Polyimide fiber sizing device

A polyimide fiber and cleaning device technology, applied in the field of fiber production, can solve the problems of uneven dryness and wetness of fiber tow, poor resin bonding interface performance, affecting production quality and efficiency, etc., to achieve stable sizing , Improve the surface function effect, avoid the effect of sizing liquid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the polyimide fiber sizing device in the present invention, the sizing solution adopts a wear-resistant oil agent, and the 1500D polyimide fiber is used as a standard, and the specific process parameters are as follows:

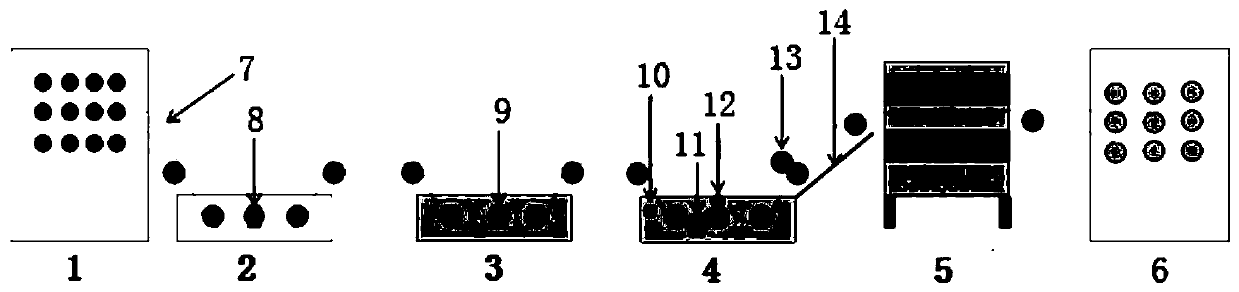

[0029] The polyimide fiber 7 is fed into the pretreatment tank 2 from the creel 1, and the surface of the fiber is modified in the pretreatment solution, and then enters the cleaning tank 3 to clean the fiber to neutral, and then passes through the sizing tank 4 for sizing. After the slurry device 13 comes out, it enters into the microwave drying device for drying, and then is wound up by the wire-receiving device 6 .

[0030] Potassium hydroxide is selected to etch the surface of the polyimide fiber 7; the concentration of the pretreatment solution is selected to be 6M, the pretreatment time is preferably 30s, and the pretreatment temperature is preferably 30°C.

[0031] The polyimide fiber 7 is cleaned in the cleaning tank 3, and the etching solut...

Embodiment 2

[0036] In the polyimide fiber sizing device in the present invention, the sizing solution adopts a wear-resistant oil agent, and the 1500D polyimide fiber is used as a standard, and the specific process parameters are as follows:

[0037] Production according to the sizing process in Example 1, it is worth mentioning that potassium hydroxide is replaced with deionized water in the pretreatment tank 2, and other conditions remain unchanged (the deionized aqueous solution is still contained in the cleaning tank 3).

[0038] Beneficial effect: the abrasion resistance of the polyimide fiber 7 after sizing is 180 times higher than that of the polyimide fiber 7 without sizing.

Embodiment 3

[0040]In the polyimide fiber sizing device in the present invention, the sizing solution adopts a wear-resistant oil agent, and the 1500D polyimide fiber is used as a standard, and the specific process parameters are as follows:

[0041] It is produced according to the sizing process in Example 1. It is worth mentioning that the drying device 5 is heated by a thermocouple, and other conditions remain unchanged.

[0042] Beneficial effects: the abrasion resistance of the polyimide fiber 7 after sizing is 255 times higher than that of the polyimide fiber 7 without sizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com