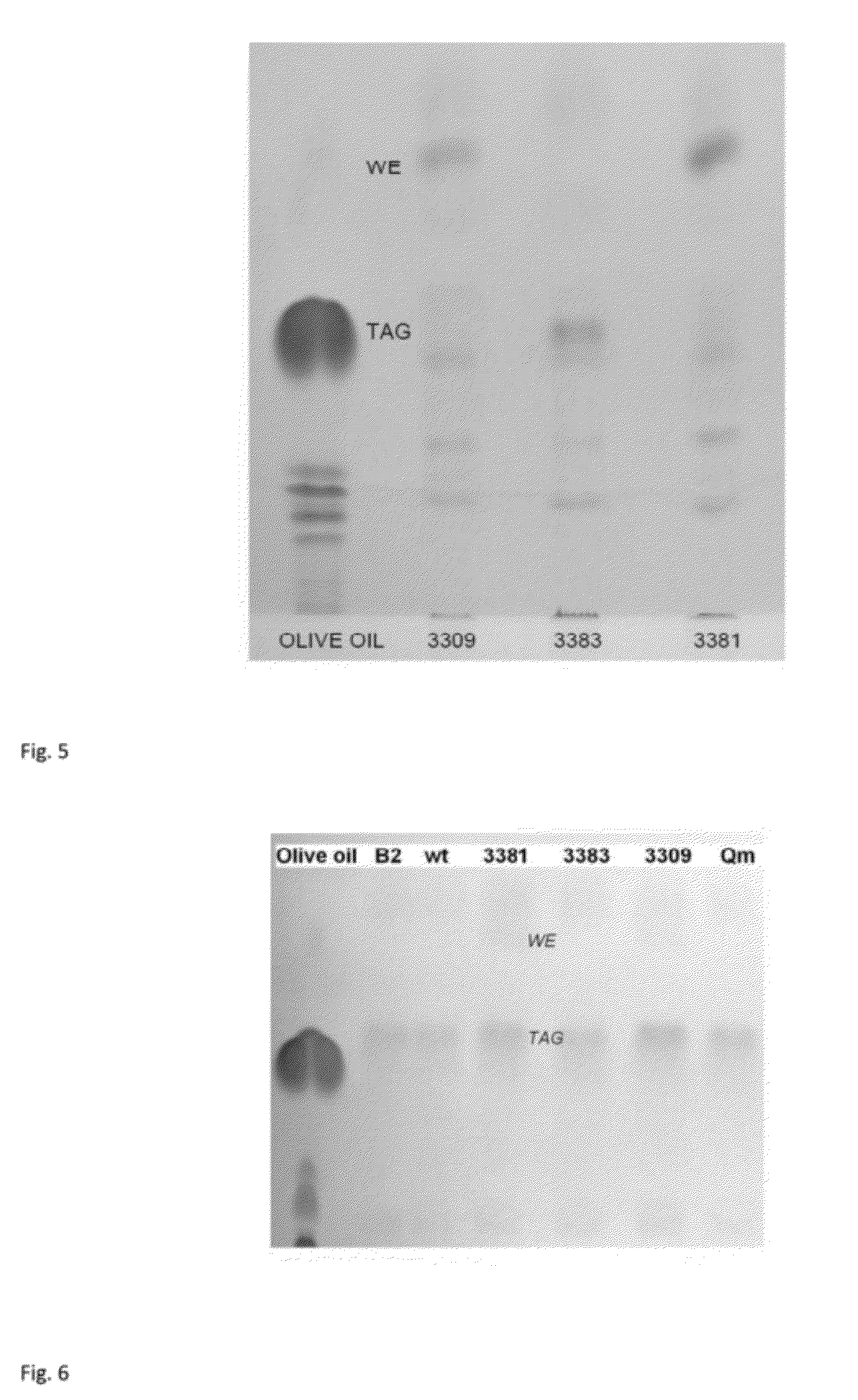

Acyltransferase

InactiveUS20060141457A1Easily calculateReduce needSugar derivativesPeptide/protein ingredientsAcyltransferaseNucleotide sequenc

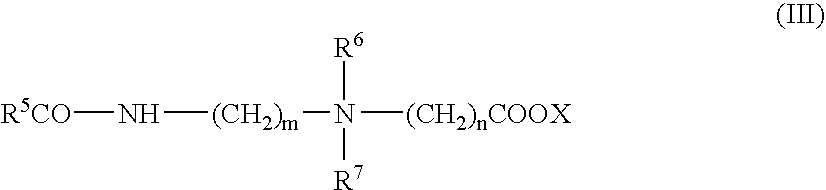

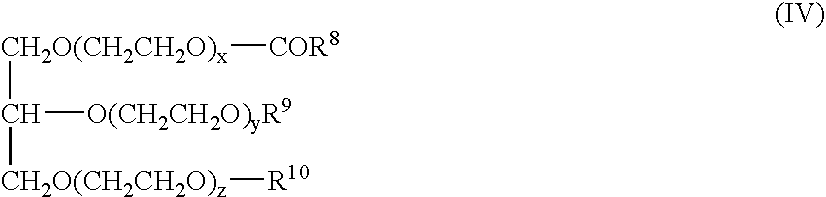

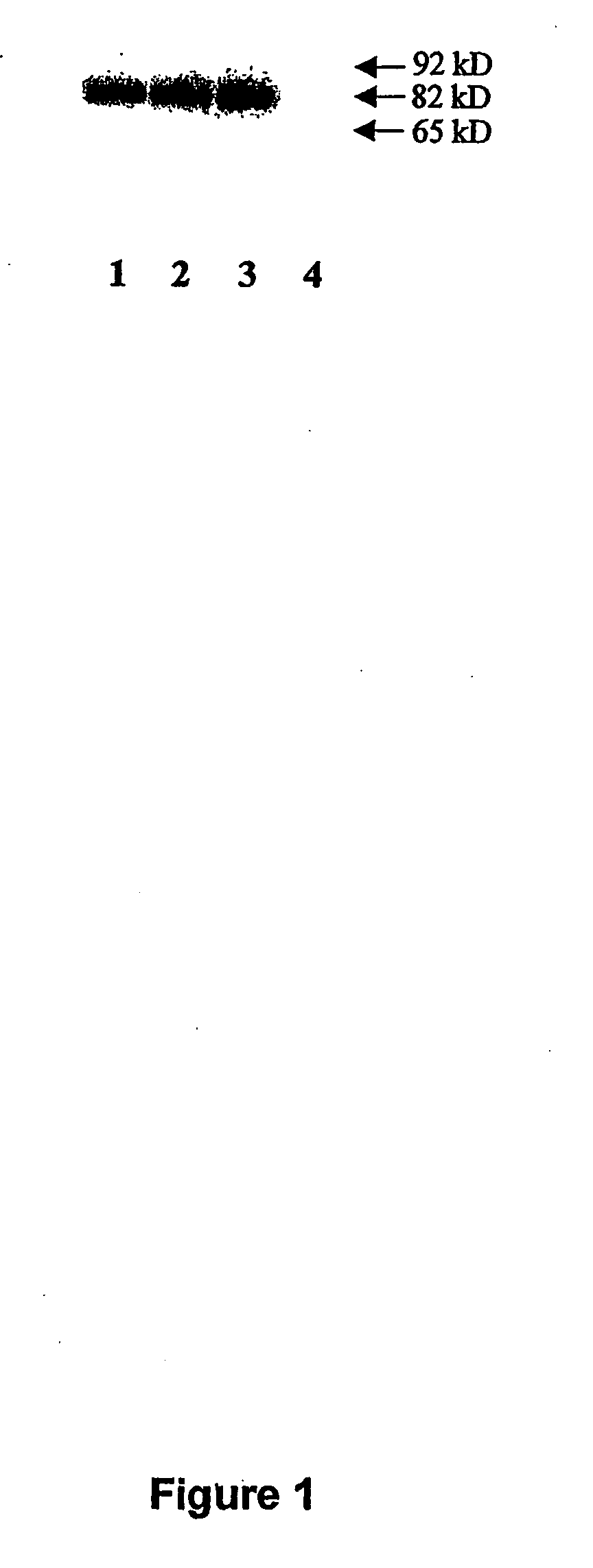

The invention relates to at least one nucleotide sequence, derived from a nucleotide sequence encoding an acyltransferase polypeptide comprising at least one membrane-spanning region, encoding an improved active membrane independent acyltransferase polypeptide in which at least one amino acid residue of the membrane-spanning region has been deleted and / or substituted as compared to the original acyltransferase polypeptide, wherein the encoded active membrane independent acyltransferase polypeptide can produce fatty acid esters and / or fatty acid thioesters such as triacylglycerols, diacylglycerols, monoacylglycerols, phospholipids, glycolipids, waxesters, acylated carbohydrates, acylated amino acids, and lysolipids, e.g. lysophosphospholipid, lysolecithin. Thereby one single acyltransferase can be used for the production of a huge number of products. The invention also relates to means and methods for the production of such an improved active membrane independent acyltransferase and the use of such a membrane independent acyltransferase in industry.

Owner:GENENCOR INT INC

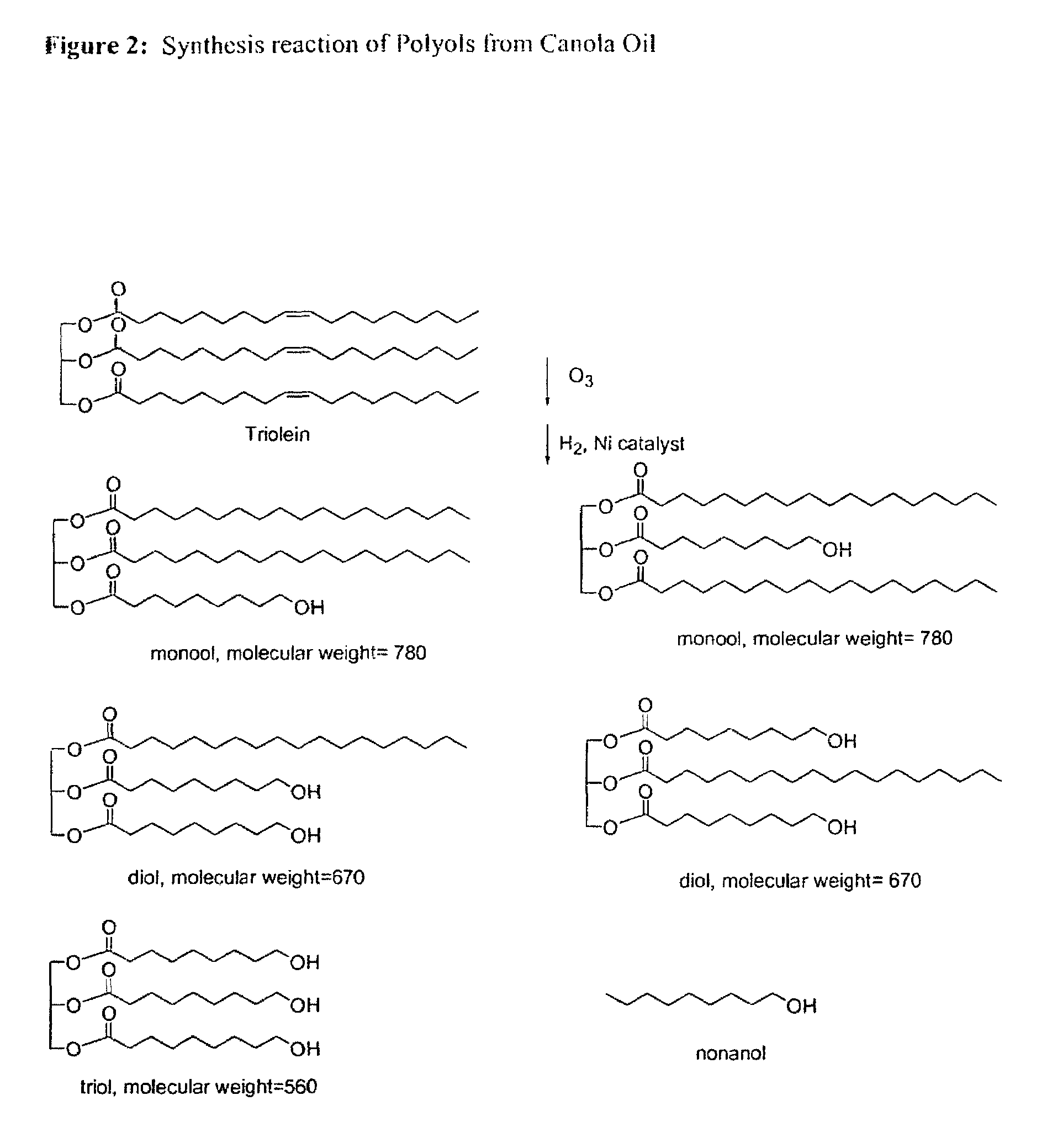

Bioplastics, monomers thereof, and processes for the preparation thereof from agricultural feedstocks

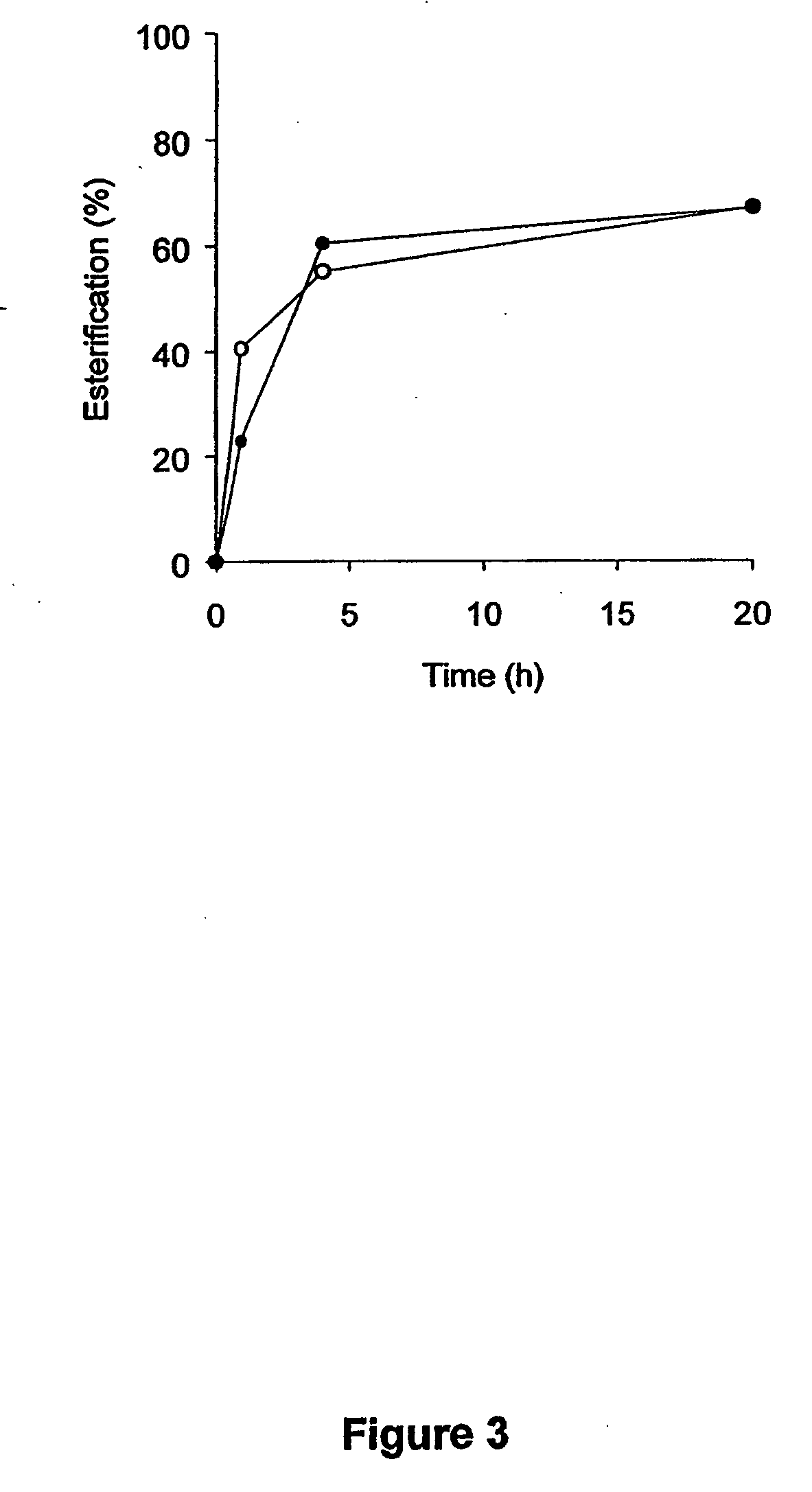

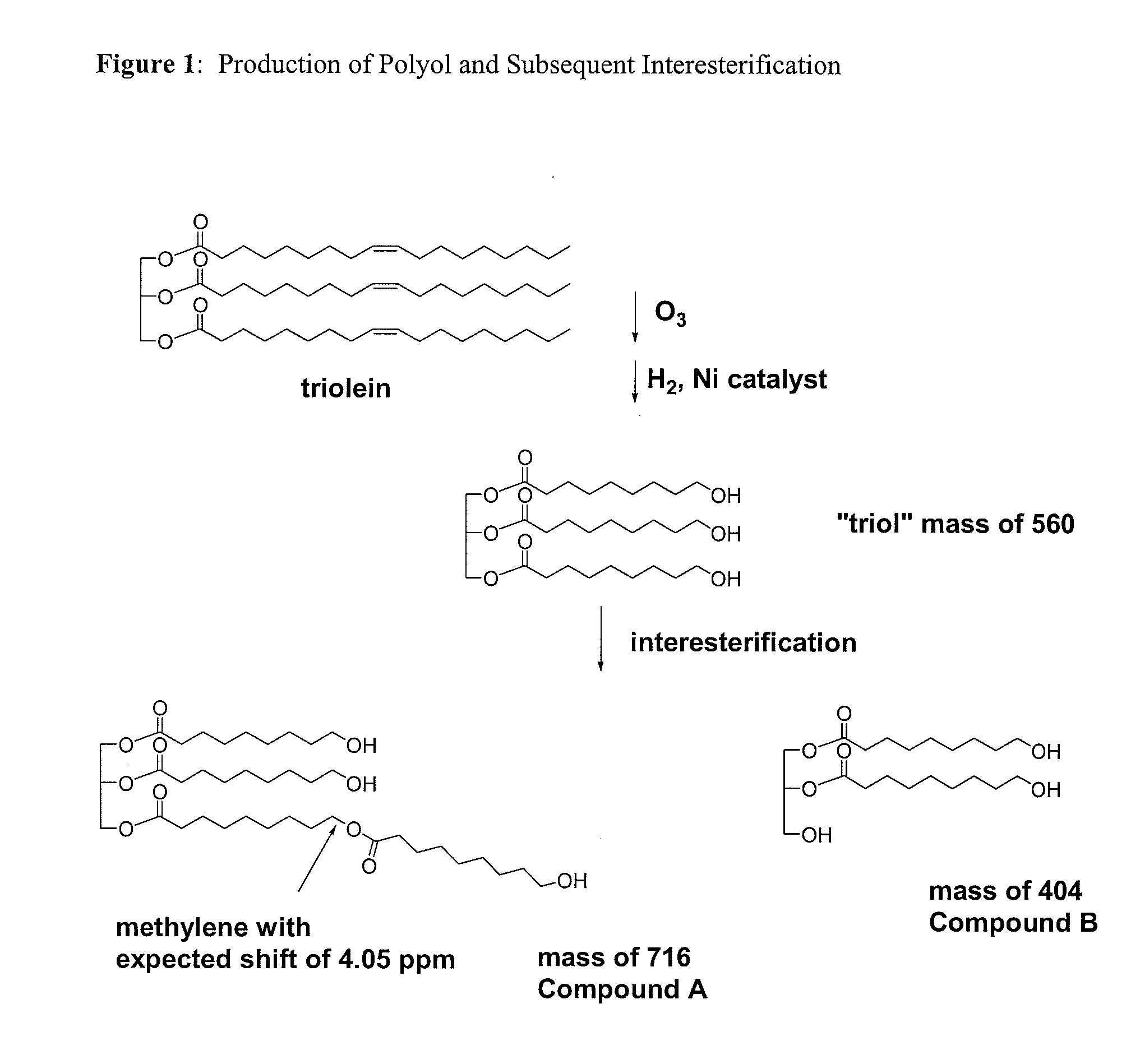

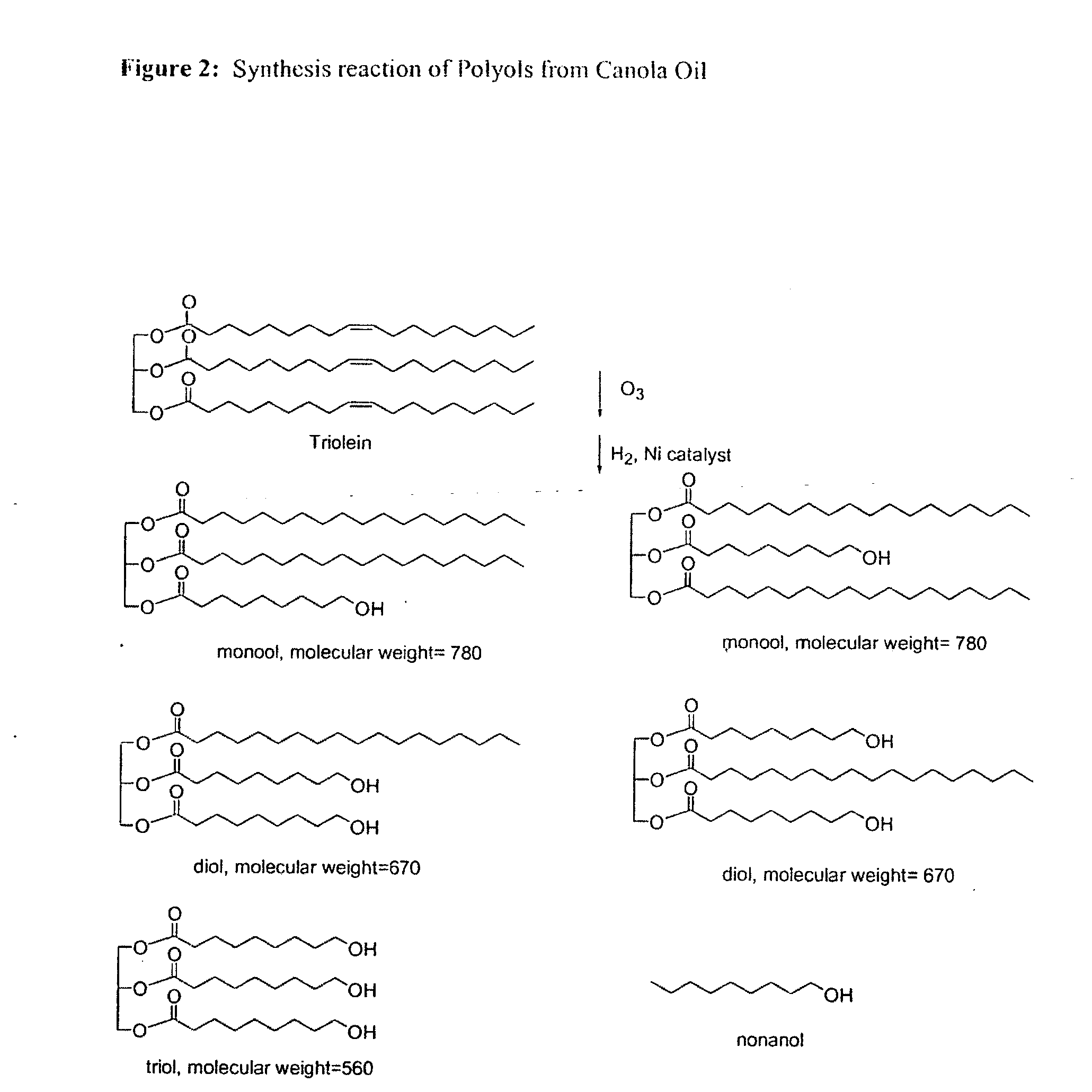

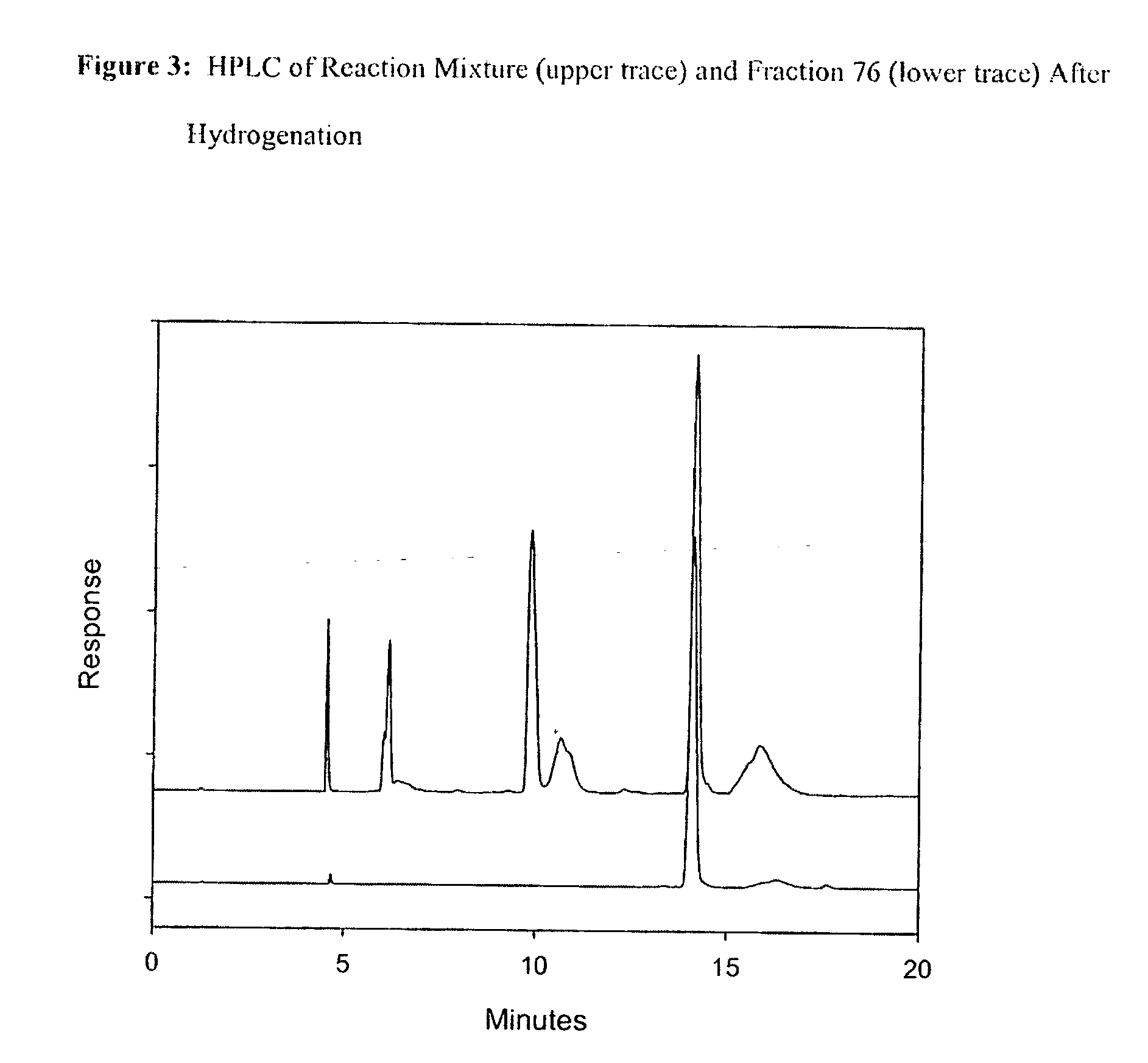

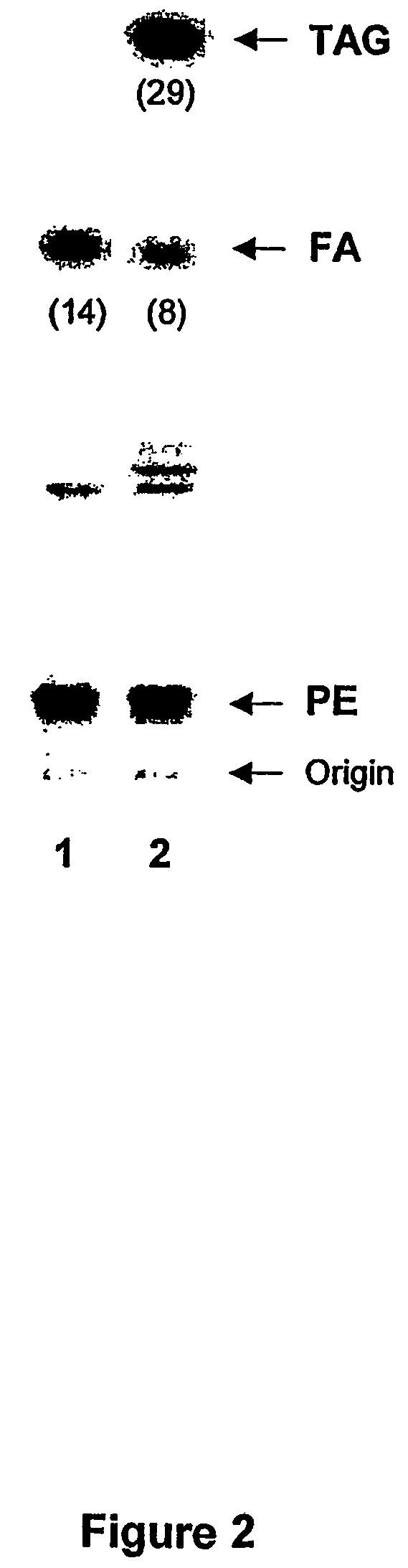

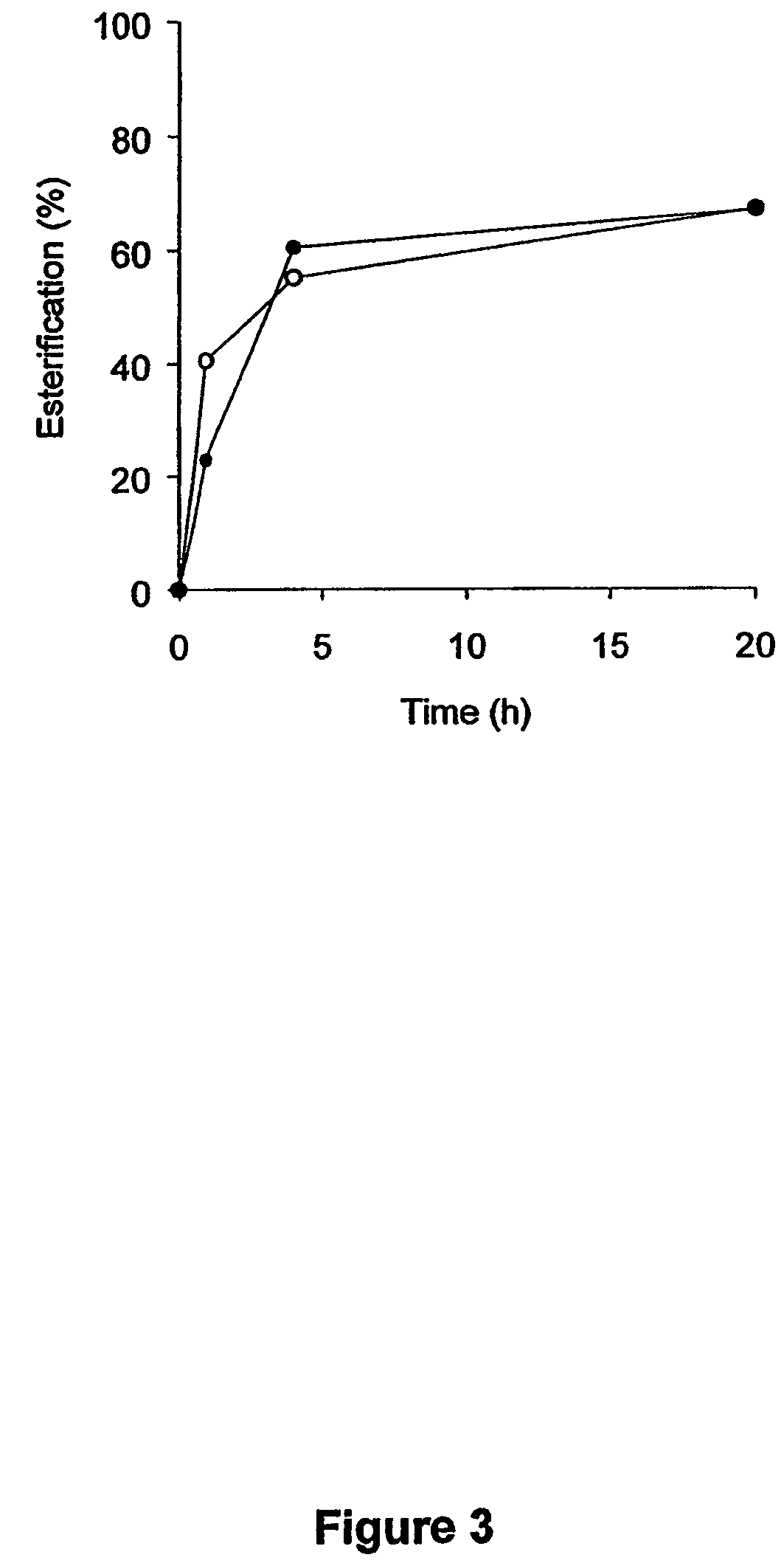

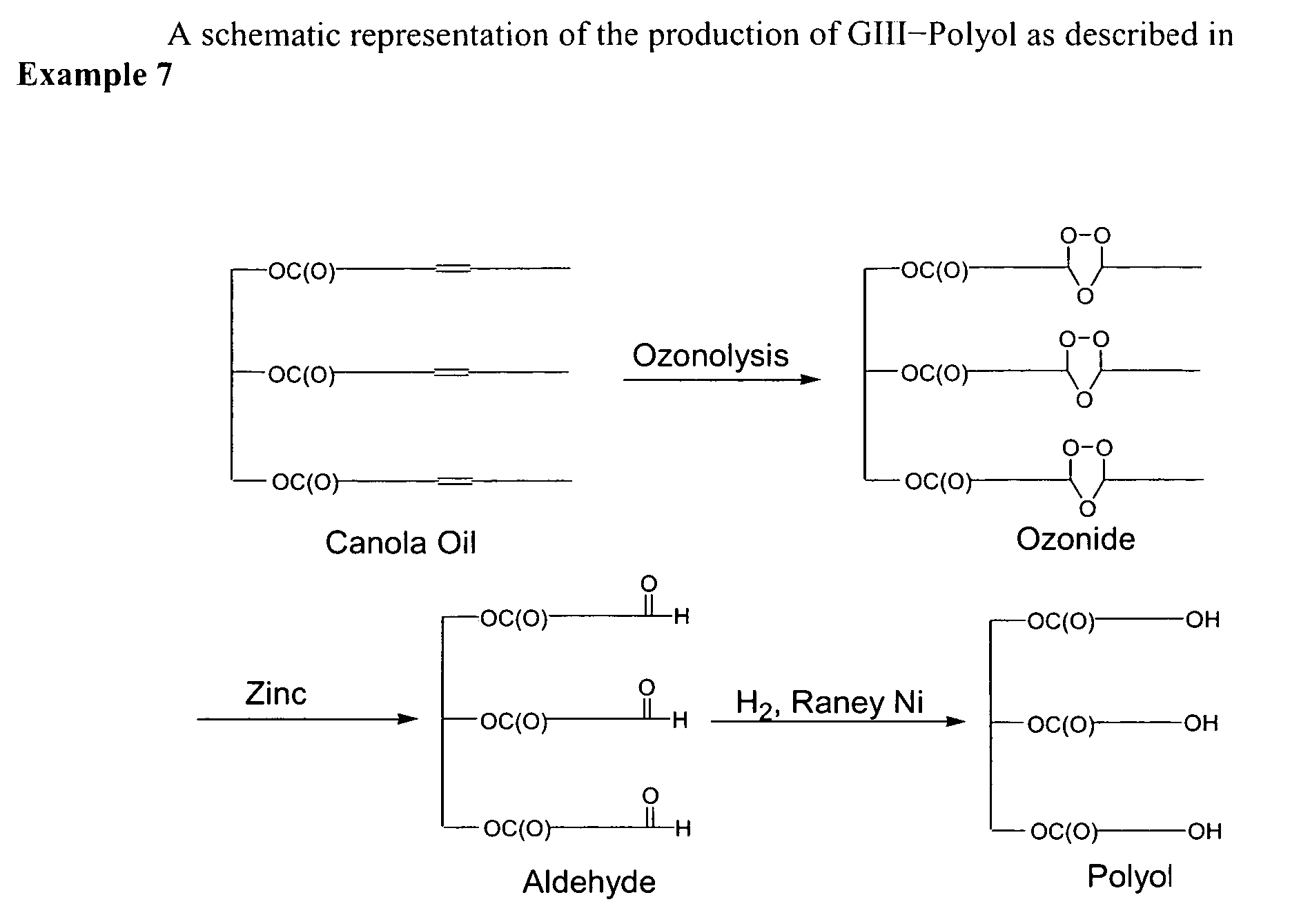

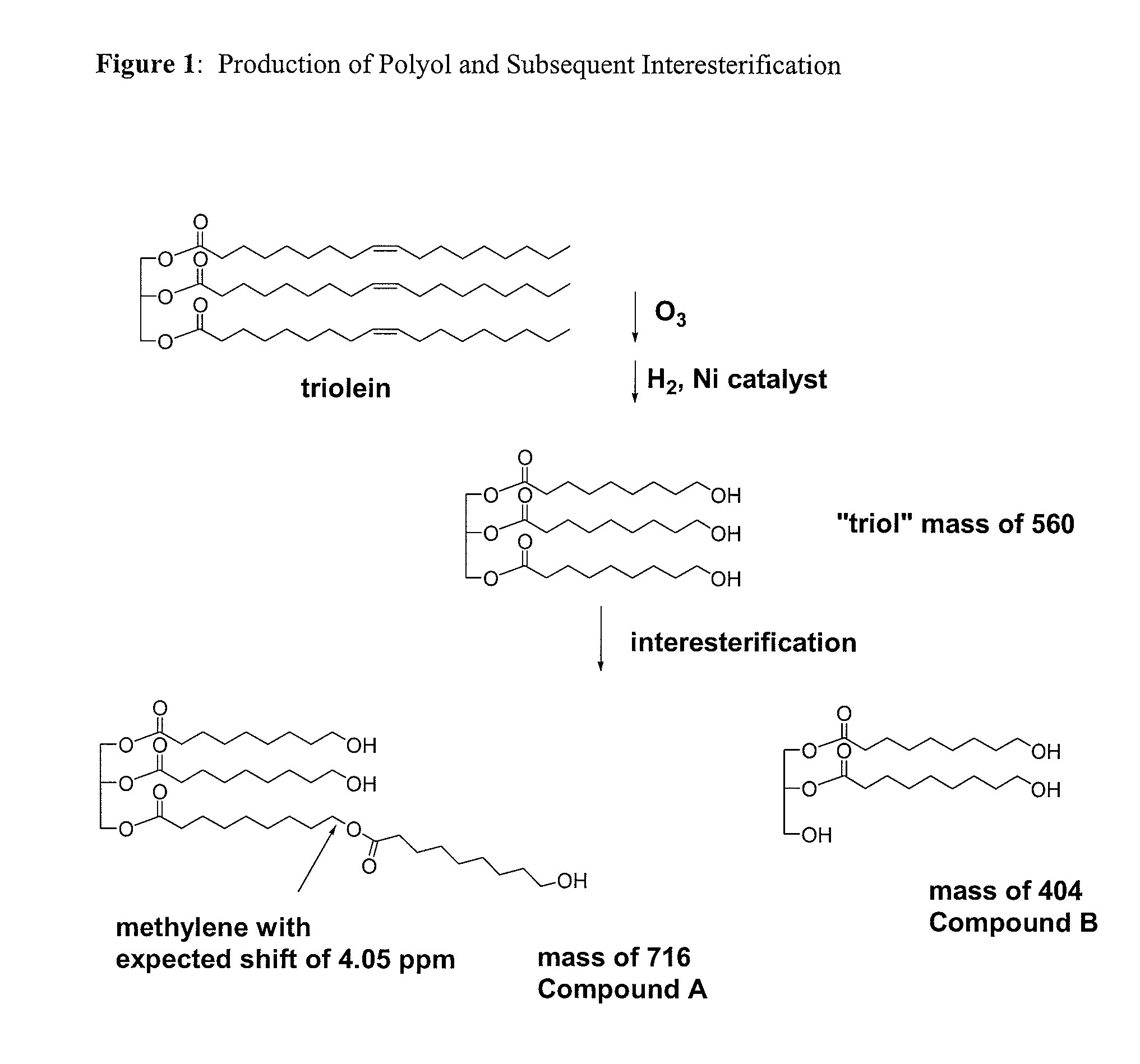

InactiveUS20070175793A1Improve responseReducing steric hindrance to crosslinkingFatty acid hydrogenationCoke ovensAlcoholWax ester

The present invention relates generally to polymers and monomers derived from agricultural feedstocks, and more particularly to methods for the production of monomers from renewable agricultural resources such as feedstocks, for example canola, flax and tallow, and polymers, in particular polyurethanes produced from monomers derived from such feedstocks. The present invention also relates to novel processes for the production of short-chain alcohols, as well as hydroxyl wax esters, from renewable feedstocks. An improved apparatus for carrying out ozonolysis reactions is also disclosed.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Acyltransferase

InactiveUS7498026B2Fatty acid esters) is increasedEasy to calculateSugar derivativesPeptide/protein ingredientsNucleotideNucleotide sequencing

Owner:GENENCOR INT INC

Ophthalmic compositions with wax esters

A suspension comprising a mixture of wax esters suspended in a formulation vehicle. The formulation vehicle comprises a lightly cross-linked carboxy-containing polymer and a concentration of ionic salt components to provide the suspension with a calculated ionic strength of less than 0.1. The suspension has the following rheological properties, (T>G″ and a suspension yield value of greater than 1 Pa. Also, upon addition of 30 mL of the suspension to a volume of 6 mL to 12 mL of simulated tear fluid, the resulting tear mixture transitions to a liquid form wherein, G″>G′ and the tear mixture has a yield value of less than 0.1 Pa.

Owner:BAUSCH & LOMB INC

Bioplastics, monomers thereof, and processes for the preparation thereof from agricultural feedstocks

InactiveUS7538236B2Reducing steric hindrance to crosslinkingProduce some attenuationFatty acid hydrogenationCoke ovensAlcoholWax ester

The present invention relates generally to polymers and monomers derived from agricultural feedstocks, and more particularly to methods for the production of monomers from renewable agricultural resources such as feedstocks, for example canola, flax and tallow, and polymers, in particular polyurethanes produced from monomers derived from such feedstocks. The present invention also relates to novel processes for the production of short-chain alcohols, as well as hydroxyl wax esters, from renewable feedstocks. An improved apparatus for carrying out ozonolysis reactions is also disclosed.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

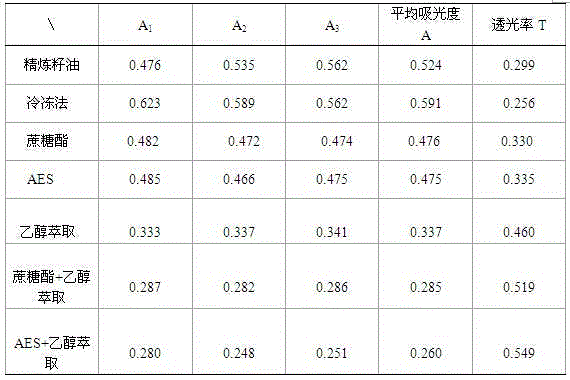

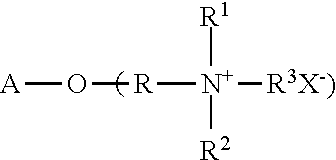

Method for dewaxing peony seed oil by combination of surfactant-crystallization copolymerization and alcohol extraction

InactiveCN104017645AHigh removal rateEasy to separateFatty-oils/fats refiningBiotechnologyAnhydrous ethanol

The invention discloses a method for dewaxing peony seed oil by combination of surfactant-crystallization copolymerization and alcohol extraction, which comprises the following steps: heating peony seed oil to 70-90 DEG C until the wax crystal precipitated at normal temperature is completely dissolved in the peony seed oil, cooling to 50-65 DEG C, adding a surfactant which accounts for 0.08-0.15 wt% of the peony seed oil, slowly cooling while stirring, stopping stirring when the temperature drops to 5-8 DEG C, growing the grain, carrying out centrifugal separation, and taking the supernatant oil for later use; adding an anhydrous ethanol solution into the supernatant oil, transferring into a separating funnel, standing, separating, taking the understratum oil, extracting once, taking the understratum oil, and finally, removing the ethanol solution. By combining the surfactant and ethanol extract phase, the low-viscosity favorable-flowability dewaxed oil with clear and bright color can be obtained; and the method improves the phenomena of premature adhesion and even waxing due to poor dewaxing effect and incapability of effectively removing wax in oil in the traditional dewaxing process.

Owner:HENAN UNIV OF SCI & TECH

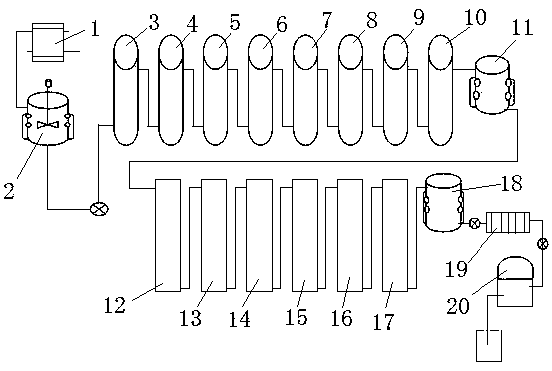

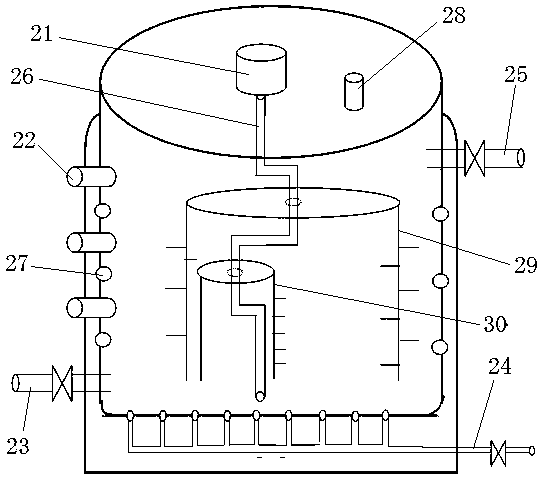

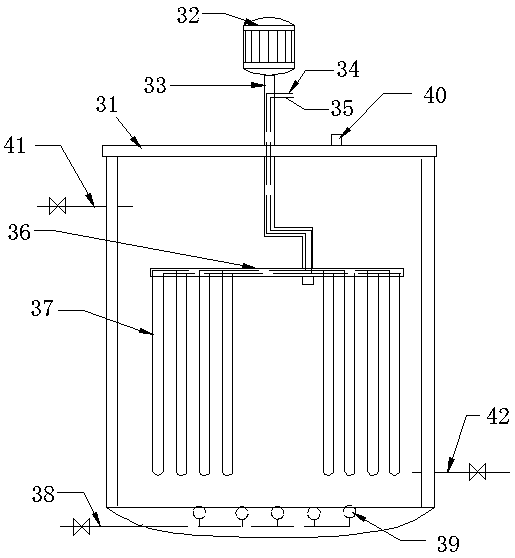

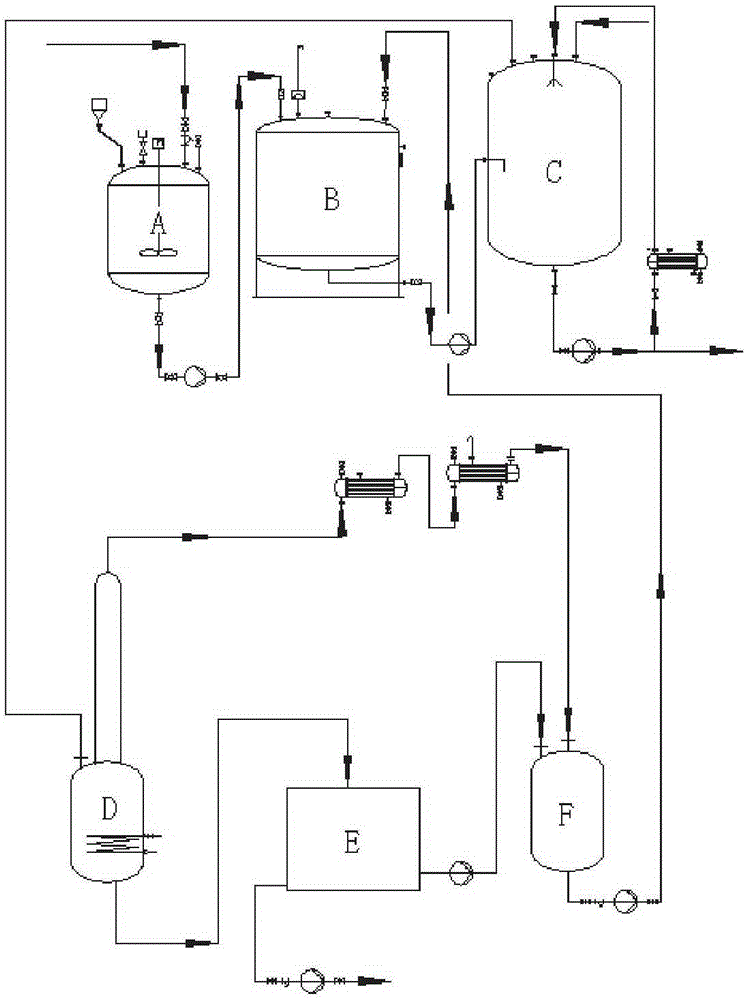

Method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining

ActiveCN107746746ALess destructiveDestructiveFatty-oils/fats refiningFatty-oils/fats separationOil and greaseVegetable oil

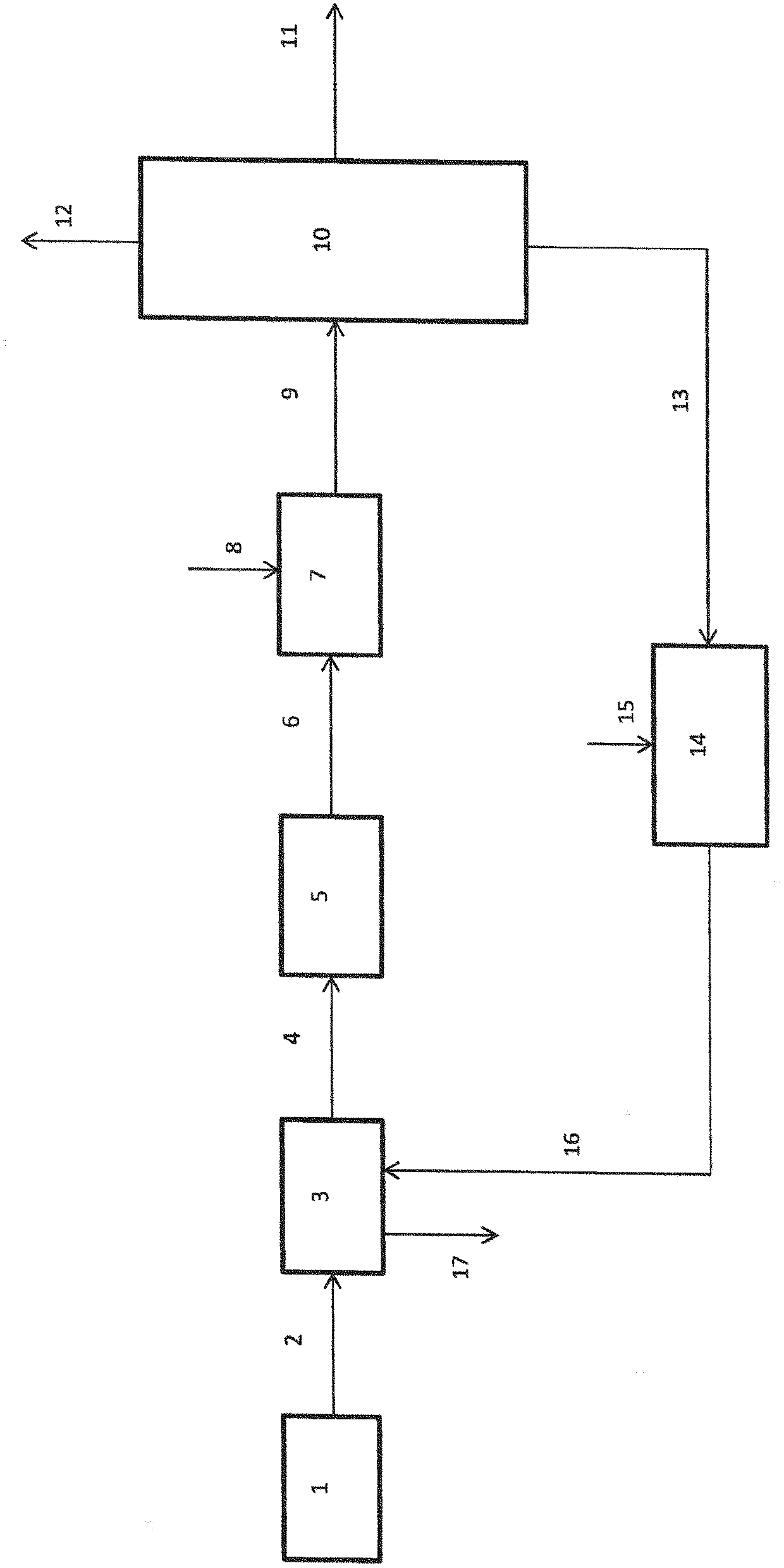

A method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining are disclosed. Oil and grease dewaxing is performed through eight-stage staged cooling crystallization, six-stage constant-temperature crystal growing, and two-stage low-temperature filtration. Special crystallization and crystal growing devices are adopted, interferences of transmission on crystallization and crystal growing processes are effectively solved as a whole, the heat conduction efficiency is higher, crystal damage caused by a transmission device and relative movement in an oil and grease system is less, energy consumption is lower, crystal dispersibility is significantly improved, and aggregation effects of wax, esters and high-melting-point fat are better. The method and the equipment can further improve dewaxing, winterization and dewaxing effects in crystallization and crystal growing processes of wax-containing vegetable oil, prolong oil product refrigeration time to 60 h or above, improve flavor and quality of oil and make oil palatability good. The method and the equipment are suitable for corn oil, sunflower seed oil, soybean oil, rice bran oil, and the like, and are particularly suitable for corn oil, sunflower seed oil, and the like.

Owner:SHANDONG XIWANG FOOD

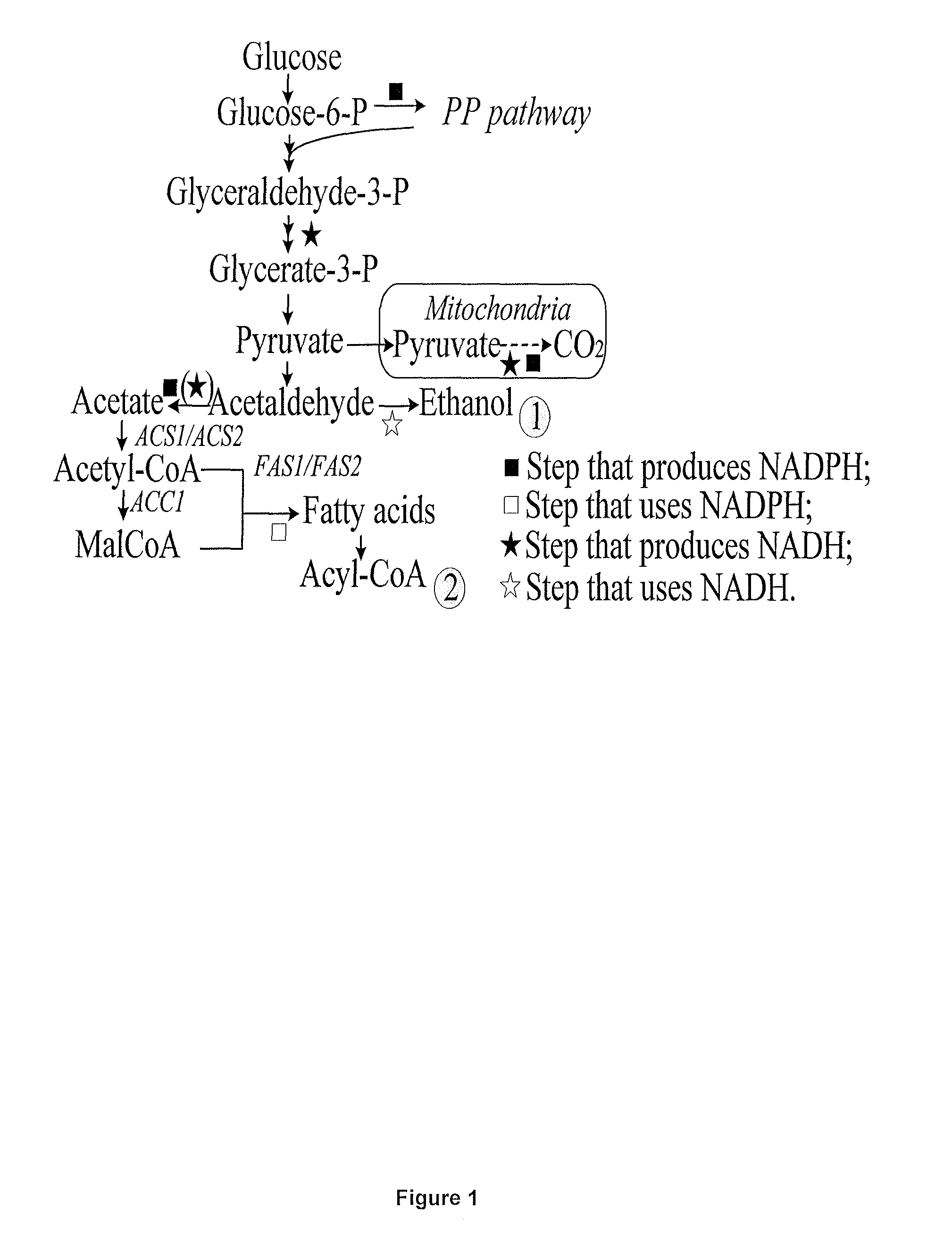

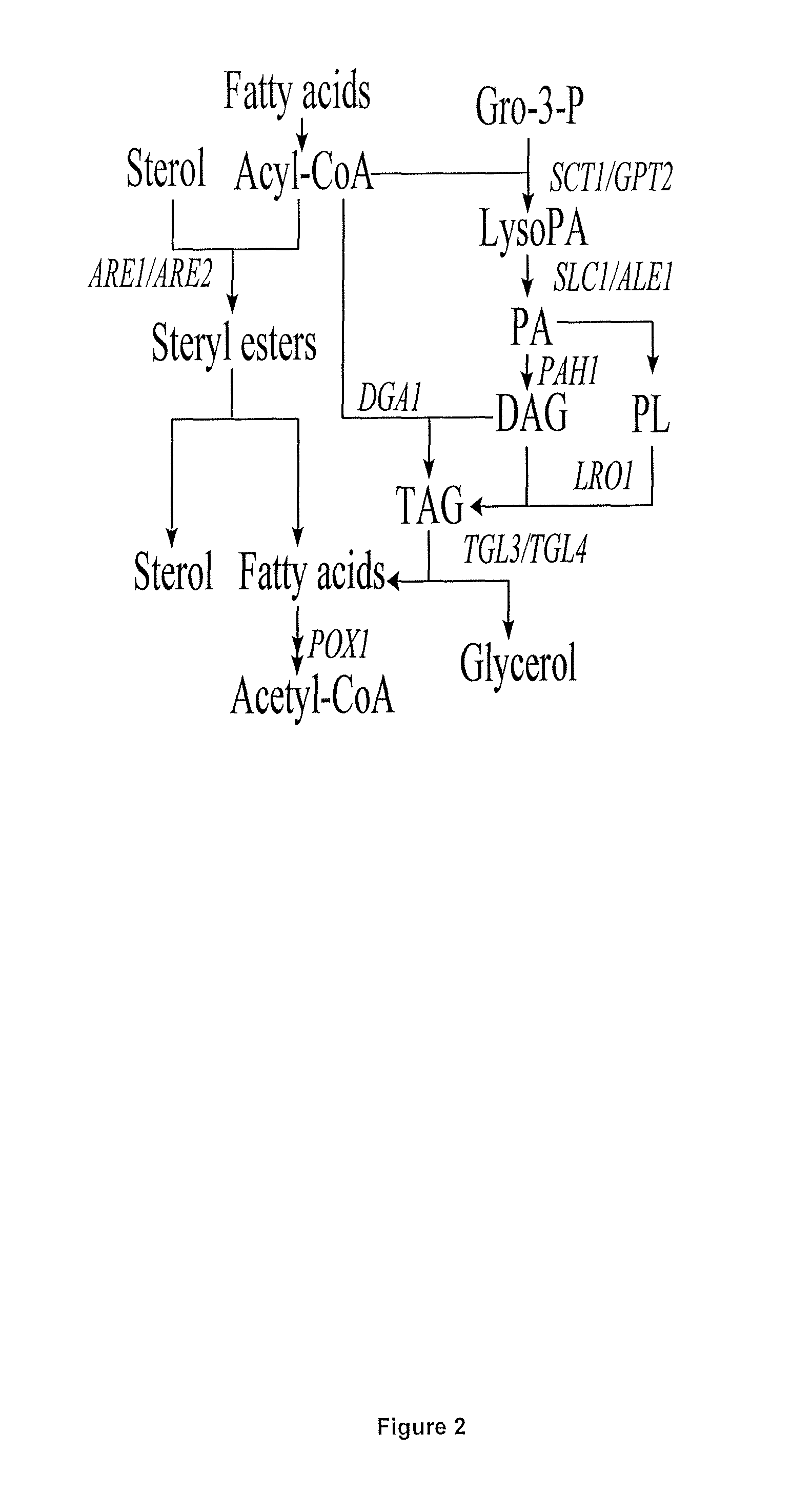

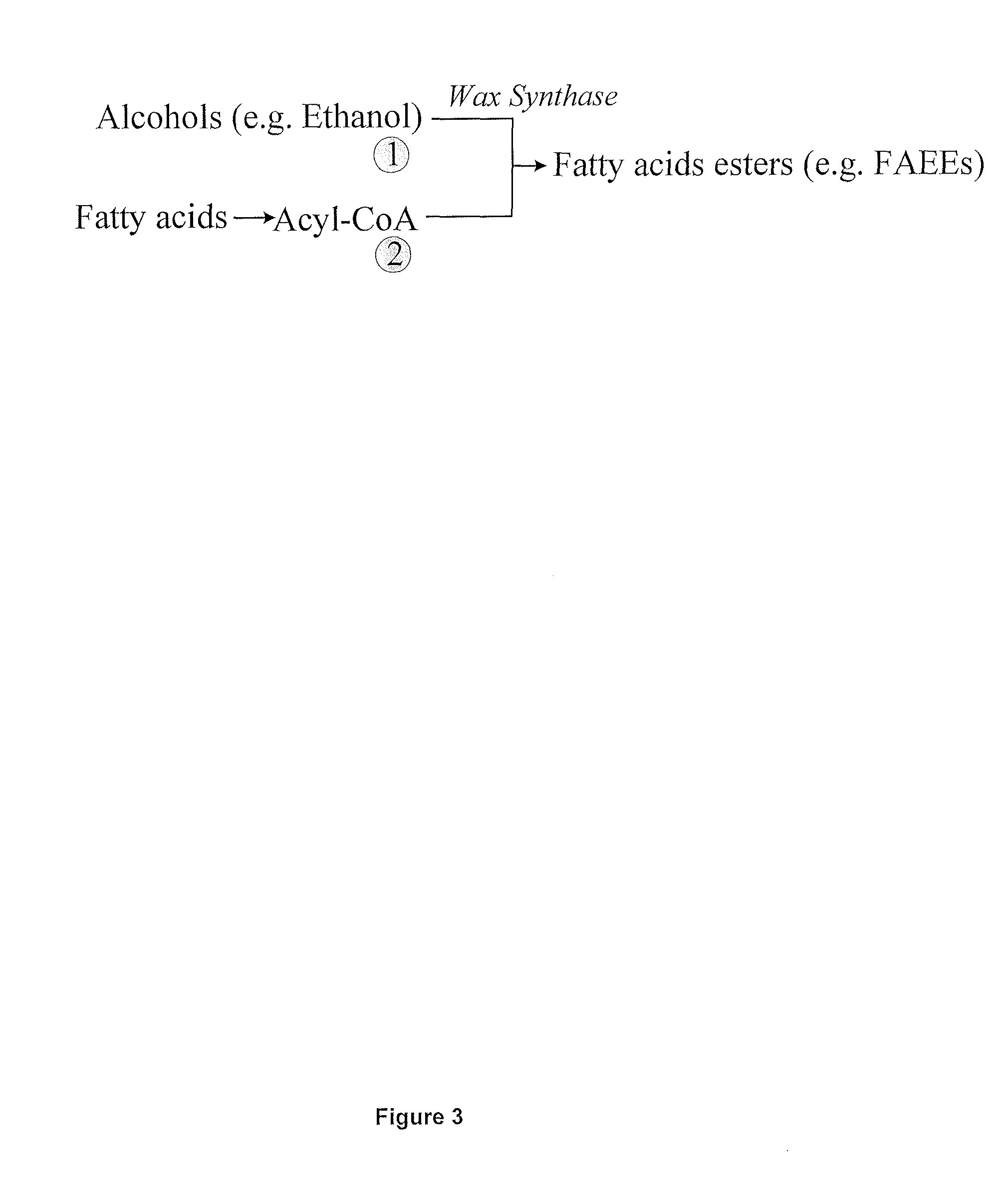

Methods and products for production of wax esters (u.s. national phase)

InactiveUS20130197248A1Improve throughputHigh level productionOrganic chemistryMicroorganismsYeastWax ester

The present invention relates to the provision of genetically modified fungal cells, such as yeast cells with an improved ability for producing different fatty acids and specifically fatty acid ethyl esters (FAEE), the main components of biodiesel. An increased in fatty acid production, and hence in FAEE, is obtained in the first place by expressing different heterologous polypeptides in combination with the down-regulation, attenuation, deletion or over-expression of specially selected genes, wherein said genes encode enzymes involved in the fatty acids synthesizing pathway, fatty acid consuming pathways, carbohydrate biosynthesis pathways or enzyme acting as wax ester transporters or a combination thereof. The methods and products of the invention would allow large-scale production of FAEE with carbohydrates as the only externally-supplied substrate.

Owner:BIOPETROLIA

Dry emollient compositions

The present invention are dry-feel emollient compositions comprising jojoba oil based esters that have use in personal care, cosmetic, cosmaceutical and pharmaceutical products. These compositions are essentially solid at room temperature, can be provided in various shapes and sizes (especially as particulates such as spheres), and can be produced from combinations of fatty alcohols, isopropyl esters and wax esters obtained from the oil contained in the seed of the jojoba plant. These new compositions also increase the range of applications for cosmetic compositions through an emollient that is more polar and hydrophilic than is found in jojoba oils. The compositions of the present invention may be obtained by a novel process of a base catalyzed alcoholysis reaction between jojoba oil and an alcohol, such as isopropyl alcohol. These components, whether exclusively jojoba esters or when combined with other carrier and vehicle components (including other emollients or binders) can form excellent carrier composition for use in the cosmetic, personal care and / or pharmaceutical field. Typical materials with which the compositions of the present invention may be blended include, but are not limited to, cosmetic oils and waxes, both natural and synthetic, (including hydrogenated or partially hydrogenated oils), silicone oils, mineral oils, long chain esters, vitamins, long chain fatty acids, cosmeceuticals, pigments, botanical extracts, esters and ethers, dimers, trimers, oligomers, and polymers, and the like. The proportions of the jojoba esters should be chosen to provide the dry-feel to the composition, which is highly desired. This will usually require a weight percent that ranges from 10% to 100% by weight of carrier material in the composition.

Owner:INT FLORA TECH

Cosmetic with no or less emulsifier and preservative

InactiveCN102488638AGrowth inhibitionReduce stimulationCosmetic preparationsToilet preparationsAlkaneAdditive ingredient

The invention relates to a cosmetic with no or less emulsifier and preservative, belonging to the technical field of cosmetics. The cosmetic comprises an A agent, namely an aqueous phase, a B agent, namely an oil phase, and a C agent, namely a nourishing and moisturizing ingredient, wherein the A agent, namely the aqueous phase, is one or a mixture of purified water, mineral water, wine, sake or ice wine; the B agent, namely the oil phase, is one or a mixture of wax ester, fatty alcohol, fatty acid, triglyceride, steroid, phospholipid, polyol ester, higher fatty acid, higher alcohol ester, fatty alcohol ester, aliphatic ester, alkane oil and fat, hydrophilic or oleophilic lanolin derivatives, hydrophilic or oleophilic beewax derivatives, silicone oil, oil soluble natural plant extracts, oil soluble vitamins and derivatives; and the C agent, namely the nourishing and moisturizing ingredient, is one or a mixture of polyatomic alcohol, polyethylene glycol, sodium hyaluronate, panthenol, water soluble vitamins and derivatives, and water soluble natural plant extracts, wherein no or less emulsifier and preservative can be added; in addition, because the aqueous phase, the oil phase and the nourishing and moisturizing ingredient are separated, single ingredient can be used, or a plurality of ingredients can be used in a mixed manner according to personal preferences and skin properties.

Owner:JIANGNAN UNIV

Process for producing fatty alcohols from fatty acids

ActiveCN103282335ATo minimize the generation ofEasy to crackFatty acid hydrogenationFatty acid esterificationIodo fatty acidDistillation

Owner:JOHNSON MATTHEY DAVY TECH LTD

Method for production of euglena containing wax ester at high cotent, and method for production of wax ester

ActiveUS20130115666A1Cheap offerImprovement in energy self-sufficiency rateUnicellular algaeFermentationNitrogenWax ester

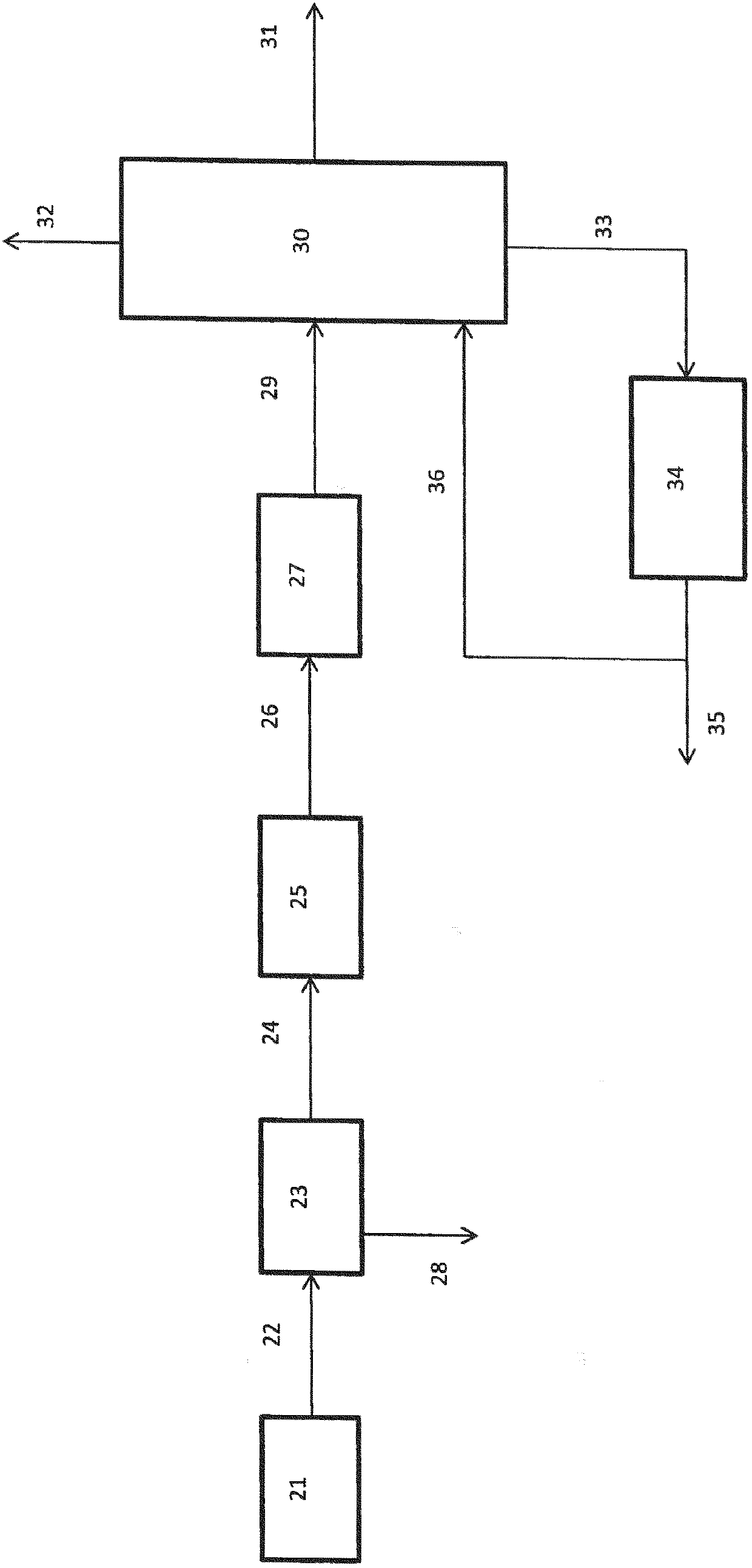

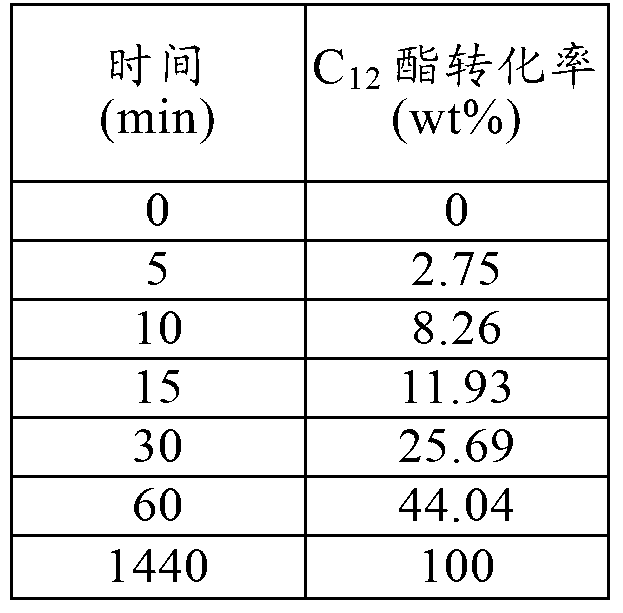

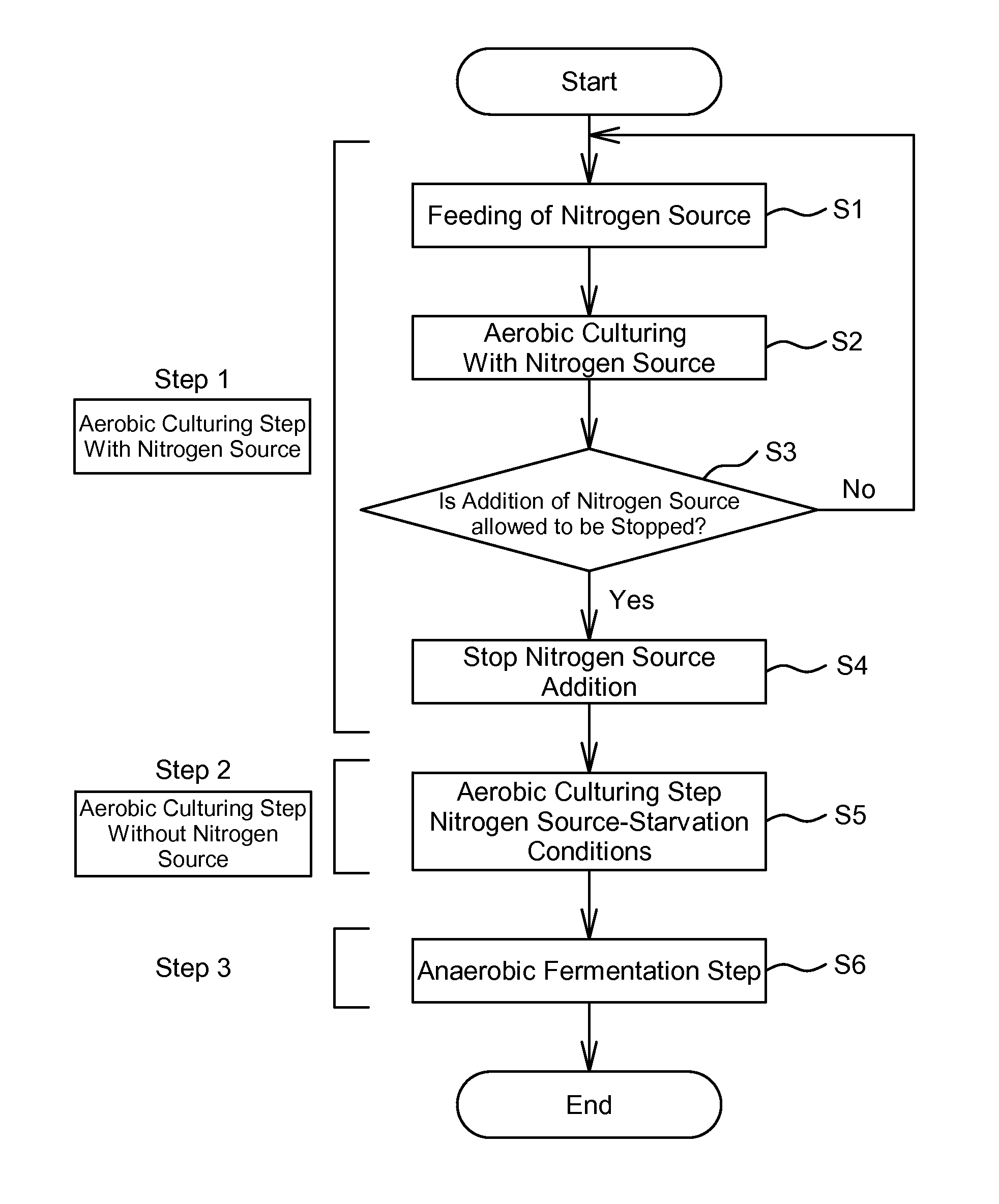

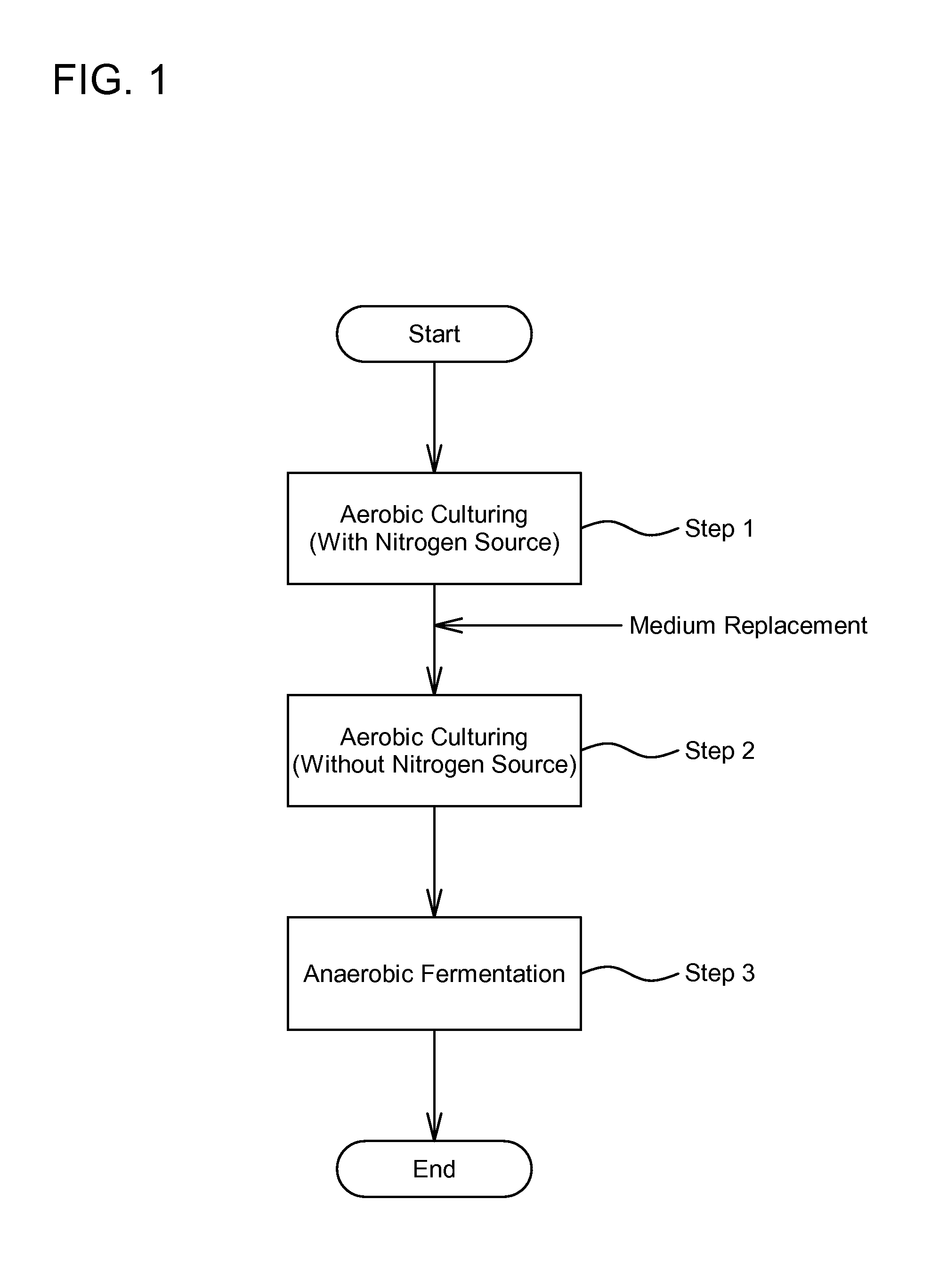

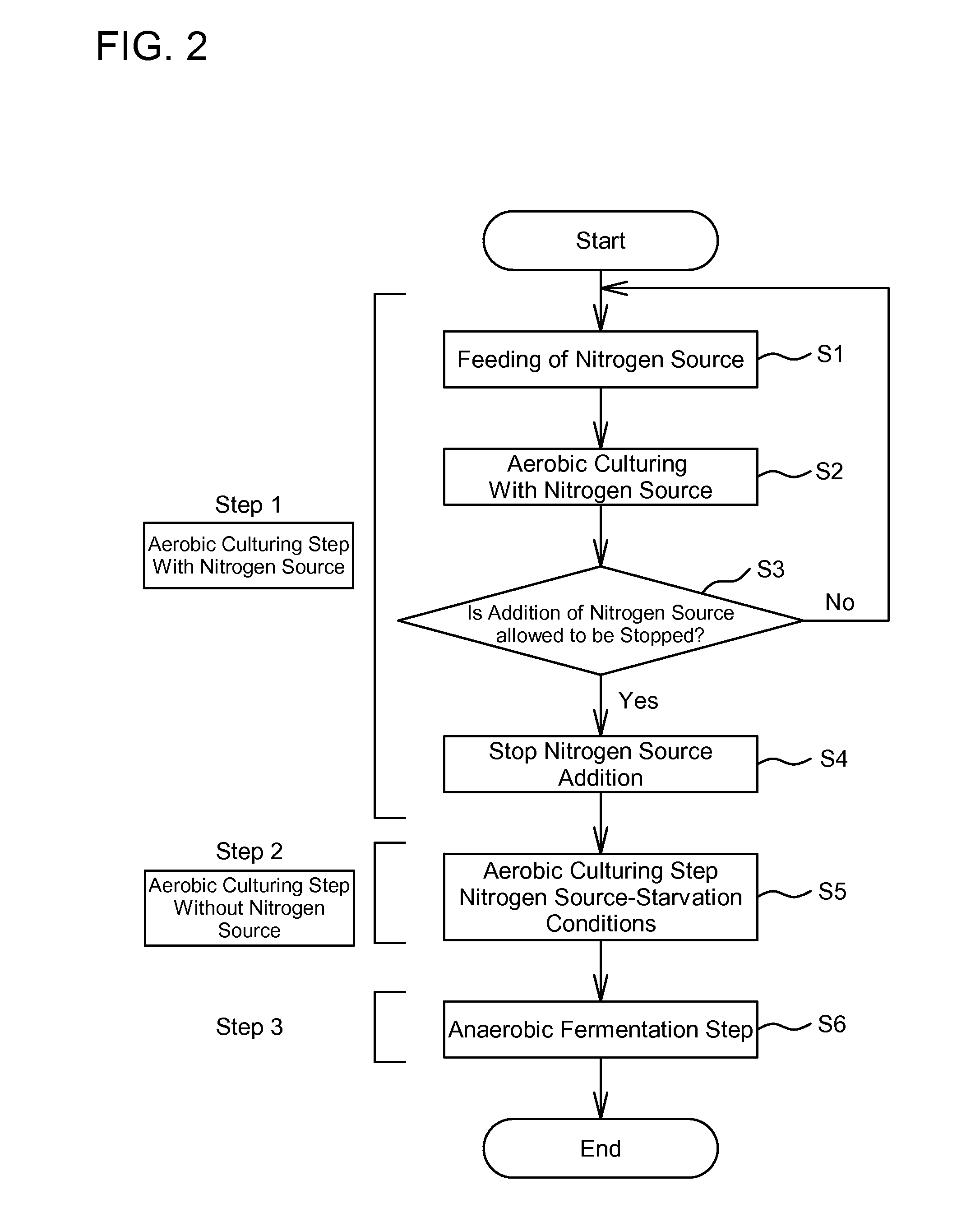

Provided is a method for producing a euglena highly containing a wax ester, comprising aerobically culturing a microalga euglena by photosynthesis using carbon dioxide as a carbon source, then further culturing the microalga euglena under nitrogen-starvation conditions to increase paramylon accumulation per cell, and subsequently putting the microalga euglena under anaerobic conditions, so that a euglena highly containing a wax ester can be produced; and a method for producing a wax ester.The present invention relates to a method for producing a euglena highly containing a wax ester. The method comprises a first step of aerobically culturing a microalga euglena, a second step of further culturing a medium under nitrogen-starvation conditions, and a third step of retaining the cells under anaerobic conditions.

Owner:EUGLENA

Compositions and methods for exfoliating particles

Various embodiments provide compositions for exfoliating particles and methods for their manufacture. In one exemplary embodiment, the exfoliating particles may comprise a derivative of a botanically-sourced emollient, stearyl stearate, and at least one of: candelilla wax, is bran wax, sunflower wax, jojoba esters, carnauba wax, bees wax, corn wax, a saturated wax-ester, castor wax, ouricury wax, hydrogenated lanolin, and a hydrogenated triglyceride wax, Exemplary methods for producing the exfoliating particles may comprise melting, combining, and / or homogenizing the components of the exfoliating particles and cooling the resultant mixture in a process to form particles of a desired shape and / or size. The exfoliating particles may be for topical use and may be stable in personal care compositions.

Owner:INT FLORA TECH

Water-free preparation

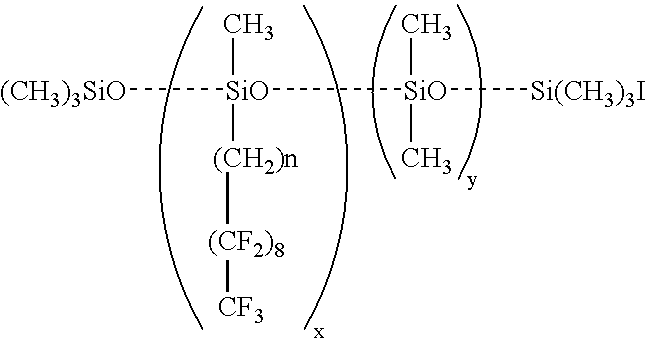

A water-free preparation, in particular for application to the lips, which contains a silicone-free phase which contains at least one polybutene and / or polyisobutene, at least one isoparaffin, at least one wax and / or wax ester and optionally conventional adjuvant and additive substances and a silicone-bearing phase which contains at least one fluorosilicone, at least one dimethicone, at least one dimethiconol and optionally a particulate phase and fillers.

Owner:SCHWAN STABILO COSMETICS

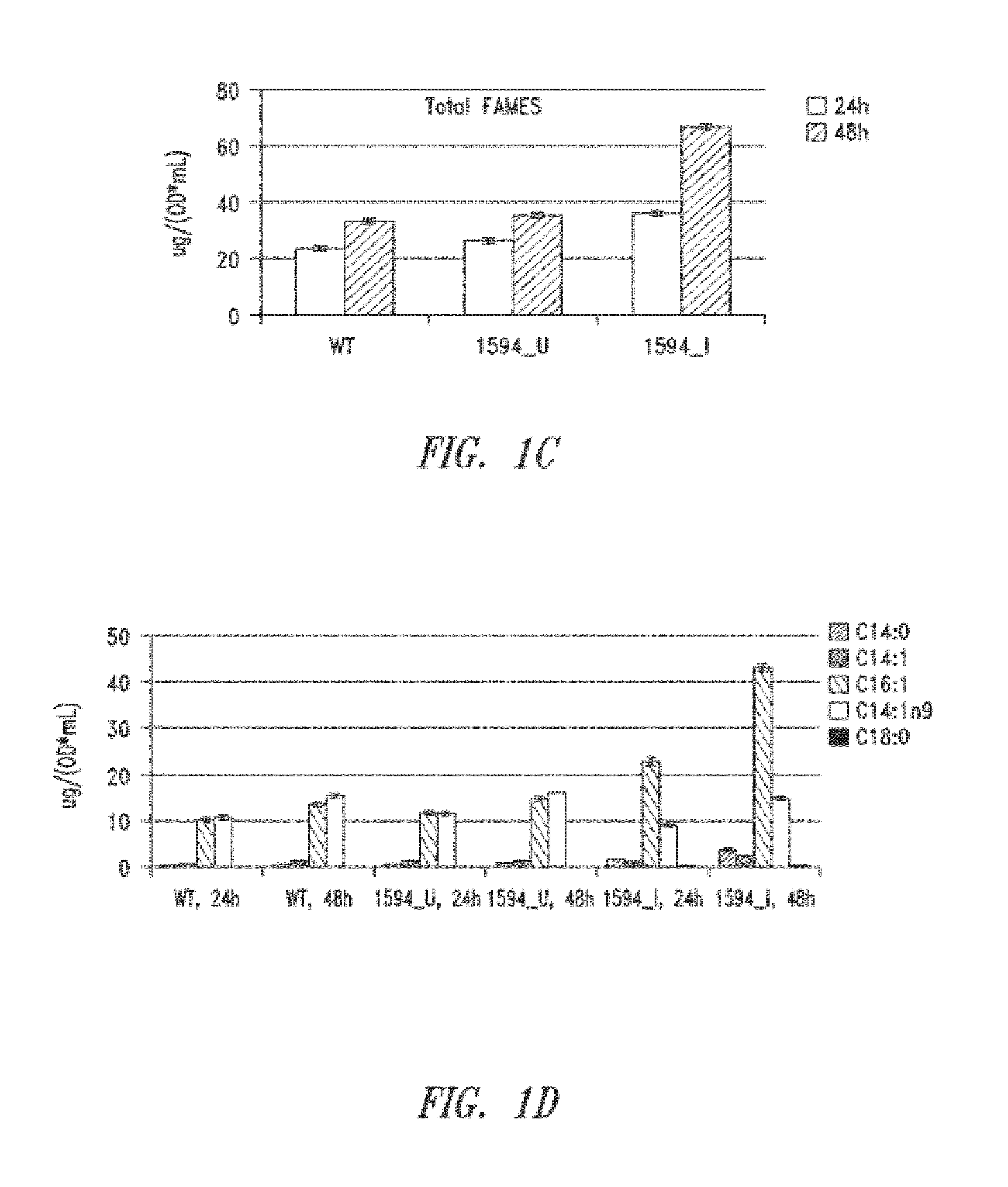

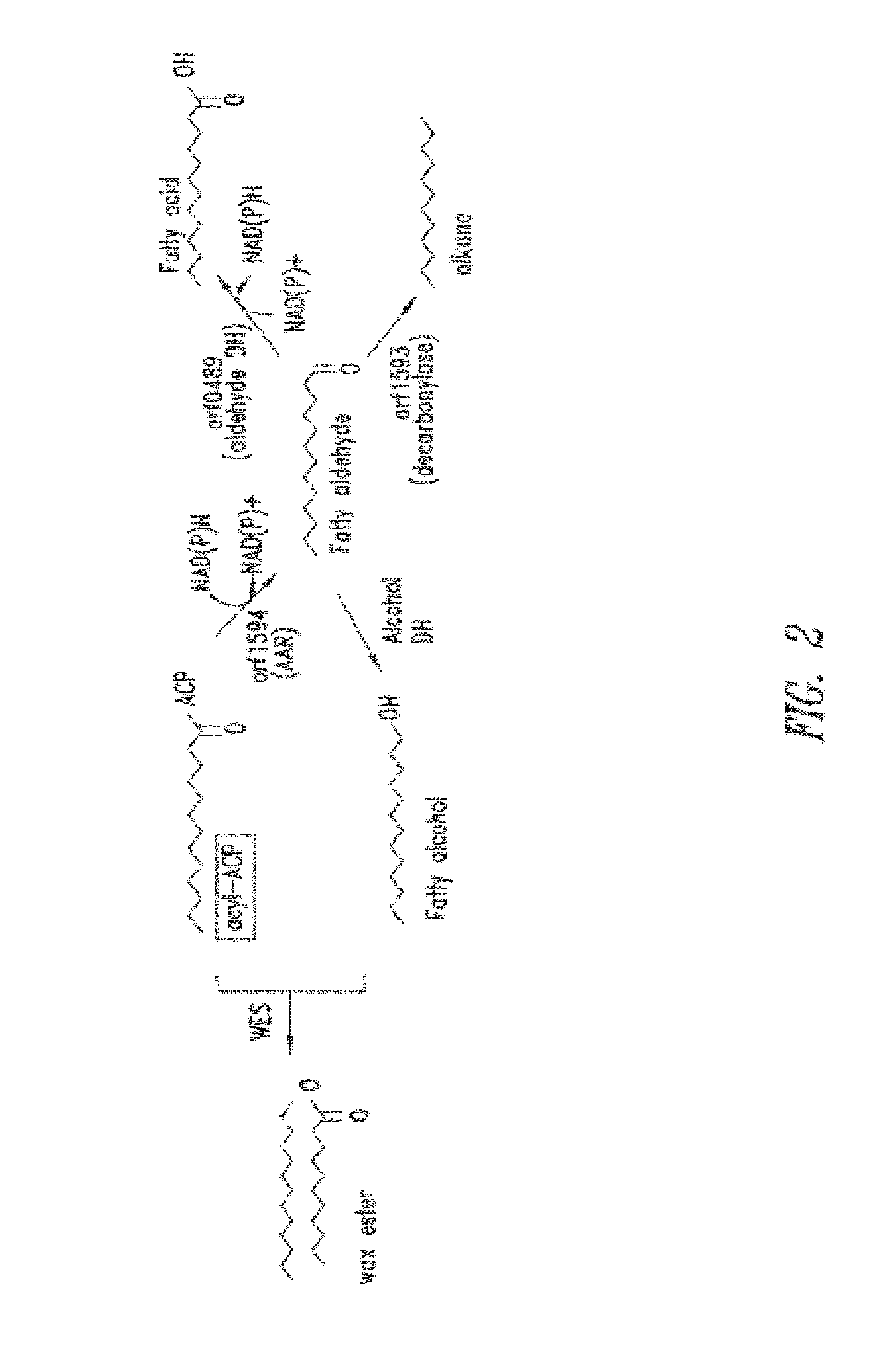

Modified photosynthetic microorganisms for producing lipids

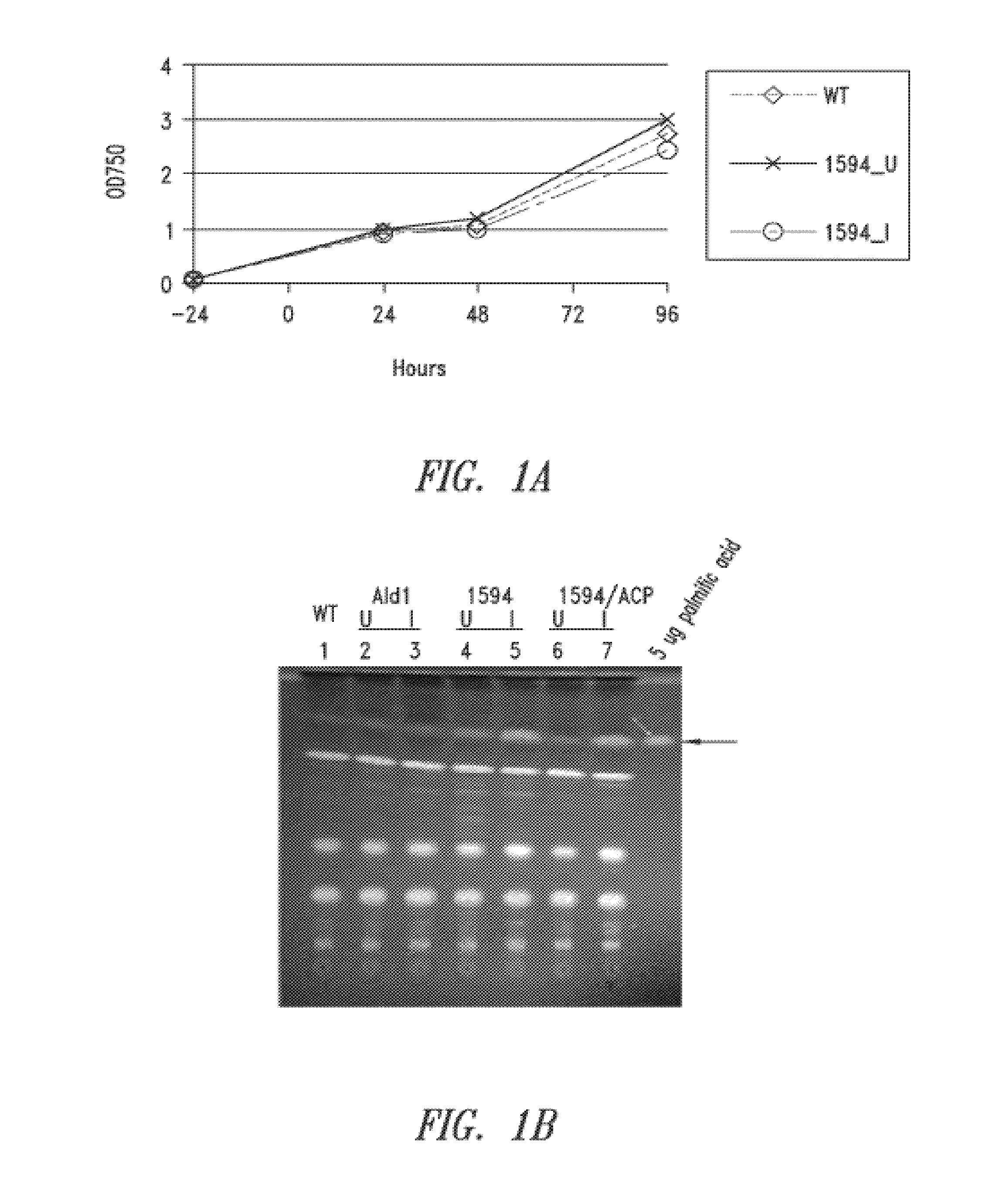

InactiveUS20140004580A1Promote cell growthIncrease productionUnicellular algaeOxidoreductasesPhylum CyanobacteriaWild type

This disclosure describes genetically modified photosynthetic microorganisms, e.g., Cyanobacteria, that overexpress an acyl-acyl carrier protein reductase (acyl-ACP reductase). These microorganisms may optionally overexpress one or more fatty acid synthesis proteins such as ACP and ACCase, and / or one or more polypeptides associated with glycogen breakdown. Also included are photosynthetic microorganisms comprising mutations or deletions in a glycogen biosynthesis or storage pathway, which accumulate a reduced amount of glycogen under reduced nitrogen conditions as compared to a wild type photosynthetic microorganism. The modified photosynthetic microorganisms provided herein are capable of producing increased amounts of lipids such as fatty acids or wax esters and / or synthesizing triglycerides.

Owner:MATRIX GENETICS

Cosmetic or pharmaceutical oil-in-water emulsion

A cosmetic or pharmaceutical oil-in-water (o / w) emulsion including an oil phase and a water phase, where at least 40% by weight of the oil phase is a wax component or a mixture of wax components is provided. A cosmetic or pharmaceutical oil-in-water (o / w) emulsion including 15% to 35% by weight of an oil phase which contains 40% to 70% by weight of a mixture of wax components comprising at least one C16-24 fatty alcohol and at least one wax ester of a C12-24 fatty alcohol and a C12-24 fatty acid; 0.5% to 5% by weight of a nonionic alk(en)yl oligoglycoside surfactant; and 50% to 80% by weight water is also provided.

Owner:GOGET CAROLINE +4

Coating with acrylic modified alkyd resin

InactiveCN104403530AGood light fastnessGood weather resistanceEpoxy resin coatingsPolyester coatingsPolyvinyl butyralEpoxy

The invention relates to a chemical industrial product, and especially relates to a coating with acrylic modified alkyd resin. The coating with the acrylic modified alkyd resin comprises the following components by weight: 15-17% of wax ester, 10-16% of epoxy resin, 20-30% of the acrylic modified alkyd resin, 12-16% of palm olein fine ester, 5-8% of methyl acrylic resin, 1-3% of a semi matt acrylic paint, 3-6% of a photo initiator, 5-10% of polyvinyl butyral, 2-4% of a polyether modified polysiloxane defoamer, 2-4% of a dispersant and balance of a thinner, and has the advantages of light resistance, good weatherability, tinting strength, strong covering power, strong adhesion, and low tendency to crack after use.

Owner:QINGDAO HOUKE INFORMATION ENG

Food grade wax and preparation thereof

The invention provides a wax composition which can be used in comestibles. The wax composition is obtained from sugar cane and comrpises wax esters, aldehydes, tri-glycerides, alcohols, free fatty acids, sterols and polar lipids. A process for preparing a wax composition from crude sugar cane wax, the process comprising the steps of: (i) heating a solution of the crude wax with a lower alcohol as sovlent at the boiling point of the solvent; (ii) allowing phase separation of the solution from (i) and decanting the upper phase while hot; (iii) allowing the separated phase from (ii) to cool and separating crystallised wax from the solvent; (iv) repeating steps (i) to (iii) using the wax from (iii) until all pitch has been removed fromthe wax; (v) heating the wax to between 90 and 140 DEG C and oxidising molten wax with oxidising material; and (vi) continuing the heating under and inert gas on completion of the oxidation step until intermediate peroxide products are removed.

Owner:JAMES COOK UNIVERSITY +1

Paint with good gloss retention

InactiveCN104403563AImprove water resistanceImprove insulation performanceEpoxy resin coatingsPolyester coatingsEpoxySolvent

The invention relates to paint, in particular to paint with good gloss retention. The paint comprises the following components in percentage by weight: 12-18% of alkyd resin, 20-30% of tung oil, 10-16% of epoxy resin, 2-5% of terephthalic acid, 3-6% of acrylate modified alkyd resin, 12-16% of palm wax ester, 5-8% of methacrylic resin, 0.5-1% of isophthalic acid, 1-3% of propylene pigment, 3-6% of phthalic anhydride, 5-10% of polyvinyl butyral, 3-5% of an antifoaming agent, and the balance of a thinner. The paint has the advantages that the use is extensive, the properties are excellent, a high-density reticular structure is formed after a paint film is dried, the paint is not easy to age, the gloss retention is good, the property of resisting mineral oil and alcohols solvents is good, and the water resistance, the insulativity and the oil resistance of the paint are greatly improved after being torrefied.

Owner:青岛市市南区隆德中医药研究所

Coloring agent capable of preventing fading of leather and preparation method of coloring agent

The invention discloses a coloring agent capable of preventing the fading of leather and a preparation method of the coloring agent. The coloring agent contains the following raw materials in parts byweight: 5-10 parts of curcumine, 5-10 parts of a chestnut shell pigment, 1-2 parts of dibutyl phthalate, 3-6 parts of triglyceride, 2-3 parts of gelatin, 4-7 parts of wax ester, 2-5 parts of a herbaviolae extracting solution, 1-3 parts of nano-composite semi-chrome tanning aid, 0.5-1 part of a surfactant, 0.5-0.8 part of a diluent and 40-50 parts of deionized water. The coloring agent is safe and environment-friendly, and the leather processed by virtue of the coloring agent has relatively good wear resistance, washing resistance and light fastness and is unlikely to fade.

Owner:安徽鞋匠世家新型鞋材科技有限公司

Wax ester microcapsules and spinning waxing method thereof

ActiveCN102953269AAvoid the effect of waxingLower coefficient of dynamic frictionFibre treatmentYarnFiber

Owner:杨建

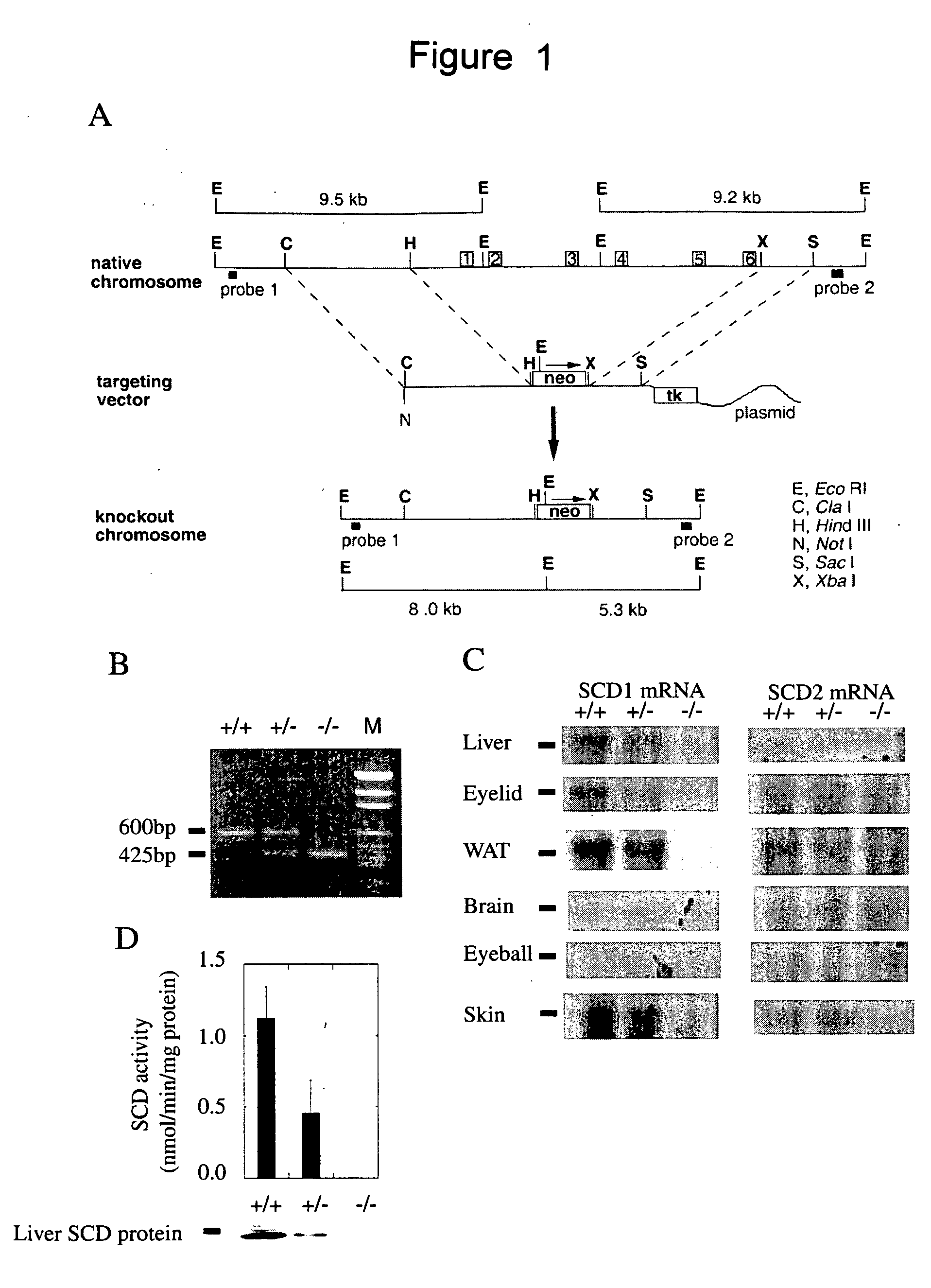

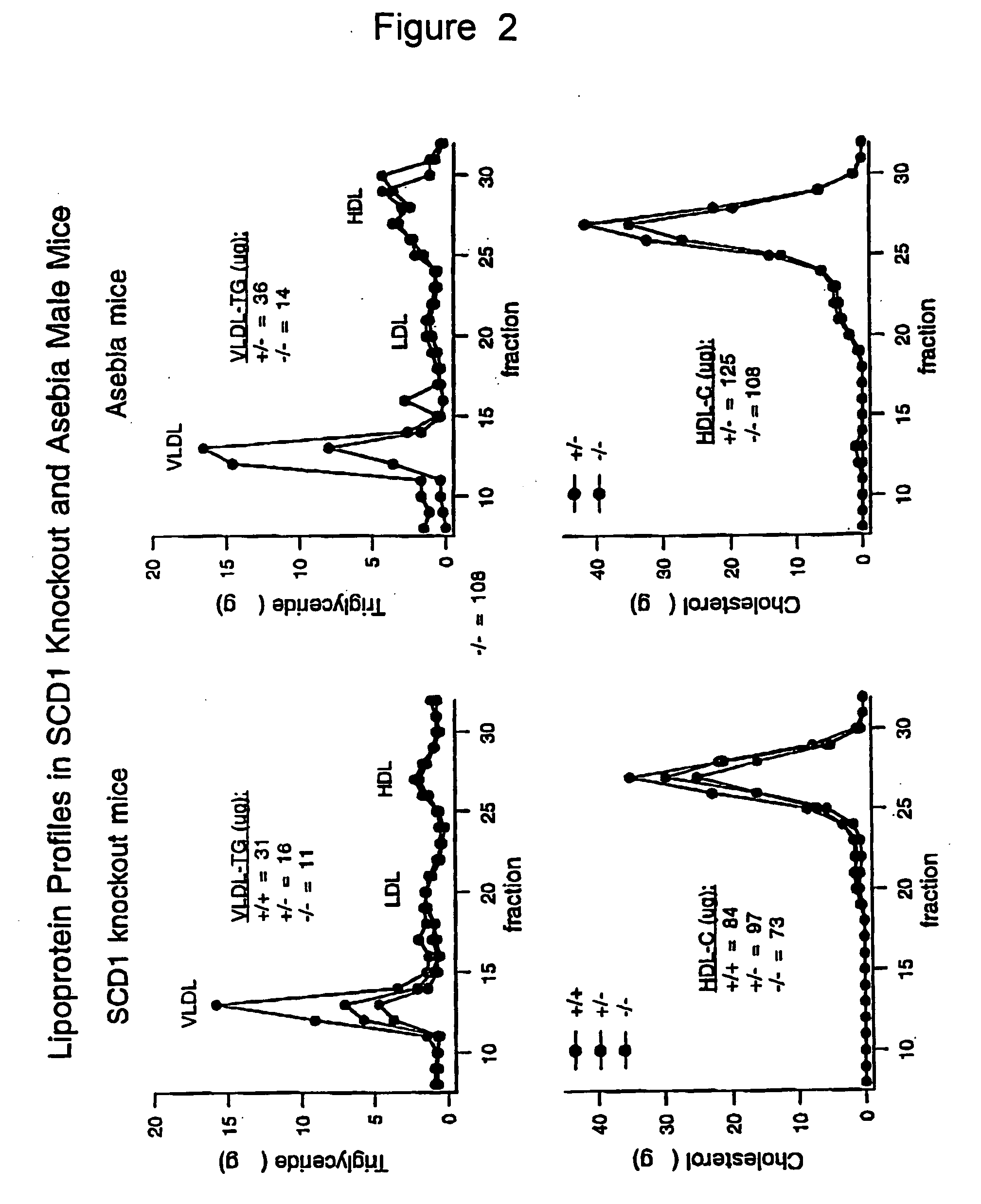

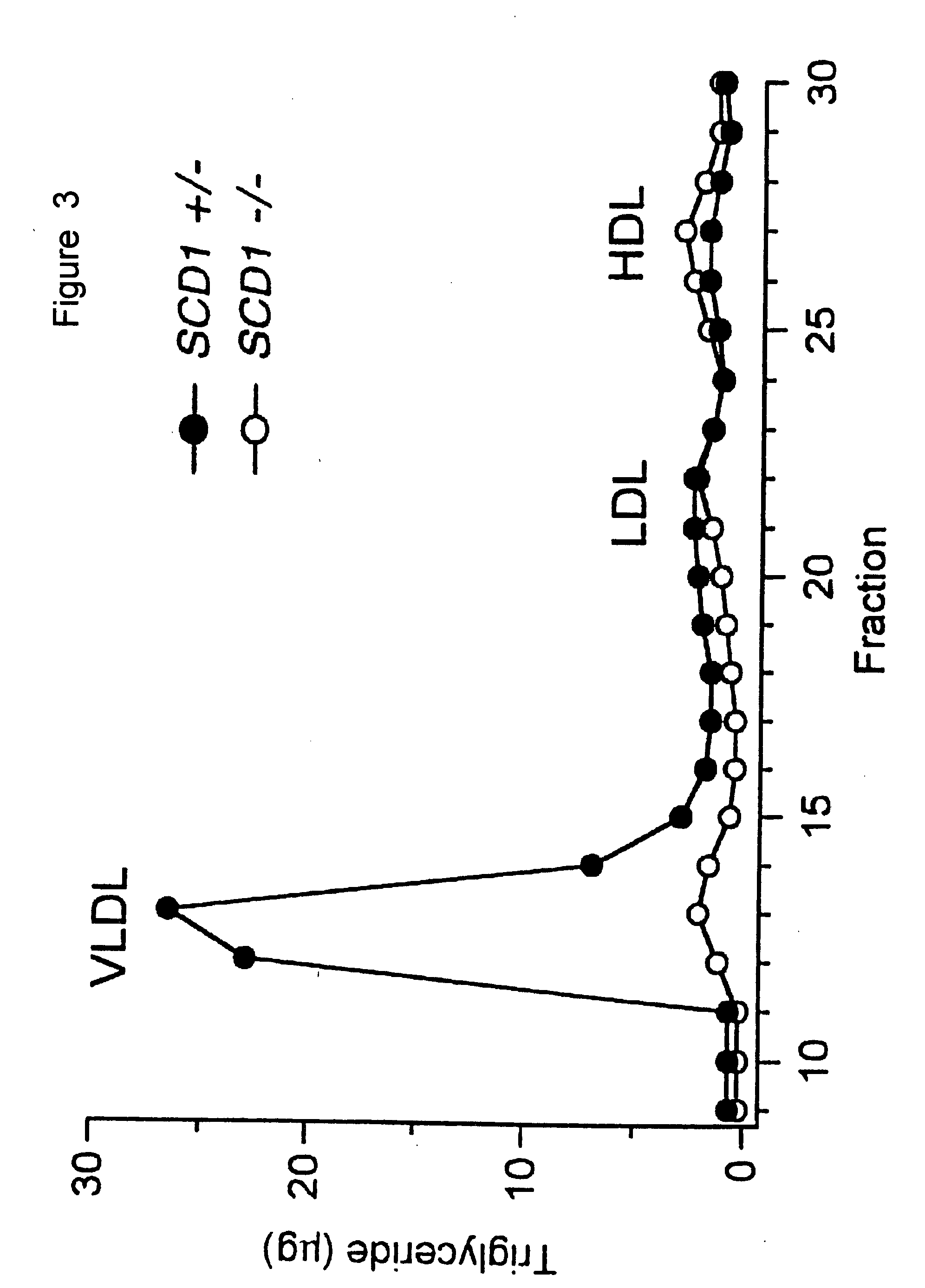

Methods and compositions using stearoyl-CoA desaturase to identify triglyceride reducing therapeutic agents

InactiveUS20050256033A1Lower levelImportant cardioprotective benefitBiocideFungiDisease causeStearoyl-CoA Desaturase

The use of screening assays based on the role of human stearoyl-CoA desaturase-1 (“hSCD1”) in human diseases, disorders or conditions relating to serum levels of triglyceride, VLDL, HDL, LDL, total cholesterol, or production of secretions from mucous membranes, monounsaturated fatty acids, wax esters, and the like, is disclosed. Also disclosed are conventions useful in the prevention and / or treatment of such diseases.

Owner:XENON PHARMACEUTICALS INC +1

Gloss-retention paint

InactiveCN105505031AWide range of usesNot easy to ageWax coatingsLuminescent paintsEpoxyPolyvinyl butyral

The invention relates to a paint, particularly a gloss-retention paint. The gloss-retention paint is composed of the following components in percentage by weight: 30-42% of liquid high-polymer resin, 0.5-1% of m-phthalic acid, 1-3% of acrylic pigment, 21-28% of tung oil, 10-16% of epoxy resin, 2-4% of photoinitiator, 12-16% of palm wax ester, 5-7% of phthalic anhydride, 6-10% of polyvinyl butyral, 3-5% of defoaming agent, 3-6% of acrylic modified alkyd resin, 2-5% of luminescent powder and the balance of thinner. The tung oil is composed of the following components in percentage by weight: 10-60% of tung oil, 5-30% of castor oil, 20-50% of linseed oil and 2-10% of glyceride. The gloss-retention paint has wide applicability. The paint film is dried to form a highly reticular structure. The paint film has the advantages of low aging tendency, favorable gloss retention, greatly higher electric insulativity and greatly higher oil resistance. The painted object is more beautiful; and thus, the paint can be used for guideposts, outdoor advertisements, nighttime roads, obstacle markers and other objects.

Owner:QINGDAO BEIDOUXINGYUN COMM TECH CO LTD

Human sebum mimetics derived from botanical sources and methods for making the same

ActiveUS20140105844A1Promote recoveryAccelerate cell turn-overCosmetic preparationsHair removalJojoba esterTriglyceride

Human sebum mimetics and methods for producing human sebum mimetics are provided. In one exemplary embodiment, a human sebum mimetic comprises a wax ester derived from interesterification of a refined botanical triglyceride oil comprising palmitoleic acid and refined jojoba oil, a phytosterol, phytosqualene, and phytosteryl macadamiate. A method for producing a human sebum mimetic comprises mixing refined macadamia oil and refined jojoba oil, interesterifying the macadamia oil and the jojoba oil, adding a phytosterol, adding phytosteryl macadamiate, and adding phytosqualene after interesterification.

Owner:INT FLORA TECH

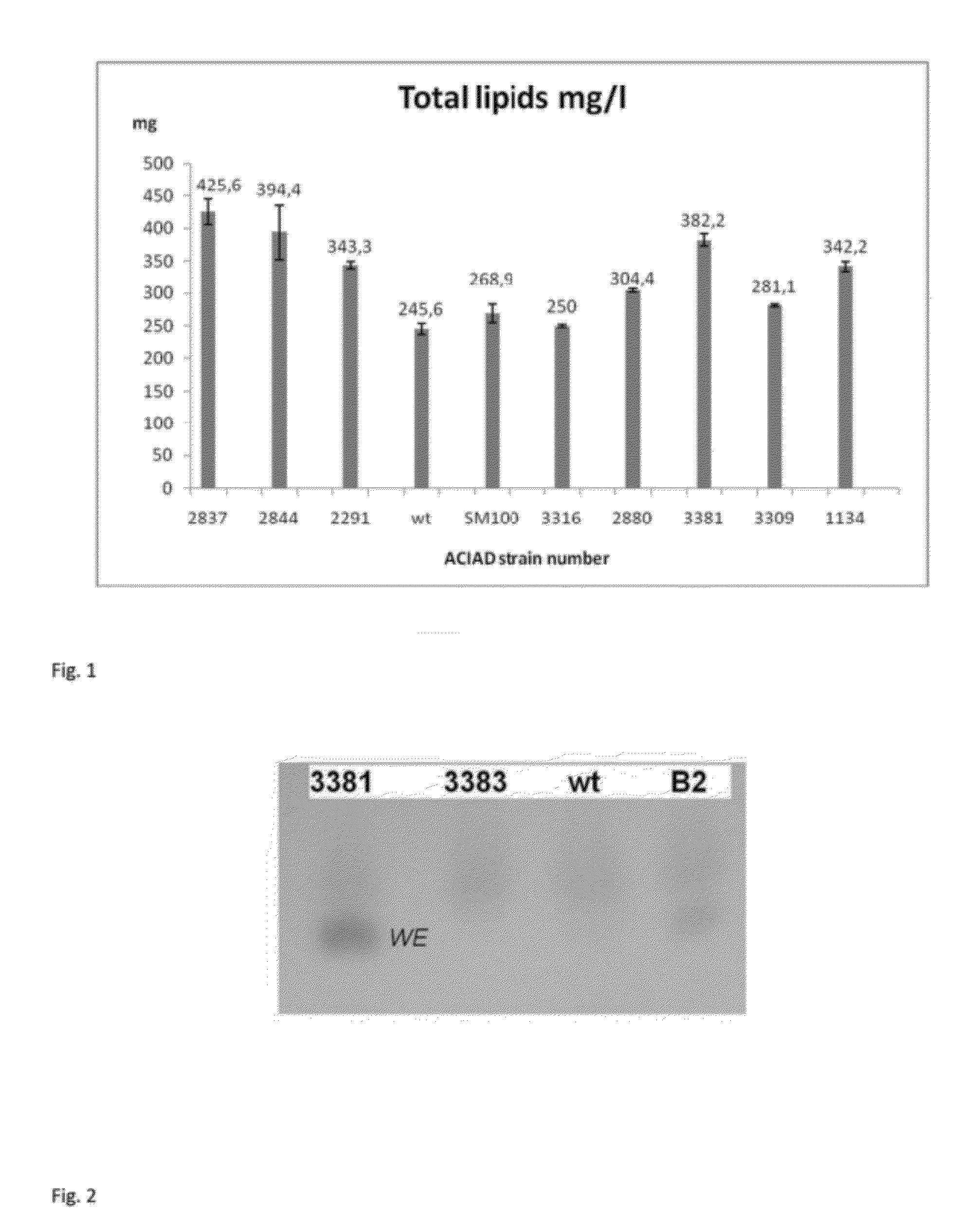

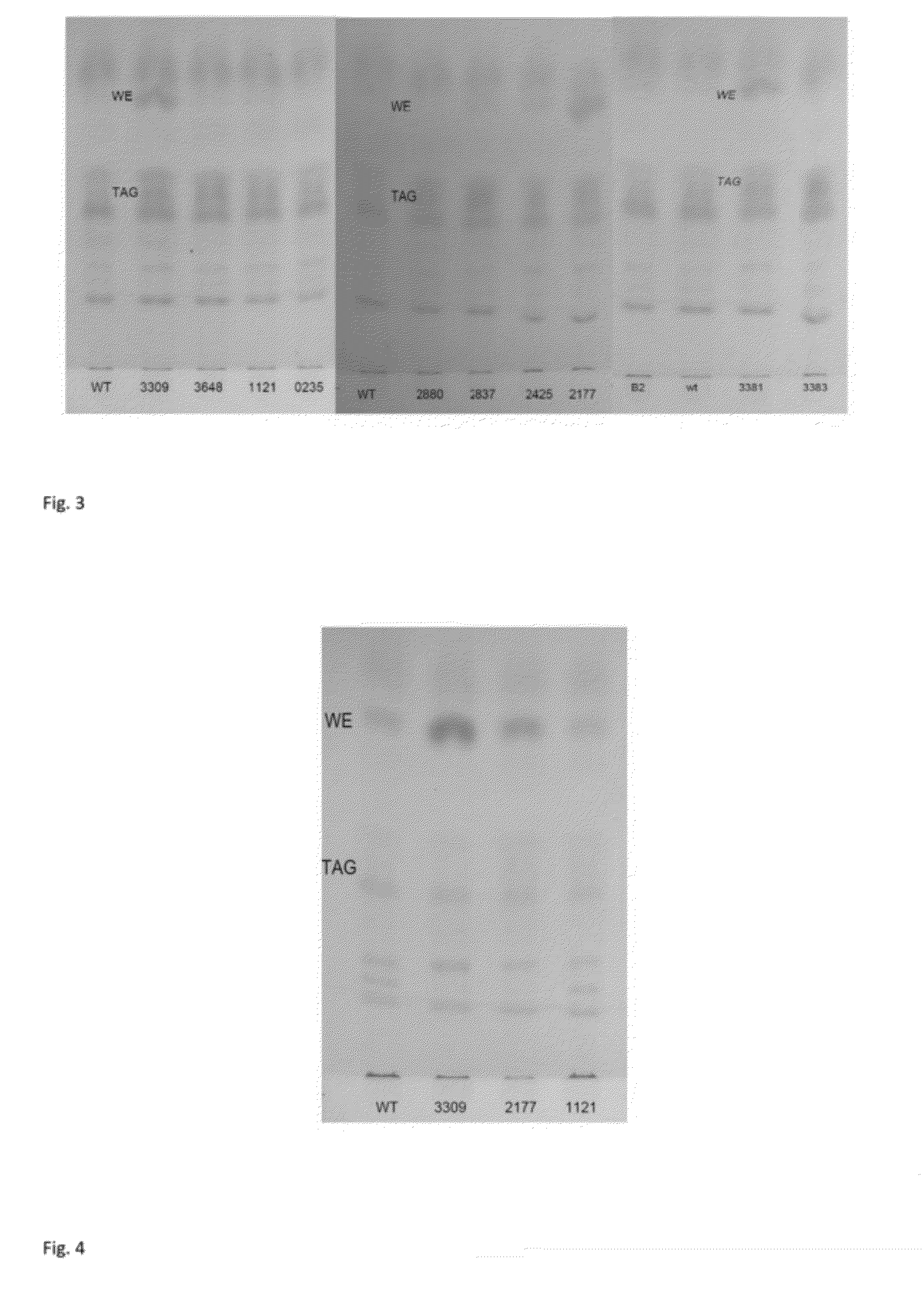

Lipid Production

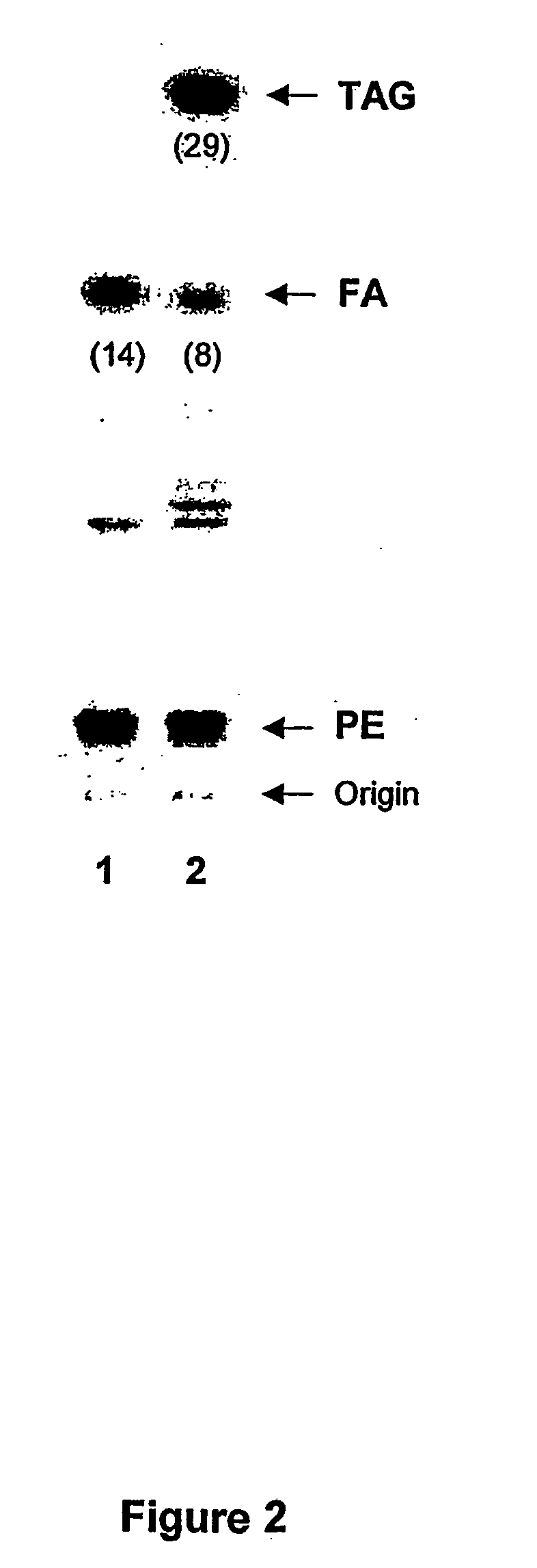

ActiveUS20120151833A1Enhance lipid productionEfficient processingBacteriaHydrolasesBiotechnologyWax ester

The present invention relates to a genetically modified Acinetobacter host for lipid production. The Acinetobacter host has been genetically modified to be deficient of one or more of genes A) a gene encoding fatty acyl-CoA reductase (EC1.2.1.n2), wherein said host is capable of increased production of TAGs and / or of total lipids compared to the parent host; and / or B) a gene encoding lipase (EC:3.1.1.3), a gene encoding pyruvate dehydrogenase (EC:1.2.2.2), and / or gene ACIAD 2177, or functional equivalents of any of said genes, wherein said host is capable of increased production of wax esters and / or total lipids compared to the parent host.

Owner:NESTE OIL OY

Natural hair conditioning composition

The present invention relates to a hair conditioning composition comprising an olive squalane, a wax, an ester, and a cosmetically acceptable carrier. The hair conditioning composition is essentially free of one or more components selected from the group consisting of silicones, anionic surfactants, amidoamines, silicone derivatives, ethoxylated emulsifiers, and mixtures thereof.

Owner:ELC MANAGEMENT LLC

Cellulose reinforced resin compositions with wax blend

InactiveUS7432317B2Improve extrusion rateHigh tensile strengthNon-fibrous pulp additionPaper/cardboardWaxCellulose

The present invention provides an extrudable reinforced resin-containing composition comprising resin capable of plastic flow, reinforcing material, and a lubricant composition comprising oxidized polyethylene wax, ester wax, and amide wax. Also provided are the lubricant composition, and extrusion methods and extruded products based on the present compositions.

Owner:HONEYWELL INT INC

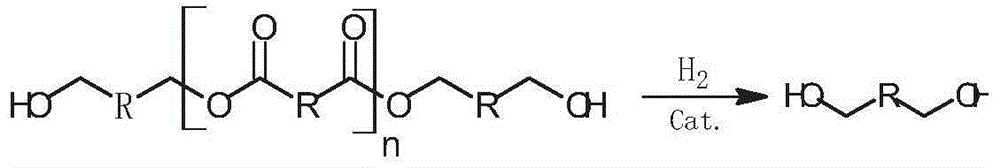

Preparation method for aliphatic mixed dihydric alcohol

InactiveCN105152858AComponent stabilityHigh purityOrganic compound preparationCarboxylic acid esters preparationAlcoholHydrogen pressure

The invention discloses a preparation method for aliphatic mixed dihydric alcohol. The preparation method comprises a preparation stage of aliphatic mixed diacid dihydric alcohol wax ester and a preparation stage of aliphatic mixed dihydric alcohol. The method specifically comprises the following steps: 1) in the preparation stage of aliphatic mixed diacid dihydric alcohol wax ester, mixing aliphatic mixed diacid and aliphatic mixed dihydric alcohol, controlling the pressure at 0.5-4MPa, and carrying out continuous reaction for 10-40 hours to generate the aliphatic mixed diacid dihydric alcohol wax ester; and 2) in the preparation stage of aliphatic mixed dihydric alcohol, carrying out reductive reaction on the aliphatic mixed diacid dihydric alcohol wax ester and hydrogen under the action of a hydrogenation catalyst and an alloy catalyst to generate the aliphatic mixed dihydric alcohol, wherein the hydrogen pressure is maintained at 1.0-15.0MPa and the flow rate of hydrogen is 300-5000 cubic meter / hour. A finished product is stable in component and high in purity, and the yield reaches up to over 95%. According to different requirements of clients, high-purity single-component aliphatic dihydric alcohol can be prepared in a rectification manner, so that the additional value of the product is further improved.

Owner:ZHEJIANG BOJU NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com