Flax fiber and tencel fiber blended yarn and preparation method thereof

A technology of tencel fiber and flax fiber, which is applied in the field of blended yarn and its preparation, can solve the problems of high noil rate, uneven evenness, easy damage, etc., reduce the impact force and noil amount, and reduce cotton The effect of increasing knots and improving evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

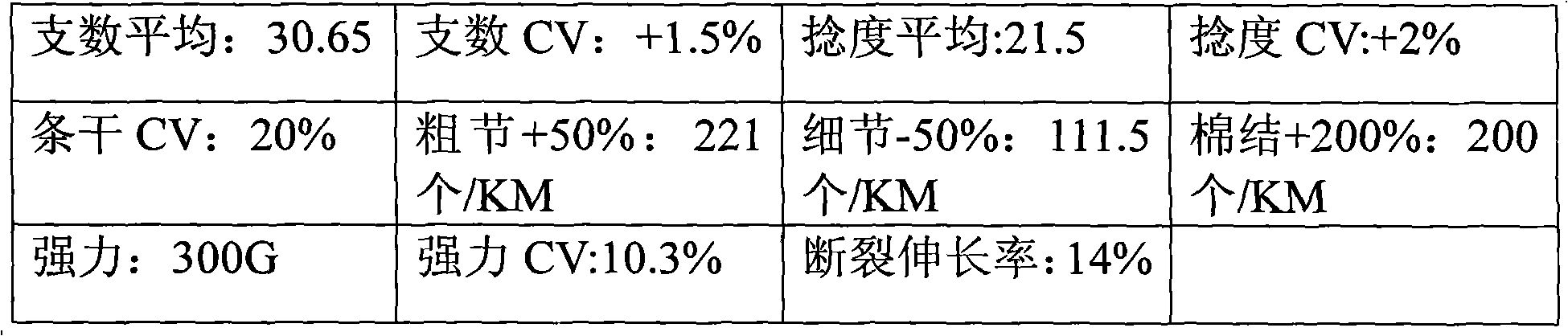

Examples

Embodiment Construction

[0028] raw material:

[0029] The dry strength of flax fiber is 3.3-4.0cN / dtex, the wet strength is 3.5-5.2cN / dtex, and the main body length is 17-20mm.

[0030] Tencel fiber fineness is 1.0~1.8dtex, main body length is 35~40mm.

[0031] Process flow:

[0032] 1. Raw material preparation process: The moisture regain of flax fiber and tencel fiber is basically maintained at about 13%, so these two raw materials should be regained. The specific method and time of moisture regain are as follows:

[0033] flax fiber

72 hours

spray water mist

tencel fiber

48 hours

spray water mist

[0034] After regaining moisture, it is necessary to test and calculate the moisture regain of the two raw materials to determine the appropriate blending ratio, which is generally 35%-40% for flax fiber and 60%-65% for tencel fiber.

[0035] 2. Opening and cleaning process: the distance between the cotton equalizing roller and the corner nail curtain is 30mm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com