Preparation method for aliphatic mixed dihydric alcohol

A technology of mixing dibasic acids and aliphatics, which is applied in the field of preparation of aliphatic mixed dibasic alcohols, can solve the problems of complex production process, high production cost, and low yield of finished products, and achieve simple production process, low production cost, The effect of stabilizing finished product components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

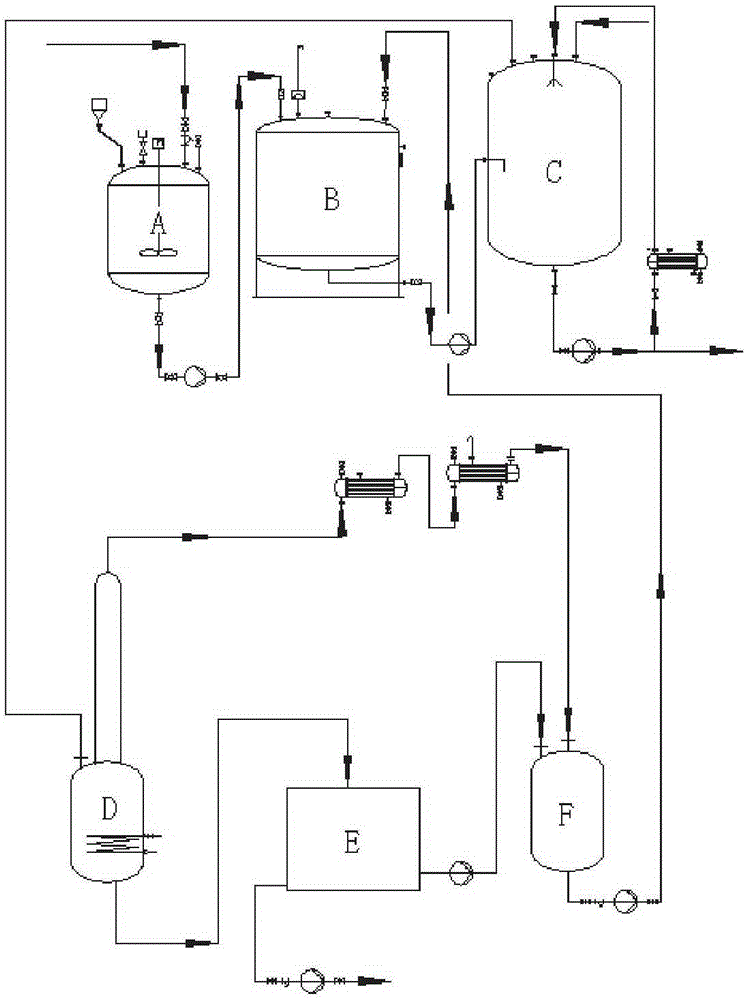

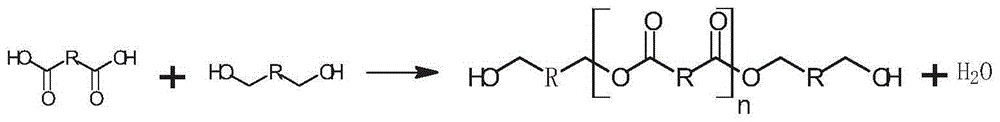

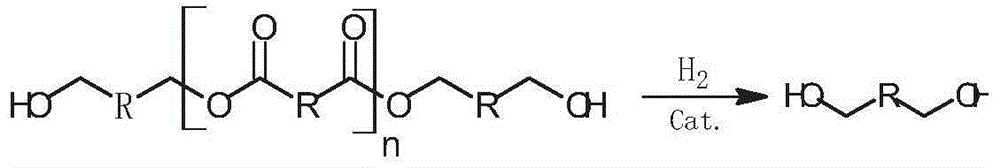

[0026] The preparation method of the aliphatic mixed dibasic alcohol in this embodiment includes the preparation stage of the aliphatic mixed dibasic acid glycol wax ester and the preparation stage of the aliphatic mixed dibasic alcohol, and the specific steps are as follows:

[0027] 1) Preparation stage of aliphatic mixed dibasic acid diol wax ester

[0028] Mix and melt aliphatic mixed dibasic acid: aliphatic mixed dibasic alcohol at a molar ratio of 1:40 and store it in batching tank B, through which the material passes continuously through five esterification reaction kettles with a diameter of 1m and a height of 5m ;The temperature of the esterification reactor is kept at 150°C, the pressure is kept at 0.5MPa, and the reaction residence time is 10h; the water generated by the reaction and a small amount of aliphatic mixed diols and mixed dibasic esters are taken away by nitrogen; The bulging water and organic matter are separated by the flash tower D, and the distilled o...

Embodiment 2

[0032] The preparation method of the aliphatic mixed dibasic alcohol in this embodiment includes the preparation stage of the aliphatic mixed dibasic acid glycol wax ester and the preparation stage of the aliphatic mixed dibasic alcohol, and the specific steps are as follows:

[0033] 1) Preparation stage of aliphatic mixed dibasic acid diol wax ester

[0034] The aliphatic mixed dibasic acid and aliphatic mixed dibasic alcohol are mixed and melted at a molar ratio of 1:25, and stored in the batching tank B, and the materials in the batching tank B are continuously passed through five esterification reaction chambers with a diameter of 1m and a height of 5m Kettle; the temperature of the esterification reactor is kept at 200°C, the pressure is kept at 4MPa, and the reaction residence time is 22h; the water generated by the reaction and a small amount of aliphatic mixed diols and mixed dibasic esters are taken away by nitrogen; nitrogen The bulging water and organic matter are ...

Embodiment 3

[0038] The preparation method of the aliphatic mixed dibasic alcohol in this embodiment includes the preparation stage of the aliphatic mixed dibasic acid glycol wax ester and the preparation stage of the aliphatic mixed dibasic alcohol, and the specific steps are as follows:

[0039] 1) Preparation stage of aliphatic mixed dibasic acid diol wax ester

[0040] The aliphatic mixed dibasic acid and aliphatic mixed dibasic alcohol are mixed and melted at a molar ratio of 1:10, and then stored in the batching tank B. The materials in the batching tank B are continuously passed through five esterification reaction chambers with a diameter of 1m and a height of 5m. Kettle; the temperature of the esterification reactor is kept at 100°C, the pressure is kept at 2.5MPa, and the reaction residence time is 35h; the water generated by the reaction and a small amount of aliphatic mixed diols and mixed dibasic esters are taken away by nitrogen; The water and organic matter blown out by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com