Antibacterial epoxy coating for anchor chains and preparation method thereof

An epoxy coating and anchor chain technology, applied in the field of coatings, can solve problems such as poor coating dispersion, and achieve the effects of strong adhesion, good paint film toughness, and excellent alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

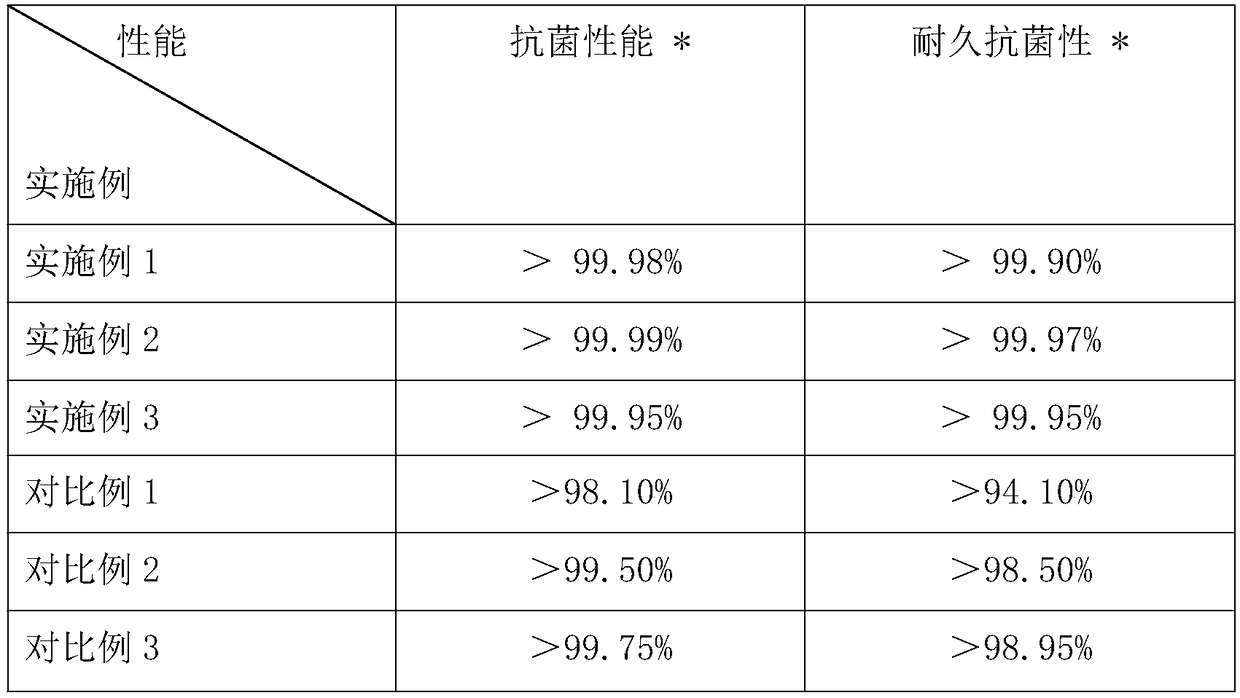

Examples

Embodiment 1

[0017] An antibacterial epoxy coating for anchor chains, comprising the following components in weight percent: 30 parts of bisphenol A epoxy resin, 10 parts of phenalkamine, 10 parts of diatom mud, 8 parts of polyurethane, 7 parts of nitrile rubber, high wear-resistant 8 parts of pigment and filler, 5 parts of polyethylene wax emulsion, 8 parts of modified silica, 1 part of dispersant, 1 part of defoamer, 3 parts of leveling agent, 2 parts of film-forming aid, 2 parts of antifreeze, 10 parts of ionized water.

[0018] The antifreeze is ethylene glycol.

[0019] A kind of preparation method of the antibacterial epoxy coating of anchor chain, comprises the following steps: the first step, takes raw material; High wear-resistant pigments and fillers, polyethylene wax emulsion and modified silica are mixed and ground until the fineness is less than 50 microns; in the third step, dispersant, defoamer, fluid Leveling agent, film-forming aid, antifreeze and deionized water are dis...

Embodiment 2

[0022] An antibacterial epoxy coating for anchor chains, comprising the following components in weight percent: 40 parts of bisphenol A epoxy resin, 15 parts of phenalkamine, 15 parts of diatom mud, 12 parts of polyurethane, 8 parts of nitrile rubber, high wear-resistant 9 parts of pigment and filler, 8 parts of polyethylene wax emulsion, 12 parts of modified silica, 2 parts of dispersant, 2 parts of defoamer, 5 parts of leveling agent, 3 parts of film-forming aid, 3 parts of antifreeze, 15 parts of ionized water.

[0023] Described antifreeze is propylene glycol.

[0024] A kind of preparation method of the antibacterial epoxy coating of anchor chain, comprises the following steps: the first step, takes raw material; High wear-resistant pigments and fillers, polyethylene wax emulsion and modified silica are mixed and ground until the fineness is less than 50 microns; in the third step, dispersant, defoamer, fluid Leveling agent, film-forming aid, antifreeze and deionized wa...

Embodiment 3

[0027] An antibacterial epoxy coating for anchor chains, comprising the following components in weight percent: 34 parts of bisphenol A epoxy resin, 13 parts of phenalkamine, 14 parts of diatom mud, 9 parts of polyurethane, 8 parts of nitrile rubber, high wear-resistant 9 parts of pigment and filler, 7 parts of polyethylene wax emulsion, 11 parts of modified silica, 1 part of dispersant, 1 part of defoamer, 5 parts of leveling agent, 3 parts of film-forming aid, 2 parts of antifreeze, 12 parts of deionized water.

[0028] Described antifreeze is propylene glycol.

[0029] A kind of preparation method of the antibacterial epoxy coating of anchor chain, comprises the following steps: the first step, takes raw material; High wear-resistant pigments and fillers, polyethylene wax emulsion and modified silica are mixed and ground until the fineness is less than 50 microns; in the third step, dispersant, defoamer, fluid Leveling agent, film-forming aid, antifreeze and deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com