Spraying type system and method for extracting moisture of clean flue gas after wet desulphurization

A wet desulfurization and flue gas purification technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of corrosion damage of cyclone separators, increased corrosivity of condensed water, and high cost of condensed water, so as to reduce corrosion performance, slow down corrosion damage, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the invention more clear, the following will be clearly and fully described by the technical solutions of the invention in conjunction with the attachment. Example. Based on the embodiments in the present invention, all other embodiments obtained by ordinary technical personnel in the art under the premise of not creating creative labor belong to the protection of the present invention.

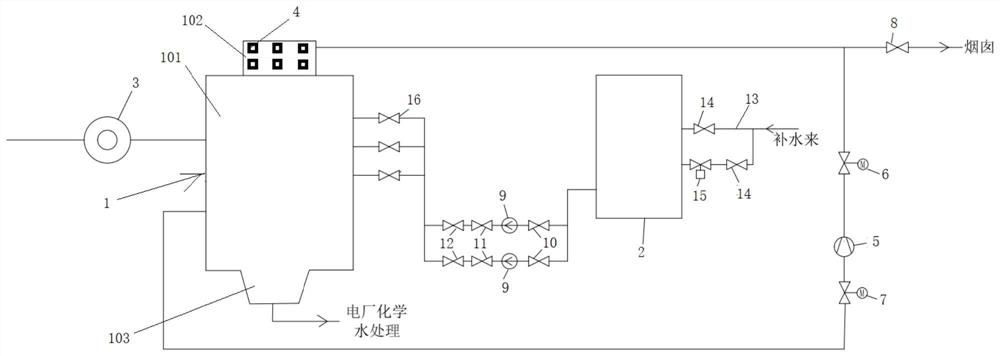

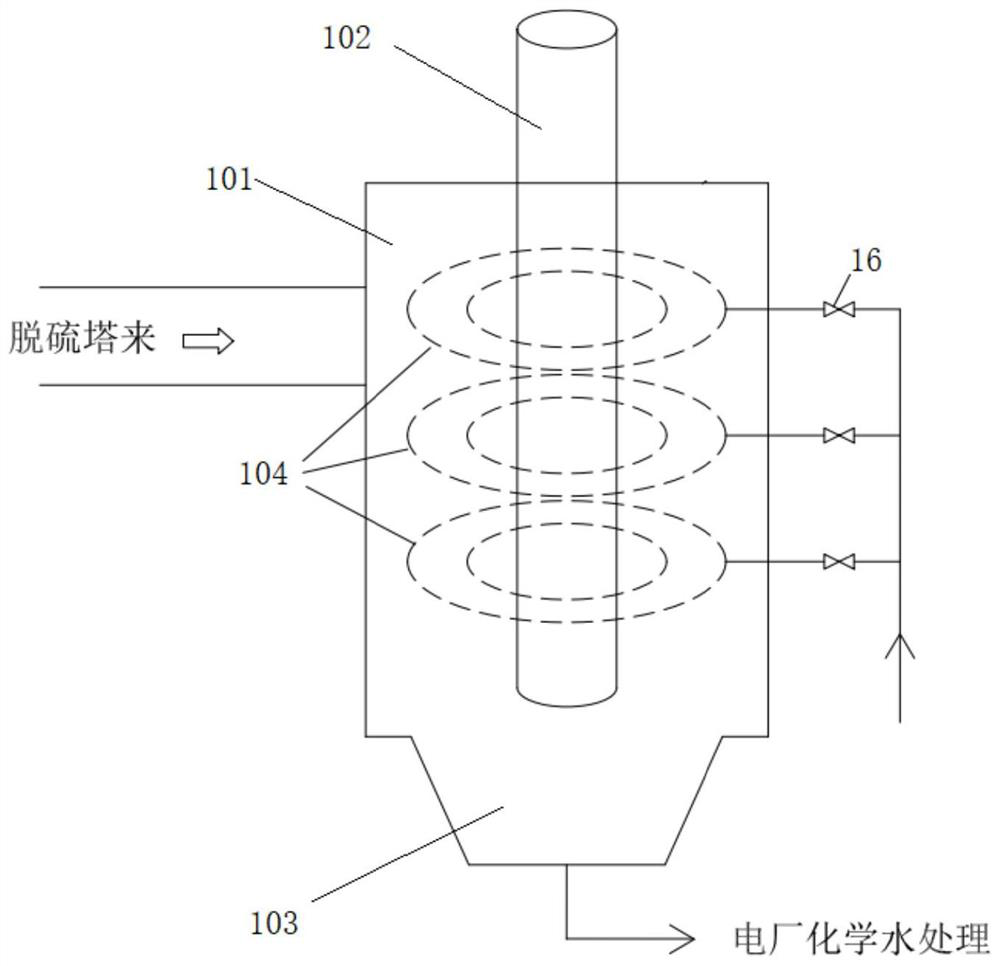

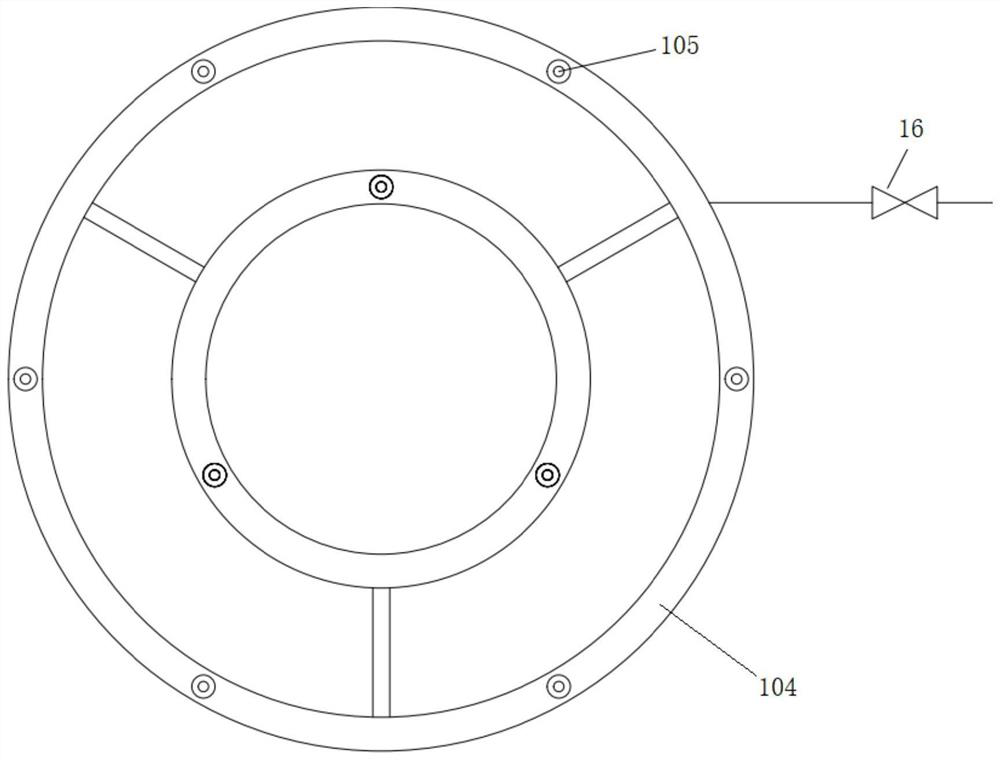

[0033] As a specific embodiment of the present invention, combined Figure 1 to Figure 3It shows that a system of spray -type wet desulfurization clean smoke water water, including the controller, whirlwind separator 1 and spray water tank 2, the cyclone separator 1 includes the outer cylinder 101 and the inner tube 102 of the separator 102 The lower end of the outer barrel 101 of the separator is connected to the water collection tank 103, the upper and lower ends of the inner tube 102 of the separator p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com