Patents

Literature

33results about How to "Natural and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flax fiber and tencel fiber blended yarn and preparation method thereof

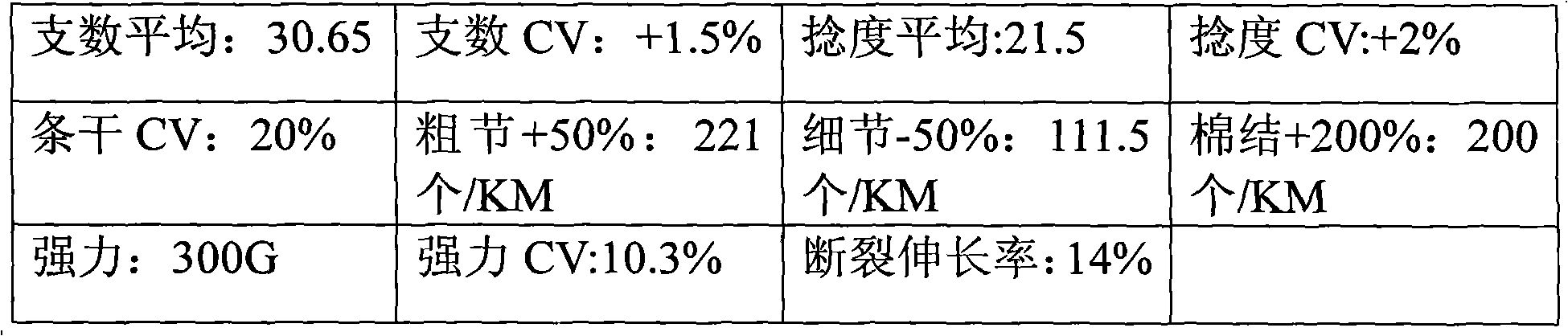

The invention provides a flax fiber and tencel fiber blended yarn and a preparation method thereof. The flax fiber and tencel fiber blended yarn comprises 35 to 40 weight percent of flax fiber and 60 to 65 weight percent of tencel fiber, wherein the twist degree of the blended yarn is 21.32 to 23 T / inch; the average strength of the blended yarn is 300 g; and the elongation percentage of the blended yarn is 14.1 percent. The flax fiber and tencel fiber blended yarn combines moisture absorption, perspiration, antibacterial effect and the like of the flax fiber and the healthy environmentally-friendly characteristic of the tencel fiber, has the advantages of natural environmental friendliness, cooling performance and antibacterium, and can be applied to clothing fabrics and other industries.

Owner:SHANGHAI FEILONG TEXTILE

Underwear using green tea dye and preparation method thereof

ActiveCN103741504AAbundant resourcesReduce usageFibre treatmentDyeing processGreen tea extractChemistry

The invention discloses underwear using green tea dye. The fabric of the underwear is dyed with the green tea extract as the dye. The preparation method comprises the steps of cooking and extracting dye liquor, soaking a cloth to be dyed into hot water, dyeing the cloth to be dyed for the first time, putting the cloth to be dyed into mordanting liquor, dyeing the cloth to be dyed for the second time, and finishing the dyeing of the cloth to be dyed. The underwear has certain hygienic and health-care effects on human body skins, has natural and environment-friendly effects, has the effect of returning to the original nature, and can reduce use of chemical dyes so as to be beneficial for environmental protection.

Owner:佛山市棉恋服饰有限公司

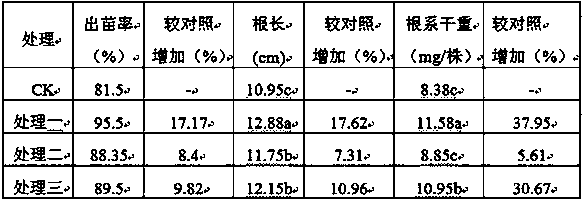

No-heading Chinese cabbage seed initiator and application method thereof

InactiveCN109757489APromote germinationControl water absorptionBiocidePlant growth regulatorsPolyethylene glycolCell membrane

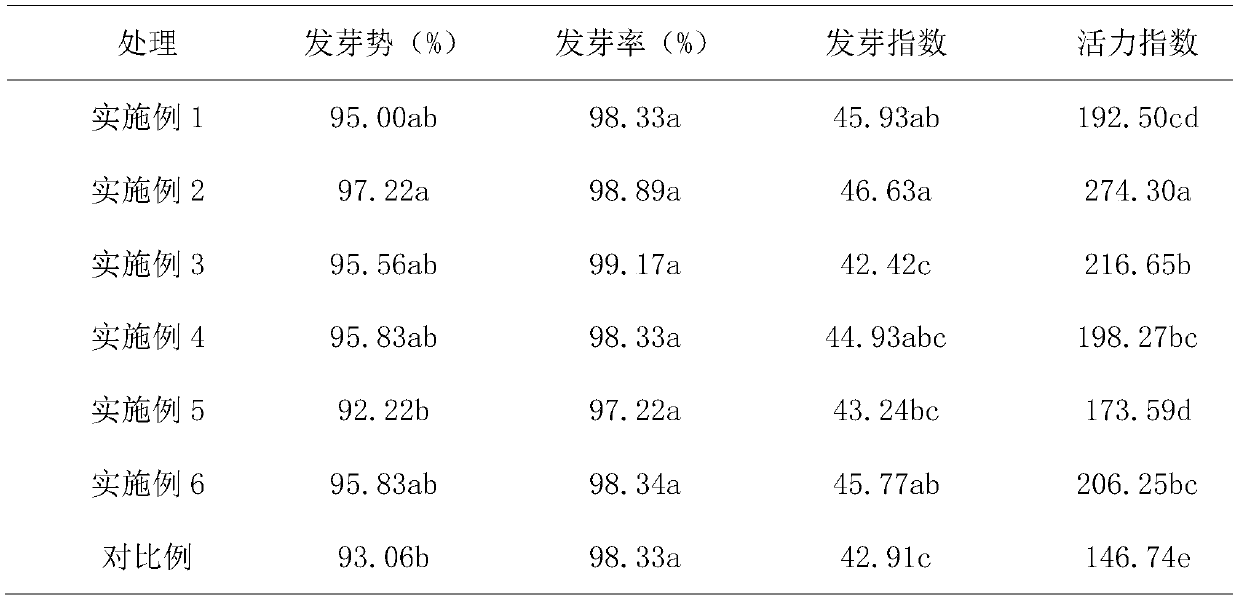

The invention relates to the technical field of seed initiation, in particular to a no-heading Chinese cabbage seed initiator, which is prepared from ascorbic acid, calcium chloride, gibberellin, polyethylene glycol, buffer agents and sterilization agents, wherein the concentration of the ascorbic acid is 20 to 200mg / L; the two optimum concentrations of the ascorbic acid in the no-heading Chinesecabbage seed initiator are respectively 50 and 80 mg / L; the buffer agents are one or several kinds of materials of glucose and fumaric acid; the sterilization agents are tetra methylthiuram disulfide.The invention also discloses an application method of the no-heading Chinese cabbage seed initiator. Through the seepage initiation effect of the ascorbic acid, the seed cell water absorption is controlled; the seed gemmation power is favorably improved; the gemmation of the no-heading Chinese cabbage seeds is promoted; the functions of preventing membrane lipid peroxidation, clearing away free radicals and maintaining cytomembrane integrality are realized; the young seedling growth is more facilitated.

Owner:NANJING AGRICULTURAL UNIVERSITY

Tencel blended yarn

InactiveCN103469399ACombining health and environmental protection featuresCombined with warmthYarnArtifical filament manufactureYarnFiber

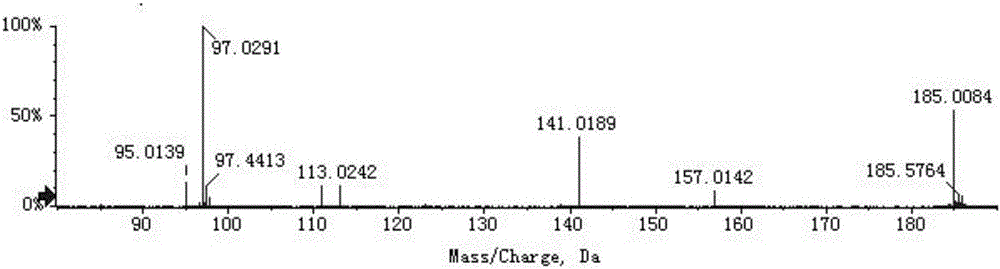

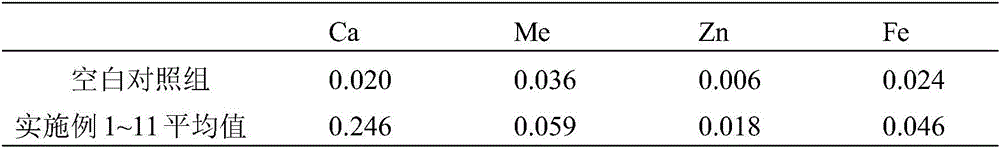

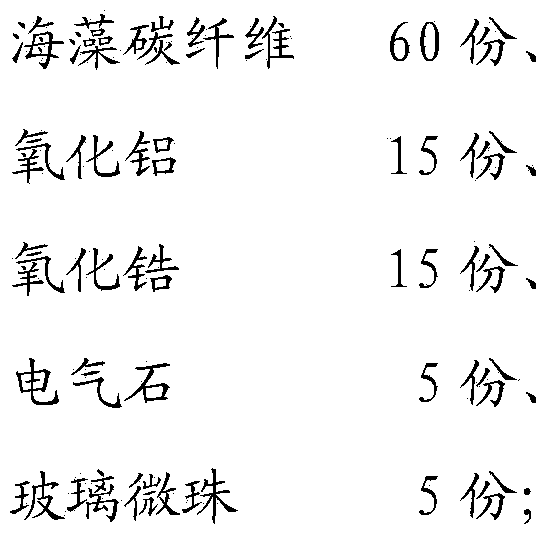

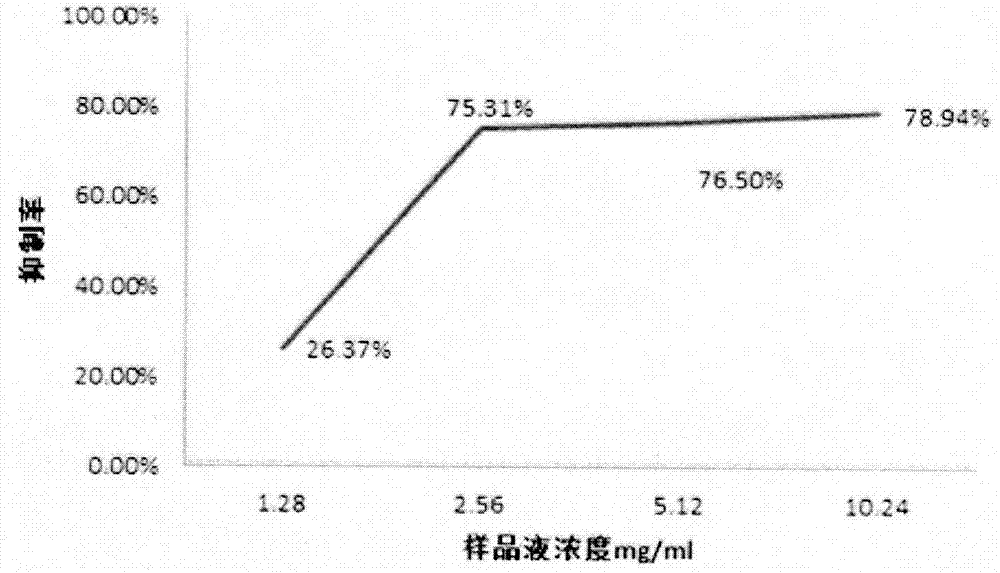

The invention discloses a tencel blended yarn. The tencel blended yarn consists of tencel fibers and far infrared fibers in a blended manner, wherein the weight content of the tencel fibers accounts for 60-65 percent of the tencel blended yarn, and the weight content of the far infrared fibers accounts for 35-40 percent of the tencel blended yarn. A preparation method for the far infrared fibers comprises the steps that far infrared ultrafine micro powder and fiber basic material are mixed and dried, a polymer spinning aid agent is added to the mixture, the mixture is fed to a screw-type extruder and is subjected to melt blending extrusion and granulation, and then far infrared master batch is obtained; the far infrared master batch and fiber chips are blended, spun, wound and stretched to form the far infrared fibers; the far infrared ultrafine micro powder consists of the following compositions in parts by weight: 60-75 parts of seaweed carbon fiber, 15-20 parts of aluminum oxide, 5-15 parts of zirconia, 5-10 parts of tourmaline and 2-5 parts of glass beads. The tencel blended yarn provided by the invention combines the health and environmental-protection characters of the tencel fibers with the warm-keeping effect of the far infrared fibers, has the advantages of natural property, environmental protection and warm keeping and the like, and is applicable to garment fabric and other industries.

Owner:KUNSHAN TIENIU SHIRT FACTORY

UV-curable waterborne coating

The invention relates to the technical field of coatings, in particular to a UV-curable waterborne coating. The UV-curable waterborne coating is prepared from the following raw materials in parts by weight: 65-75 parts of waterborne polyurethane acrylate, 15-25 parts of 25wt% tea polyphenol solution, 15-20 parts of ethylidene urea ethyl acrylate, 5-10 parts of chitosan, 5-10 parts of titanium dioxide photocatalysis, 2-4 parts of photoinitiator, 0.3-0.6 parts of flatting agent, 5-10 parts of cosolvent, 0.2-0.5 parts of anti-settling agent, 1-1.5 parts of antifoaming agent and 140-250 parts of water. The prepared coating can effectively absorb and decompose harmful substances such as benzene, formaldehyde, methylbenzene, xylene and the like, reduce the content of the harmful substances indoors, and is safe and environmentally friendly.

Owner:CHENGDU NASHUO TECH

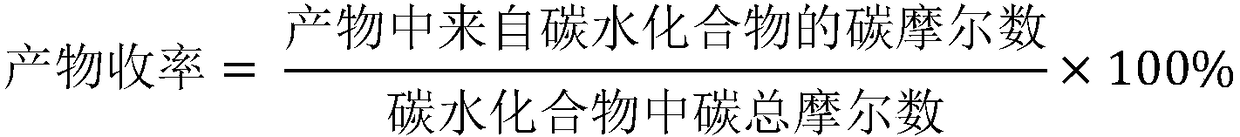

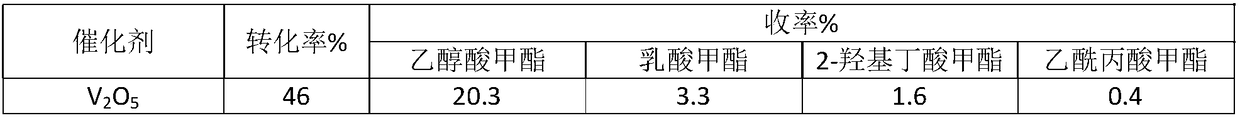

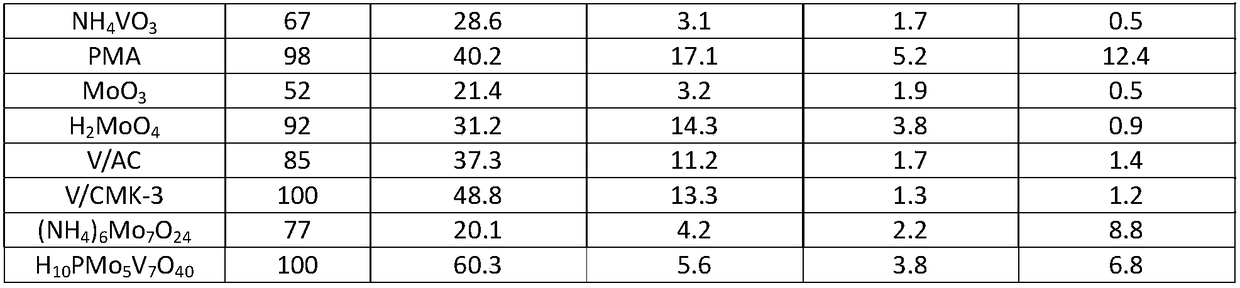

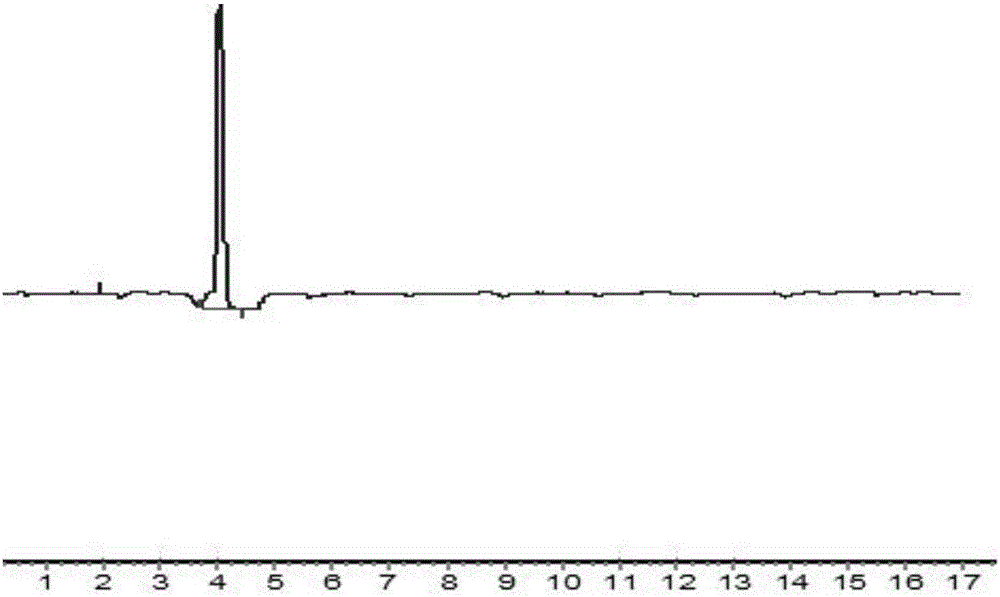

Method for preparing glycolate from carbohydrates

InactiveCN108129320AMeet the requirements of sustainable developmentEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAir atmosphereFiber

The invention provides a method for efficiently preparing glycolate from carbohydrates as a raw material. Raw materials comprise carbohydrates and natural wood fiber containing carbohydrates, whereincarbohydrates contain cellulose, starch, hemicellulose, sucrose, glucose, fructose, fructan, xylose and soluble xylo-oligosaccharide. The method has the following advantages: carbohydrates or the natural wood fiber raw material containing carbohydrates is used, a catalyst is a compound containing vanadium or molybdenum, the reaction temperature is 100-450 DEG C in air atmosphere, the catalytic conversion process is completed in one step in an alcohol solvent, glycolate is prepared from carbohydrates with high conversion rate, high selectivity and high yield, raw materials used in the preparation process are renewable, and glycolate has the significant advantages of being natural, environmentally friendly, widely sourced and high in atom economy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing celandine acid salt from arenga pinnata fruits

InactiveCN106008432ANatural and environmentally friendlyGood biocompatibilityOrganic chemistryOrganic acidAlcohol

The invention provides a method for preparing celandine acid salt from arenga pinnata fruits and relates to a method for preparing a compound from the arenga pinnata fruits. The method for preparing the celandine acid salt from the arenga pinnata fruits includes the steps that 1, the arenga pinnata fruits are placed into an ethyl alcohol solution to be soaked; 2, ethyl alcohol is removed, organic acid is added and stands still, and white needle-shaped crystals are obtained. The method is simple, and a new way is provided for application of the arenga pinnata fruits.

Owner:王伟明

Preparation method for tencel blended yarn

InactiveCN103469398ACombining health and environmental protection featuresCombined with warmthYarnYarnPolymer science

The invention discloses a preparation method for a tencel blended yarn. Tencel fibers and far infrared fibers are blended sequentially through the procedures of opening and cleaning, carding, drawing, roving and spinning to form the tencel blended yarn, the weight content of the tencel fibers accounts for 60-65 percent of the tencel blended yarn, and the weight content of the far infrared fibers accounts for 35-40 percent of the tencel blended yarn; the far infrared fibers are prepared through the following method: far infrared ultrafine micro powder and fiber basic material are mixed and dried, a polymer spinning aid agent is added to the mixture, the mixture is fed to a screw-type extruder and is subjected to melt blending extrusion and granulation, and then far infrared master batch is obtained; the far infrared master batch and fiber chips are blended, spun, wound and stretched to form the far infrared fibers. The tencel blended yarn produced through the preparation method for the tencel blended yarn, disclosed by the invention, combines the health and environmental-protection characters of the tencel fibers with the warm-keeping effect of the far infrared fibers, has the advantages of natural property, environmental protection and warm keeping and the like, and is applicable to garment fabric and other industries.

Owner:KUNSHAN TIENIU SHIRT FACTORY

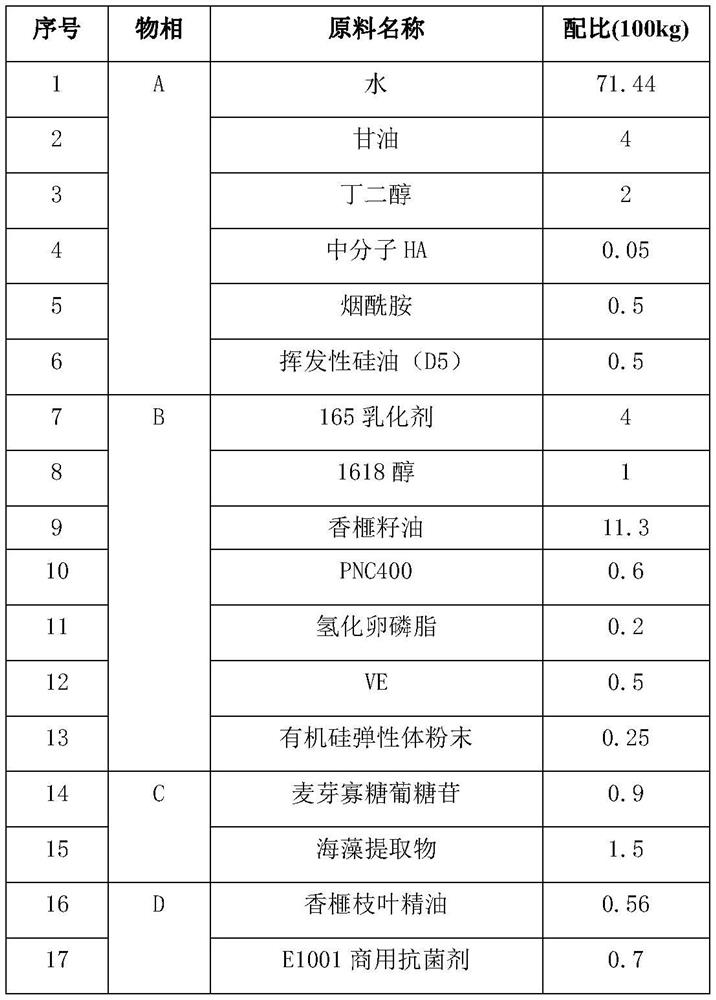

Composite essential oil moisture lotion and preparing method thereof

ActiveCN107049832APerfume hasNatural and environmentally friendlyCosmetic preparationsToilet preparationsWrinkle skinSalicylic acid

The invention discloses a composite essential oil moisture lotion and a preparing method thereof. The composite essential oil moisture lotion is prepared from, by mass, 60% of refined water, 0.3% of triethanolamine, 0.3% of methylparaben, 5% of glycerin, 2% of tween-80, 10% of 1,3-butanediol, 2% of beewax, 5% of stearic acid, 3% of glyceryl monostearate, 0.4% of sandalwood essential oil, 1% of Schisandra chinensis root bark essential oil, 2.5% of lanolin, 2% of salicylic acid, 2.5% of vaseline and 4% of liquid paraffin. Plant essential oil is used as preservatives and flavoring agents instead of chemical components like artificial flavors, pigments and preservatives, so that environment friendliness is realized, safety performance is high, and absorption is easy. Lanolin and beewax are natural emulsifiers and can make emulsification easier, so that a stable lotion system can be formed. Moisture absorbents like glycerin and 1,3-butanediol and oil materials like natural lanolin and beewax can make skin elastic, reduce wrinkles and relieve chromatosis. Natural Chinese herbal medicine essential oil like sandalwood essential oil and Schisandra chinensis root bark essential oil have flavoring, moistening and anti-free radical functions.

Owner:BAOJI UNIV OF ARTS & SCI

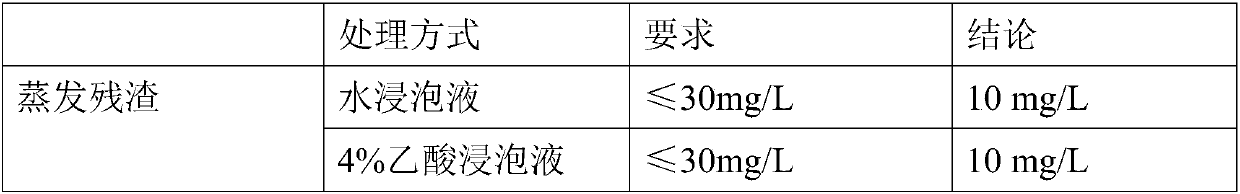

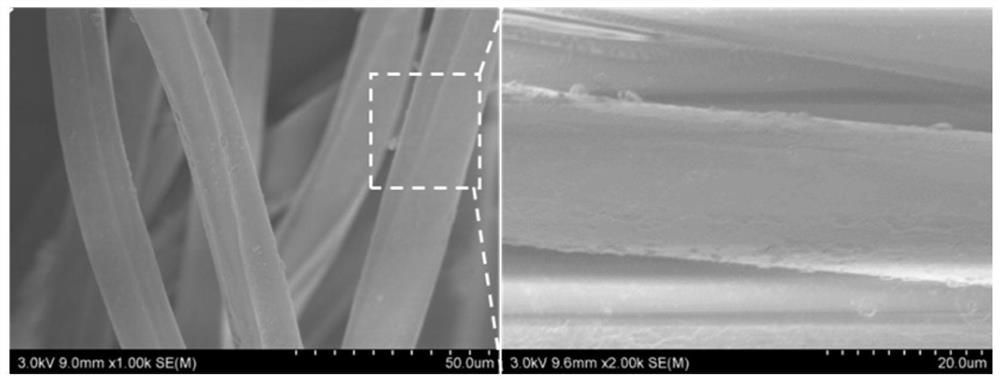

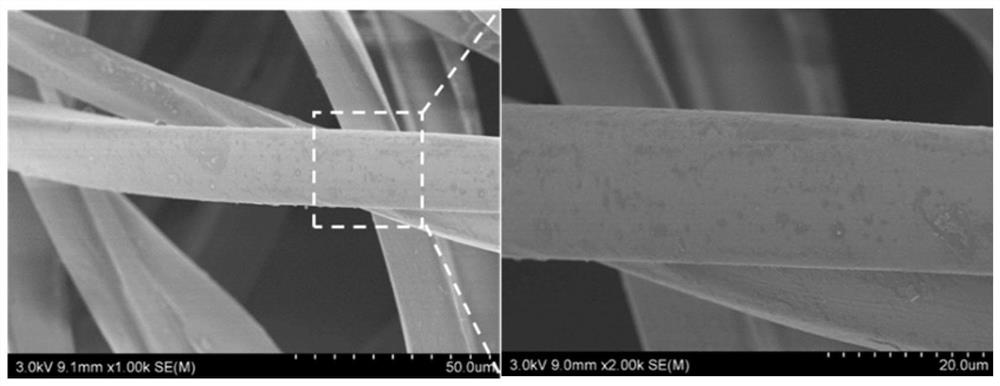

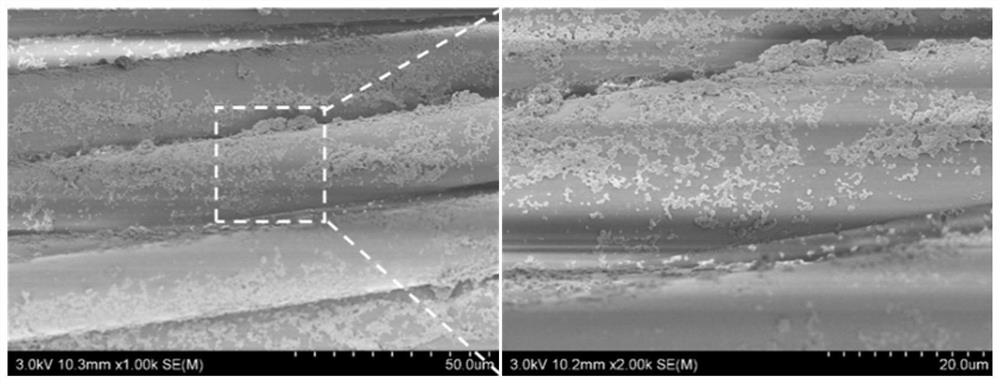

Preparation method of polyester raschel blanket with natural long-acting antibacterial function

ActiveCN109440462ANatural and environmentally friendlyImprove antibacterial propertiesBiochemical fibre treatmentFibre typesPolyesterEscherichia coli

The invention discloses a preparation method of a polyester raschel blanket with a natural long-acting antibacterial function. A multifunctional solution is obtained from chitosan carried by silk fibroin and used for modifying a polyester raschel blanket. The modified blanket has Escherichia coli resistance of 50%-90% and antistatic decay time of 7-28 s. The problems of low air and water vapor permeability, poor handfeel and the like of the polyester raschel blanket modified with the traditional method are solved, the polyester raschel blanket is endowed with lasting natural antibacterial andantistatic functions and other functions, and additional value and market competitiveness of the polyester raschel blanket are increased.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Formaldehyde removing ultraviolet curing water-based paint

InactiveCN104927623ASpecial structureNo pollutionAntifouling/underwater paintsPaints with biocidesWater basedFiber

The invention relates to the field of paint, particularly to a formaldehyde removing ultraviolet curing water-based paint which is prepared from the following components in parts by weight: 65-75 parts of waterborne polyurethane acrylate, 15-25 parts of bamboo carbon fiber, 15-20 parts of grapheme, 5-10 parts of chitosan, 5-10 parts of titanium dioxide photocatalyst, 2-4 parts of a photoinitiator, 0.3-0.6 part of a flatting agent, 5-10 parts of a cosolvent, 0.2-0.5 part of an anti-settling agent, 1-1.5 parts of a defoamer and 140-250 parts of water. The prepared paint can effectively absorb and decompose hazardous substances of benzene, formaldehyde, methylbenzene, xylene and the like, reduces the content of the indoor hazardous substances, and is safe and environment-friendly.

Owner:CHENGDU NASHUO TECH

Diatomite art lacquer coating containing inorganic salts

InactiveCN108359356AImprove performanceStrong adhesionFireproof paintsEpoxy resin coatingsFiberEpoxy

The invention provides a diatomite art lacquer coating containing inorganic salts. The diatomite art lacquer coating is prepared from the following raw materials in percentage by weight: 75-85% of water-soluble epoxy modified acrylic resin, 2-6% of pearl powder, 0.3-0.6% of water-soluble fibers, 0.2-0.5% of dispersants, 1-3% of moisture retention agents, 0.2-0.4% of anti-bacterial agents, 2-6% ofbactericides, 1-3% of defoaming agents, 0.4-0.7% of pH regulators, 2-4% of thickening agents, 0.6-1.2% of silicon dioxide, 10-15% of silicate, 0.3-0.6% of silane coupling agents, 4-8% of diatomite, 2-8% of nano calcium carbonate powder, 2-4% of inorganic pigments, 2-9% of odor removing agents and a proper amount of water. The diatomite art lacquer coating is simple to prepare and mild in color, isnatural and environmentally friendly, and is capable of purifying air, absorbing water and resisting flame.

Owner:白山和一硅藻科技股份有限公司

Indoor wall coating

The invention provides an indoor wall coating. The content of harmful matter in the indoor wall coating is small, and the indoor wall coating has anti-radiation and mould-prevention functions. The indoor wall coating is characterized by being prepared from a backing material and water, wherein the backing material is prepared from Portland cement, expanded perlite, fiber powder, kieselguhr, plant colored cotton cellulose, lignocellulose, adhesive, antifreezing agent, cyanuric melamine salt, hollow glass microballoon and the balance of water.

Owner:武汉金中海高新科技有限公司

Preparation technology of lotus fiber convenience bag

InactiveCN101731811AProduction of convenience bagsNatural and environmentally friendlyHandbagsLuggageNatural fiberPollution

The invention relates to a preparation technology of a convenience bag, in particular to a preparation technology of a lotus fiber convenience bag. The preparation technology has the following steps: harvesting and binding lotus root stalk-river water dipping-picking lotus fiber-boiling for 3 hours in caustic soda with a concentration of 1%-washing with cold water-washing with sulfuric acid with a concentration of 0.1% for 30min-washing with cold water- boiling for 3 hours in caustic soda with a concentration of 1%- washing with sulfuric acid with a concentration of 0.1% for 30min-washing with cold water-dehydrating-drying-mixing the obtained lotus fiber with jute and dacron according to a certain proportion in an opening and scutching manner-carding and forming-dipping binding agent-thermocompression drying-cutting for producing convenience bags.The preparation technology of the invention features wide source of raw materials, low cost, simple production technology process and no pollution; in addition, the convenience bag is mainly composed of natural fiber which can be degraded in the natural environment, thus being economical and practical and widely applicable.

Owner:CHANGZHOU TEXTILE GARMENT INST

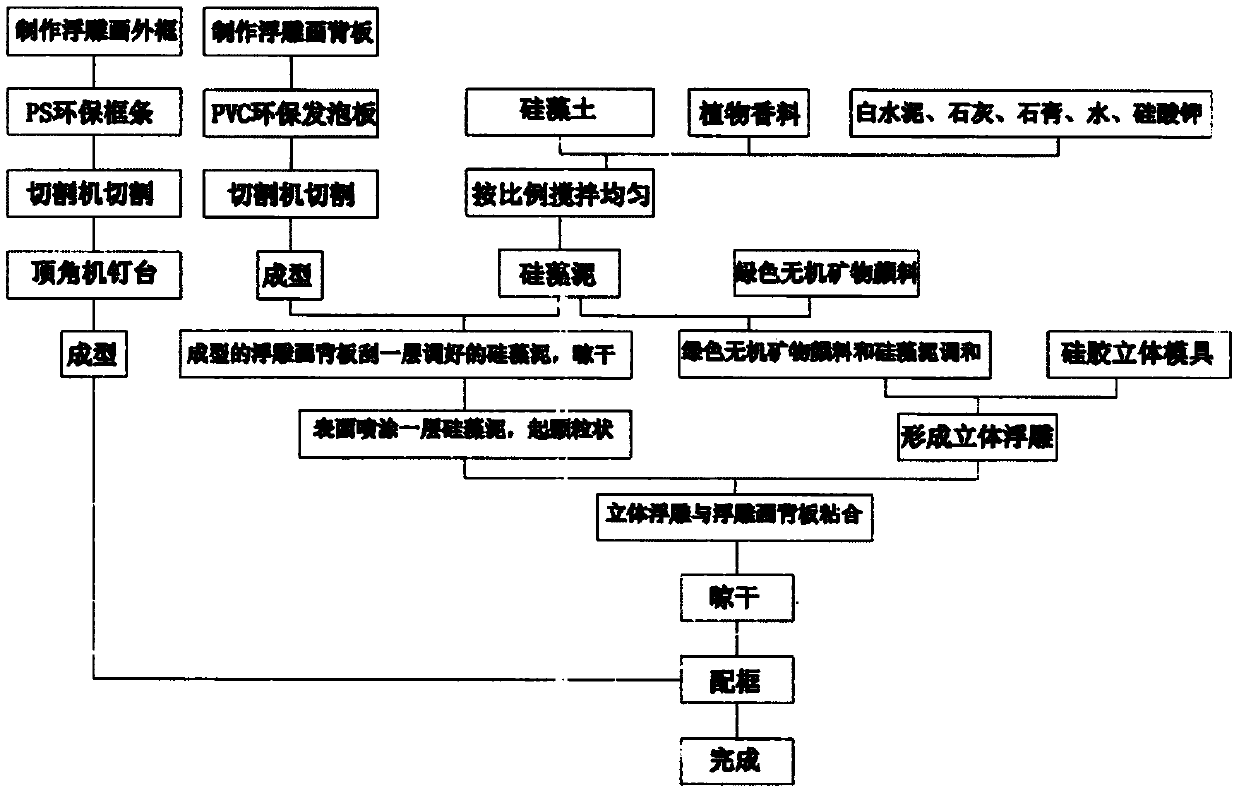

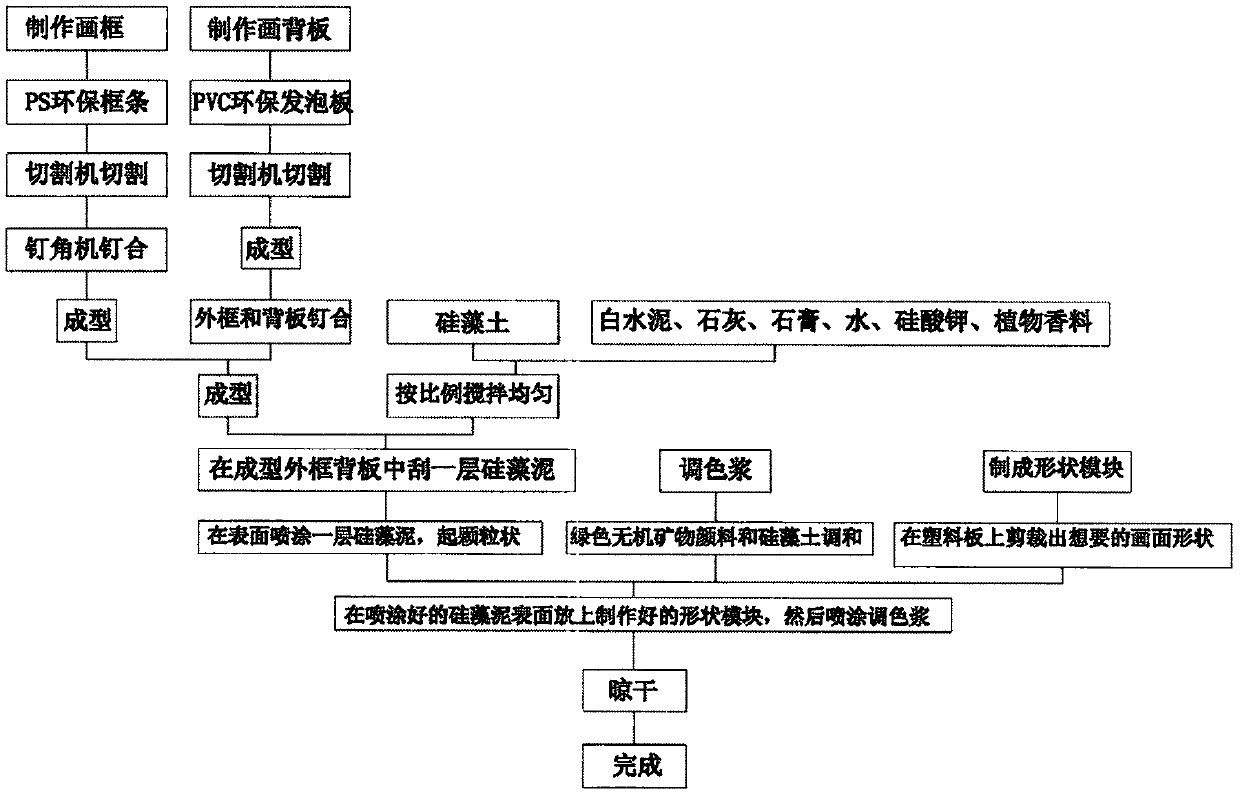

Manufacturing method of diatom ooze embossment hanging picture

InactiveCN110001263AGood decorative effectImprove durabilityOrnamental structuresSpecial ornamental structuresEngineering

The invention provides a manufacturing method of a diatom ooze embossment hanging picture and relates to the technical field of decorative pictures. The manufacturing method comprises the following steps that an embossment picture outer frame is manufactured, an embossment picture back plate is manufactured, mixed diatom ooze is scraped on the embossment picture back plate and dried in air, a second layer of diatom ooze is sprayed to a first layer of diatom ooze dried in the air, and the second layer of diatom ooze is granulated; the mixed diatom ooze and environment-friendly inorganic mineralpigment are mixed, and mixed mixture is placed into a silica gel three-dimensional die to form a three-dimensional embossment; the three-dimensional embossment is bonded to the embossment picture back plate coated with the diatom ooze and dried in the air; and the embossment picture back plate in the step e is fixed to the embossment picture outer frame. The method has the beneficial effects thatthe hanging picture adopting the diatom ooze has the advantages of being natural and environmentally friendly, resisting mildew and bacteria and purifying and humidifying air. Meanwhile, the embossment design is adopted, the decorating effect is better, the diatom ooze has the advantages of being fast, preventing falling off and being capable of being preserved in good condition for a long term,and use durability of the hanging picture is effectively improved.

Owner:唐山艺趣艺术品有限公司

Polylactic acid fiber food grade binding rope

PendingCN107724135AImprove securityNatural and environmentally friendlyBio-packagingClimate change adaptationFood packagingPolylactic acid

The invention relates to a polylactic acid fiber food grade binding rope, and belongs to the technical field of food packaging materials. The problem that an existing cotton rope is poor in safety issolved. The polylactic acid fiber food grade binding rope is characterized in that the binding rope is made of pure polylactic acid fiber. The polylactic acid fiber food grade binding rope is made ofpolylactic acid fiber. Due to the fact that the polylactic acid fiber has the natural antiseptic antibacterial activity, and the food safety is effectively improved; particularly, if the food bindingrope obtained by plying polylactic acid fiber filaments is adopted, the surface is smooth and clean, has little hair and is not likely to be provided with sundries in a sticky mode, and the food safety is further improved. By adding polylactic acid fiber, the high-temperature retraction rate can be controlled to be within 5-30%, the binding strength is better after high-temperature digestion, foodis not likely to be scattered, and the food appearance and quality are improved. In addition, due to the 100% degradation property of polylactic acid fiber, no damage is caused to the environment, and the food packaging material environmental friendliness is improved.

Owner:润益(嘉兴)新材料有限公司

Antibacterial epoxy coating for anchor chains and preparation method thereof

InactiveCN109486344AStrong adhesionGood chemical resistanceAntifouling/underwater paintsConjugated diene hydrocarbon coatingsAntibacterial propertyDefoaming Agents

The invention belongs to the field of coatings and particularly relates to an antibacterial epoxy coating for anchor chains and a preparation method thereof. The antibacterial epoxy coating for anchorchains comprises, by weight, 30-50 parts of bisphenol A epoxy resin, 10-15 parts of phenalkamines, 10-15 parts of diatom ooze, 8-12 parts of polyurethane, 7-8 parts of nitrile butadiene rubber, 8-9 parts of a high-wear-resistance pigment filler, 5-8 parts of polyethylene wax emulsion, 8-12 parts of modified silica, 1-2 parts of a dispersant, 1-2 parts of a defoaming agent, 3-5 parts of a levelingagent, 2-3 parts of a film-forming aid, 2-3 parts of an anti-freezing agent, and 10-15 parts of deionized water. The antibacterial epoxy coating for anchor chains prepared herein has good corrosion resistance, impact resistance, toughness, antibacterial property and dispersibility.

Owner:镇江宝海船舶五金有限公司

Efficient tea dyeing method

The invention relates to an efficient tea dyeing method. The efficient tea dyeing method comprises the following steps: 1) drying tea raw material till water content below 7%, and then smashing into 300-800 mesh ultrafine tea powder; 2) adding water into the tea powder and uniformly mixing tea powder and water at ratio of 1:(50-80); placing a mixed solution in an ultrasonoscope for preparing a dyeliquor under the conditions of frequency of 50-80 KHz, time of 40-60min and temperature at 70-80 DEG C; cooling and filtering the mixed solution after ultrasonic treatment, thereby acquiring a tea dye liquor; 3) adding 1-3%wt acid solution into the tea dye liquor till PH value of the tea dye liquor is 3.5-4.5; 4) putting a to-be-dyed fabric into the tea dye liquor at liquor ratio of 1:(40-50), and placing into the ultrasonoscope under the conditions of frequency of 50-80 KHz, time of 5-10min and temperature at 70-80 DEG C; 5) taking the ultrasonically soaked fabric from the tea dye liquor, performing microwave drying dyeing under the conditions of power of 0.1-5W / g and time of 1-3min, and then performing far infrared dry fixation for 1-3min under the conditions of power of 500-800W and temperature at 60-80 DEG C. The efficient tea dyeing method has the advantages of natural and environment-friendly properties, energy-efficient property and high color fastness.

Owner:SUZHOU VOCATIONAL UNIV

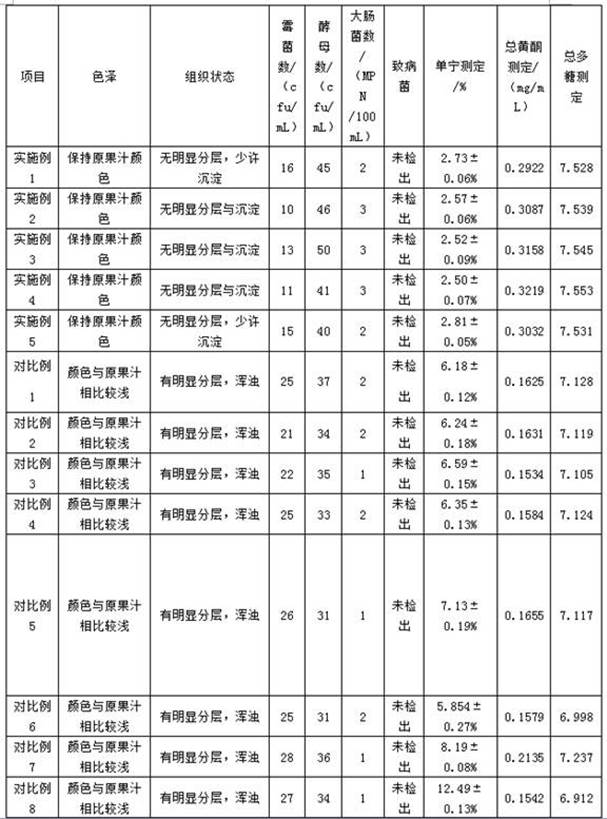

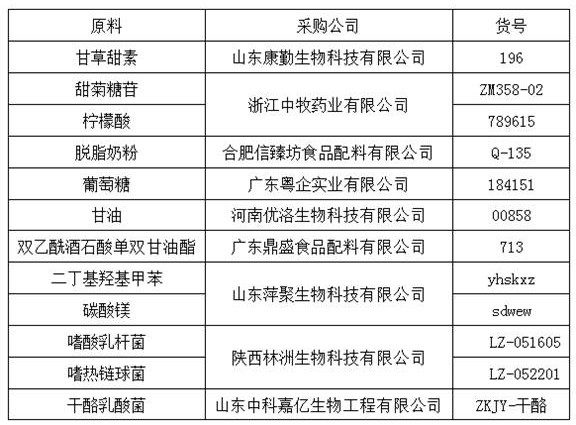

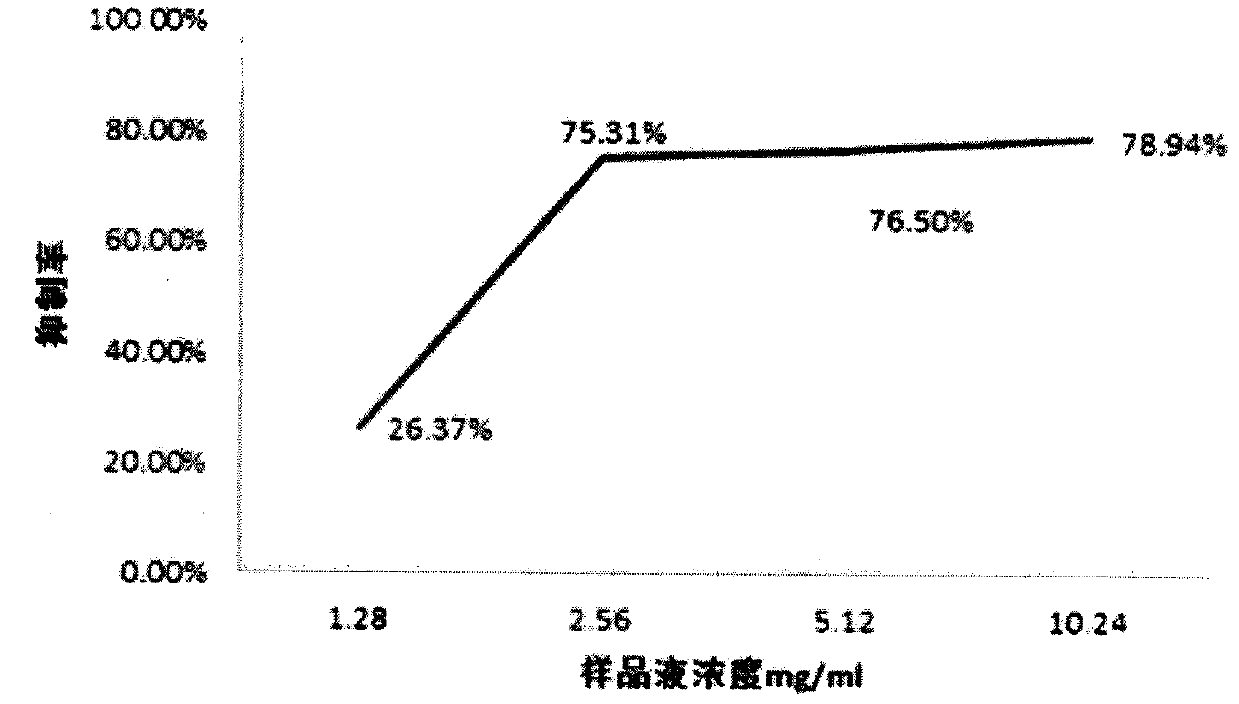

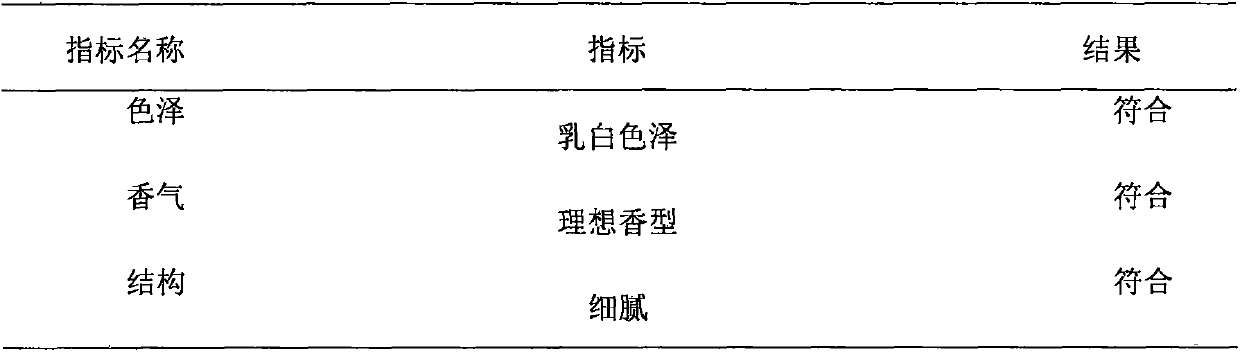

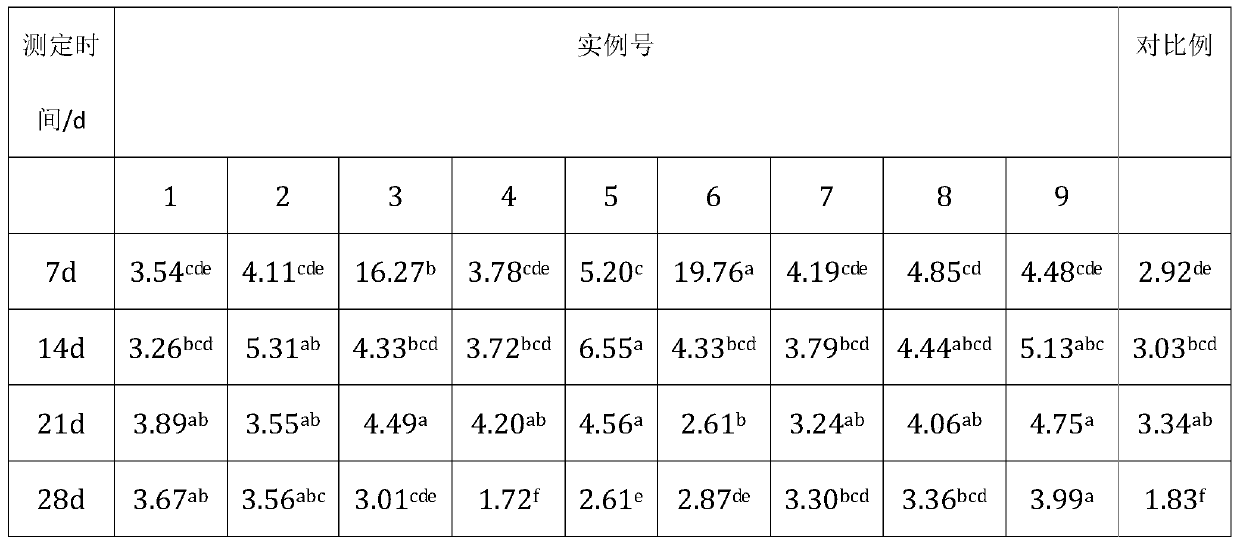

Sugar-free lactic acid bacteria beverage and preparation method thereof

InactiveCN113273609AMaintain colorSmooth tasteMilk preparationMilk preservationBiotechnologyLactic acid bacterium

The invention relates to the technical field of lactic acid bacteria beverages, and particularly discloses a sugar-free lactic acid bacteria beverage and a preparation method thereof. The sugar-free lactic acid bacteria beverage comprises the following raw materials: fermented milk, Phyllanthus Emblica juice and stabilizers, with the balance being water; The stabilizers comprise the following raw materials: glycerol, diacetyl tartaric acid ester of mono (di) glycerides, butylated hydroxytoluene and magnesium carbonate. The preparation method comprises the following steps: weighing the Phyllanthus Emblica juice, the stabilizers and the water, subjecting the Phyllanthus Emblica juice, the stabilizer and the water to sterilizing and disinfecting, and then stirring and mixing the Phyllanthus Emblica juice, the stabilizers and the water until the stabilizers are completely dissolved, thereby obtaining a mixture; adding the mixture into the fermented milk, and carrying out homogenizing to obtain homogenized liquid; and subjecting the homogenized liquid to sterilizing and disinfecting to obtain the sugar-free lactic acid bacteria beverage. According to the invention, the sugar-free lactic acid bacteria beverage and the preparation method thereof can be used for producing the sugar-free lactic acid bacteria beverage, and the sugar-free lactic acid bacteria beverage has the advantages of low calorie and high nutritional value; in addition, the preparation method in the invention has advantages of being easy and convenient to operate and rapid in production.

Owner:宁波益富乐生物科技有限公司

A kind of compound essential oil moisturizing lotion and preparation method thereof

ActiveCN107049832BPerfume hasNatural and environmentally friendlyCosmetic preparationsToilet preparationsBiotechnologyGlycerol

The invention discloses a composite essential oil moisture lotion and a preparing method thereof. The composite essential oil moisture lotion is prepared from, by mass, 60% of refined water, 0.3% of triethanolamine, 0.3% of methylparaben, 5% of glycerin, 2% of tween-80, 10% of 1,3-butanediol, 2% of beewax, 5% of stearic acid, 3% of glyceryl monostearate, 0.4% of sandalwood essential oil, 1% of Schisandra chinensis root bark essential oil, 2.5% of lanolin, 2% of salicylic acid, 2.5% of vaseline and 4% of liquid paraffin. Plant essential oil is used as preservatives and flavoring agents instead of chemical components like artificial flavors, pigments and preservatives, so that environment friendliness is realized, safety performance is high, and absorption is easy. Lanolin and beewax are natural emulsifiers and can make emulsification easier, so that a stable lotion system can be formed. Moisture absorbents like glycerin and 1,3-butanediol and oil materials like natural lanolin and beewax can make skin elastic, reduce wrinkles and relieve chromatosis. Natural Chinese herbal medicine essential oil like sandalwood essential oil and Schisandra chinensis root bark essential oil have flavoring, moistening and anti-free radical functions.

Owner:BAOJI UNIV OF ARTS & SCI

A kind of preparation method of natural long-lasting antibacterial function polyester raschel blanket

ActiveCN109440462BNatural and environmentally friendlyImprove antibacterial propertiesBiochemical fibre treatmentFibre typesEscherichia coliPolyester

The invention discloses a preparation method of a polyester raschel blanket with a natural long-acting antibacterial function. A multifunctional solution is obtained from chitosan carried by silk fibroin and used for modifying a polyester raschel blanket. The modified blanket has Escherichia coli resistance of 50%-90% and antistatic decay time of 7-28 s. The problems of low air and water vapor permeability, poor handfeel and the like of the polyester raschel blanket modified with the traditional method are solved, the polyester raschel blanket is endowed with lasting natural antibacterial andantistatic functions and other functions, and additional value and market competitiveness of the polyester raschel blanket are increased.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

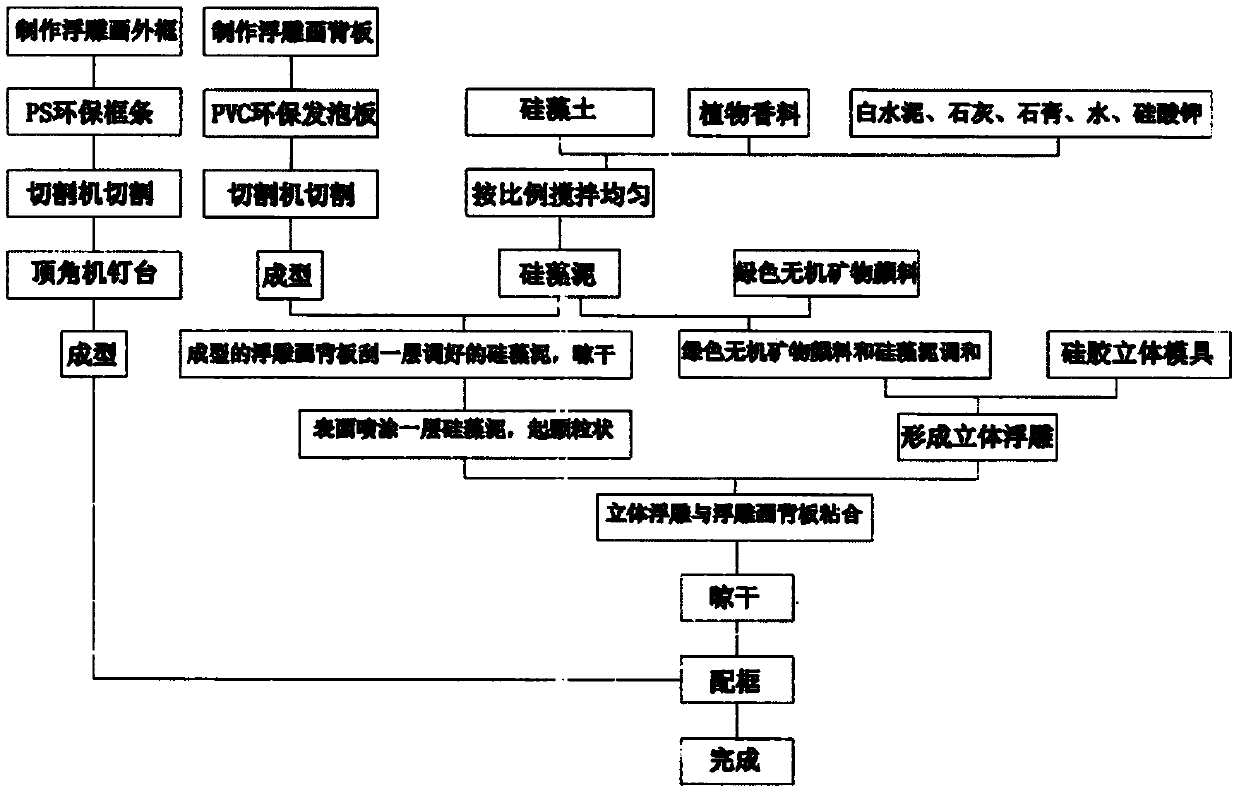

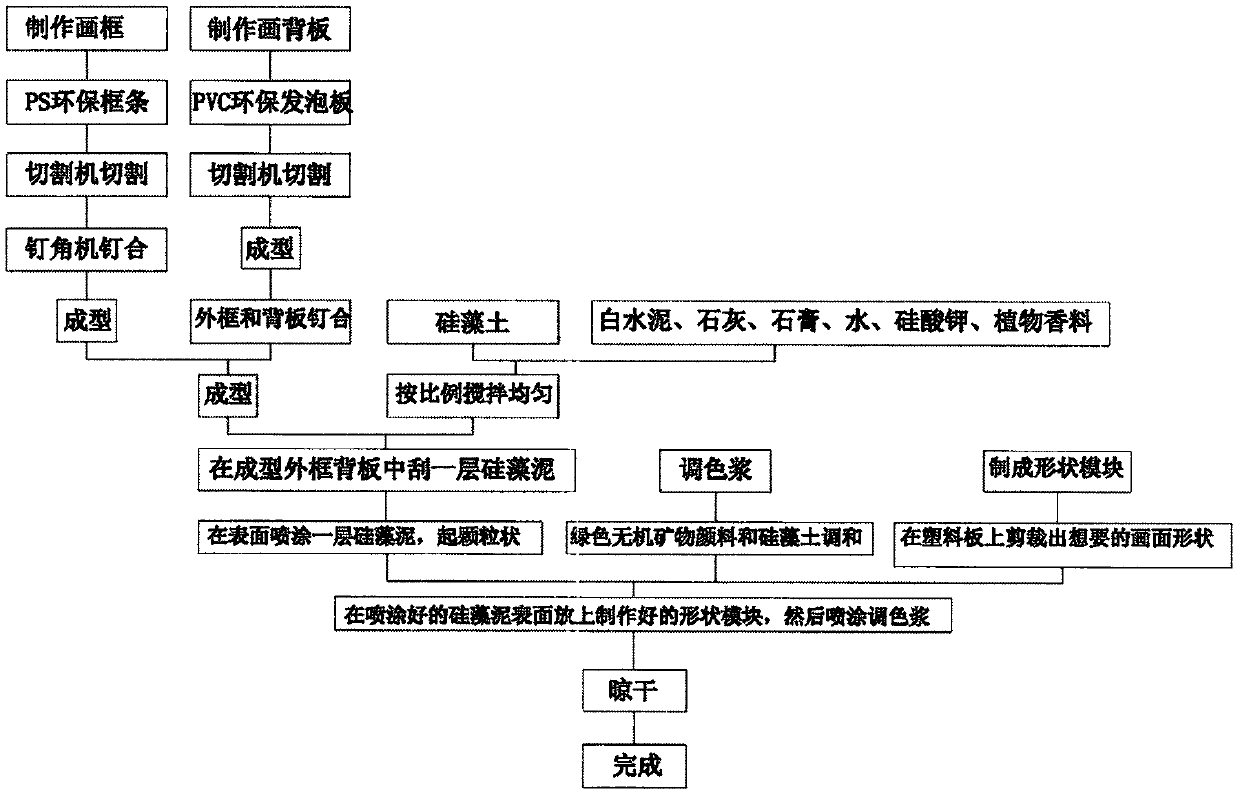

Manufacturing method of painting diatom ooze

InactiveCN110001271AGood decorative effectImprove durabilityOrnamental structuresSpecial ornamental structuresEnvironmentally friendlyEngineering

The invention provides a manufacturing method of painting diatom ooze, and relates to the technical field of decorative pictures. The manufacturing method includes the following steps that a paintingframe is manufactured, a painting back plate is manufactured, and the painting back plate and the painting frame are nailed; diatom ooze coating is carried out, wherein the mixed diatom ooze is scraped on the formed outer frame painting back plate obtained in the step c and aired, a second layer of diatom ooze is sprayed to the surface of the first layer of aired diatom ooze, and the second layerof diatom ooze is granular; tinting paste is manufactured, wherein green inorganic mineral pigments and the diatom ooze are mixed, and the tinting paste is obtained; and shape modules are manufactured, wherein needed picture shapes are cut from a plastic plate, the shape modules are obtained, the shape modules are put on the formed outer frame painting back plate to which the diatom ooze is sprayed, then the tinting paste is sprayed, and the painting diatom ooze is obtained after the tinting paste is aired. A painting adopting the diatom ooze has the beneficial effects of being natural and environmentally friendly, resisting mould and bacteria and purifying and humidifying air, has a good tripoli decorative effect, and has the beneficial effects of being free of color fading and disengaging and capable of being saved perfectly for a long time, and the use durability of the painting is effectively improved.

Owner:唐山品画艺术品有限公司

Method for preparing fabric finishing agent from sericin recycled from silk processing wastewater

The invention discloses a method for preparing a fabric finishing agent from sericin recycled from silk processing wastewater. The method comprises the following steps of: (1) treating sericin wastewater generated in a silk processing process with a flocculant by a coagulation process to obtain a flocculated crude product; (2) hydrolyzing and refining the flocculated crude product; and (3) preparing the finishing agent by any one of the following methods: uniformly stirring 2-6 parts by weight of the product obtained in the step (2), 0.4-0.8 part by weight of cross-linking agent, 0.3-0.6 part by weight of magnesium sulfate and the balance water to obtain a finishing liquid for cotton padding; or uniformly stirring 2-6 parts by weight of the product obtained in the step (2), 0.4-0.8 part by weight of cross-linking agent, 2-6 parts of sodium bisulfite and the balance water and reacting in 30-50 DEG C water bath for 50-80 minutes to obtain a finishing liquid for chemical fiber. The obtained product can be widely applied to modification treatment of cotton and chemical fiber fabric.

Owner:ZHEJIANG SCI-TECH UNIV

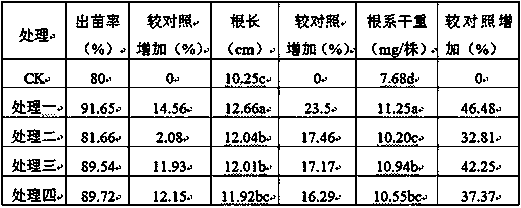

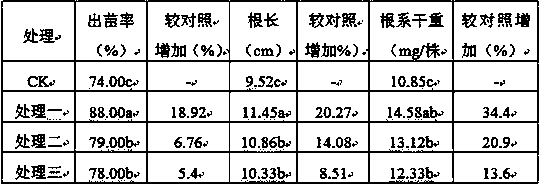

A kind of wheat seed initiator that improves germination rate and its application method

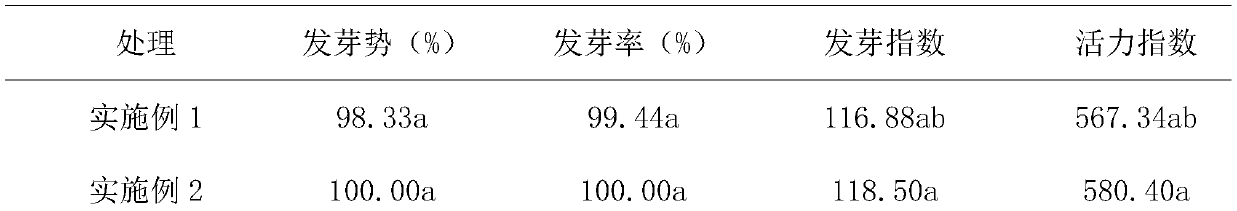

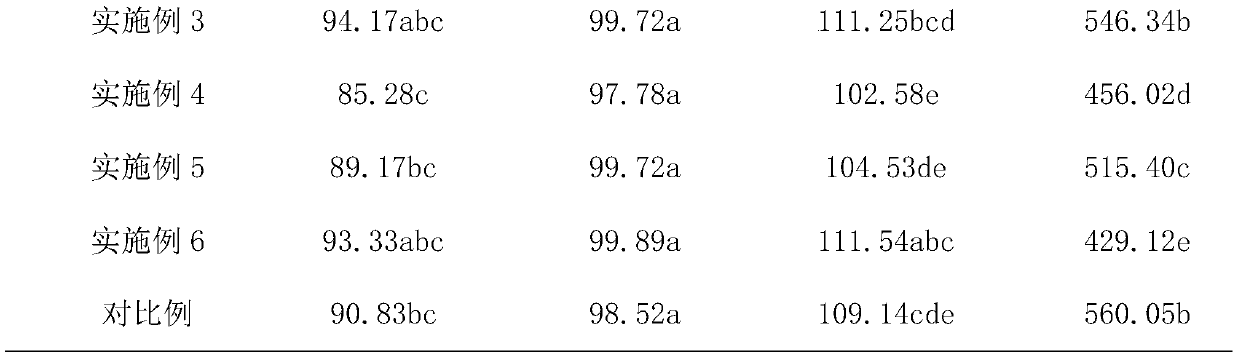

ActiveCN105660700BImprove uniformityIncrease growth potentialBiocidePlant growth regulatorsRoot growthPolyethylene glycol

The invention relates to a wheat seed initiator for increasing germination rate and a method of use thereof.The wheat seed initiator comprises the materials as follows: 1-10% of a high phosphorus compound, 0.01-1% of gamma- polyglutamic acid, 0.01-1% of glutathione, 0.1-10% of potassium fulvate, 1-20% of polyethylene glycol, 0.01-0.5% of a plant growth regulator, 0.1-5% of auxiliary materials, and the balance of water.The materials of the initiator are selected and rationed such that wheat root environment is greatly improved, wheat root growth is promoted and root strengthening, seedling strengthening and cold resisting are achieved, and the reasonable use with growth promoting components such as potassium fulvate and glutathione significantly improves wheat germinating uniformity and wheat growth vigor.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

A low-temperature curing environmentally friendly water-based flocking adhesive

ActiveCN107286868BNatural and environmentally friendlyEasy to useNon-macromolecular adhesive additivesCyclodextrin adhesivesWater basedArray data structure

The invention provides a low-temperature setting environment-friendly water-based flocking adhesive which consists of the following components in parts by weight: 30 to 40 parts of modified glutinous rice glue, 5 to 8 parts of citric acid, 3 to 5 parts of thickener, 1 to 3 parts of emulsifier, 1 to 3 parts of antifoaming agent, 3 to 5 parts of preservative, 2 to 4 parts of D-glucose, 3 to 5 parts of silane coupling agent and 8 to 10 parts of deionized water. A preparation method of the improved glutinous rice glue comprises: after uniformly mixing glutinous rice flour, potato starch and water, carrying out high-temperature gelatinization, compound enzyme enzymolysis and enzyme denaturing; cooling to a temperature of 50 to 60 DEG C; then sequentially adding organic improved montmorillonite, chitosan and beta-cyclodextrin. The flocking adhesive provided by the invention uses the natural environment-friendly glutinous rice glue as a main ingredient, has the advantages of high environment-friendliness, low-temperature setting and good weather resistance and meanwhile, solves the problems of low cohesiveness, poor antibacterial property and easiness for generating cracks of common glutinous rice glue.

Owner:深圳市美之电实业有限公司

Torreya grandis compound oil as well as preparation method and application

ActiveCN113730291AIncrease the fragranceNatural and environmentally friendlyCosmetic preparationsToilet preparationsBiotechnologyPreservative

Owner:ANHUI KANGXINXIANG AGRI SCI & TECH GRP CO LTD +1

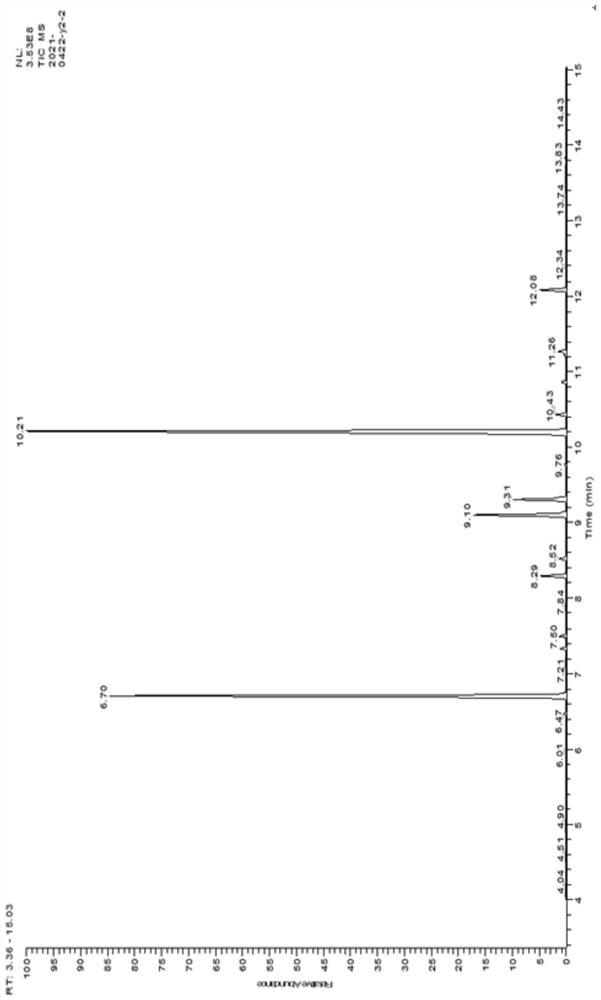

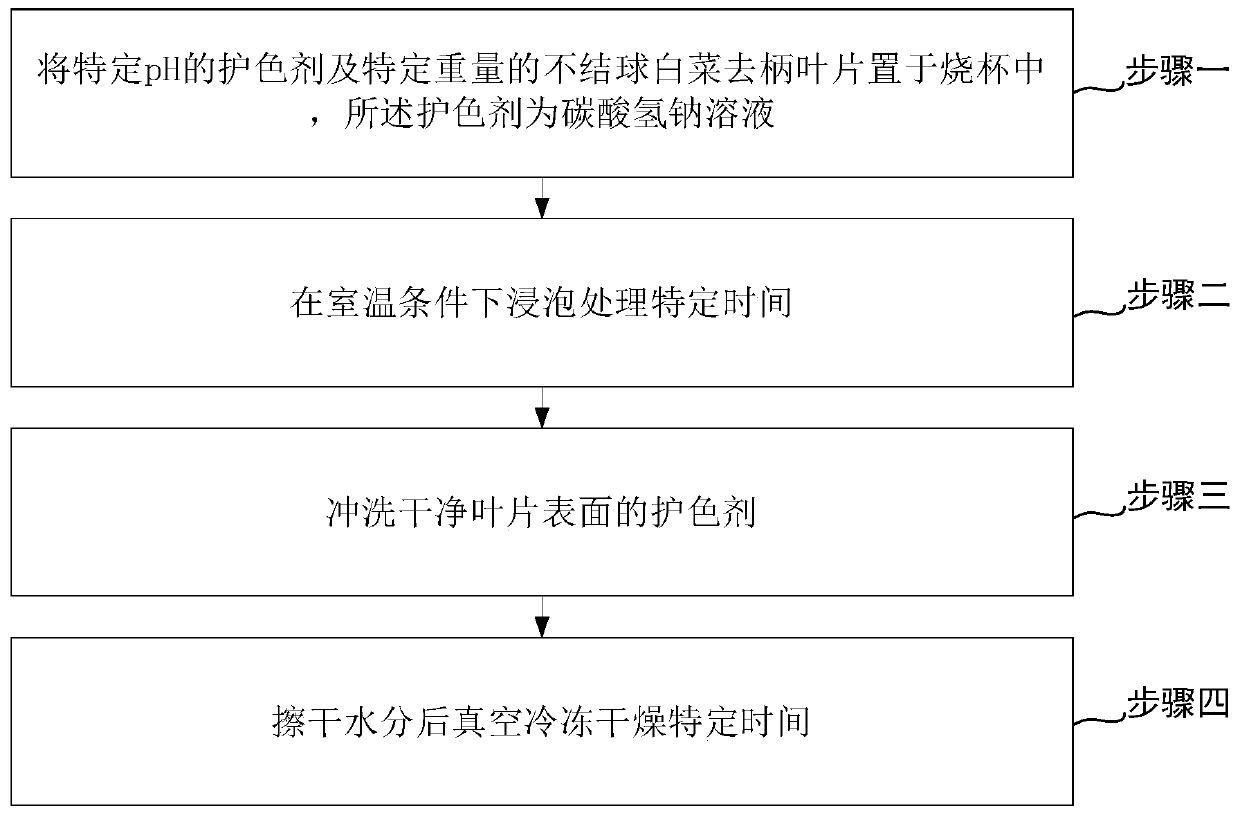

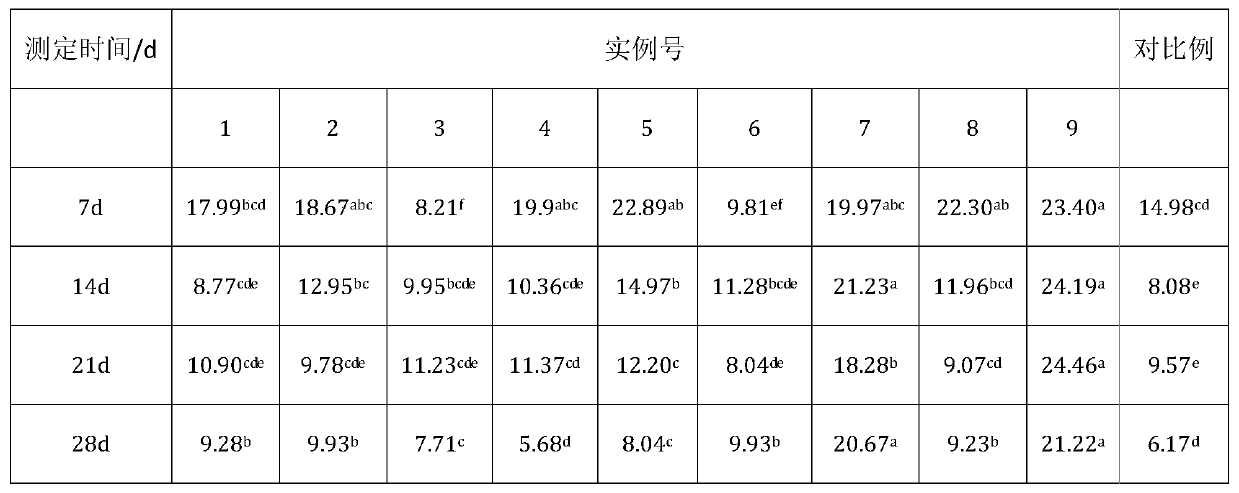

Color fixative for vacuum freeze-dried non-heading Chinese cabbage green leaves and use method thereof

InactiveCN111357805AImprove qualityEasy to operateFruit and vegetables preservationSodium bicarbonateFreeze-drying

The invention discloses a color fixative for vacuum freeze-dried non-heading Chinese cabbage green leaves and a use method thereof. The invention provides the color fixative for vacuum freeze-dried non-heading Chinese cabbage green leaves and the use method thereof, and the method comprises the following steps: adopting sodium bicarbonate as a color fixative, controlling the pH value and treatmenttime of the color fixative, and soaking vegetables with the sodium bicarbonate before freeze-drying non-heading Chinese cabbage leaves, so that chlorophyll is subjected to saponification reaction togenerate alkali salt of chlorophyll. The original central nucleus structure of the chlorophyll can still be kept in dead cells after the alkali salt is dried. The the color fixative for vacuum freeze-dried non-heading Chinese cabbage green leaves and the use method thereof provided by the invention are easy to operate. According to the invention, the technology of vacuum freeze drying of the non-heading Chinese cabbage leaves is improved, and the quality of freeze-dried products is improved. The color fixative for vacuum freeze-dried non-heading Chinese cabbage leaves has the advantages of being natural, environmentally friendly, easy to degrade, non-toxic and harmless.

Owner:NANJING AGRICULTURAL UNIVERSITY

A preparation method of regenerated cellulose-based cross-linked modified nanofiltration membrane

ActiveCN107551832BEasy to makeLow costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkRaw material

The invention provides a preparation method of a regenerated cellulose based cross-linked modified nanofiltration membrane. The preparation method comprises the following steps: firstly, producing a cellulose membrane casting solution by adopting NMMO (N-methylmorpholine-N-oxide), propyl gallate and a cellulose membrane casting solution; secondly, preparing a regenerated cellulose membrane by adopting an immersion gel method, wherein the thickness of the membrane is 2mu m to 50mu m; then, preparing an ALG / CMC blended solution; taking the prepared regenerated cellulose membrane as a basic membrane and uniformly coating the basic membrane with the ALG / CMC (sodium alginate / carboxymethylcellulose sodium) blended solution; carrying out air drying for 12h to 36h at room temperature to obtain a composite cellulose membrane; immersing the obtained composite cellulose membrane into an epichlorohydrin ethanol solution and regulating the pH (Potential of Hydrogen) of the system to 9 to 12; carrying out cross-linking reaction for 4h to 24h under the condition that the temperature is 30 DEG C to 70 DEG C, so as to obtain the regenerated cellulose based cross-linked modified nanofiltration membrane. The preparation method provided by the invention has the advantages of simple preparation process, cheap raw materials and wide sources; the prepared regenerated cellulose based cross-linked modified nanofiltration membrane has the characteristic of high additional value and environment friendliness.

Owner:FUJIAN AGRI & FORESTRY UNIV

A healthy and environmentally friendly green interior wall coating

ActiveCN104163608BNatural and environmentally friendlyWith radiation protectionCelluloseThermal insulation

The invention discloses a healthy environment-friendly green indoor wall paint which comprises a base material and water. The base material is composed of the following components in percentage by weight: 50-75 parts of Portland cement, 3-5 parts of open-cell expanded perlite, 5-8 parts of Chinese hemp fiber powder, 3-5 parts of kendir fiber powder, 4-8 parts of kieselguhr, 5-6 parts of bamboo fiber particle, 3-4 parts of plant colored cotton cellulose, 5-8 parts of lignocellulose, 1-4 parts of adhesive, 2-4 parts of rutile titanium white, 4-6 parts of film formation assistant, 1-6 parts of antifreezing agent, 3-5 parts of chitosan cellulose, 1-3 parts of melamine cyanurate, 1-3 parts of hollow glass microsphere and the balance of water. The healthy environment-friendly green indoor wall paint is a natural environment-friendly paint, which is natural and environment-friendly and has the advantages of radiation resistance, mold and bacteria resistance, air permeation, moisture absorption, sound insulation, thermal insulation and high firmness and durability.

Owner:江西奇信集团股份有限公司

Reed straw, or sorghum straw, or corn straw, or sugar cane straw toothpick

InactiveCN101856274AAvoid health effectsReasonable structureGum massageTooth cleaningEnvironmental resistanceSorghum

The invention relates to a reed straw, or sorghum straw, or corn straw, or sugar cane straw toothpick, which is characterized in that: a toothpick body takes a reed straw, or a sorghum straw, or a corn straw, or a sugar cane straw as a raw material, and the toothpick is in a flaky shape; the thickness of the toothpick body is 0.2-0.5mm, the width is 1.8-2.0mm, and the length is 50-70mm; the toothpick body has the following six structural forms that: the surface of the toothpick body is in a rectangular flat head shape; one end part is arranged at an inclined angle; the end part of one end or two ends of the rectangle is in a sharp corner shape; the end part is in a round head shape or provided with a round hole; the surface is in a sword shape; and the surface is engraved with a miniature sculpture or a graphic. The invention has the characteristics of reasonable structure, simple manufacturing process, easy obtainment of raw materials, convenient carry and use, natural environment protection, comfort use, safety and the like, can effectively overcome the defects that when people pick teeth after dinner, the gashes are larger, the teeth are damaged and the health of the teeth is affected, and has certain health-care function for the teeth.

Owner:王刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com