Blended yarn of fine denier modal with hemp and its blow spinning process

A production process and blended yarn technology, which is applied in the field of fine denier modal and hemp blended yarn and its air-jet spinning production process, which can solve the problems that hemp fiber cannot enter and cannot be sprayed into yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Fine denier modal and linen blended yarn: fine denier modal 80% / linen 20%; 28s / 1.

[0011] The specification of fine denier modal fiber is: 1.0dtex×38mm

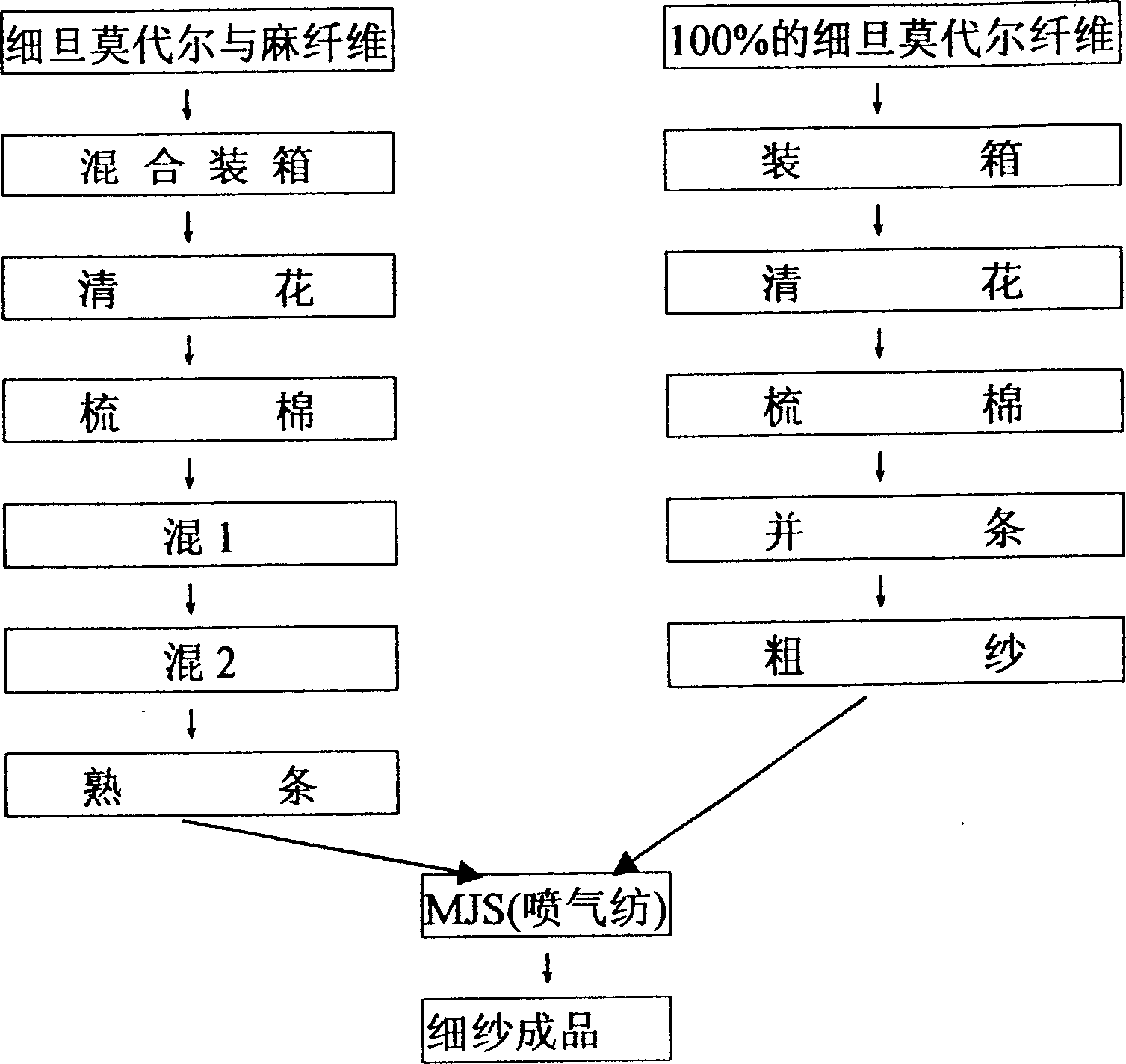

[0012] Routing:

[0013] Fine Denier Modal 78% / Flax 22%-Mixed Phase-Blooming-Carding-And 1-And 2-And 3--A strip, its basis weight is 2.0 g / m; the other group is Fine Denier Modal Fiber- Loading phase - cleaning - carding - parallel 1 - parallel 2 - roving - B roving, the quantitative is 2.8 g / 10 meters. A + B rovings merge into the nozzle of MJS (air-jet spinning), the nozzle pressure of air-jet spinning is N1=0.35mpa, N2=0.45mpa; the total draft is 110 times, the main draft is 30 times, and it can be spun into 28s / 1 .

Embodiment 2

[0015] Fine denier modal and hemp blended yarn: fine denier modal 70 / ramie 30; 26s / 1.

[0016] The specification of fine denier modal fiber is 1.0dtex×38mm

[0017] Routing:

[0018] Fine denier modal 67% / flax 33%-mixed phase-cleaning-carding-and 1-and 2-and 3——A strip; the basis weight is 2.8 g / m; the other group is fine denier modal fiber-pack Phase-cleaning-carding-parallel 1-parallel 2-roving——B roving, the basis weight is 3.2 g / 10 meters. A + B rovings are merged into the MJS nozzle. The nozzle pressure of air-jet spinning is N1=0.35mpa, N2=0.5mpa; the total draft is 138 times, and the main draft is 35 times to spin into 26s / 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com