soil drying box

An air-drying box and soil technology, which is applied in the field of soil analysis, can solve the problems of affecting the efficiency of soil testing, the inability to adjust the exhaust volume, etc., and achieve the effect of improving the efficiency of soil testing and facilitating regular replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

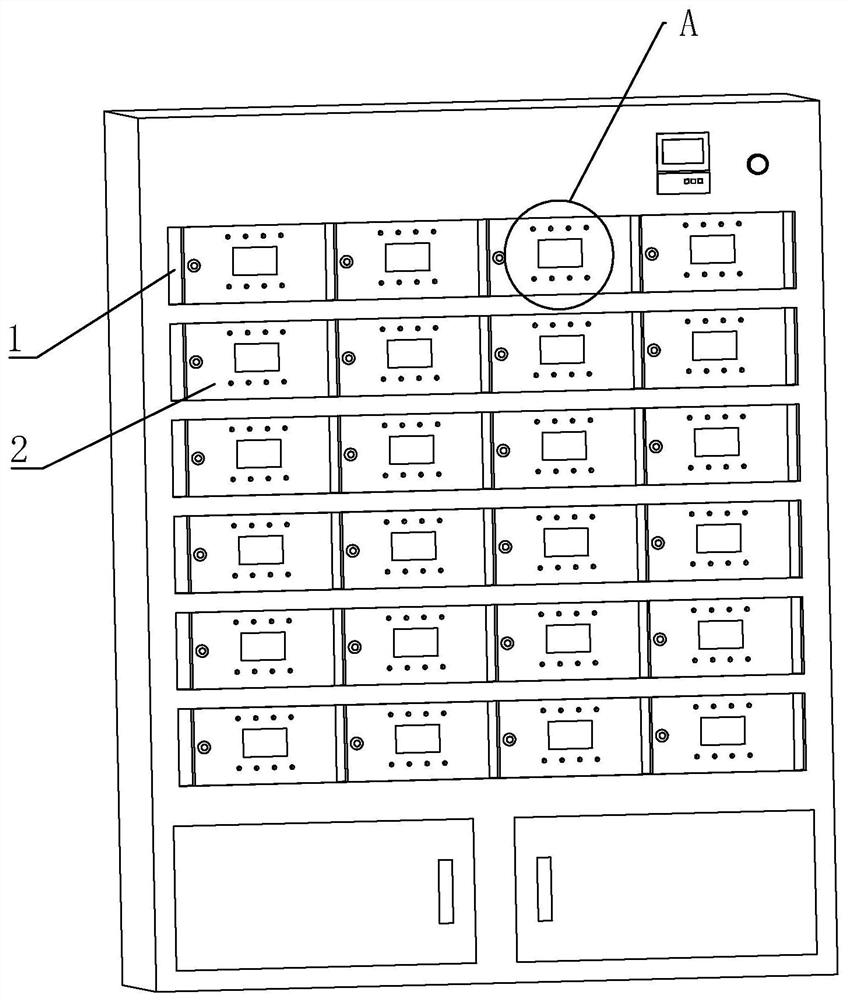

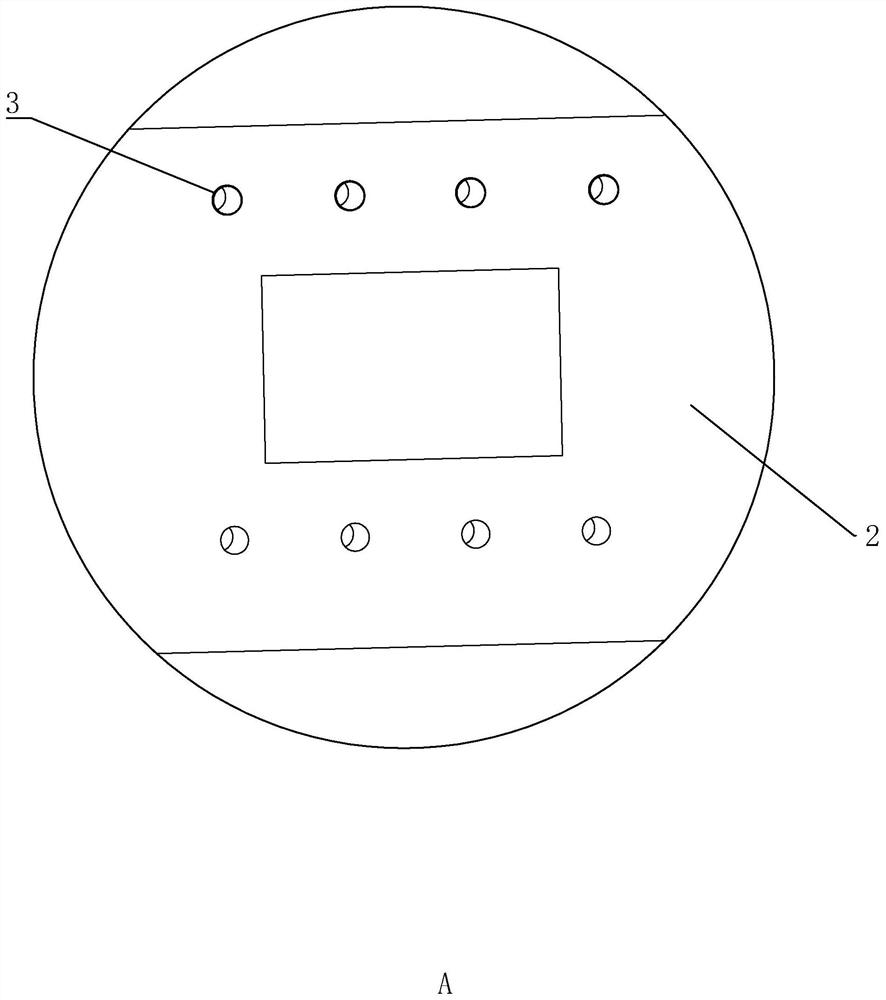

[0036] Embodiment 1: A kind of soil air-drying box, with reference to figure 1 and figure 2 , including a number of air-drying box boxes 1 evenly arranged on the air-drying box, the box body is arranged in a cuboid shape, an opening is provided on the side wall of the box body, and a box cover 2 for sealing the box body is hinged on the box body. A number of cylindrical exhaust holes 3 are provided on the box cover 2, and the exhaust holes 3 are arranged in a straight line along the horizontal direction. The upper ring of the side wall of the exhaust hole 3 is provided with an installation groove (not shown in the figure), and the installation groove is arranged in a circular shape and arranged along a direction perpendicular to the exhaust hole 3 .

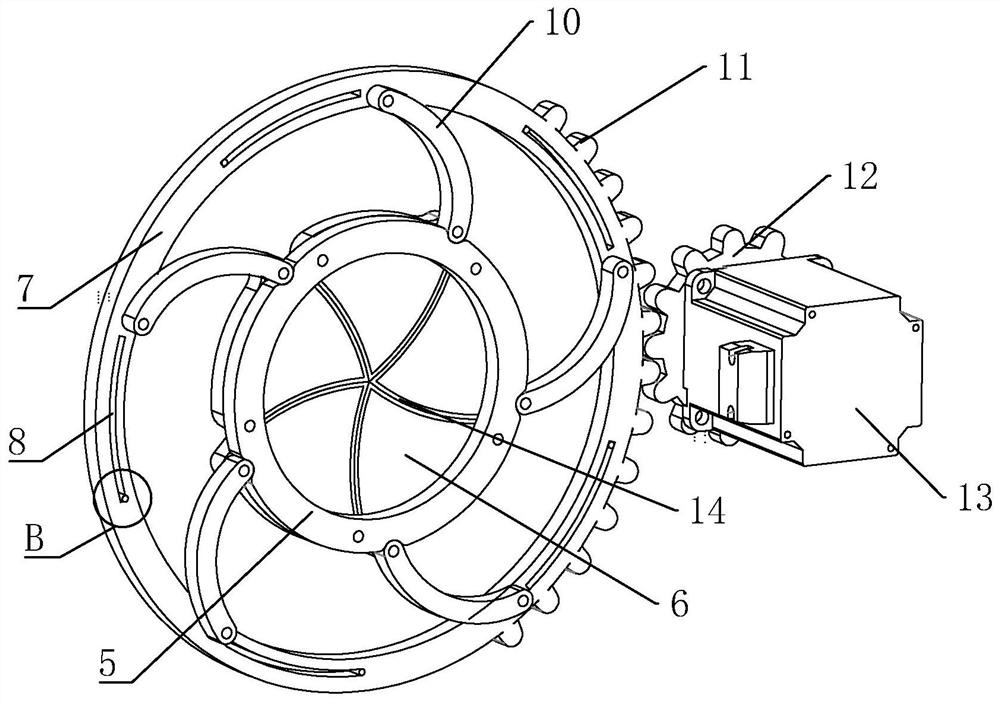

[0037] refer to image 3 and Figure 4 , a mounting plate 5 is fixedly connected to the mounting groove, the mounting plate 5 is arranged in a circular shape, and a circular plate hole is opened on the mounting plate 5, and t...

Embodiment 2

[0043] Embodiment 2: a kind of soil air-drying box, with reference to Figure 7 and Figure 8 , the difference from Embodiment 1 is that the fixing device 16 is a fixing block 163 fixedly connected to the left and right sides of the outer wall of the installation sleeve 15, and is set on the side wall of the exhaust hole 3 to cooperate with the fixing block 163 to slide the locking groove 164 , the fixing block 163 is arranged in the form of a cuboid and arranged along a direction perpendicular to the side wall of the outer tub, and the locking slot 164 is arranged along the depth direction of the exhaust hole 3 . During the sliding and plugging process of the installation sleeve 15 and the exhaust hole 3, the fixed block 163 is mated with the locking groove 164, and the mounting sleeve 15 is fixedly connected to the installation through the mating insertion of the fixing block 163 and the locking slot 164. In the groove, this fixing method is easy to operate, and is convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com