Wax ester microcapsules and spinning waxing method thereof

A technology of microcapsules and wax fat, which is applied in the field of wax fat microcapsule spinning wax, wax fat microcapsule and its spinning wax, which can solve the problem of reducing yarn dynamic friction coefficient, wax circle waste, increasing fiber cohesion, etc. Problems, to achieve the effect of reducing the coefficient of dynamic friction, reducing the phenomenon of flying hair, and improving the rate of genuine products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

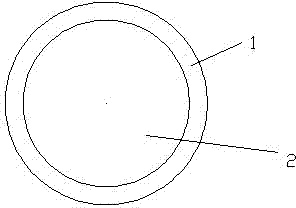

[0017] Combine below The drawings further illustrate the present invention.

[0018] A method for spinning wax on wax lipid microcapsules is as follows: wax lipid microcapsules use chitosan as the wall material, and the microcapsule core material includes textile softeners, antistatic agents or textile surfactants, waxes and greases. , The wax lipid microcapsules are prepared by spray-drying method or complex agglomeration method. The wax lipid microcapsules are placed on the spinning wax equipment, and the wax lipid microcapsules are crushed by an instant release mechanical crushing method to make the microcapsule core The material adheres to the surface of the yarn or between the fibers to wax the yarn.

[0019] The present invention is modified to use powder form of microencapsulation and waxing. The wax lipid microcapsules are prepared by spray drying method or complex coacervation method. On the spinning wax equipment, the wax lipid microcapsules are instantly released by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com