Preparation method for tencel blended yarn

A technology of blended yarn and Tencel, which is applied in the field of preparation of Tencel blended yarn, and can solve problems such as poor durability and insufficient bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

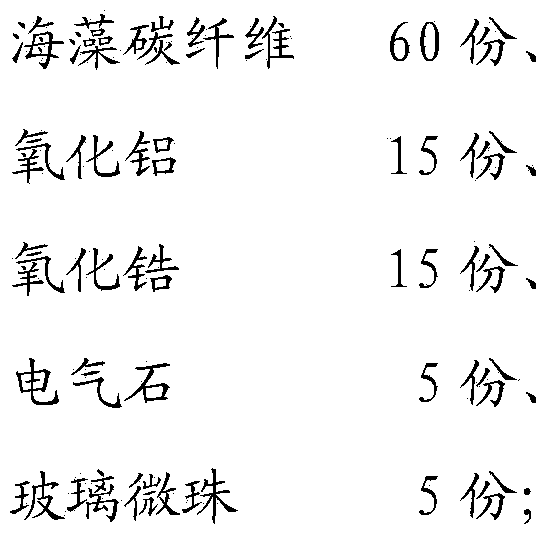

[0029] Preparation of far-infrared ultrafine powder:

[0030]

[0031] After mixing the above components, the mixture is ground into a far-infrared ultrafine powder with an average particle size of ≤0.4 microns and a maximum particle size of ≤0.5 microns by a jet mill.

[0032] Preparation of far infrared masterbatch:

[0033] The far-infrared ultrafine powder is blended and dried with the fiber base material, added with a polymer spinning aid, and then entered into a screw extruder for melting, blending and extruding, and granulated to obtain a far-infrared masterbatch; the fiber base material and the far-infrared ultrafine The weight ratio of micropowder is 100:5;

[0034] Far infrared fiber production:

[0035] After the far-infrared masterbatch and fiber chips are blended, the Tencel blended yarn is formed after spinning, winding and stretching. The far-infrared masterbatch and fiber chips are mixed in a mass ratio of 1:10.

[0036] Tencel blended yarn production pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com