Method for dewaxing peony seed oil by combination of surfactant-crystallization copolymerization and alcohol extraction

A peony seed oil and dewaxing technology, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems of high cloud point, oil rancidity, easy deformation, etc., achieve color and fluidity, enhance skin penetration, The effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

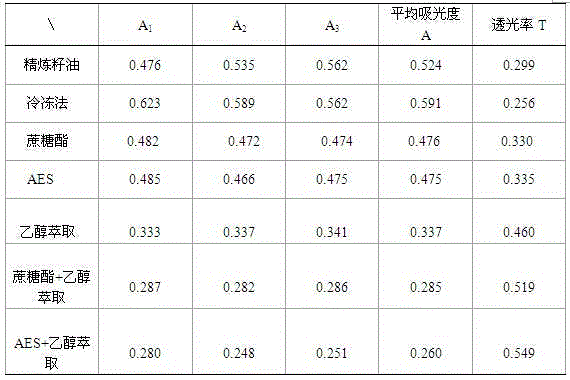

Image

Examples

Embodiment 1

[0021] A method for combining surface crystal copolymerization and alcohol extraction of peony seed oil for dewaxing, the specific steps are as follows:

[0022] Take peony seed oil that has been degummed, deacidified, decolorized and deodorized as a raw material, heat the peony seed oil to 70°C until the waxy crystals precipitated at room temperature are completely dissolved in the peony seed oil, and then cool down to 50°C after the dissolution is complete , then add 0.08% surfactant of peony seed oil weight to the peony seed oil while stirring, the surfactant is fatty alcohol polyoxyethylene ether, then slowly cool down under stirring conditions, control the hourly decrease of 2 ℃, the cooling process Control the stirring speed at 10r / min, stop stirring when the temperature drops to 5°C, and keep it warm for 4h to grow crystals. After the crystal growth is completed, centrifuge at 3000r / min for 15min, take the supernatant oil, and set aside;

[0023] Add an anhydrous ethano...

Embodiment 2

[0025] A method for combining surface crystal copolymerization and alcohol extraction of peony seed oil for dewaxing, the specific steps are as follows:

[0026] Take peony seed oil that has been degummed, deacidified, decolorized and deodorized as a raw material, heat the peony seed oil to 90°C until the waxy crystals precipitated at room temperature are completely dissolved in the peony seed oil, and then cool down to 65°C after the dissolution is complete , then add 0.15% surfactant of peony seed oil weight to the peony seed oil while stirring, the surfactant is sucrose ester, then slowly cool down under stirring conditions, control the hourly decrease of 3 ℃, control the stirring speed in the cooling process 15r / min, stop stirring when the temperature drops to 8°C, and keep it warm for 8 hours to grow crystals. After the crystal growth is completed, centrifuge at a speed of 3000r / min for 20min, take the supernatant oil, and set aside;

[0027] Add an anhydrous ethanol solu...

Embodiment 3

[0029] A method for dewaxing the surface crystal copolymerization of peony seed oil combined with alcohol extraction, the specific steps are as follows:

[0030] Take the peony seed oil that has been degummed, deacidified, decolorized and deodorized as raw material, heat the peony seed oil to 80°C until the waxy crystals precipitated at room temperature are completely dissolved in the peony seed oil, and then cool down to 60°C after the dissolution is completed , then add 0.12% surfactant of peony seed oil weight to the peony seed oil while stirring, the surfactant is fatty alcohol polyoxyethylene ether, then slowly cool down under stirring conditions, control the hourly reduction of 3 ° C, the cooling process Control the stirring speed at 12r / min in the medium, stop stirring when the temperature drops to 7°C, and keep warm for 6h to grow crystals. After the crystal growth is completed, centrifuge at a speed of 3000r / min for 18min, take the supernatant oil, and set aside;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com