High performance polypropylene film and preparation method thereof

A technology of polypropylene film and polypropylene, applied in chemical instruments and methods, types of packaging items, special packaging items, etc., can solve the problem that polypropylene film is difficult to meet multiple performance requirements at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

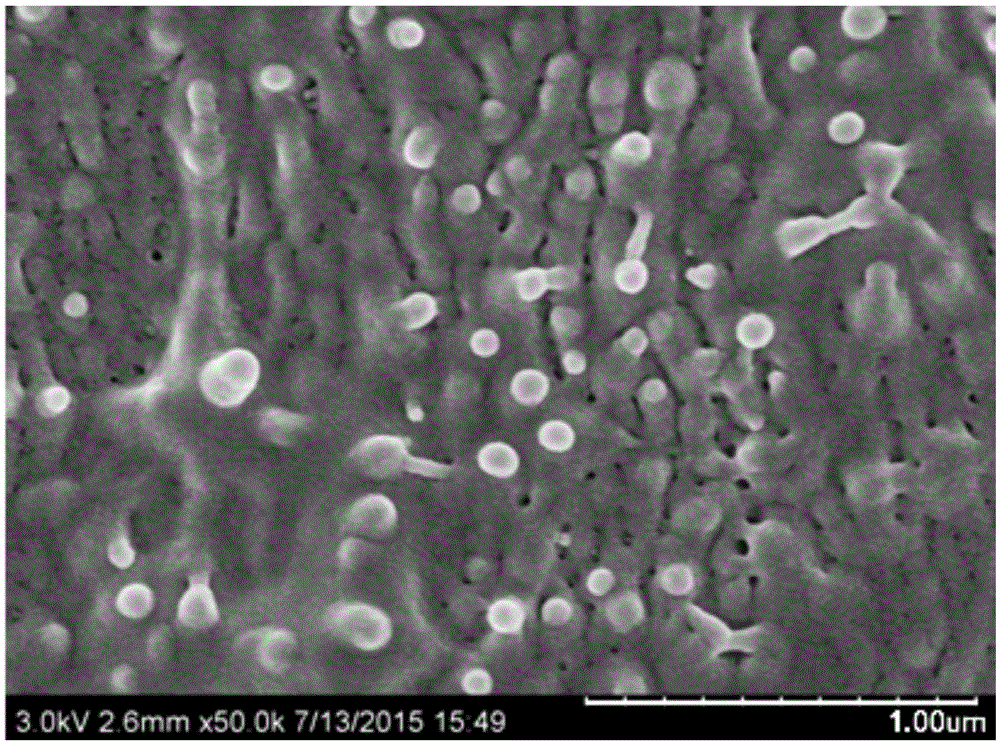

Image

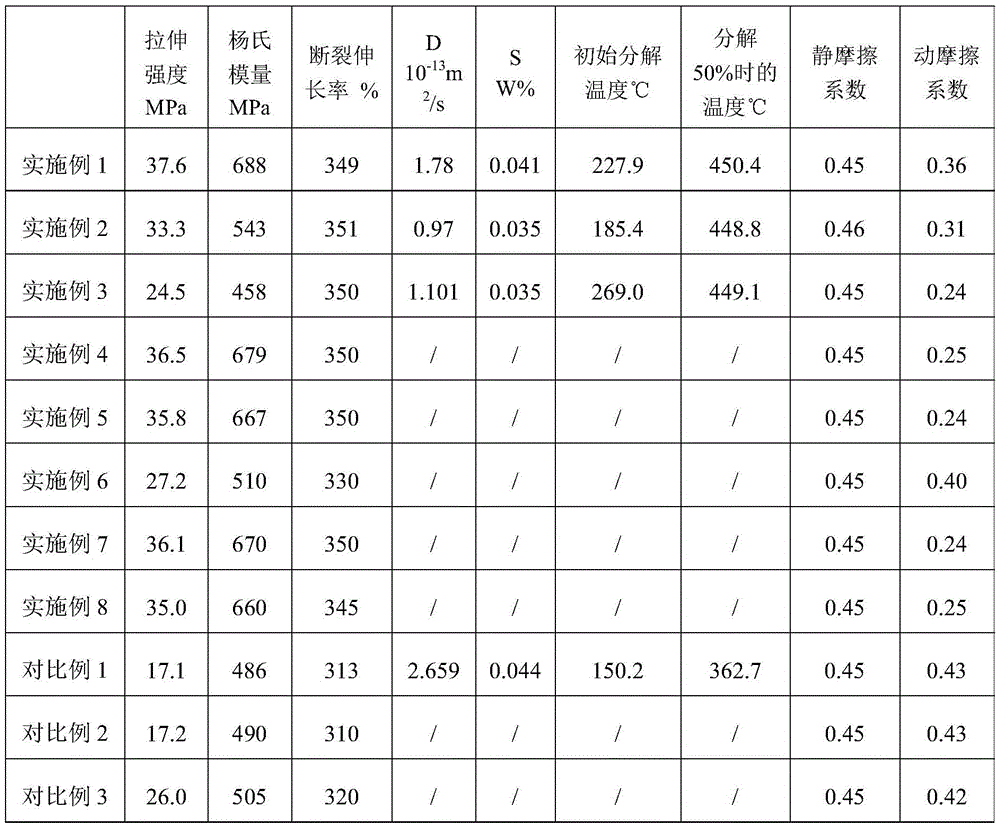

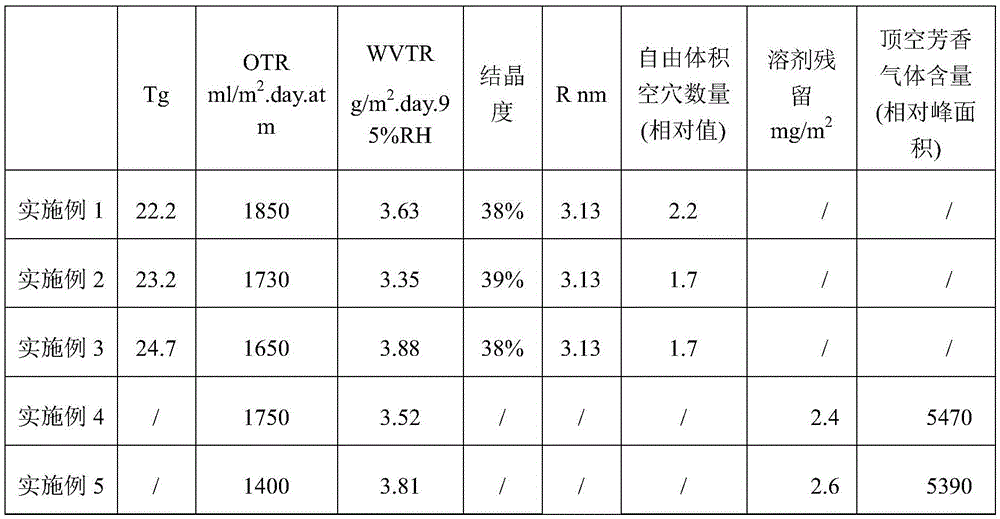

Examples

preparation example Construction

[0038] According to another aspect of the present invention, there is also provided a method for preparing the above-mentioned high-performance polypropylene film, which includes the following steps: combining the nano-silica composition with the first polypropylene, the second polypropylene and the third polypropylene respectively. Propylene is melt-blended to obtain the first modified polypropylene, the second modified polypropylene and the third modified polypropylene respectively; the first modified polypropylene, the second modified polypropylene and the third modified polypropylene Perform three-layer co-extrusion biaxial stretching to form a high-performance polypropylene film.

[0039] In the above preparation method provided by the present invention, the nano-silica composition is melt-blended with the first polypropylene, the second polypropylene and the third polypropylene respectively, and then three-layer co-extrusion biaxial stretching is used to form a film, A p...

Embodiment 1

[0060] Referring to the methods proposed in patents CN101724176, CN102020796 and CN103189441, a nano-silica composition is prepared, wherein the nano-silica particles account for 54% of the total mass of the composition, and the specific operation steps are as follows:

[0061] Add 10Kg of EVA emulsion with a solid content of 50% in a reactor with a capacity of 50 liters of stirring, dropping funnel, and thermometer. Set the stirring speed at 100 rpm and the temperature at 50 degrees, add powdered polyethylene oxide resin 50g and polylactic acid 50g. After stirring for 30 minutes, add 25Kg of water glass solution with silicon dioxide content of 24%, stir for 30 minutes, add 40% sulfuric acid dropwise until PH=5.5, then heat up to 70 degrees, add 40% sulfuric acid dropwise until PH=7.0, Continue to stir for 30 minutes, then wash to remove sulfate ions, press filter, dry, and pulverize to prepare a nano-silica composition.

[0062] Melt-blending 1.0Kg of nano-silica composition...

Embodiment 2

[0065] Other conditions are the same as in Example 1, changing the content of the nano silicon dioxide composition. 2.6Kg of nano-silica composition and 97.4Kg of F280 polypropylene resin were melt-blended, granulated and dried to obtain the upper resin raw material;

[0066] The upper layer resin is added to the three extruders of the three-layer co-extrusion biaxial stretching equipment, the temperature of the three extrusion screws is set to 230 °C, the transverse stretch ratio is 9, and the longitudinal stretch ratio is 4. The rotating speed is 48rpm, the pressure is 45bar, and the die temperature is 230°C. A single-structure polypropylene film (same composition and structure as the upper film) with a thickness of 18 μm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Radial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com