Raw dark green tea and production process thereof

A production process and technology for black hair tea, applied in the field of tea, can solve problems such as tea caking, tea quality deterioration, and black hair tea quality instability, and achieve the effect of tight and straight shape and improve commodity value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

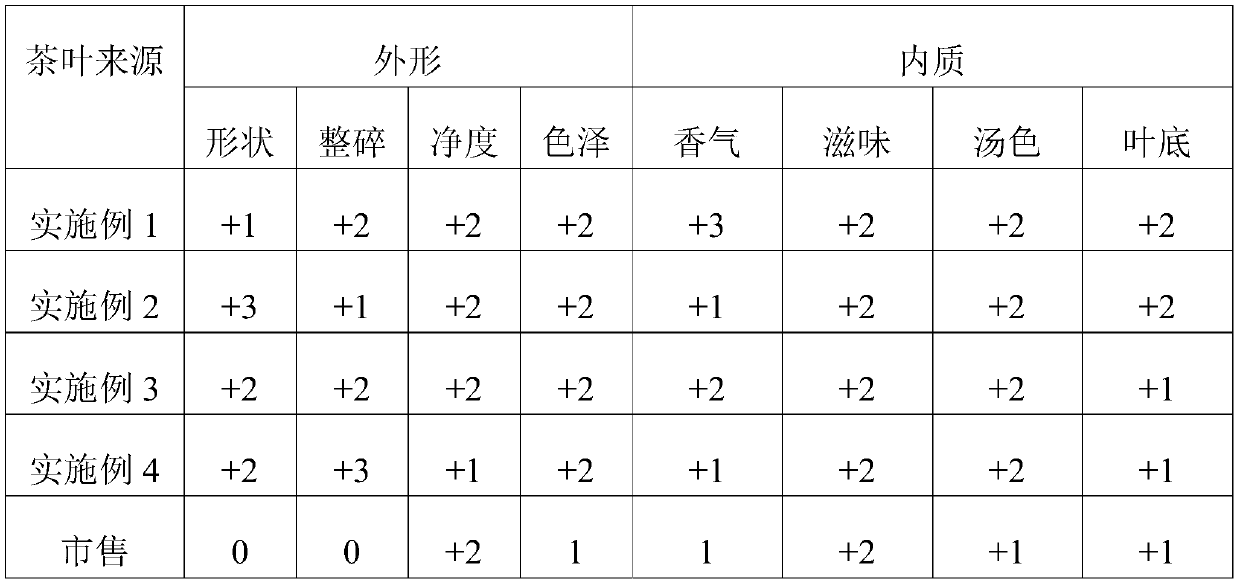

Embodiment 1

[0032] The present embodiment provides a kind of manufacturing process of black hair tea, comprising the following steps:

[0033] (1) Harvesting and greening: the fresh leaves of one bud and one leaf of the tea tree are picked by hand to ensure the uniformity of the fresh leaf grade, and then the roller greening machine is used to kill the young leaves at 220°C After 5 minutes of greening, you can get green tea;

[0034] (2) Kneading: Put the green tea in the kneading machine, the amount of leaves thrown is 85% of the volume of the kneading barrel, and knead according to the principle of "light-heavy-light". 5min, you have to knead the tea;

[0035] (3) Heap: put the rolled tea into a heap with a height of 1.2m, and ferment it at 25°C for 10 hours. When water droplets appear on the surface of the tea dregs, the leaf color changes from dark green to yellowish brown, with distiller's grains or With a hot and sour smell, the stickiness of the tea ball becomes smaller, and when...

Embodiment 2

[0041] The present embodiment provides a kind of manufacturing process of black hair tea, comprising the following steps:

[0042] (1) Harvesting and greening: the fresh leaves of one bud and two leaves of the tea tree are picked by hand to ensure the uniformity of the fresh leaf grade, and then the roller greening machine is used to kill the young leaves at 250°C After 6 minutes of greening, green tea is obtained;

[0043] (2) Kneading: Put the green tea in the kneading machine, and the amount of leaves thrown is 85% of the volume of the kneading barrel. Knead according to the principle of "light-heavy-light". 8min, you have to knead the tea;

[0044] (3) Heap: put the rolled tea into a heap with a height of 1.5m, and ferment it at 20°C for 15 hours. When water droplets appear on the surface of the tea dregs, the leaf color changes from dark green to yellowish brown, with distiller's grains or With a hot and sour smell, the stickiness of the tea ball becomes smaller, and wh...

Embodiment 3

[0050] The present embodiment provides a kind of manufacturing process of black hair tea, comprising the following steps:

[0051] (1) Picking, spreading and finishing: pick the fresh leaves of the tea tree with one bud and three leaves by hand picking to ensure the uniformity of the fresh leaves, and then spread the fresh leaves of the tea tree to a thickness of 10cm. For 2 hours, when the water content of the fresh leaves of the tea tree is 68%, then use a roller degreening machine to degreen under the condition of 220 ° C for 7 minutes according to the principle of killing young leaves to get green tea;

[0052] (2) Kneading: Put the green tea in the kneading machine, the amount of leaves thrown is 85% of the volume of the kneading barrel, and knead according to the principle of "light-heavy-light". 5min, you have to knead the tea;

[0053] (3) Heap: put the rolled tea into a heap with a height of 1.2m, and ferment it at 25°C for 10 hours. When water droplets appear on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com