Bleaching work fluid of flax, flax/cotton fabric and low temperature bleaching technology

A technology of working liquid and cotton fabric, which is applied in the field of low-temperature bleaching process, can solve the problems of reducing strength loss, long time consumption, and large fabric damage, and achieve the effects of reducing dosage, shortening stacking time, and lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

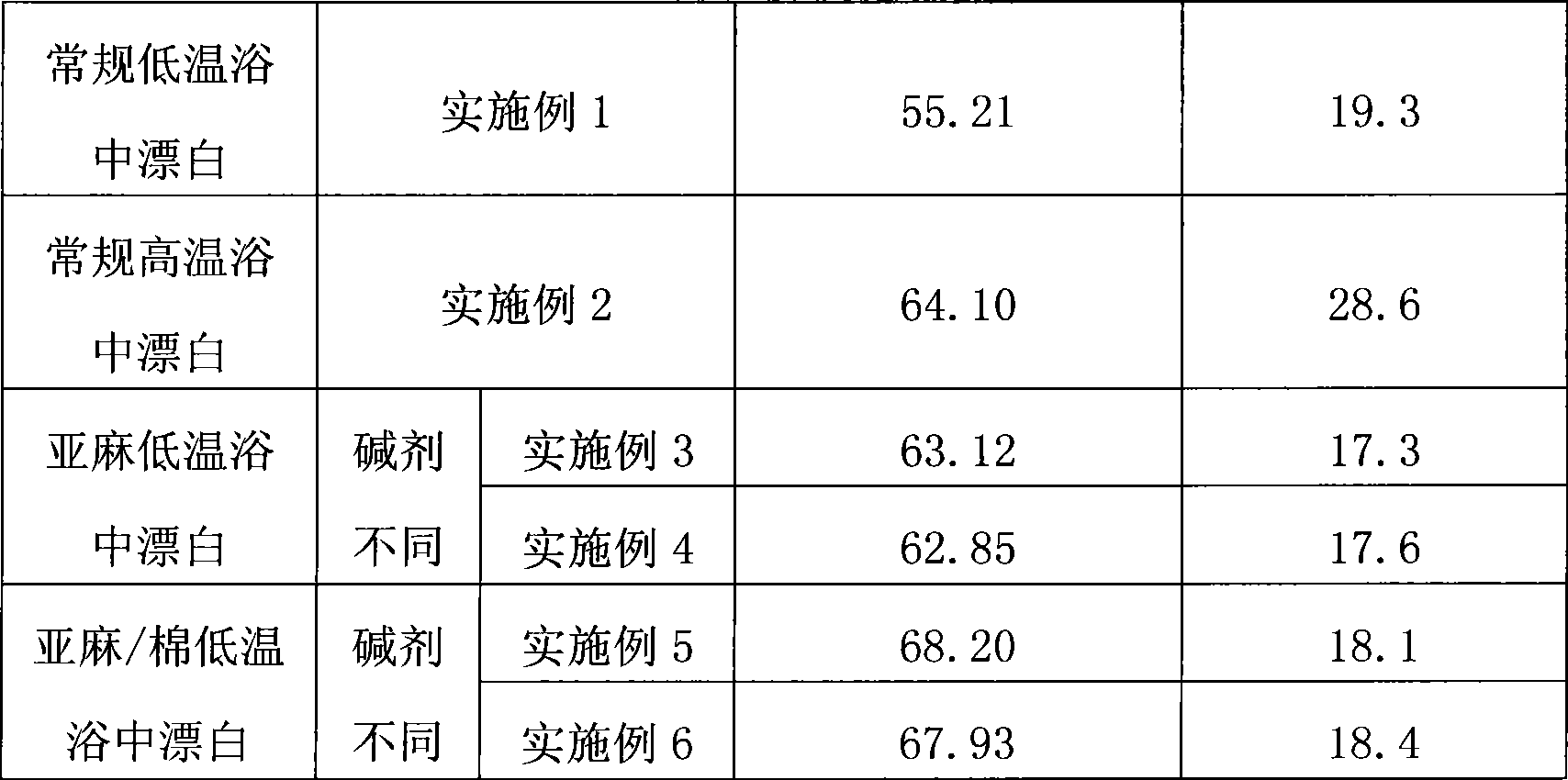

Examples

Embodiment 1

[0052] (1) Prepare bleach working solution: in a 300ml container, add 50mL of water, 0.05g of penetrant JFC, 0.05g of stabilizer Ciba G-100, and 30% H 2 o 2 0.4g, stir well;

[0053] (2) padding stage: 2.5g flax fabric padding prepared bleaching working solution, adding concentration is 0.1g of ammoniacal liquor of 25%, the pH value of dipping working solution is controlled in the scope of 7~10;

[0054] (3) Bleaching stage: raise the temperature of the bleaching working solution to 70-80°C, keep it warm in this temperature range for 60 minutes, keep stirring the working solution during this period, and immerse the fabric in the working solution;

[0055] (4) Washing stage: take out the linen fabric, wash it twice with hot water at 60-95°C, and then fully wash it with cold water;

[0056] (5) Drying stage: natural air drying or low temperature (20-60° C.) drying can be selected. In this embodiment, the linen fabric is air-dried naturally.

Embodiment 2

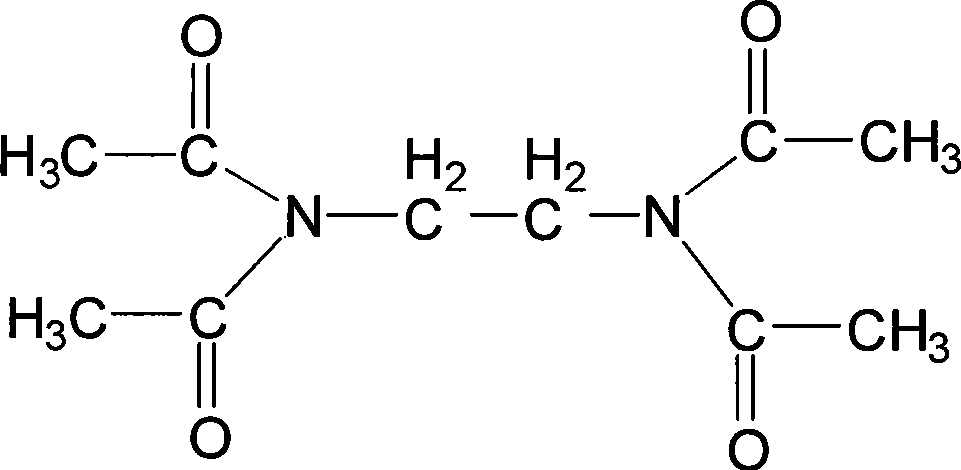

[0058] (1) Prepare bleach working solution: in a 300ml container, add 50mL of water, 0.05g of penetrant JFC, 0.05g of stabilizer Ciba G-100, and 30% H 2 o 2 0.4g, activator tetraacetylethylenediamine (TAED), stir well;

[0059] (2) padding stage: 2.5g flax fabric padding prepared bleaching working solution, adding concentration is 0.1g of ammoniacal liquor of 25%, the pH value of dipping working solution is controlled in the scope of 7~10;

[0060] (3) Bleaching stage: raise the temperature of the bleaching working solution to 105°C, keep it warm at this temperature for 60 minutes, keep stirring the working solution during this period, and immerse the fabric in the working solution all the time;

[0061] (4) Washing stage: take out the linen fabric, wash it twice with hot water at 60-95°C, and then fully wash it with cold water;

[0062] (5) Drying stage: natural air drying or low temperature (20-60° C.) drying can be selected. In this embodiment, the linen fabric is air-dr...

Embodiment 3

[0064] (1) Prepare bleach working solution: in a 300ml container, add 50mL of water, 0.05g of penetrant JFC, 0.05g of stabilizer Ciba G-100, and 30% H 2 o 2 0.4g, activator tetraacetylethylenediamine (TAED), n(TAED):n(H 2 o 2 ) is 1 / 4:1, stir evenly;

[0065] (2) padding stage: 2.5g flax fabric padding prepared bleaching working solution, adding concentration is 0.1g of ammoniacal liquor of 25%, the pH value of dipping working solution is controlled in the scope of 7~10;

[0066] (3) Bleaching stage: raise the temperature of the bleaching working solution to 70-80°C, keep it warm in this temperature range for 60 minutes, keep stirring the working solution during this period, and immerse the fabric in the working solution;

[0067] (4) Washing stage: take out the linen fabric, wash it twice with hot water at 60-95°C, and then fully wash it with cold water;

[0068] (5) Drying stage: natural air drying or low temperature (20-60° C.) drying can be selected. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com