Weaving method of moisture-absorbing heating antibacterial fabric

An antibacterial fabric, moisture absorption and heat generation technology, applied in the field of fabric weaving, can solve the problems of poor wear resistance, increased embrittlement of kapok fibers, damage to kapok fibers, etc., to improve the performance of moisture absorption and heat generation, protect kapok fibers, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

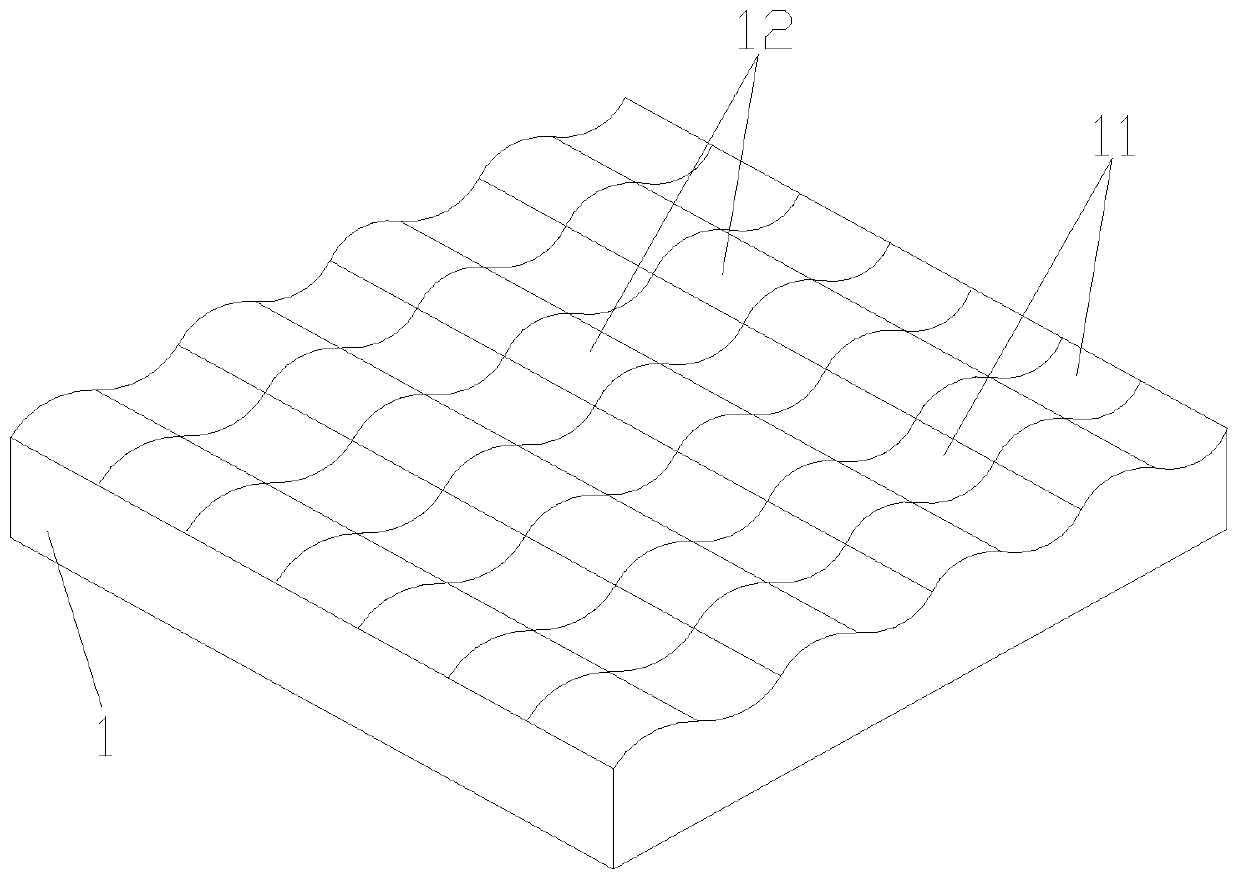

Image

Examples

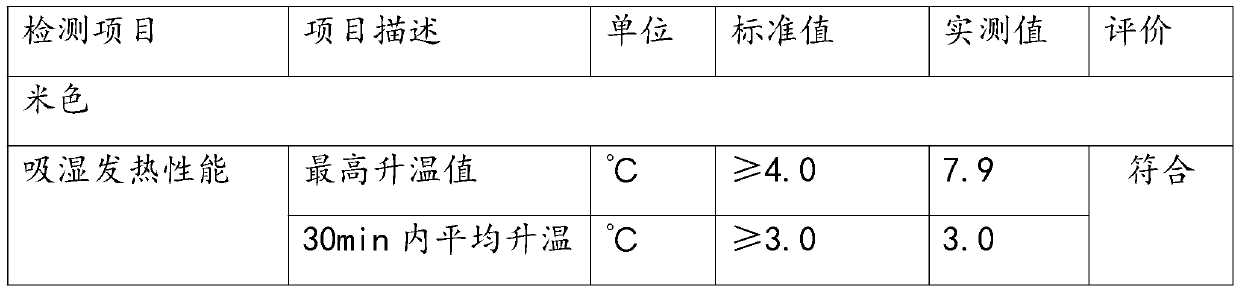

Embodiment 1

[0040] A method for weaving a moisture-absorbing, heat-generating, antibacterial fabric, comprising the following steps:

[0041] S1. Obtain kapok fiber and cotton fiber, and blend the two into cotton and kapok blended yarn, and spin rough yarn that meets the requirements in the same way; the rough yarn specification is 32 pounds, and the thick yarn is made of 100% cotton fiber Cotton yarn, cotton kapok blended yarn 36 pounds;

[0042] S2. Obtain 40dtex spandex filament;

[0043] S3. Pretreat cotton and kapok blended yarn to make it moist and soft (generally required indicators: humidity 55-75%, moisture regain 15-22%);

[0044] S4. Weaving on the upper machine: the upper line is a cotton and kapok blended yarn, which is lined with a spandex filament, and the next line is a thick yarn, which is lined with a spandex filament, using a double-sided large circular knitting machine Alternate weaving up and down into cotton kapok spandex knitted double-sided plain weave;

[0045]...

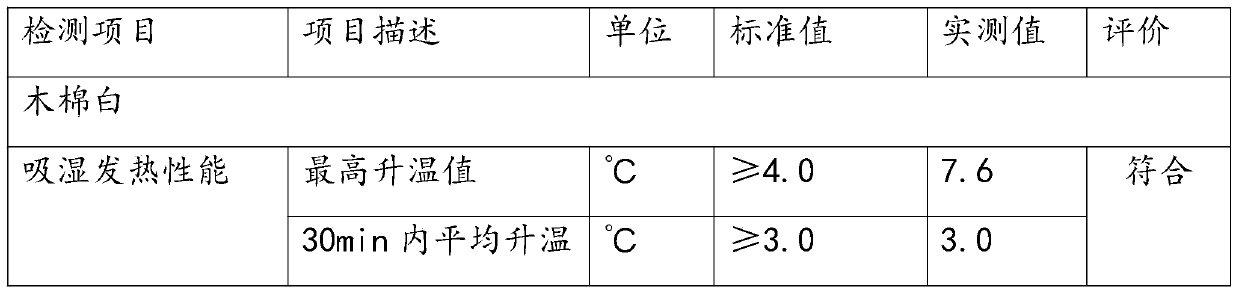

Embodiment 2

[0054] S1. Obtain kapok fiber and cotton fiber, and blend the two into cotton and kapok blended yarn, and similarly spin rough yarn that meets the requirements; thick yarn is also a yarn that is blended by kapok fiber and cotton fiber, And the diameter of the thick yarn and the blended cotton and kapok yarn is the same; the cotton fiber content is 15%; the size of the thick yarn is 40 pounds, and the cotton and kapok blended yarn is 40 pounds;

[0055] S2. Pretreat the cotton and kapok blended yarn and the thick yarn, so that both can be humidified and soft (generally required indicators: humidity 55-75%, moisture regain 15-22%);

[0056] S4. Weaving on the upper machine: a cotton and kapok blended yarn on the upper road, and a thick yarn on the lower road, using a double-sided circular knitting machine to weave alternately up and down to form a cotton and kapok knitted double-sided plain weave;

[0057] S5. Dyeing and finishing: process the cotton and kapok knitted double-fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com