Composite board

A composite board and ceramsite technology, applied in building materials, covering/lining, construction, etc., can solve the problems of high cost, poor fire performance, strength, and poor fire performance, and achieve the effect of high strength and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

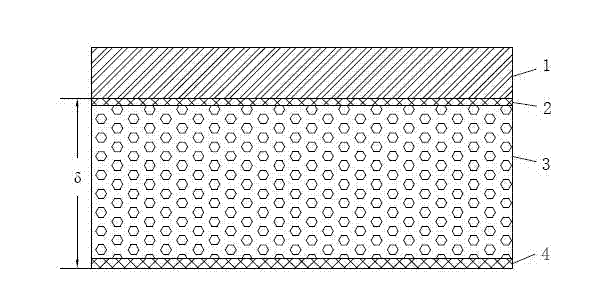

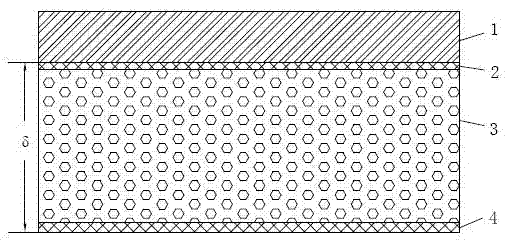

[0013] This embodiment is formed by bonding a base material and a stone panel 1 , and the base material is formed by bonding an upper glass fiber mesh cloth layer 2 , a ceramsite concrete layer 3 and a lower glass fiber mesh cloth layer 4 . The upper glass fiber mesh cloth layer 2 and the lower glass fiber mesh cloth layer 4 are the same, the thickness of the glass fiber mesh cloth is 2-3 mm, and the glass fiber mesh cloth can be used after being purchased from the market. Stone panel 1 can adopt marble or granite. Marble or granite is bonded on the upper fiberglass mesh cloth layer 2 . The ceramsite concrete layer is composed of quick-drying cement, clay ceramsite and polyvinyl chloride foamed grains, adding appropriate amount of water and cement strengthening agent and solidifying at room temperature after stirring, wherein quick-drying cement, ceramsite and polyvinyl chloride The weight ratio of the foamed particles is: 1:0.60-0.74:0.018-0.022, and the particle diameter o...

Embodiment 2

[0017] In this embodiment, the thickness δ of the ceramsite concrete layer is 30 mm, the particle size of the polyvinyl chloride foamed particles is 2 mm, and the weight ratio of quick-drying cement, clay ceramsite, and polyvinyl chloride foamed particles is The formula is: 1:0.7:0.021, adding water 0.3 to 0.4 times the weight of quick-drying cement and cement strengthening agent 0.2-0.3 times the weight of quick-drying cement for stirring. Among the clay ceramsite, the 8mm size accounts for 75-85% of the total ceramsite weight, and the rest is 15mm size ceramsite. There are no strict requirements for the ratio of 8mm and 15mm specifications in ceramsite, as long as they are within their respective ranges. All the other are identical with embodiment 1.

[0018]

Embodiment 3

[0020] In this embodiment, the thickness δ of the ceramsite concrete layer is 25 mm, the particle size of the polyvinyl chloride foamed particles is 2 mm, and the weight ratio of quick-drying cement, clay ceramsite, and polyvinyl chloride foamed particles is The formula is: 1:0.67:0.020, adding water 0.3 to 0.4 times the weight of quick-drying cement and cement strengthening agent 0.2-0.3 times the weight of quick-drying cement for stirring. Among the ceramsite, the 8mm size accounts for 65-75% of the total ceramsite weight, and the rest is 15mm size ceramsite. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com