Methods and products for production of wax esters (u.s. national phase)

a technology of wax esters and products, applied in the field of genetically engineered microorganisms, can solve the problems of increasing demands, reducing production efficiency, and reducing and achieves the effect of high-level production of faeces and increasing the flux of fatty acid biosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Construction of Biodiesel Production Host Saccharomyces cerevisiae CB1

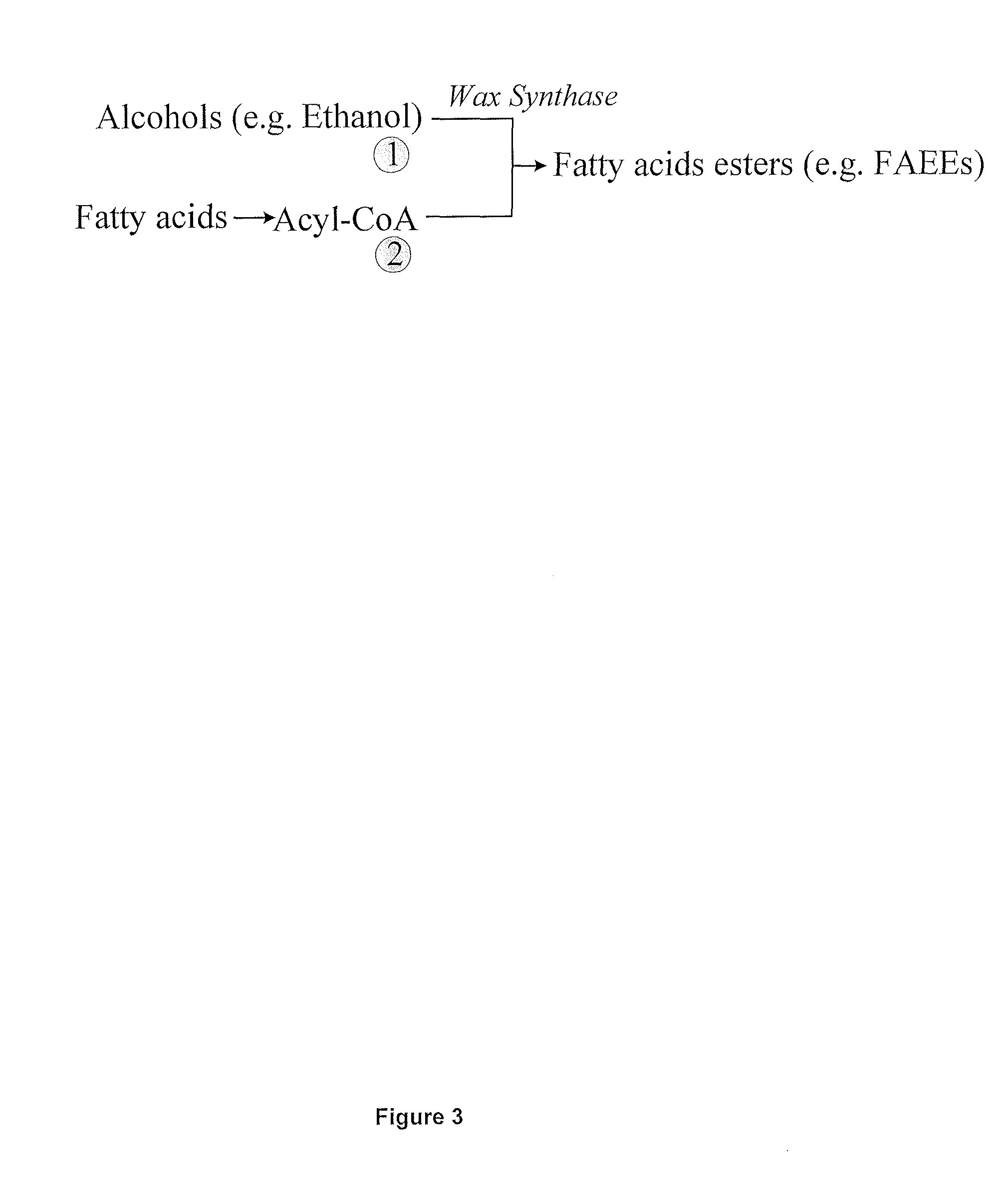

[0128]In this experiment the wax ester synthase from A. baylyi ADP1 was expressed in a laboratory strain Saccharomyces cerevisiae CEN.PK113-5D (MAT-alpha ura3-52 HIS3 LEU2 TRP1 MAL2-8c SUC2) to create biodiesel producer, Saccharomyces cerevisiae CB1.

[0129]Briefly, cloning and DNA manipulations were all carried out in E .coli DH5α and were performed by standard procedures (Sambrook and Russell 2001). The sequence of the gene atfA with the reported wax synthase from Acinetobacter baylyi ADP1 was optimized for expression in a yeast host. The optimized sequence is given as SEQ ID NO 1, which was based on the published gene sequence (Gene bank accession no. AF529086). It was synthesized and provided by the DNA2.0 Company (Menlo Park, Calif.). SEQ ID NO 1 was amplified using the following oligonucleotides: 5′-CGGGATCCCGCTCGAGATGCGTCCATT-3′ (SEQ ID NO 2) introducing BamHI restriction site (underlined) and; 5′-GGGGTACCCCA...

example 2

Characteristics of the Recombinant Host

[0130]The inoculated transformants S. cerevisiae CB0 and S. cerevisiae CB1 were cultured to late exponential growth period in 100 mL SD medium lacking uracil and containing 2% (w / v) glucose at 30° C. The cultures were then harvested. Cell-free extracts were prepared using a previously reported fast prep method for enzyme analysis (Hou, Vemuri et al. 2009). The lipid analysis were extracted from the lyophilized cell pellets using the reported method (Gu, Valianpour et al. 2004).

[0131]The wax synthase activities in the transformants were testified in vitro using [1-14C] palmitoyl-CoA and 1-hexadecanol or ethanol as the substrates. Table 1 summarizes the results of enzyme analysis. A low wax synthase activity could be detected in negative control S. cerevisiae CB0 using 1-hexadecanol or ethanol as the substrates. In contrast, a significant high wax synthase activity was detected in S. cerevisiae CB1.

[0132]The lipid extraction was analyzed with Gas...

example 3

Evaluation of the Substrate Preference of Different WSs in Yeast

[0133]

TABLE 2Specific oligonucleotides used for PCRamplification of the synthesized WS sequencesPrimer Sequence 5′→3′UpstreamDownstreamWS fromCGGGATCCCGCTCGGGGTACCCCAAGCTTGMarinobacterGAGATGAAGAGATTGGTTACTTTCTAGTACGhydrocarbo-AGG(SEQ ID NO 9)noclasticus(SEQ ID NO 8)DSM 8798WS fromCGGGATCCCGCTCGGGGTACCCCAAGCTTGRhodococcusGAGTTGACCGACGGGTTAGCTAGCCACCACCopacus PD630TGATTAC(SEQ ID NO 11)(SEQ ID NO 10)WS from MusCGGGATCCCGCTCGGGGTACCCCAAGCTTGmusculusGAGATGTTCTGGCCGGTTAAACAATGACCAACC57BL / 6AACC(SEQ ID NO 13)(SEQ ID NO 12)WS fromCGGGATCCCGCTCGGGGTACCCCAAGCTTPsychrobacterGAGATGAGATTACTGGGTTAAGGGGCCAACTarticus 273-4GACCGCTGT(SEQ ID NO 15)(SEQ ID NO 14)

[0134]In this example, except for the wax synthase from Acinetobacter baylyi ADP1, four other putative WSs from Marinobacter hydrocarbonoclasticus DSM 8798, Rhodococcus opacus PD630, Mus musculus C57BL / 6, and Psychrobacter articus 273-4 were optimized for expression in a yeast host....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com